Page 1

Date: Jul. 25, 1995

COPIER : SF-2014

1.CHANGE IN THE VFM AND DISCONTINUANCE OF THE VFM PWB.

2.MEASURES FOR PREVENTING THE CRIM PING OF THE HEATER LAMP LEAD WIRE IN THE FUSING UNIT.

3.TROUBLE SHOOTING DETEC TI ON MALF UNCTIONS IN THE OPERATION PANEL KEYS.

4.MEASURES TO PREVENT VOLTAGE CHANGES IN THE COPY LAMP DUE TO VOLTAGE FLUCTUATION

IN THE POWER SUPPLY.

5.MEASURES FOR PREVENTION OF H2 TROUBLE.

No. : SP-1892

1. Change in the VFM and disc ontinuance of the VFM PWB.

1.Model name: SF-2014/21 14/2214

SF-2014/21 14/2214 (SEEG, UK only)

2.General: The VFM (exhaust fan) installed in the upper frame is a one-speed model. By using a

VFM PWB, this fan had been converted to two-speed capacity, but to improve

productivity the VFM itself has been changed to a two-speed model and the VFM PWB

has been discontinued. This change does not affect the functionability of the unit in any way.

(The change in VFM and t he addition of the VFM PWB was reported in Technical

Reports no. S-154.)

3.Action: From the start of 1995 May production.

2. Measures for preventing the crimping of the heater lamp lead wire in the fusing unit.

1.Model name: SF-2014/21 14/2214

Z-800, SN-1420/1430(USA only)

2.General: There is a danger of the heater lamp lead wire in the fusing unit becoming crimped

when the fusing cover is attached to the fusing unit during the assembly stage of the

production process. To alleviate this danger, the rib on the inside surface of t he fusing

cover has been cut away.

3.Description: The ribs designated by nos. ➀ through ➃ in the figure below have been cut away.

Inside surface of the fusing cover

SHARP CORPORATION Reprography Division

1/4

Green

C

Page 2

4.Action: Japanese production: Running change from 1995 mid-May production.

Chinese(SOCC) production: Running change from the start of 1995 May production.

French(SFM) production: Running change from the start of 1995 J uly production.

3. Trouble shooting detection malfunctions in the operation panel keys.

1.Model name: SF-2014/21 14/2214

Z-800, SN-1420/1430(USA only)

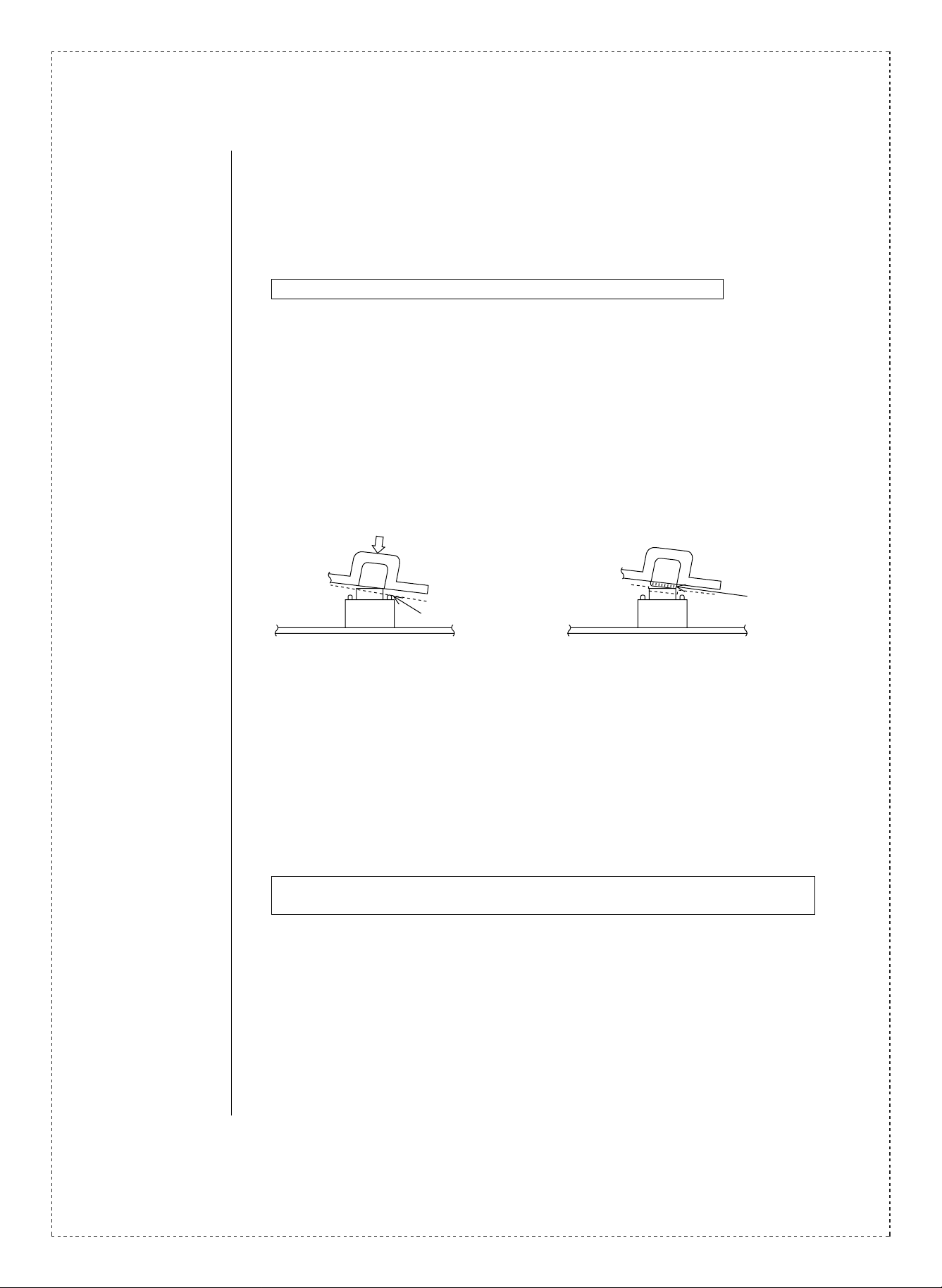

2.General: Problems have arisen in the production process when the edge of the panel keys (3, 4,

7, 8, 9) are depressed causing the key to tilt to a diagonal position. This causes it to

come in contact with the edge of the switch and makes it difficult for the switch to

register. To alleviate this problem, a rib has been added to the section of the panel key

which depresses the switch.

(Old) (New)

3.Description:

Added rib

Contact is made here

The change described above has already been carried out on all keys other than the

panel keys.

4.Action: Japanese production: Running change from 1995 mid-May production.

Chinese(SOCC) production: Running change from 1995 mid-June production.

French(SFM) production: Running change from 1995 mid-July production.

4. Measures to prevent voltage c hanges in the copy lamp due to voltage fluctuation in

the power supply.

1.Model name: SF-2014/21 14/2214 (only for models bound for countries using the 120V series)

Z-800, SN-1420/1430 (USA only)

2.General: Problems of voltage changes occurr ing in the copy lamps during voltage fluctuations in

the power supply have arisen in the models listed above bound for countries using the

120V line. To alleviate this problem, the 2 measures described below have been carried

2/4

Page 3

out.

3.Description: 2 Types of resistors used in the main P WB have been changed to make the unit less

susceptible to adverse effects of voltage fluctuations. In accordance with t his change

the main PWB of each of the models in the 120V series have been redesigned.

• Change in resistance:

Old New

[R167] 24KΩ→ 15KΩ

[R170] 120 KΩ→ 82 KΩ

• Change in the main PW B:

SF-2014/21 14/2214 (only for models bound for countries using the 120V series):

CPWBF1051FC51 → CPWBF1051FC60.

Z-800, SN-1420/1430 :

No changes have been carried out in the parts codes for the main PWB for

these models.

4.Action: Japanese prduction: F rom 1995 mid-February production.

Chinese(SOCC) production: From the start of 1995 May production.

5. Measures for prevention of H2 trouble.

1.Model name: SF-2014/21 14/2214

Z-800, SN-1420/1430(USA only)

2.General: The balance in the temperature detection circuits changes during drops in temperature,

and cases of thermostat open detection (H2) even when the thermostat is in contact

have occurred in machines in locations of cold weather. To alleviate this problem, the

measures described below have been carried out.

3.Description: The resistance of the resistor (R148) in the main PWB has been changed, to establish

a proper balance.

Old New

[R148] 56KΩ→200K Ω

4.Action: Japanese production: From 1995 mid-April production.

Chinese(SOCC) production: From the start of 1995 June production.

3/4

Page 4

Ref.

Model

No.

name

1 SF-2014

SF-2114

SF-2214

Version P/G No.

UK

All

5 -15

5

11 -3

SEEG

only

Current parts New parts

Parts code Parts code

RMOTE0762FCZZ

(Q’ty: 2)

CPWBF1078FC51 Discontinuance — VFM PWB

RMOTE0762FCZ1

(Q’ty: 2)

Price

Parts name

rank

AZ VFM

Effec-

tive

time

1 st lot

’95/5

Inter-

change-

ability

5

Note

Z-800

2

SN-1420

SN-1430

SF-2014 All

Z-800

3

SF-2114

SF-2214

SN-1420

SN-1430

SF-2014

SF-2114

SF-2214

Z-800

SN-1420

SN-1430

SF-2014

4

SF-2114

SF-2214

Z-800

SN-1420

SN-1430

SF-2014

SF-2114

SF-2214

USA

only

USA

only

All

USA

only

120 V

series

only

USA

only

120 V

series

only

USA

only

120 V

series

only

10 -3

11 -3

4-5

3-5

4-5

4-5

20 -64

18 -64

19 -64

20 -82

18 -82

19 -82

5 -62

20 -901

PCOVQ1231FCZZ PCOVQ1231FCZ1 AW Fusing cover

CBTN-0192FC01 CBTN-0192FC02 AR

CBTN-0184FC01 CBTN-0184FC02 AR

VRS-TS2AD243F VRS-TS2AD153F AA Resistance [167]

VRS-TS2AD124F VRS-TS2AD823F AA Resistor [R170]

CPWBF1051FC51 CPWBF1051FC60 BV Main PWB

Operation panel

key

Operation panel

key

1

See

text

3

4/4

SF-2014

SF-2114

SF-2214

5

Z-800

SN-1420

SN-1430

<Interchange>

1. Interchangea bl e. 4. Not i nt erc h an ge ab l e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

speci fied on es fo r m ai n ta in ing the sa fe ty an d pe r fo r ma nce o f the set .

All

USA

only

20 -78

18 -78

19 -78

!

VRS-TS2AD563J VRS-TS2AD204F AA Resistor [R148]

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Other s .

Page 5

.

Loading...

Loading...