Page 1

Date: Jun. 13, 1995

COPIER : SF-2014

[Service Information]

1. CONCERNING PREPARA T IONS TO BE MADE BEFORE

A TT ACHING THE GLASS TABLE’S RUBBER WASHER.

2. A CHANGE IN THE HANDLING OF THE CL LEAD.

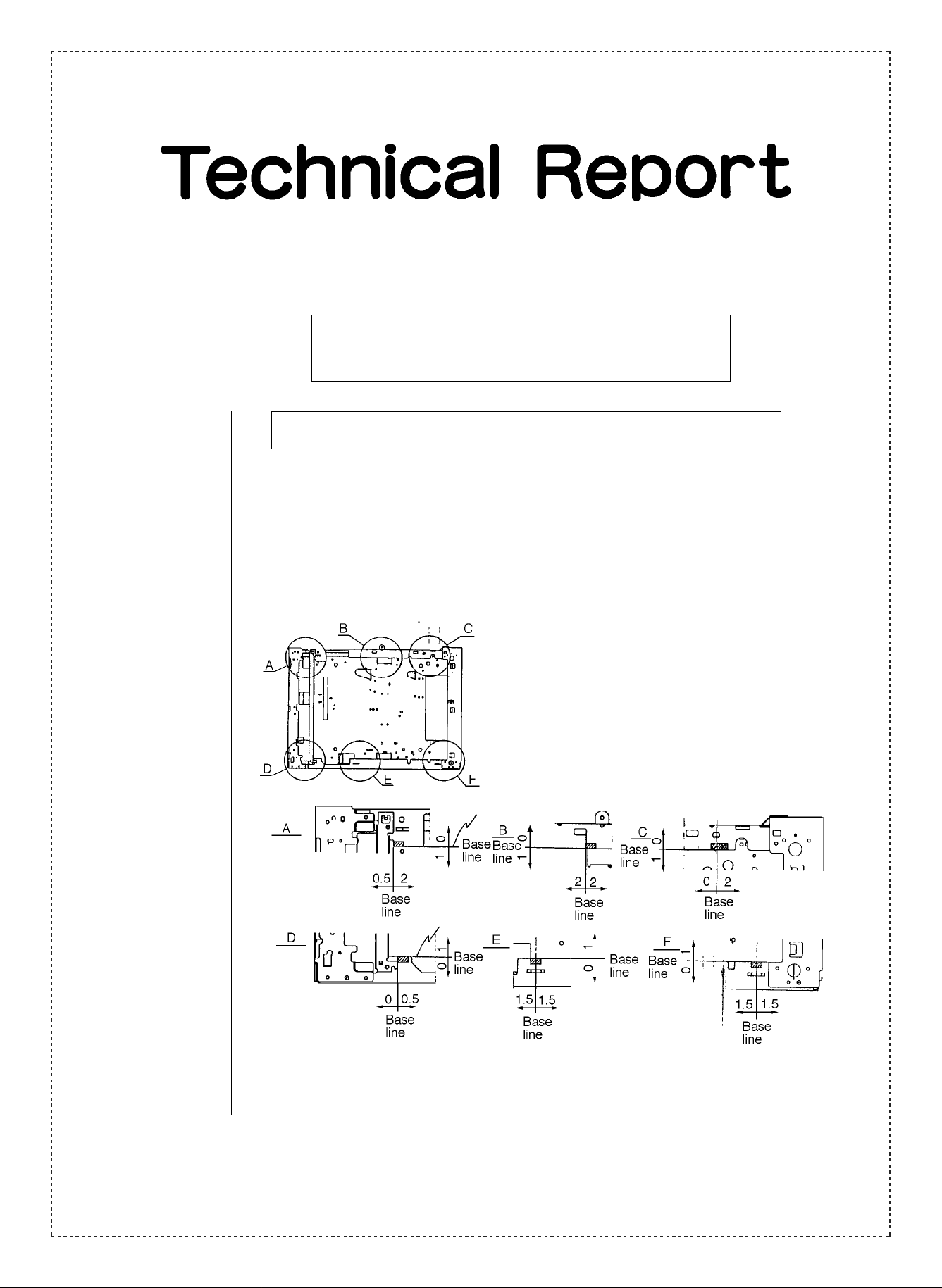

1. Concerning preparations to be made before attaching the glass table’s rubber

washer.

1. Model name: SF-2014/21 14/2214

Z-800, SN-1420/1430 (U.S.A. only)

No. : SP-1890

2.General: The positioning to be used when attaching the glass table’s rubber washer was not

stated clearly. Please use the following diagram as a guide to the preparations for

placement and actual positioning of said rubber washer.

<R side>

<F side>

Ege base plate

Ege base plate

SHARP CORPORATION Reprography Division

1/2

Green

C

Page 2

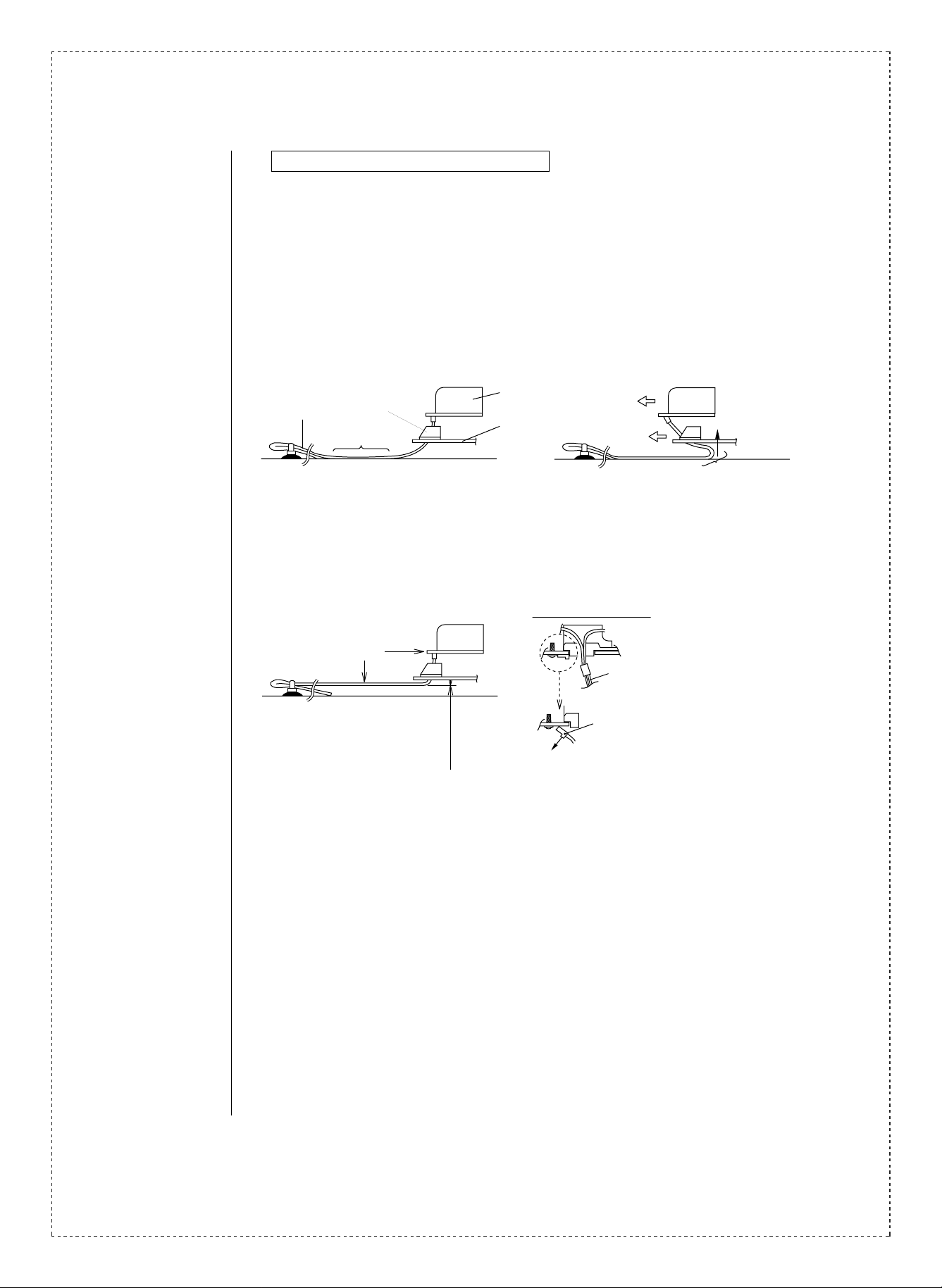

2. A change in the handling of the CL lead.

1.Model name SF-2014/21 14/2214

Z-800, SN-1420/1430 (U.S.A. only)

2.General: It was noted during production and development that due to extra slack in the CL lead,

the lead is getting caught under the 2/3 mirror unit’s CL guide. This causes the 2/3

mirror to float momentarily, which affects copy quality negatively. Please examine the

following diagram.

3.Description:

CL lead

Resting position of the light source unit.

CL guide

Slack

Optical unit base

Lamp unit

Mirror unit 2/3

Move

Move

Scanning position of the light source unit

The 2/3 mirror floats towards the guard

P

Trapping of the CL lead

When the light source unit is in resting position, please make sure that there is a gap

between the bottom of the optical unit and the CL lead as follows:

Drawing seen from Q

Q

R

Gap present

(pulled tight)

CL lead

Do not allow the ground terminal to hang

in the direction indicated by the arrow.

(If you do, it will touch the pulley)

4.Action: From 1995 mid-March production. (running change)

2/2

Loading...

Loading...