Page 1

Date: Jul. 31, 1995

COPIER : SF-2116

No. : SP-1916

1.PRECAUTIONS TO BE TAKEN DURING

MAINTENANCE TO THE OPTICAL UNIT

2.REGARDING PROBLEMS WITH THE L4-01

1.Precautions to be taken during maintenance to the optical unit.

1.Model Name: SF-2116/ 21 18/1016/1018

2.General: In order to help prevent problems during market use, please take note of the following.

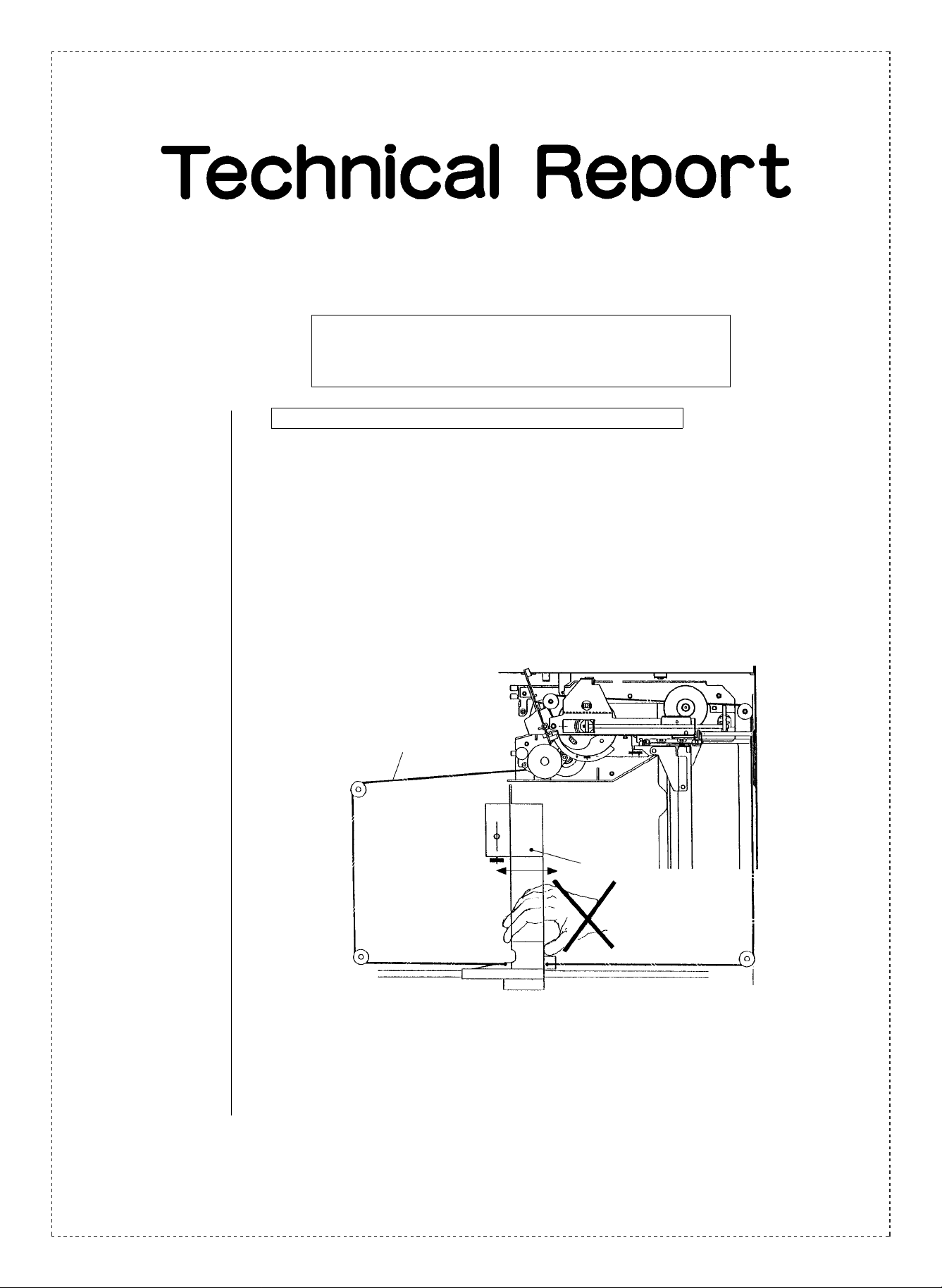

3.Description: Do not handle the zoom mechanism for models with only one cam and one motor in the

same way as has been done for past models (SF-2022/2027, which have two motors).

If you move the lens of the one motor models by hand, (as was the procedure for the

two motor models), the lens drive wire is likely to get caught in the lens carriage. (see

Fig. 1).

Fig. 1

Lens drive wire

Lens carriage

SHARP CORPORATION Reprography Division

1/4

Green

C

Page 2

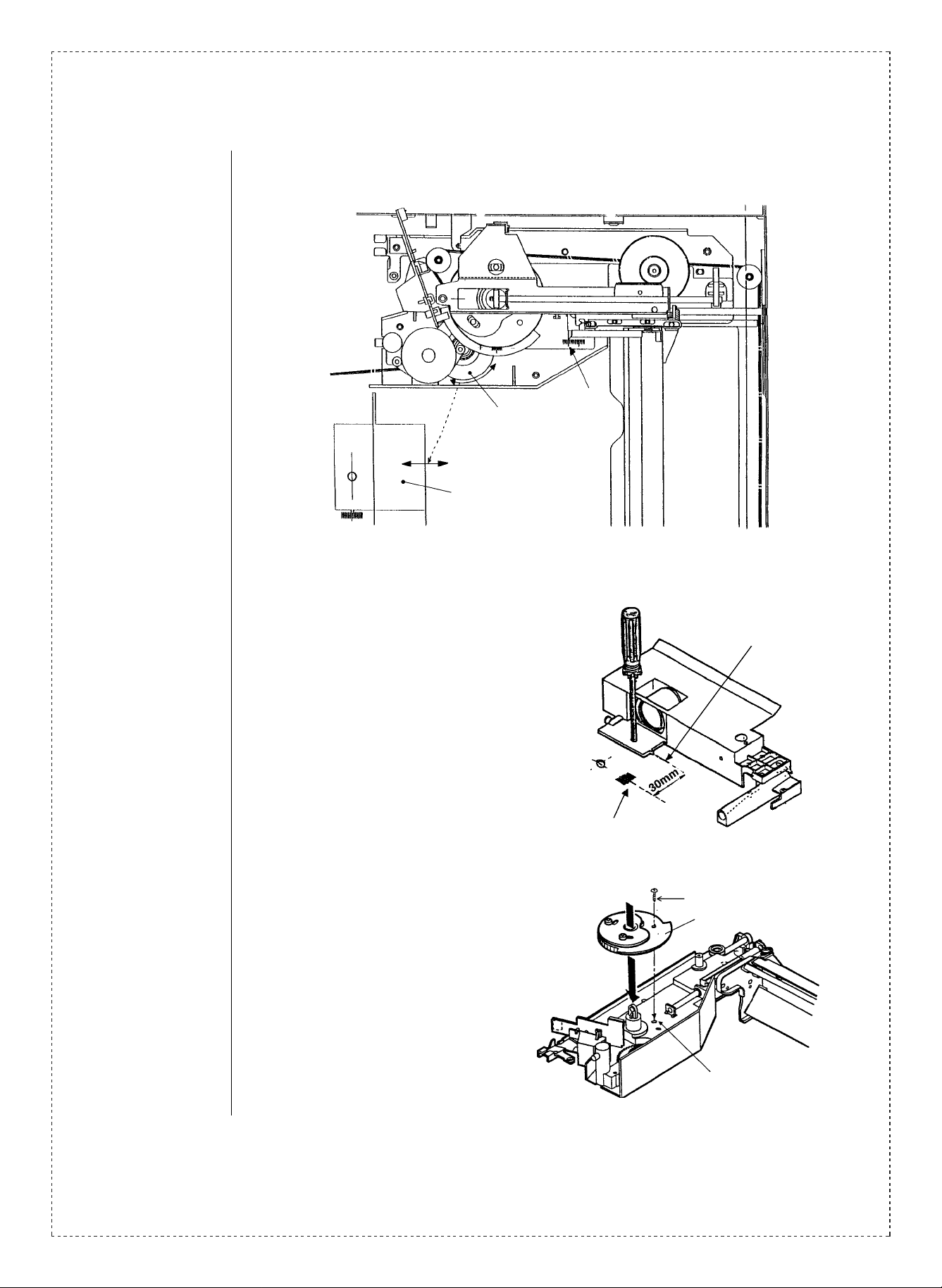

If you must move the lens by hand, do it by rotating the step gear which is connected to

the mirror motor. (See Fig. 2)

Fig. 2

4/5 Mirror UN

Step gear

(rotating this gear moves

the lens)

Lens

Base sticker

If the lens wire has come off of the teeth of its guide, please carry out the following

procedure.

(1) Remove the lens wire (see the Service Manual)

(2) When reattaching the wire, place a pin

or screwdriver (as a temporary fixing

measure) in the opening which you will

find slightly closer to the other end than

the home position and then proceed to

attach the wire. (See Fig. 3)

The original home position

Fig. 3 - the lens carriage in its temporarily fixed position

(3) While the pin or screwdriver of (2) is still

attached, use φ4 pins or M4 screws to fix

the openings in the scaling cam drive

gear to the openings in the zoom base

temporarily. Then attach the scaling

drive gear. (See Fig. 4)

There is a sticker here

φ4 pins (or longer M4 screws) used

as a temporary f i xing measure

The scaling cam drive gear

2/4

Fig. 4 - Attaching the scaling cam drive gear

Note: this opening

Page 3

(4) Take out the pin or

screwdriver which was being

used to fix the position of the

lens carriage temporarily.

Then rotate the scaling cam

drive gear clockwise by hand.

This will increase magnification. When the parts are at

their home position, the

sensor on the scaling cam

drive gear will be lined up

with the MHP sensor.

(When the parts are in this

position, Sim. 48-1A shows

a base value of 50).

(See Fig. 5)

(5) After turning the power off

temporarily, follow the

instructions in the service

manual to attach and adjust the

“koro” holder and the 4/5 mirror

unit.

Fig. 5 - The position of the sensor of the scaling cam

drive gear when it is in home position

This rotation angle

is equivalent to 50

steps/counts of

the lens motor.

Lens drive motor

Optical PWB

The scaling cam drive gear

MHP sensor (in the PWB)

2.Trouble with the L4-01.

1.Model Name: SF-2116/ 21 18/1016/1018

2.General: The margin in the setting for the power supply boundary is very narrow, and in some

machines the burden carried by the drivers may become very large. During multiple

copying, the power supply boundary may shift and cause L4 problems. Please follow

the procedure outlined below should this occur.

3.Description: The basic boundary will be changed from its current value of 3.0 A to a new value of 4.1

A.

3/4

Page 4

For models already out on the market, solder a 22KΩ resist or between the 3rd and 7th

pin of the IC20, which is located at the bottom right of the main PWB.

Main PWB

IC 20

IC 21

ICIO

Additional resistor (22KW) placed

between the 3rd and 7th pins

CN-D

Resistance 22kΩ

VRD-HT2EY223J

Available as service parts

There is also the possibility that L4 problems are occurring due to malfunctions in the

main motor/encoder (the font sensor). Please investigate this possibility as well.

The notes above are only in regards to models which are already on the market.

Information regarding altered production will be provided at another time.

4/4

Loading...

Loading...