Page 1

Date: Apr. 20, 1995

COPIER : SF-2014

1. CHANGE IN THE RESISTANCE FACTOR ADJUSTMENT SETTINGS

2. MEA SURES TO PREVENT T HE A C RELA Y HARNESS FRO M C OM IN G

IN CONTACT WITH THE FAN DUC T

1. Change in the resistance factor adjustment settings

1.Model name: SF-2014/21 14/2214

Z-800, SN-1420/1430 (USA only)

2.General: Problems of RZS folding of the copy paper and wrinkles occurring on the original

documents during SPF operations were discovered in sample machines before mass

production. To alleviate this problem, the values of the resistance factor adjustment

settings (simulation 51-2) when shipped from the factory have been changed.

No. : SP-1880

3.Description: Changes in each of the resistance factor settings

(Old) ( New )

Resistance fa ct or for cassette

paper feed operations: 50 → 22 (to alleviate problems of “Z”

Resistance factor for SPF operations: 50 → 25

4.Action: From the start of mass production

2. Measures to prevent the AC relay harness from coming in contact with the fan duct

1.Model name: SF-2014/21 14/2214

Z-800, SN-1420/1430 (USA only)

folding of the copy paper)

The values have been changed to 30

to improve slant feeding of A4 sized

paper since January 1995 production.

For SEEG machine only

SHARP CORPORATION Reprography Division

1/2

Green

C

Page 2

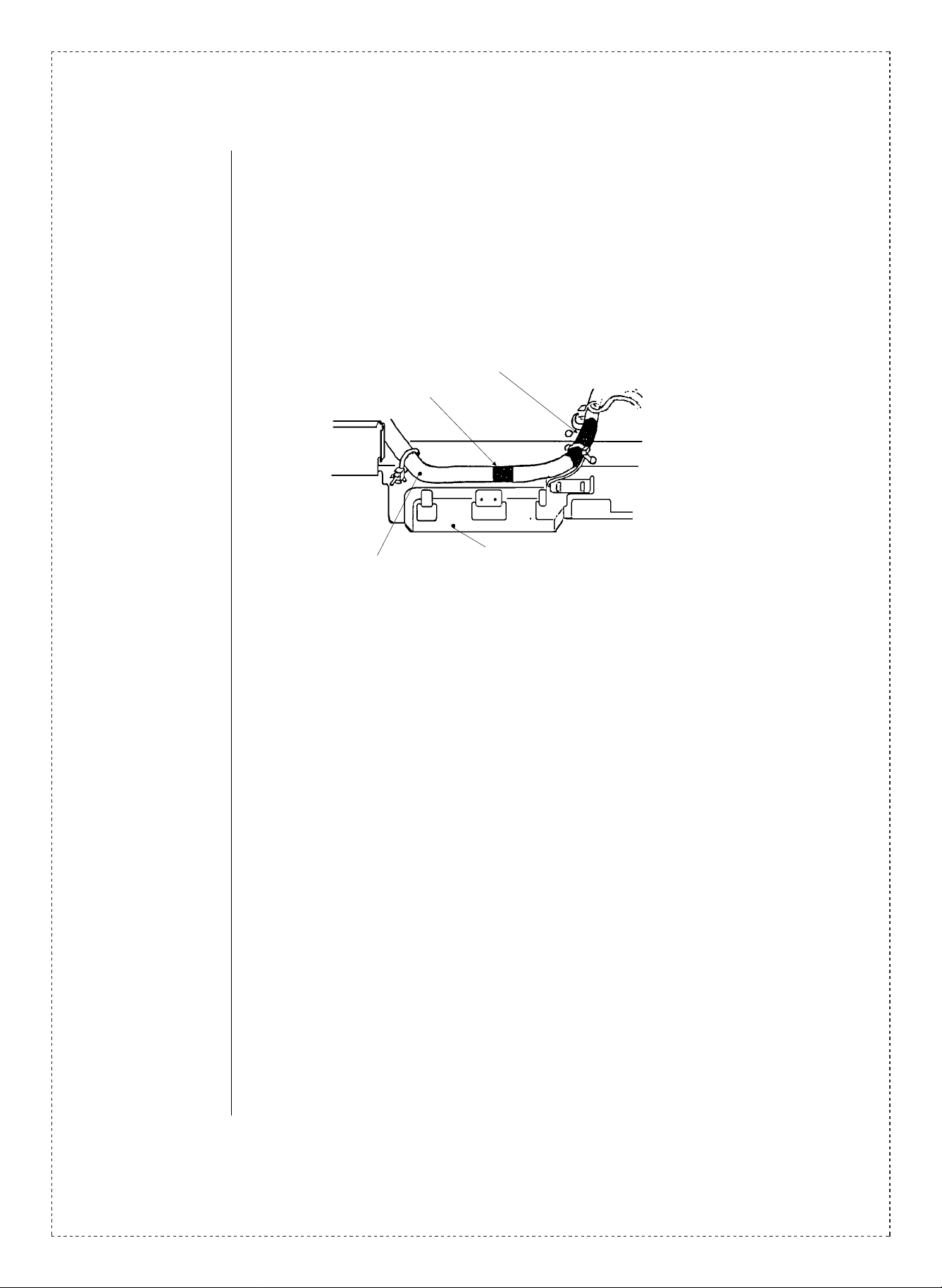

2.General: The upper frame fan duct sometimes raised up during the assembly process of the

machine, a problem caused when the head of the wire band attached to the AC relay

harness came in contact with the duct. Also, there was a possibility of the wires of the

relay harness separating, and becoming snagged in the section of the fan duct with the

fixing screws. To alleviate these problems, UL tape has been wrapped around the

harness.

3.Description: UL tape has been wrapped at locations ➀ and ➁ in the figure shown at right.

➁ Wrapped UL tape

The wires are wrapped so that they do not separate.

➀ The wire band has been

changed to UL tape.

Upper frame connection plate

AC Relay harness

(DHAI-2293FCZZ.11 to 14)

4.Action: Running change from 1995 mid-March production

2/2

Loading...

Loading...