Page 1

Date: Jul. 19, 1995

COPIER : SF-2022

1. MEASURES TO PREVENT ABNORMAL NOISE AND DOUBLE FEEDING IN THE 500

CASSETTE PAPER FEEDER UNIT .

2. CHANGE IN THE TENSION SPRING (TO PREVENT CONTACT WITH THE DEVELOPING UNIT).

3. EARTH CONDUCTION IMPROVEMENT MEASURES FOR THE TC CASE.

4. CHANGE IN SCREWS DUE TO A CHANGE IN SUPPLIERS.

1. Measures to prevent abnormal noise and double feeding in the 500 cassette paper

feeder unit.

1.Model name: SF-2022/2027/2035/1025

SF-CM1 1/D19/D20/D21

No. : SP-1902

2.General: Double feeding and abnormal noise sometimes occurs when paper feeding operations

are carried out on the 500 cassette paper feeder unit. To alleviate this problem the

following measures have been taken.

3.Description: The load of the reverse roller lever spring has been slightly lessened (315g ±15). The

changed spring has been painted yellow to differentiate it from the original springs.

4.Action: From 1995 mid-February production.

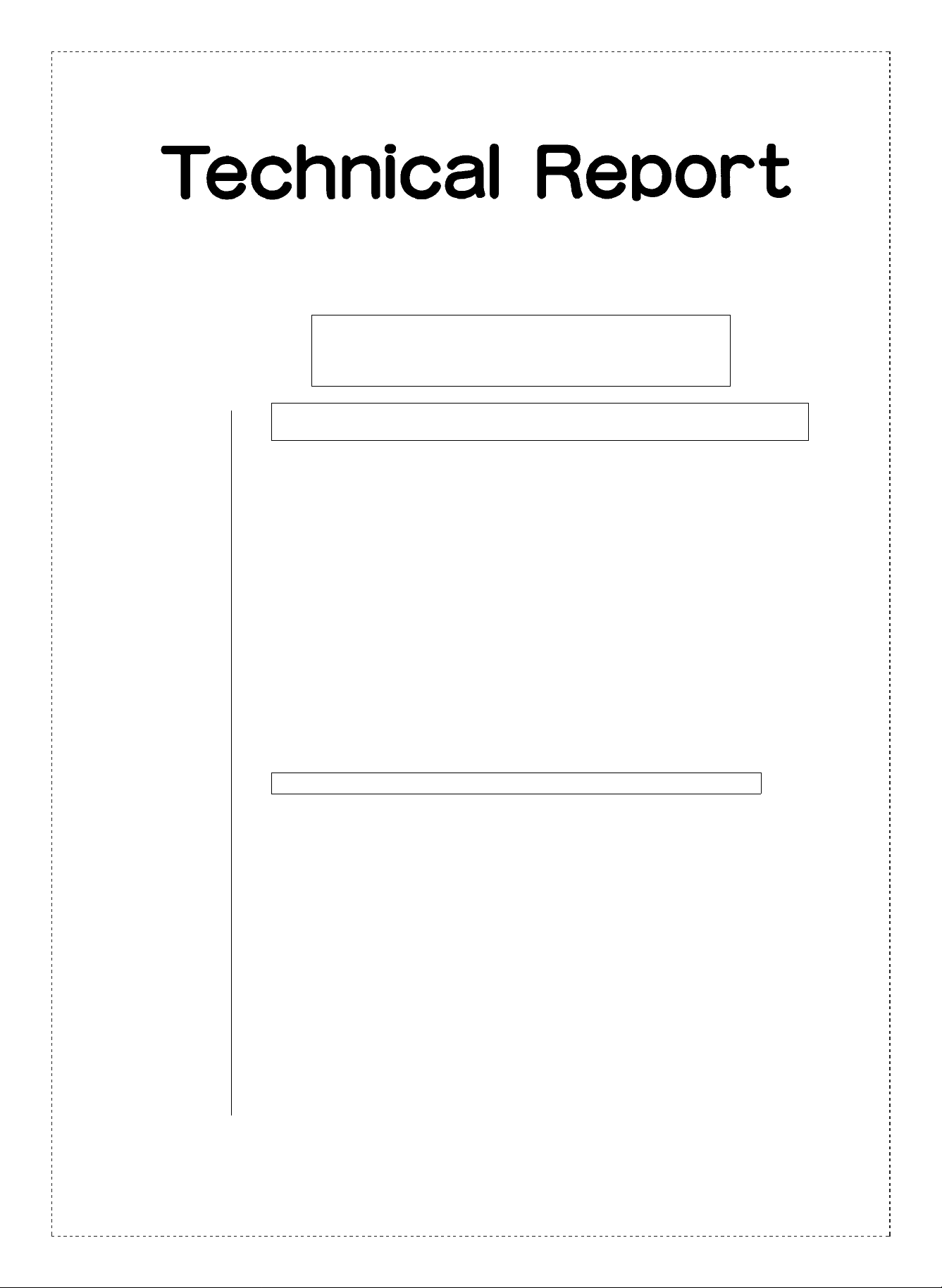

2 Change in the tension spring (To prevent contact with the developing unit.)

1.Model name: SF-2022/2027/2035/1025

2.General: The tension fulcrum spring was too long and there was danger of it coming in contact

with the developing unit. To alleviate this problem the spring has been changed to a

shorter spring. (This change is designated by the arrows in the figure).

SHARP CORPORATION Reprography Division

1/3

Green

C

Page 2

3.Action: SF-1025: From 1994 mid-August production.

SF-2027/2035: From the start of 1994 September production.

SF-2022: From 1994 mid-September production.

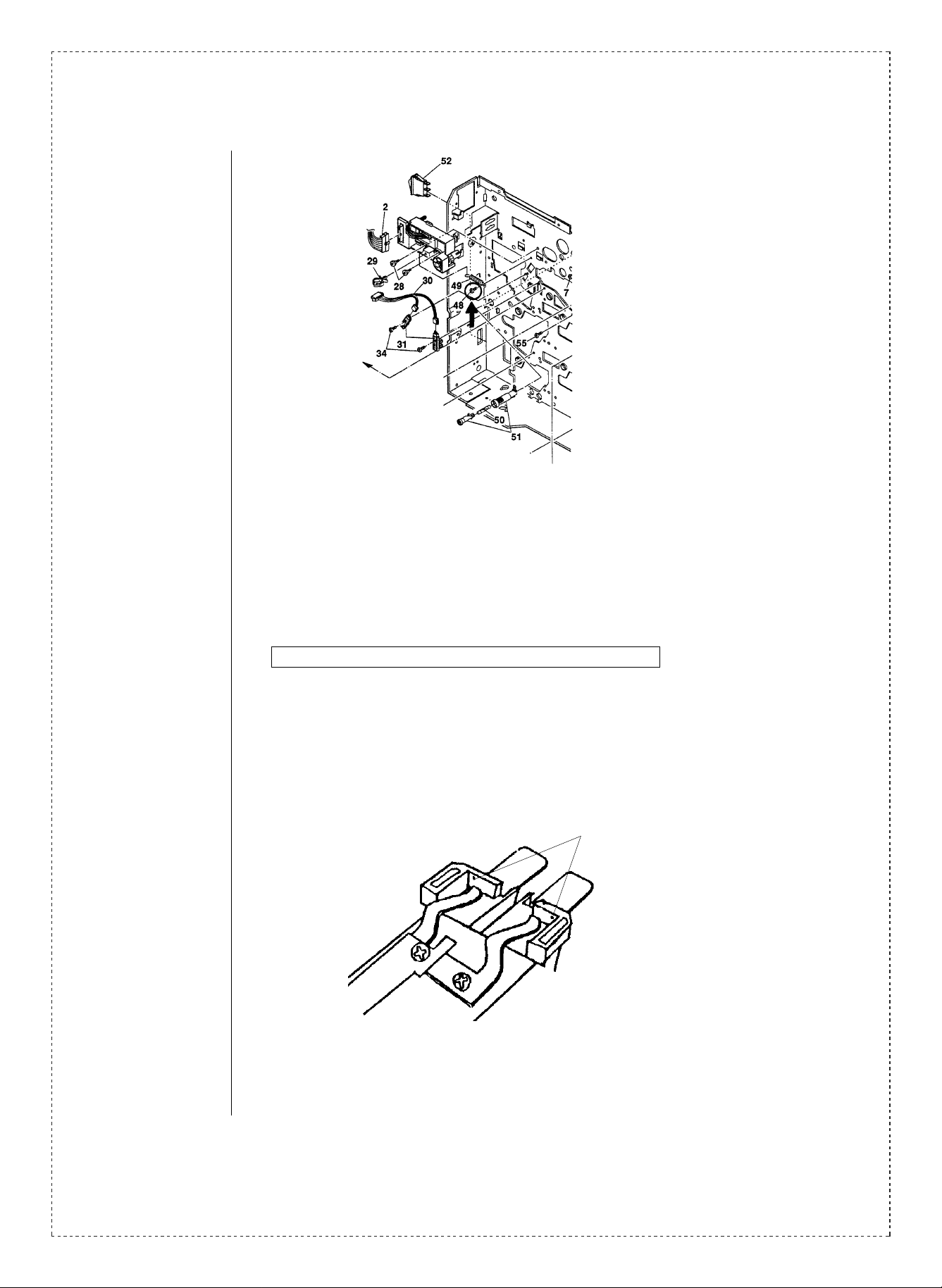

3. Earth conduciton improvement measures for the TC case.

1.Model name: SF-2022/2027

2.General: In order to improve the earth conducting of the TC case unit, the material of the charger

case plate spring and the shape of the spring has been changed. (This change has

been carried out on the right side only.) In accordance with this change the parts codes

for the TC case unit have also been changed.

The plate spring ends should not come above the wall.

3.Action: From the start of 1995 May production.

2/3

Page 3

4. Change in screws due to a change in suppliers.

1.Model name: SF-2022/2027/2035/1025

2.General: In accordance with a change in the maker, the screws in the front frame side as shown

by the arrows in the figure to the right have been changed.

3.Action: From the start of 1995 July production.

Ref.

Model

No.

SF-2022

SF-2027

SF-2035

SF-1025

1

SF-CM11 40 -36

SF-D19

SF-D20

SF-D21

SF-2022

SF-2027

2

SF-2035

SF-1025

SF-2022

3

SF-2027

SF-2022

SF-2027

4

SF-2035

SF-1025

<Interchange>

1. Interc ha ng ea bl e. 4. N ot i nt er ch an ge ab l e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

speci fi e d on es for m ain taining t he s a fe ty and pe r fo r ma nce o f th e set.

name

Version P/G No.

26 -36

66 -36

All

9 -48

25 -9 MSPRP1933FCZZ MSPRP2394FCZZ AE

25 -901 CCASZ0235FC54 CCASZ0235FC57 BF TC case unit

8

!

Current parts New parts

Parts code Parts code

MSPRC1943FCZ1 MSPRC1943FCZ2 AC

LX-BZ0659FCZZ LX-BZ0056FCZZ AA Screw

XHBSE40P10000

(Q’ty: 2)

LX-BZ0502FCZZ

(Q’ty: 2)

Price

rank

Roller lever

spring

Charger case

plate spring

AA Screw

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others .

Parts name

Effec-

tive

time

Mid-

’95/2

See

text

1st lot

’95/5

1st lot

’95/5

1st lot

’95/7

Inter-

change-

ability

3

3

3

3

1

Note

3/3

Page 4

Loading...

Loading...