Page 1

Date: Jul. 25, 1995

COPIER : SF-2014

1. Measures to improve the SPF guide movement.

1.Model name: SF-2214

SN-1430 (USA only)

No. : SP-1898

1.MEASURES TO IMPROVE THE SPF GUIDE MOVEMENT.

2.MEASURES PREVENTING PS GATE WARPING AND SPF PAPER DELIVERY ROLLER GRINDING.

3.CHANGE IN THE OC HINGE GUIDE TO PREVENT LOOSENE SS AND CHANGE IN THE METAL MOLDS.

4.MEASURES TO PREVENT THE MB WIRE FROM COMI NG LOOSE.

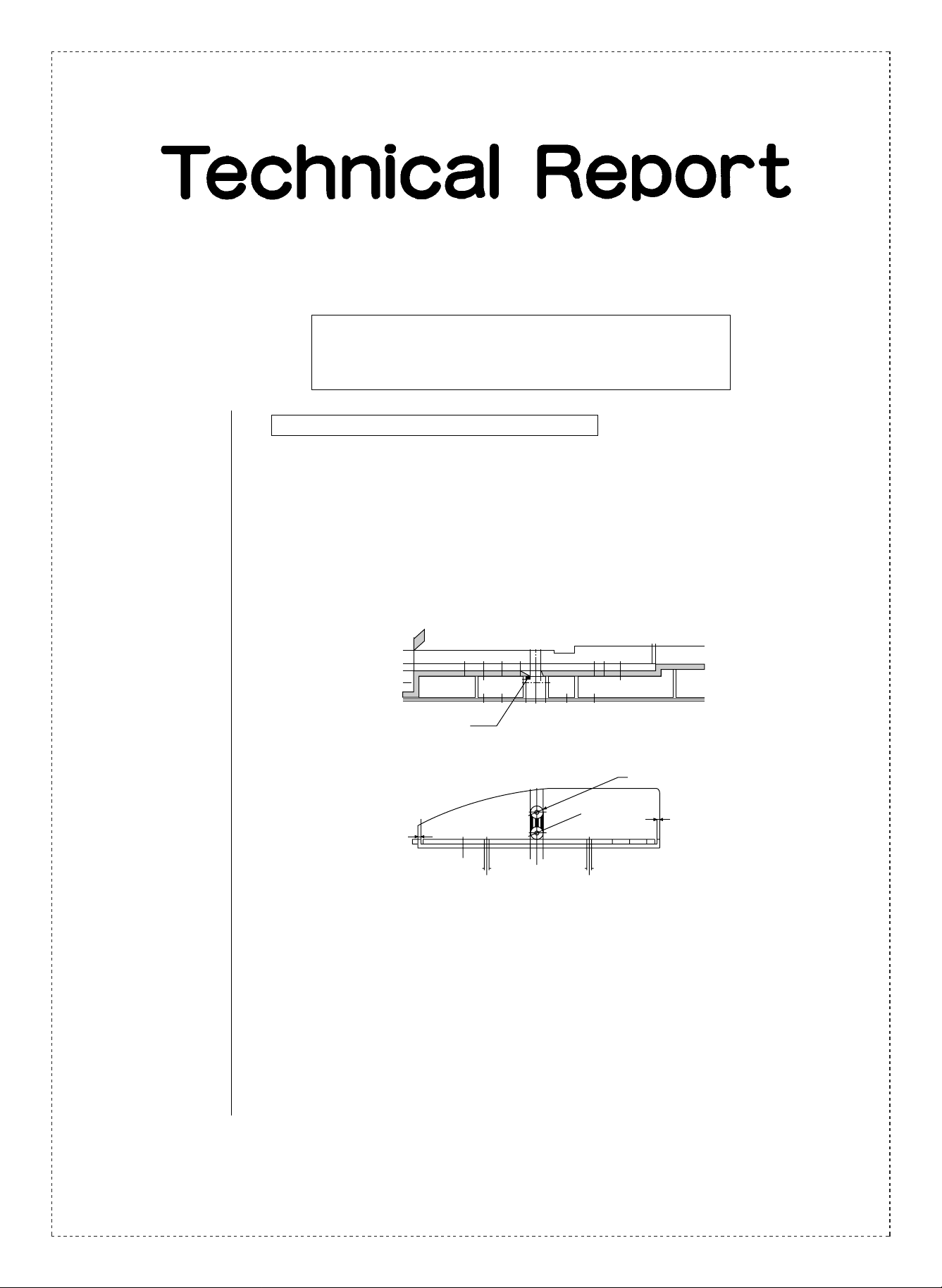

2..General: When the SPF copy paper guide in the SPF unit is in operation, friction sometimes

occurs between the SPF base tray and the SPF copy paper guide. T o alleviate this

problem, the following measures have been taken.

3.Description:

SPF Base tray

2

Added built-up section

Added rib

2-φ6

-0.07

-0.02

SPF Copy paper guide

2-φ2.4

2

2

2

4.Action: Running change from 1995 March production.

SHARP CORPORATION Reprography Division

1/5

Green

C

Page 2

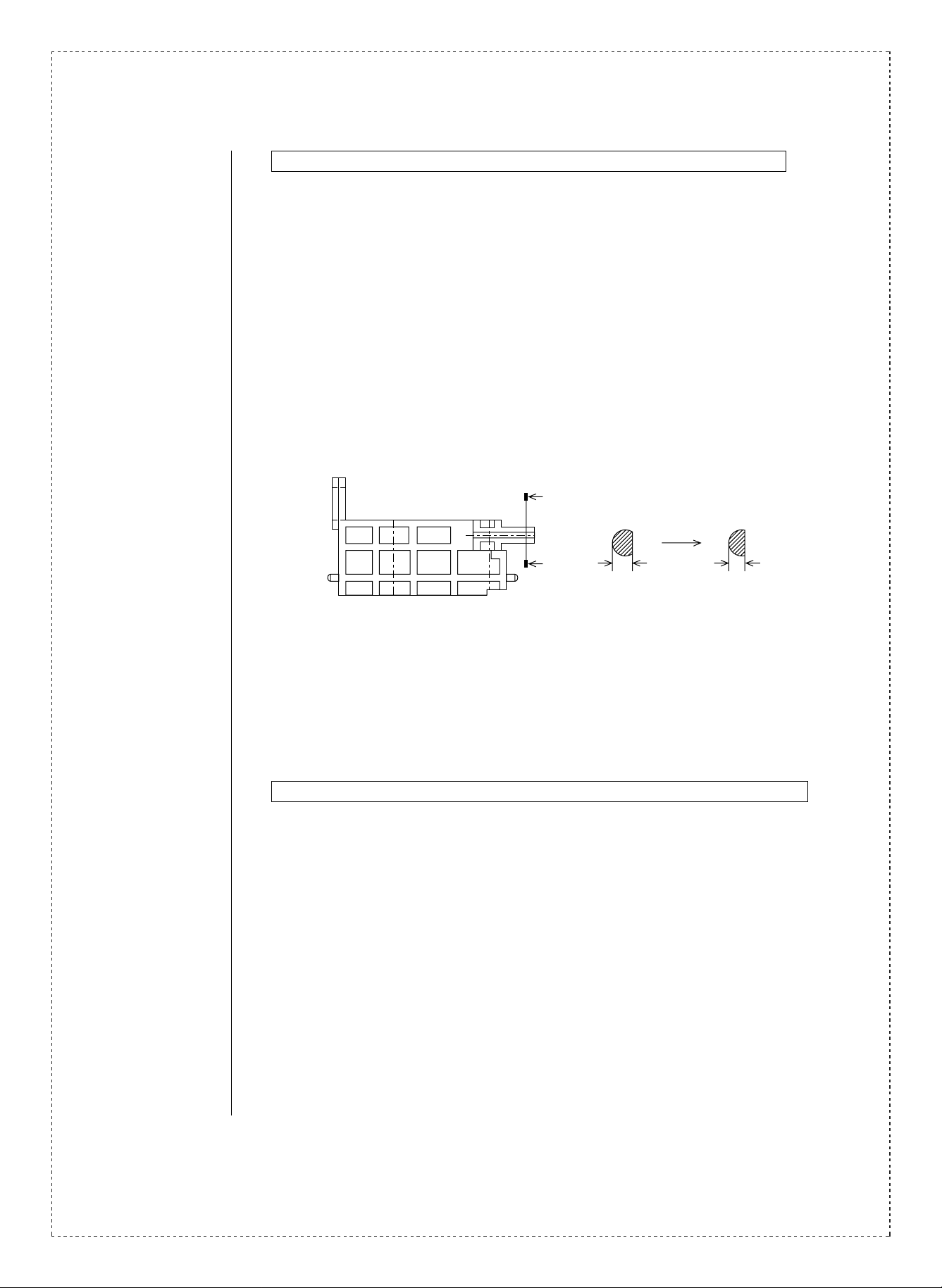

2. Measures preventing PS gate warping and SPF paper delivery roller grinding.

1.Model name: SF-2214

SN-1430 (USA only)

2.General: Problems of grinding of the F side delivery roller in the SPF paper feeder section and

warping of the PS gate (which occurs when original documents are inserted too

strongly) have occurred. To alleviate these problems the changes in shape described

below have been carried out.

3.Description: SPF delivery roller:

Changed roller diameter: 15.5 mm → 15.3 mm.

Changed roller material: (color: gray) (color: opaque).

Changed shape of the SPF roller movement arm.

A

A

Cross section A-A

3.3 2.9

4.Action: Japanese production: From the start of 1995 April production.

Chinese (SOCC) production: From the start of 1995 May production.

French (SFM) production: From the start of 1995 June production.

3. Change in the OC hinge guide to prevent looseness and change in the metal molds.

1.Model name: SF-2014/21 14/2214

Z-800, SN-1420/1430 (USA only)

2.General: As a measure to prevent the left OC hinge guide from loosely moving after it has been

installed in the optical unit, ribs have been added to the locations shown in the figure

below to increase the strength of the part, enabling it to sustain repeated opening and

closing. In accordance with a request from a portion of the market, ribs have been

added to the right OC hinge guide, to immobilize the OC opening and closing detection

sensor harness.

2/5

Page 3

3.Description:

OC Hinge guide left

Added rib Added rib

C2 C2

OC Hinge guide right

Harness retainer mylar

P

Edge surface standard

0

-2mm

15

Rib

Detail of the P section

Edge surface standard

±1mm

4.Action: Japanese production: Running change from 1995 mid-March production.

Chinese (SOCC) production: Running change from 1995 mid-April production.

French (SFM) production: Running change from 1995 mid-May production.

4. Measures to prevent the MB wire from coming loose.

1.Model name: SF-2014/21 14/2214

Z-800, SN-1420/1430 (USA only)

2.General: When the MB wire is trapped by the wire attachment plate in the light source unit, the

front edge of the wire attachment plate sometimes becomes deformed due to the

weakened holding power of the plate. When this occurs, the MB wire occasionally

becomes detached from the wire attachment plate. To alleviate this problem, the

following measure has been carried out.

3.Description: As shown in the figure below, the MB wire is prevented from coming loose by the bent

section of the leading edge of the wire attachment plate. The height is 0.5 mm.

Sintered wire holder

Old New

wire

Added lip

Difference in height: 0.5 mm

F/R Wire attachment plate

3/5

Page 4

4.Action: Running change from 1995 mid-February production.

<Reference>

Confirmation of whether or not the changes have been carried out is possible for the

manufacturing numbers of the light source units listed below (the manufacturing

numbers are printed on labels which have been attached to the humidity fuse sections).

Light source unit s (100V series) : 4031 1 t o 41000, 41235 to 42000, 42197 to all num bers aft er .

Light source unit s (200V series) : 23902 to 24070, 24891 to 24900, 25432 t o all numbers aft er .

Ref.

Model

No.

name

SF-2214 All

SN-1430

1

SF-2214 All

SN-1430

SF-2214 All

SN-1430

2

SF-2214 All

SN-1430

SF-2014

SF-2114

SF-2214

Z-800

SN-1420

SN-1430

3

SF-2014

SF-2114

SF-2214

Z-800

SN-1420

SN-1430

SF-2014

SF-2114

SF-2214

Z-800

SN-1420

SN-1430

4

SF-2014

SF-2114

SF-2214

Z-800

SN-1420

SN-1430

Version P/G No.

USA

only

USA

only

USA

only

USA

only

USA

only

USA

only

USA

only

USA

only

3-4

3-3

3 -77

3 -58

6-2

All

7-2

8-2

6-6

All

7-6

8-6

8 -23

All

6 -23

7 -23

8 -22

All

6 -22

7 -22

Current parts New parts

Parts code Parts code

LSOU-0131FCZZ LSOU-0131FCZ1 BB SPF base tray

PGIDM1499FCZZ PGIDM1499FCZ1 AF SPF paper guide

NROLR1034FCZ2 NROLR1034FCZ3 AS

MARMP0179FCZ1 MARMP0179FCZ2 AD

PGIDM1495FCZZ PGIDM1495FCZ1 AF OC hin g e gu i de L

PGIDM1496FCZZ PGIDM1496FCZ1 AF OC hin g e gu i de R

LPLTM4715FCZZ LPLTM4715FCZ1 AF Wire fixing p late F

LPLTM4716FCZZ LPLTM4716FCZ1 AF Wire fi x in g p l a te R

Price

Parts name

rank

SPF delivery

roller

SPF roller

movement arm

Effec-

tive

time

See

text

Inter-

change-

ability

1

3

Note

4/5

Page 5

Ref.

Model

No.

SF-2014

SF-2114

SF-2214

Z-800

4

SN-1420

SN-1430

SF-2014

SF-2114

SF-2214

<Interchange>

1. Interc ha ng ea bl e. 4. N ot i nt er ch an ge ab l e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

spec i fi e d on es for mai n ta in i ng t he s a fe ty an d pe rf o rma nc e o f th e s et .

name

Version P/G No.

100V

series

USA

only

200V

series

6 -85

8 -901

7 -85

6 -901

8 -85

7 -901

6 -85

8 -901

!

Current parts New parts

Parts code Parts code

CREFL0150FC31 CREFL0150FC33 BQ

CREFL0150FC32 CREFL0150FC34 BQ

Price

rank

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others.

Parts name

Light source unit

(100V series)

Light source unit

(200V series)

Effec-

tive

time

See

text

Inter-

change-

ability

3

Note

5/5

Loading...

Loading...