Page 1

Date: Jul. 20, 1995

COPIER : SF-2014

1. DECREASE IN INSERTION STRENGTH OF THE DV CARTRIDGE.

2. CHANGE IN THE SHAPE OF THE STOPPER RING TO IMPROVE OPERATIONABILITY.

3. MEASURES TO PREVENT ABNORMAL NOISE FROM THE VFM (EXHAUST FAN).

4. MEASURES TO PREVENT PULLING MOVEMENT MALFUNCTIONS IN THE TC CASE UNIT.

5. COUNTE R MEASURE FOR BROKEN RIBS IN MANUAL CABINET M.

No. : SP-1895

1. Decrease in insertion strength of the DV cartridge.

1.Model name: SF-2014/21 14/2214

Z-800, SN-1420/1430 (USA only)

2.General: A change in the shape of the suede used for the cover seals has been carried out to

prevent the surface of the suede from peeling and to lessen the load when inserting the

DV cartridge into the developing unit.

3.Description:

Cover seal W

4.Action: From 1995 mid-January production.

2. Change in the shape of the stopper ring to improve operationability.

1.Model name: SF-2014/21 14/2214/CM14

Z-800, SN-1420/1430/CM11

Cover seal Z

Cover seal X

Cover seal Y

2.General: The shape of the stopper ring used with the paper feeder roller shaft and the second

paper feeder roller shaft has been changed to improve operationability.

Green

C

SHARP CORPORATION Reprography Division

1/4

Page 2

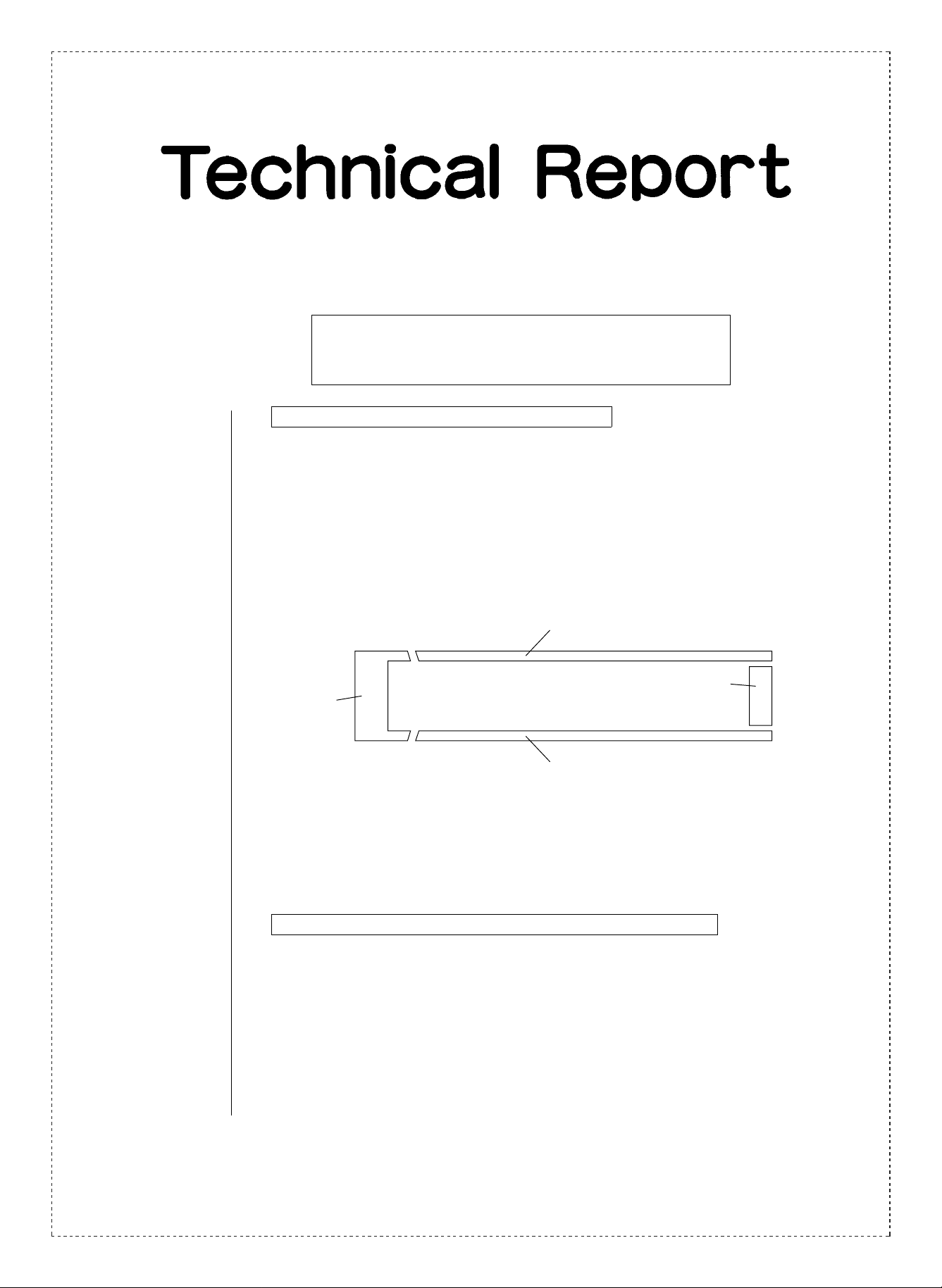

3.Description:

LSTPP0279FCZZ PRNGP0081FCZZ

Paper feeder roller shaft

4.Action: Running change after all present units in stock have been used.

3. Measures to prevent abnormal noise from the VFM (Exhaust fan).

1.Model name: SF-2014/21 14/2214

Z-800, SN-1420/1430 (USA only)

2.General: Abnormal noise has occurred between the upper frame fan duct and the VFM (exhaust

fan). To alleviate this problem, the fan retainer teeth in the upper frame fan duct have

been built-up in 2 locations to increase the retainer pressure.

<Location of the change in shape>

Built-up area

3.Action: Running change from 1995 mid-March production.

4. Measures to prevent pulling movement malfunctions in the TC case unit.

1.Model name: SF-2014/21 14/2214

Z-800, SN-1420/1430 (USA only)

2.General: TC case units with inferior pulling movement were produced due to variance in the

assembly process when attaching the socket holder unit to the base plate. As a temporary

measure to alleviate this problem, the assembly method for the socket holder unit had been

controlled, but as a permanent measure the shape of the socket holder has been changed.

In accordance with this change, and even if the control of the method of assembly is no

longer carried out, the pulling motion malfunctions no longer occur.

2/4

Page 3

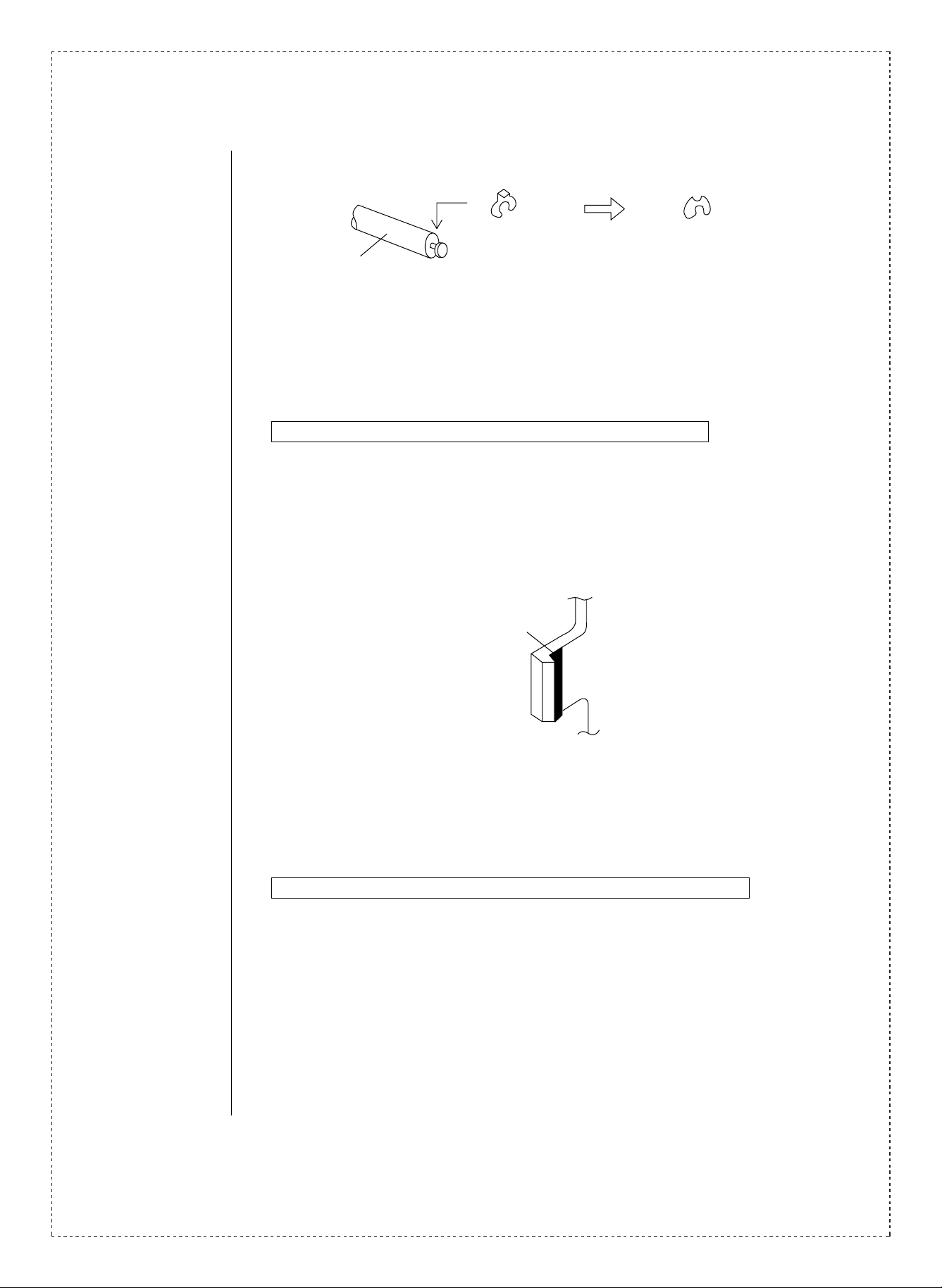

3.Description:

<Location of the change in shape>

➀ The φ4 standard has been moved toward the rear side 0.5

(looking at the machine from the direction of attachment

operations).

➁ Change in the circular ribs (2 locations).

b

a

Socket holder

<a dimensions>

φ8.3 → φ7.8

<b dimensions>

φ10.6 → φ9.3

4.Action: Running change from 1995 mid-April production.

5. Counter measure for broken ribs in manual cabinet M.

1.Model name: SF-2014/21 14/2214

Z-800, SN-1420/1430 (USA only)

2.General: When the manual cabinet of the manual multi- and single-paper feeder units were

strongly hit during the assembly process, there was a danger of the ribs breaking (not a

problem under normal assembly operation conditions). To alleviate this problem, the

shape of the ribs has been changed to strengthen them.

+0.15

0

±0.1

Added rib

10

Added "R" at the base

10

Added rib

Added surface "C"

Note: Compatibility exists between old and new units of both the manual cabinet S

(single paper feeder unit) and the manual cabinet M (multi paper feeder unit).

Only the parts codes for manual cabinet M have been changed.

3.Action: * Manual cabinet S: Running change after all present units in stock have been used.

Manual cabinet M: Japanese production: Running change from 1995 mid-March

production.

Chinese (SOCC) production:From the start of mass production.

French (SMF) production: From the start of 1995 June production.

3/4

Page 4

Ref.

Model

No.

name

SF-2014

SF-2114

SF-2214

Z-800

SN-1420

SN-1430

1

Z-800

SN-1420

SN-1430

Z-800

SN-1420

SN-1430

Z-800

SN-1420

SN-1430

SF-2014

SF-2114

SF-2214 All

Version P/G No.

9 -41

9 -39

All

9 -65

9 -66

8 -41

9 -41

8 -39

USA

9 -39

only

8 -65

9 -65

8 -66

9 -66

18 -23

Current parts New parts

Parts code Parts code

PSEL-0602FCZ1 PSEL-0663FCZZ AE Cover seal w

PSEL-0600FCZ1 PSEL-0666FCZZ AD Cover seal Z

PSEL-0627FCZZ PSEL-0664FCZZ AC Cover seal X

PSEL-0628FCZZ PSEL-0665FCZZ AD Cover seal Y

PSEL-0602FCZ1 PSEL-0663FCZZ AE Cover seal W

PSEL-0600FCZ1 PSEL-0666FCZZ AD Cover seal Z

PSEL-0627FCZZ PSEL-0664FCZZ AC Cover seal X

PSEL-0628FCZZ PSEL-0665FCZZ AD Cover seal Y

Price

Parts name

rank

Effec-

tive

time

Mid-

’95/1

Mid-

’95/1

Inter-

change-

ability

4

Note

SF-CM14

2

SF-1420

SF-1430

SN-CM11 52 -21

Z-800

SF-2014

SF-2114

SF-2214

3

Z-800

SN-1420

SN-1430

SF-2014

SF-2114

SF-2214

4

Z-800

SN-1420

SN-1430

SF-MF14 All 17 -43

5

SN-MF11

<Interchange>

1. Interc ha ng ea bl e. 4. N ot i nt er ch an ge ab l e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

sp ec if ie d ones fo r m aintaini ng t he s a fe ty an d pe r fo rma nc e o f th e s et .

USA

only

All

USA

only

All

USA

only

USA

only

52 -21

17 -23

16 -23

5 -11

4 -11

5 -11

14 -1

12 -1

13 -1

53 -43

!

LSTPP0279FCZZ PRNGP0081FCZZ AA Stopper

PDUC-0086FCZZ PDUC-0086FCZ1

LHLDZ1202FCZZ LHLDZ1202FCZ1 Socket holder N

GCAB-0799FCZZ GCAB-0799FCZ1 AR Manual cab i n et M

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others .

Upper frame fan

duct

AP

See

text

*

See

text

1

3

1

4/4

Page 5

1.

Loading...

Loading...