Page 1

Date: Jul. 26, 1995

COPIER : SF-2014

1. PREVENTION OF DUAL END MIS-COPIES DURING FULL-FACE HALF-TONE COPY

OPERATIONS.

2. MEASURES TO IMPROVE EXPOSURE LIGHT ADJUSTMENT OPERATIONS.

3. MEASURES TO PREVENT DISLODGING OF THE DARK BOX COVER.

4. COUNTER MEASURE FOR PARTIALLY TIGHTENED SCREWS IN THE SPF PAPER FEEDER

DRIVE UN IT.

No. : SP-1900

1. Prevention of dual side mis-copies during full-face half-tone copy operations.

1.Model name: SF-2014/21 14/2214

Z-800, SN-1420/1430

2.General: The volume of light from the copy lamp in the copy check operations during the

production process is sometimes slightly less at the right and left edges of the copy

paper than in the center. As a result, when half-tone copy operations are carried out,

both sides of the paper (right and left) are sometimes a little darker than the center of

the paper. To improve production efficiency, the measures described below have been

instituted.

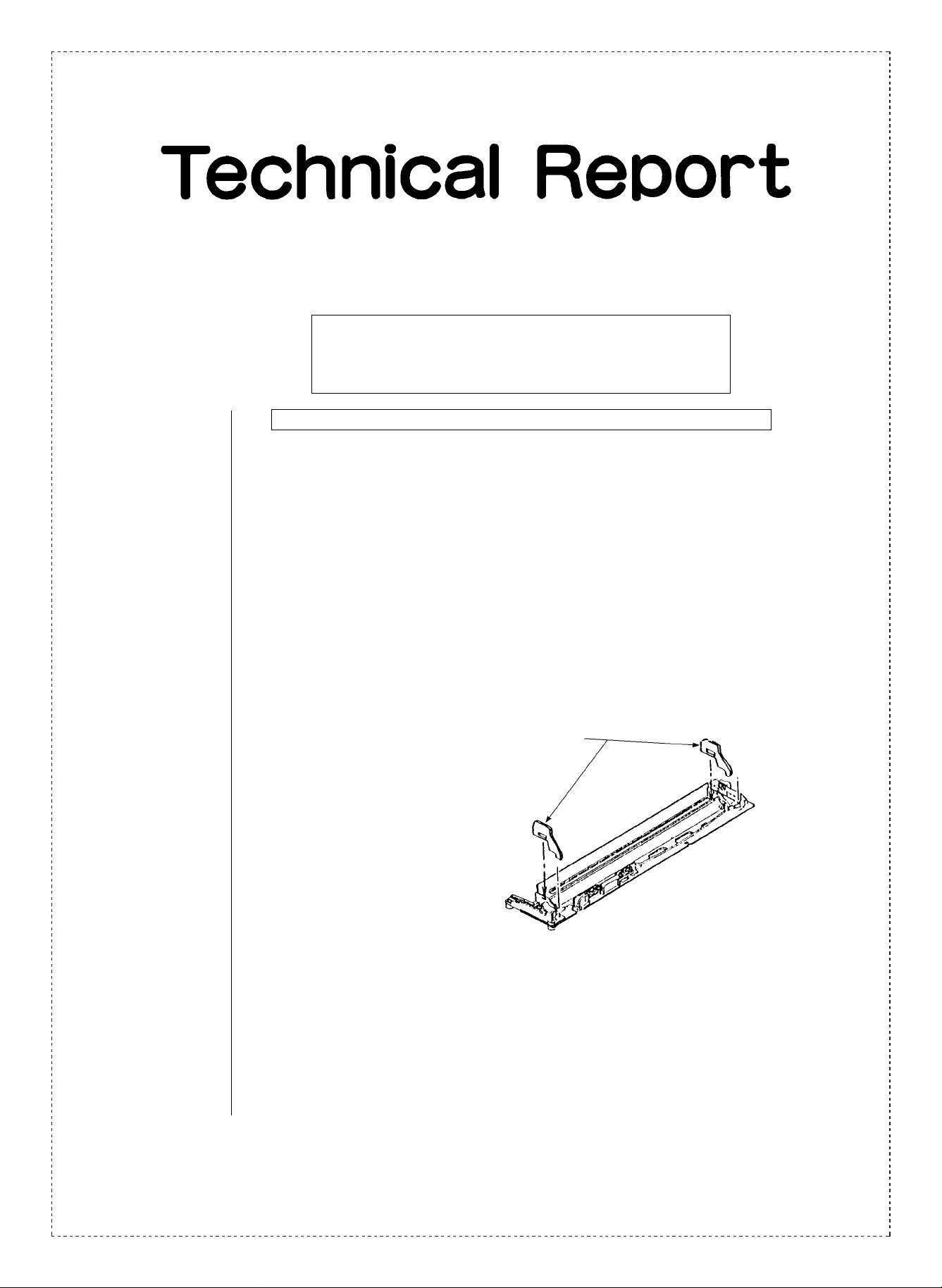

3.Description: Side reflectors have been installed in the lamp unit to increase the amount of light

received by both sides of the copy paper.

Side reflectors.

Because the side reflectors are not

necessary in the market, they have not

been offered as standardized service parts.

4.Action: Japanese production:

SF-2214 (all locations): From 1994 mid-December production.

SF-2014/2114 (bound for SEEG): From 1995 mid-January production.

SF-2014/2114 (except for SEEG): From 1995 mid-May production.

Chinese(SOCC)production : From the start of mass production.

French(SMF)production : From 1994 November production.

SHARP CORPORATION Reprography Division

1/4

Green

C

Page 2

2. Measures to improve exposure light adjustment operations.

1.Model name: SF-2114/ 2214

SN-1420/1430

2.General: There is no margin for adjustments for the photographic mode exposure adjustments

during the copy check operations of the production line. T o remedy this situation the

following measures have been taken.

3.Description: The tightening of the lens has been changed as an improvement measure, from the

previous F8 setting to an F9 setting.

4.Action: Japanese production: From 1995 mid-July production.

Chinese(SOCC)production: From 1995 mid-April production.

French(SMF)production: From 1995 mid-August production.

3. Measures to prevent dislodging of the dark box cover.

1.Model name: SF-2014

Z-800 (USA only)

2.General: The cover of the dark box sometimes became dislodged during transport of the

machine itself. To alleviate this problem the following measures were taken.

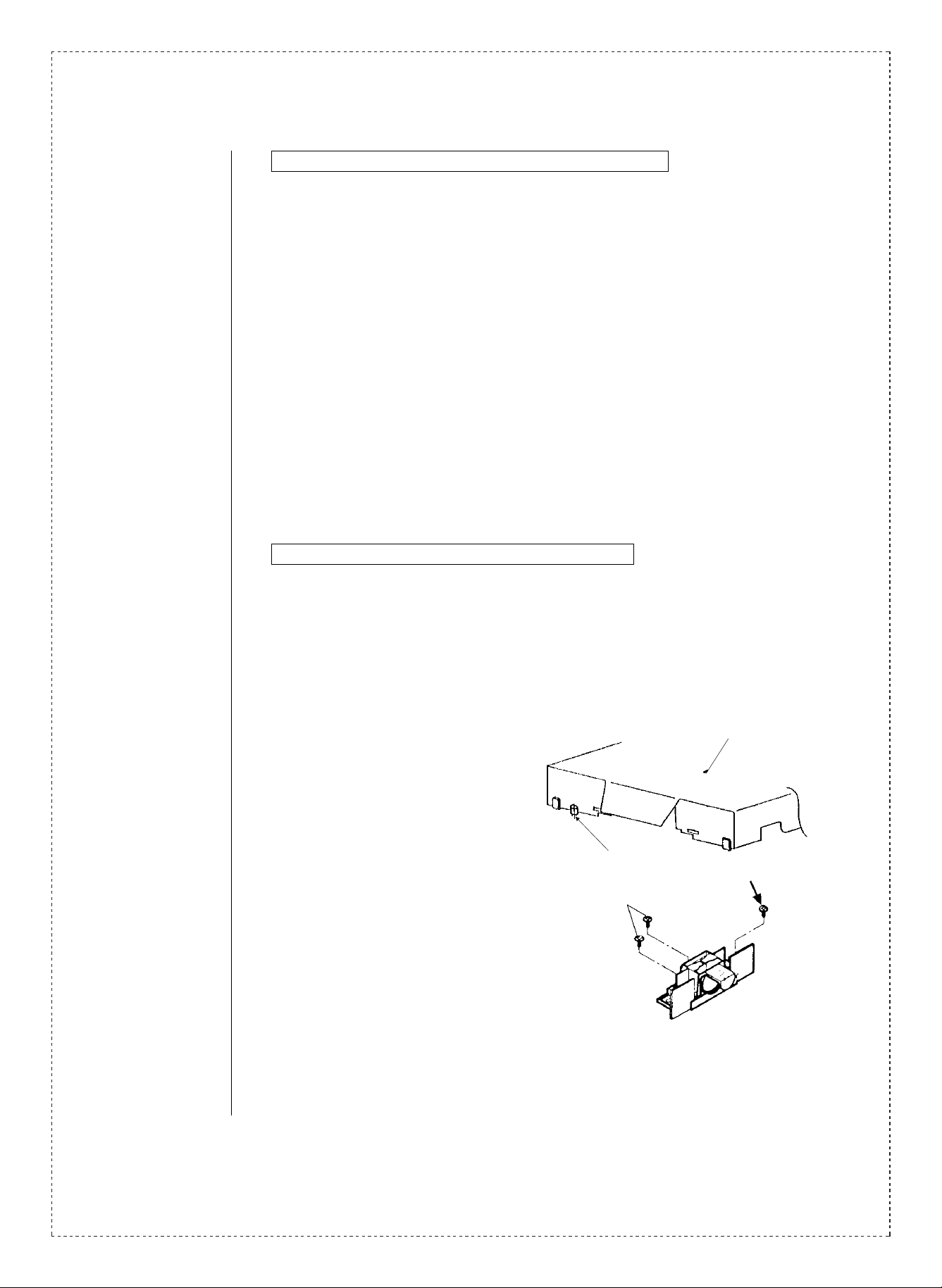

3.Description: (1) Step screws were added as stoppers

100 Cover of the dark box.

as shown in the figure to the right, to

prevent the cover of the dark box from

moving.

Step screw used as a stopper.

(2) Until the measure described in (2) above

was implemented, the screw designated by

the arrow in the figure to the left was changed

and used as a stopper. The change described

above, however, the original screw has been

replaced.

LX-BZ0512FCZZ → LX-BZ0353FCZZ

(All three screws have become the same).

Note: The parts code listed in the parts guide is “XBPSD40P08KS0", but as

described above, the actual parts code is different, and the parts code listed in

the parts guide is an error. A correction of this parts code is requested.

2/4

Page 3

(3) Because there is little space between the drying heater and the dark box, the

cutaway section has been enlarged as shown in the picture.

The section designated by the

diagonal lines should be cut away.

Cut away section.

4.Action: (1), (2): Japanese production: From 1995 mid-April production.

Chinese(SOCC)production: From 1995 mid-May production.

French(SMF)production: From 1995 mid-June production.

(3): Japanese production: From 1995 mid-May production.

Chinese(SOCC)production: From the start of 1995 July production.

French(SMF)production: From the start of 1995 June production.

4. Counter measure for partially tightened screws in the SPF paper feeder drive unit.

1.Model name: SF-2214

SN-1430 (USA only)

2.General: Some of the screws in the SPF paper feeder drive unit were too short, and as a result

did not sufficiently tighten during the assembly process. To alleviate this problem the

screws were changed to those longer in length.

3.Description: The screws circled in the figure below (7 total) have been changed from M4 x 6 screws

to M4 x 8 scr e w s.

3/4

Page 4

4.Action: Japanese production: From the start of 1995 August production.

Chinese(SOCC)production: From the start of 1995 September production.

French(SMF)production: From the start of 1995 October production.

Ref.

Model

No.

SF-2114

SF-2214

2

SN-1420

SN-1430

SF-2014 All

3

(1)

Z-800

SF-2014 All

3

(2)

Z-800

SF-2014 All

3

(3)

Z-800

<Interchange>

1. Intercha ng ea bl e. 4. N ot i nt er ch an ge ab l e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

spec ifi e d on es fo r m ai n ta ini ng t he s a fe ty an d pe r fo rma nc e o f the set .

name

Version P/G No.

6 -93

All

USA

only

USA

only

USA

only

USA

only

8 -93

6

7

6

7

6-1

7-1

!

Current parts New parts

Parts code Parts code

CLNS-0050FC31 CLNS-0050FC33 BF Lens unit A2

— LX-BZ0156FCZZ AA Screw

LX-BZ0512FCZZ LX-BZ0353FCZZ AA Screw

PCOVP1230FCZZ PCOVP1230FCZ1 AN Drak box cover

Price

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others .

Parts name

rank

Effec-

tive

time

See

text

Inter-

change-

ability

1

1

—

—

4

4

3

3

Note

4/4

Loading...

Loading...