Page 1

Date: Jul. 19, 1995

COPIER : Z-20

1. PREVENTION OF JAM DISPLAYS DUE TO STATIC ELECTRICITY DISCHARGE.

2. CHANGE IN SPRINGS AND DISCONTINUANCE OF WASHERS IN THE DRIVE

UNIT TO IMPROVE PRODUCTIVITY.

3. DISCONTINUANCE OF WASHERS IN THE FAN TO IMPROVE PRODUCTIVITY.

No. : SP-1903

1. Prevention of JAM displays due to static electricity discharge.

1.Model name: Z-20/25/27

2.General: Static electricity discharge in the main motor section occasionally causes the jam

display even though no feeding jam has occurred. To alleviate this problem, the

following measures were taken.

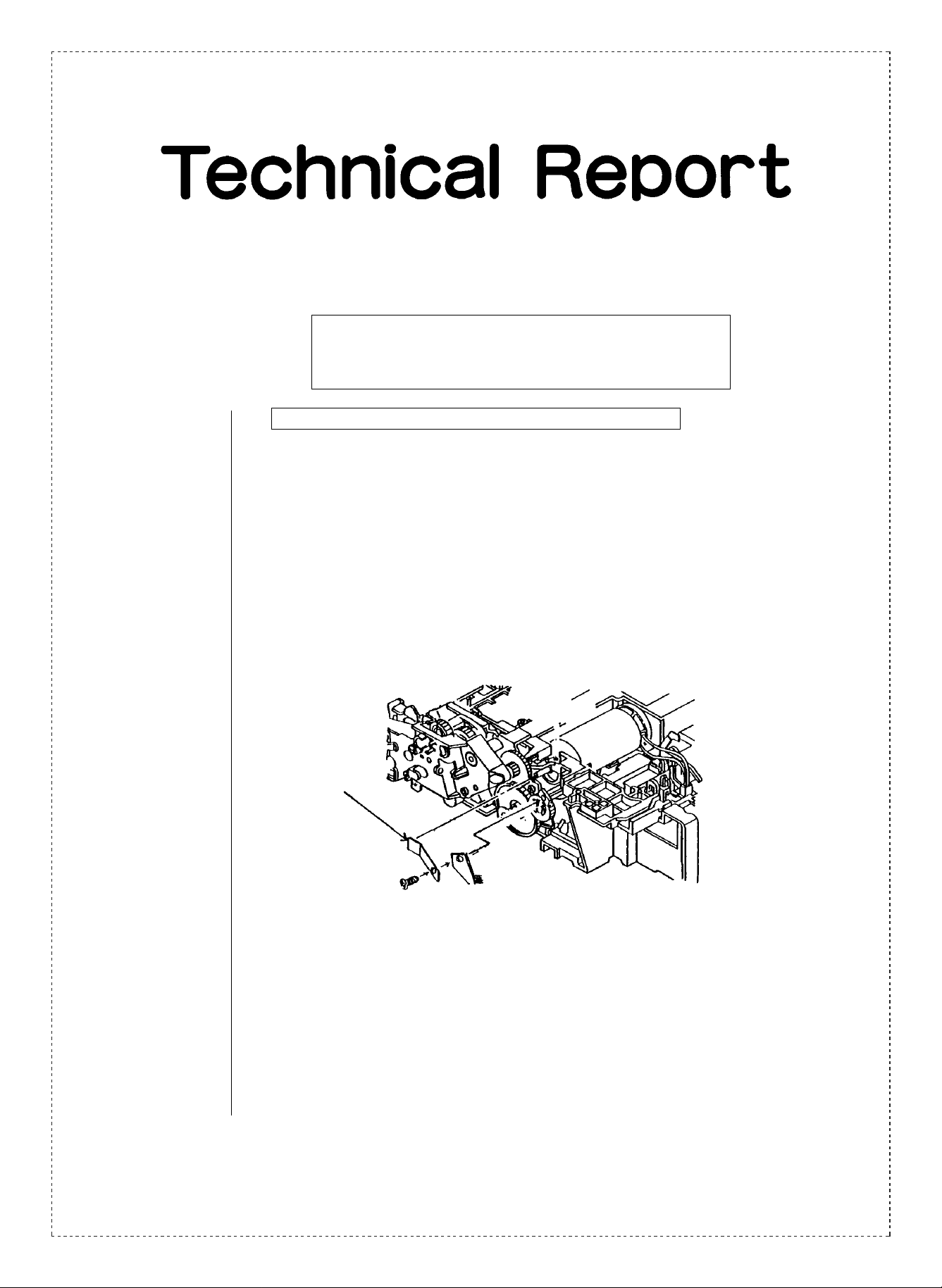

3.Description: (1)<Temporary measure>

A copper plate has been added and static electricity on the motor shaft has been

grounded in motors made in China to alleviate the problem described above.

Copper plate

This preventive measure was implemented from 1994 mid-August production to 1994

mid-November production. The problem described above has not occurred in

machines produced before this period because the motors were made in Japan. The

permanent measure described below was implemented directly to the motors in

machines produced after 1994 mid-November, and the copper ground plate was

discontinued.

SHARP CORPORATION Reprography Division

1/3

Green

C

Page 2

(2)<Permanent measure>

An conductor washer has been added between the shaft and the electrode brush in the

motor section. The static electricity on the shaft is discharged to the brush electrode,

preventing static electricity buildup on the shaft.

Conductor washer

Brush electrode

<Note>

The inscription label attached to the main motor (shown in the

figure to the right) has a blue line printed for units with the temporary

measure implemented. Labels attached to units with the permanent

measure implemented are entirely blue.

The main motors offered as service parts are made in Japan, and no changes in parts

codes have been carried out. Furthermore, the temporary measures described above

are not necessary.

4.Action: From 1994 mid-November production.

Magnet

Rotor

Magnet

Shaft

HOSIDEN

R3614

Blue line

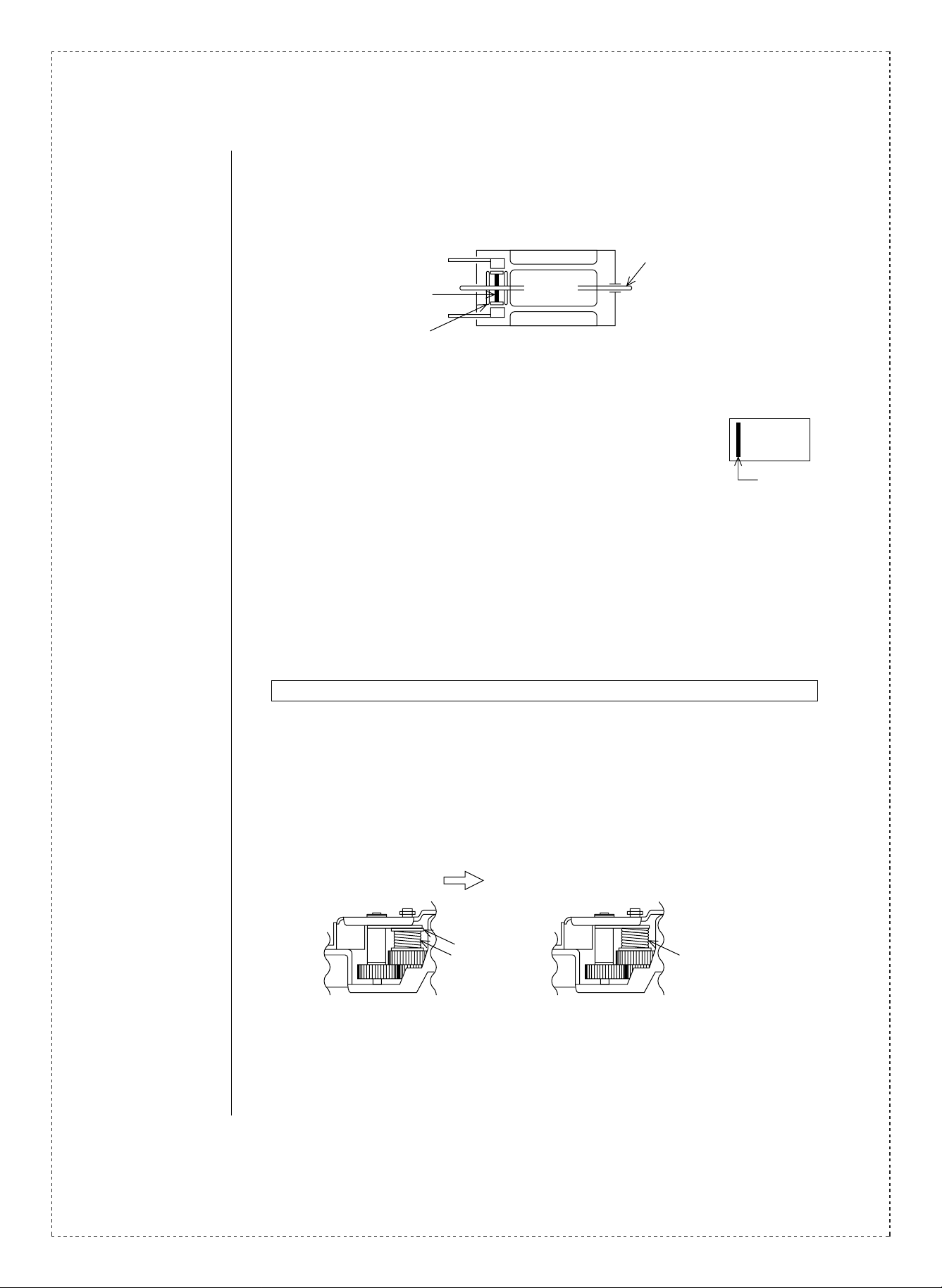

2. Change in springs and discon tinuance of washer s in the drive un it to improve produ ctivity.

1.Model name: Z-20/25/27

2.General: The washers have been discontinued in the drive unit ad the springs have been

changed to improve productivity. In accordance with these changes the parts codes of

the drive unit have also been changed.

3.Description:

(Old) (New)

PS Brake SP

(Shaft length: 13 mm)

2 Washers

PS Brake SP

PS Brake SP-N

(Shaft length: 19.6 mm)

PS Brake SP-N

4.Action: From the start of 1994 December production.

2/3

Page 3

3. Discontinuance of washers in the fan to improve productivity

1.Model name: Z-20/25/27

2.General: The plastic washers used in the fan have been discontinued to improve productivity .

3.Description:

(Old) (New)

4.Action: Running change from 1995 April production.

Ref.

Model

No.

2

3

<Interchange>

1. Inte r cha ng eable. 4. Not i nt er changeab l e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

specifie d ones fo r m aintaini ng t he s a fe ty an d pe r fo rma nc e o f th e s et .

name

Z-20

Z-25

Z-27

Version P/G No.

4

4

All

4 -901

7 -10

!

Current parts New parts

Parts code Parts code

LX-WZ0089FCZZ (Discontinued) — Washer

MSPRT0735FCZ1 MSPRT0735FCZ2 AB PS brake spring

CPLTM4495FC31 CPLTM4495FC32 BC Drive unit

NFANC0040FCZZ NFANC0040FCZ1 AN Fan

FanFan Washer

Effec-

Price

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Othe rs .

Parts name

rank

tive

time

1st lot

’94/12

1st lot

’94/12

1st lot

’94/12

See

text

Inter-

change-

ability

5

5

1

1

Note

3/3

Loading...

Loading...