Page 1

Date: Jul. 26, 1995

COPIER : SF-2014

1. MEASURES TO PREVENT SLIP JAMS AND ABNORMAL

NOISE IN THE CASSETTE PA PER FEEDER UNIT.

2. IMPROVEMENT MEASURES FOR THE MANUAL ARM.

1. Measures to prevent slip jams and abnormal noise in the cassette paper feeder unit.

1.Model name: SF-2014/2114/2214, SF-CM14

Z-800, SN-1420/1430, SN-CM11 (USA only)

No. : SP-1896

2.General: Slip jams in the cassette paper feeder and abnormal noise from the separator roller

sometimes occurs when using standard paper. To alleviate these problems, the

measures described below have been carried out.

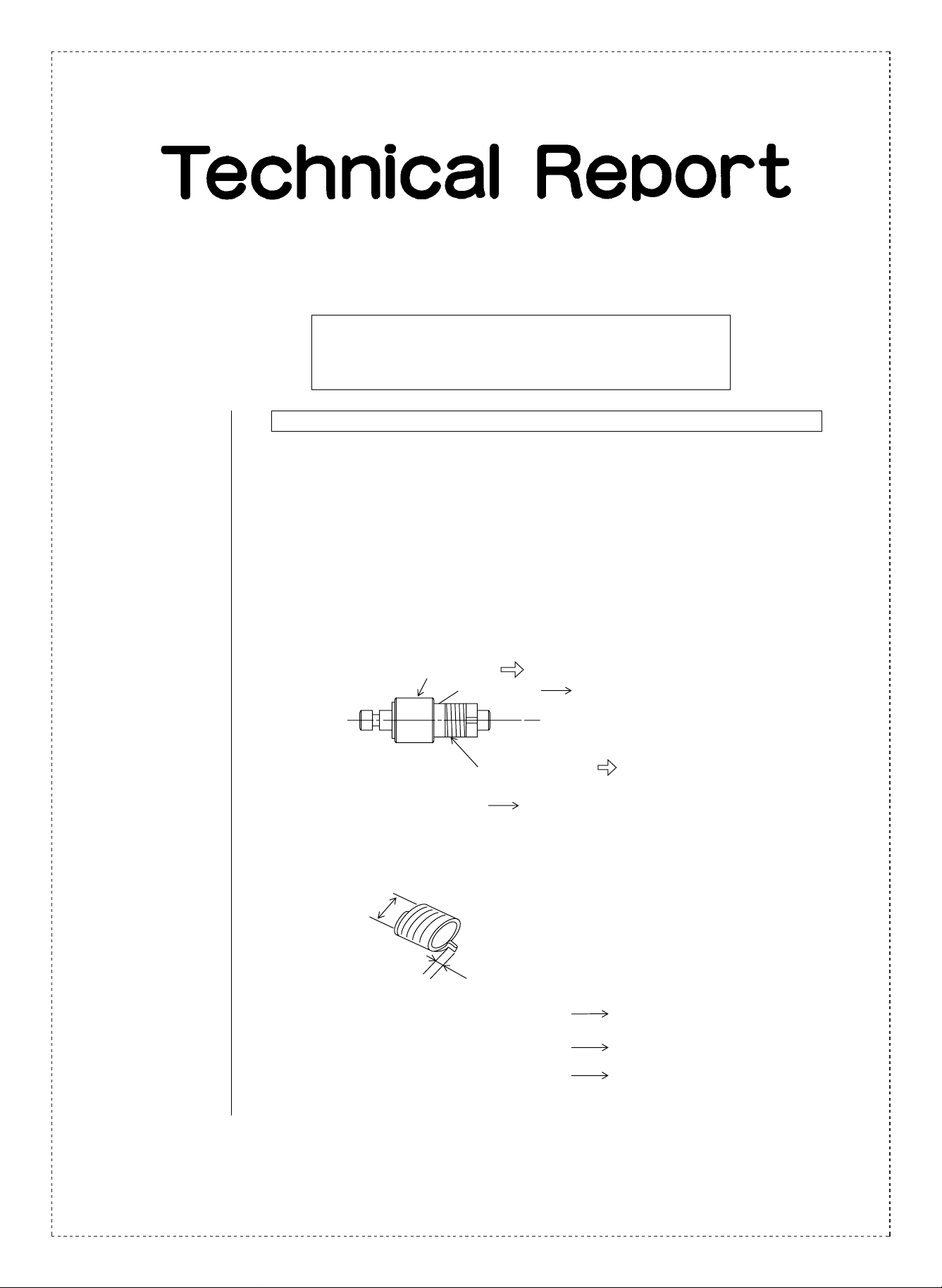

3.Description: (1) Discontinuance of the roller cushion.

(2) Change in the reverse roller unit.

Uretain 80° 60°

Color: (white) (black)

Torque: 275 g•cm 300 g•cm

CROLR1052FC31 FC33

±50

±50

(3) Change in the limiter spring.

Diameter

Hook length

MSPRC2202FCZ1 MSPRC2357FCZZ

Diameter: φ13.5 φ13.4

Hook length: 2.5 4

SHARP CORPORATION Reprography Division

1/5

Green

C

Page 2

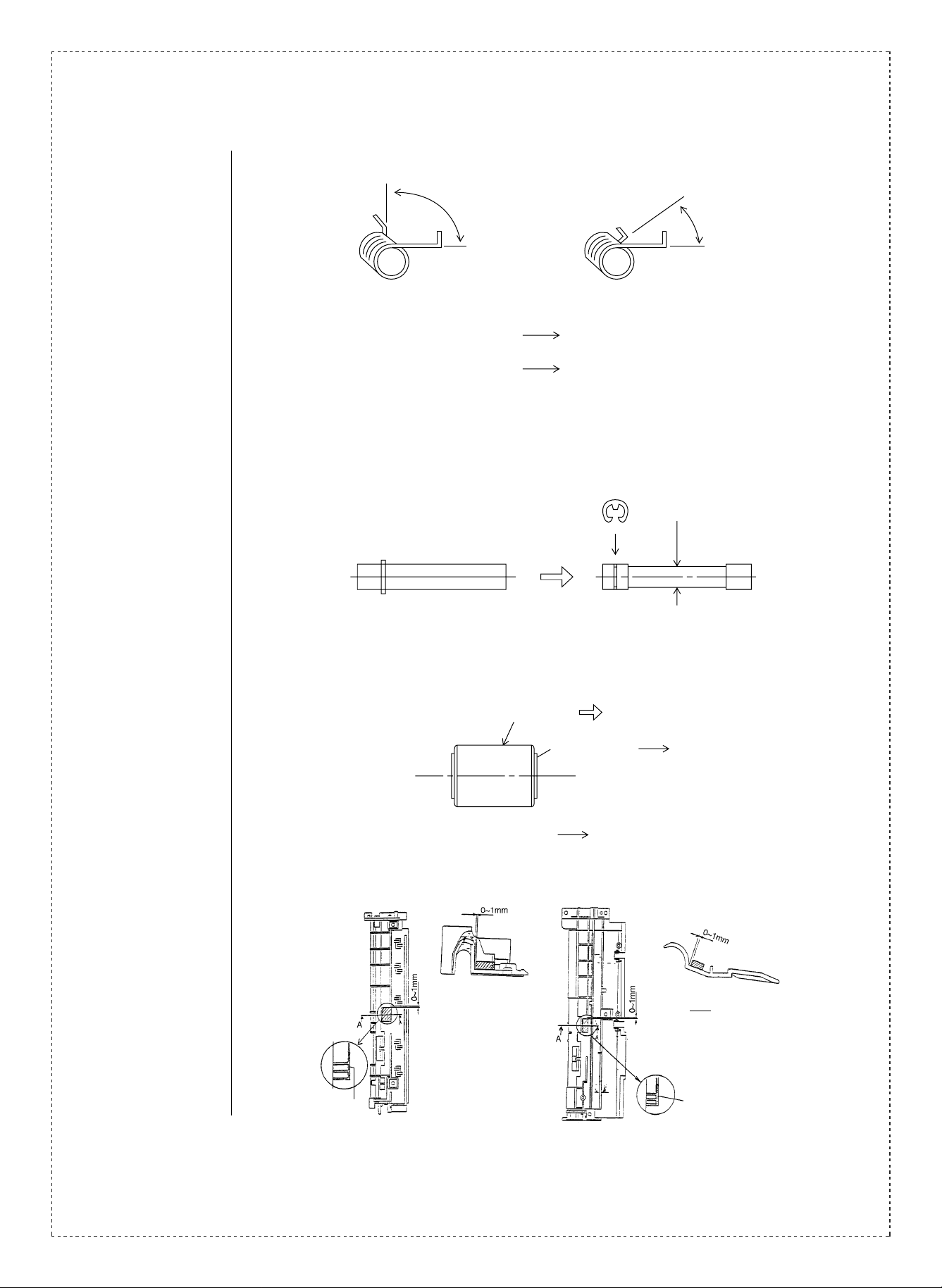

(4) Change in the roller release arm spring.

90°

MSPRC2201FCZ1 MSPRC2358FCZZ

Number of coils: 10.75 10.61

(5) Discontinuance of paper feeder weight.

(6) Change in the shape of the roller shaft and addition of E-ring.

E7

40°

φ6

NY66

NSFTZ2118FCZZ

(7) Change in the paper feeder roller material.

EPDM

30°

NROLR1049FCZZ NROLR1049FCZ1

(8) Addition of ribs to the paper feeder frame.

Second paper feeder frame.

250 cassette paper feeder frame.

SUM24L

NSFTZ2218FCZZ

NOSOLEX (NSS)

25°

Color: (white) (black)

A-A

2/5

Rib

Rib

Page 3

(9) Addition of ribs to the inclined diagonal surface of the cassette front green section.

2. Improvement measures for the manual arm.

1.Model name: SF-MF14

SN-MF1 1 (USA only)

1mm Built-up portion

2.General: Movement errors sometimes occur in the manual multi-paper feeding unit due to the

slight margin between the calling arm which carries out the operations and the manual

arm which maintains the calling roller. To alleviate this problem, changes in the arm

fulcrum and the position of the guide ribs have been carried out.

3.Description:

It is difficult to distinguish between the old and

new parts. To remedy this problem 3Z has

been printed on the inside surface of the location

designated by the arrow

manual arm

4.Action: * Japanese production: From 1995 mid-April production.

Chinese(SOCC)production: From the start of 1995 July production.

French(SMF)production: From the start of 1995 July production.

3/5

Page 4

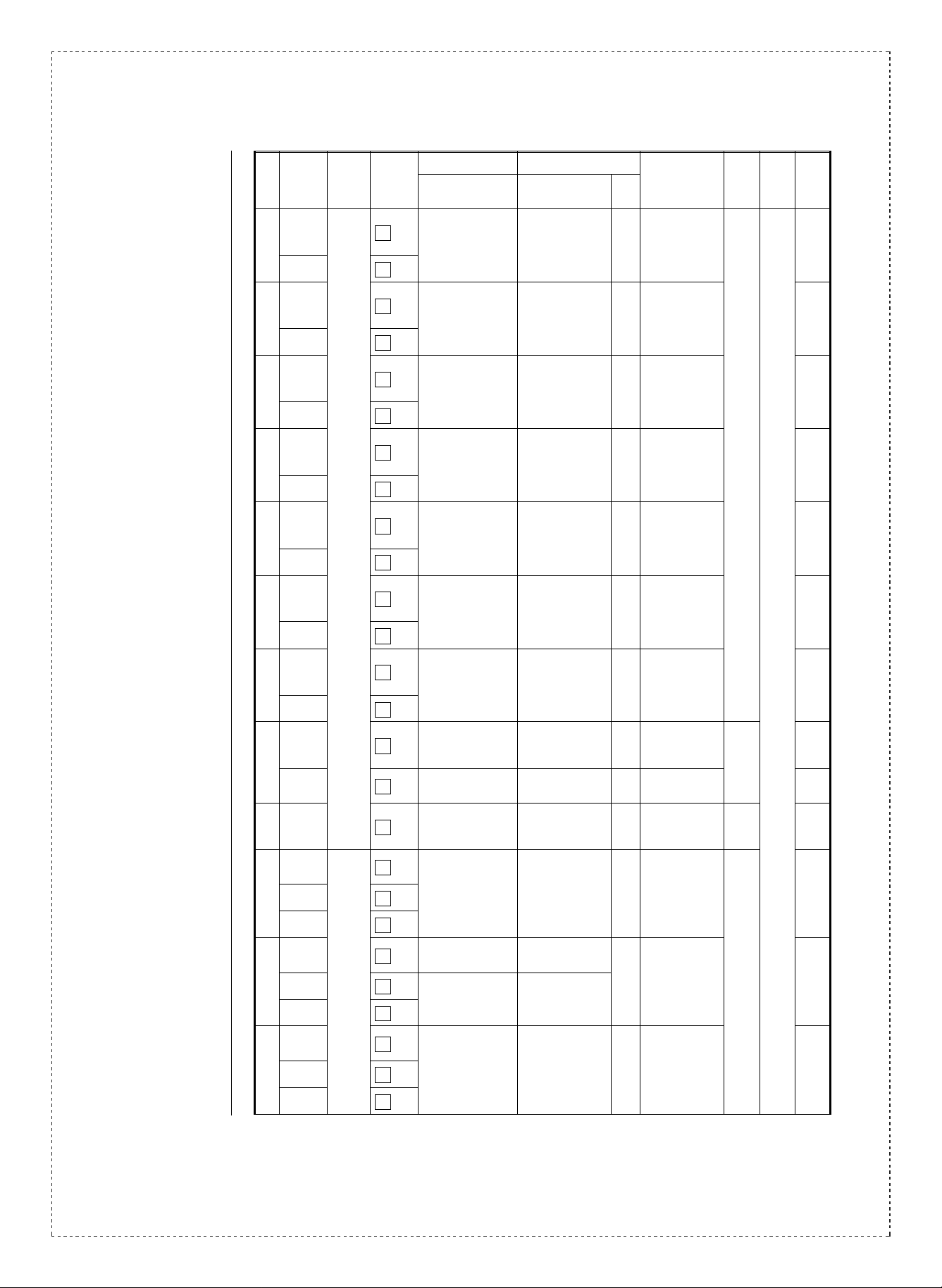

Ref.

No.

1

(1)

Model

name

SF-2014

SF-2114

SF-2214

SF-CM14

Version P/G No.

18 -42

51 -39

Current parts New parts

Parts code Parts code

Price

Parts name

rank

PCUSS0315FCZZ Discontinued — Roller cushion

Effec-

tive

time

Inter-

change-

ability

Note

1

(2)

1

(3)

1

(4)

1

(5)

1

(6)

1

(7)

SF-2014

SF-2114

SF-2214

SF-CM14

SF-2014

SF-2114

SF-2214

SF-CM14

SF-2014

SF-2114

SF-2214

SF-CM14

SF-2014

SF-2114

SF-2214

SF-CM14

SF-2014

SF-2114

SF-2214

SF-CM14

SF-2014

SF-2114

SF-2214

SF-CM14

13 -38

CROLR1052FC31 CROLR1052FC33 AX

Reversing roller

unit

51 -15

18 -30

MSPRC2202FCZZ MSPRC2357FCZZ AE 250 limiter spring

52 -14

Running

18 -28

MSPRC2201FCZZ MSPRC2358FCZZ AC

250 rol ler r el ea se

arm spring

change

’95/5

18 -16

All

18

PWET-0027FCZZ Discontinued —

Paper feeder

weight

52

18 -33

NSFTZ2118FCZZ NSFTZ2218FCZZ AL Roller shaft

52 -24

18 -24

NROLR1049FCZZ NROLR1049FCZ1 AU

Paper feeding

roller

3

52 -19

4/5

SF-2014

SF-2114

1

SF-2214

(8)

SF-CM14

SF-2014

1

SF-2114

(9)

SF-2214

SN-1420

SN-1430

1

(1)

SN-CM11 51 -39

Z-800

SN-1420

SN-1430

1

(2)

SN-CM11 51 -15

USA

only

Z-800

SN-1420

SN-1430

1

(3)

SN-CM11 52 -14

Z-800

18 -3 LFRM-0805FCZZ LFRM-0805FCZ1 AQ

52 -27 LFRM-0807FCZZ LFRM-0807FCZ1 AN

Paper feeding

frame

Second paper

feeder frame

19 -9 GCASP0164FCZZ GCASP0164FCZ1 AZ 250 cassette

17 -42

PCUSS0315FCZZ Discontinued — Roller cushion

16 -42

14 -38 CROLR1052FC31 CROLR1052FC33

Reversing roller

AX

unit

CROLR1052FC31 CROLR1052FC33

13 -38

17 -30

MSPRC2202FCZZ MSPRC2357FCZZ AE 250 limiter spring

16 -30

Mid-

’95/3

Mid-

’95/5

Running

change

’95/5

Page 5

Ref.

Model

No.

SN-1420

SN-1430

1

(4)

SN-CM11 52 -16

name

Version

P/G No. Current parts New parts

Parts code Parts code

17 -28

MSPRC2201FCZZ MSPRC2358FCZZ AC

Price

rank

Parts name

250 rol ler r el ea se

arm spring

Effec-

tive

time

Inter-

change-

ability

Note

Z-800

SN-1420

SN-1430

1

(5)

SN-CM11 52

Z-800

SN-1420

SN-1430

1

(6)

SN-CM11 52 -24

Z-800

SN-1420

SN-1430

1

(7)

SN-CM11

Z-800

Z-800

SN-1420

1

SN-1430

(8)

SN-CM11

Z-800

1

(9)

SN-1420

SN-1430

USA

only

16 -28

17

PWET-0027FCZZ Discontinued —

16

17 -33

NSFTZ2118FCZZ NSFTZ2218FCZZ AL Roller shaft

16 -33

17 -24

52 -19

16 -24

16 -13

17 -13

52 -27 LFRM-0807FCZZ LFRM-0807FCZ1 AN

17 -9

18 -9

NROLR1049FCZZ NROLR1049FCZ1

AU

NROLR1049FCZZ NROLR1049FCZ1

LFRM-0805FCZZ LFRM-0805FCZ1 AQ

GCASP0164FCZZ GCASP0164FCZ1 AZ 250 cassette

Paper feeder

weight

Paper feeding

roller

Paper feeding

frame

Second paper

feeder frame.

Running

change

’95/5

3

Mid-

’95/3

Mid-

’95/5

SF-MF14 All 17 -16

Z-800

2

SN-1420

SN-1430

<Interchange>

1. In te r cha ngeable. 4. Not i nt er c h an ge ab le.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

specified on es for mai n ta in i ng t he s a fe ty an d pe rformance o f th e set.

USA

only

51 -16

53 -16

!

MARMP0180FCZ2 MARMP0180FCZ3 AF Manual feed arm

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Ot he r s.

*

5/5

Loading...

Loading...