Page 1

Date: Apr. 12, 1995

COPIER : SF-2014

1. IMPROVEM ENT OF CONDUCTIVITY IN THE SOCKET HOLDER UNIT

2. DISCONTINUANCE OF BLACK PAINT IN THE BL HOLDER SECTION

3. ATTACHMENT OF BSI LABEL

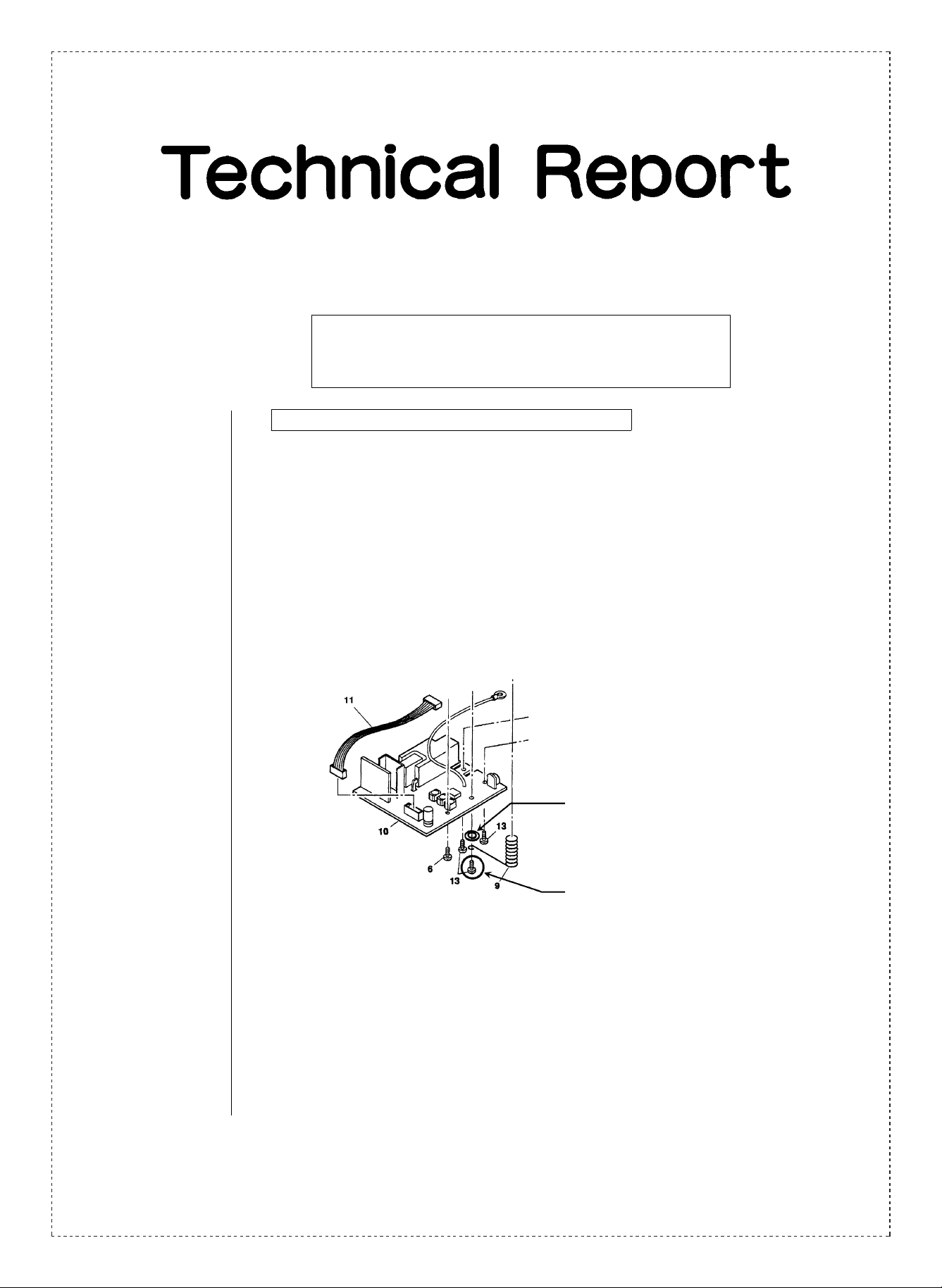

1. Improvement of conductivity in the socket holder unit

1.Model name: SF-2014/21 14/2214

Z-800, SN-1420/1430 (USA only)

2.General: A washer has been added and the length of the screws shortened to improve

conductivity between the soldered section of the back side of PWB and a portion of the

screws in the socket holder unit.

Note: The absence of the washer does not particularly present a problem, but the

changes described above have been carried out as improvement measures.

No. : SP-1877

3.Description:

4.Action: Running change from 1994 October production

Washer (added) XWHSD30-05070

Screw (changed)

XBPSD30P06K00 → XBPSD30P08K00

SHARP CORPORATION Reprography Division

1/3

Green

C

Page 2

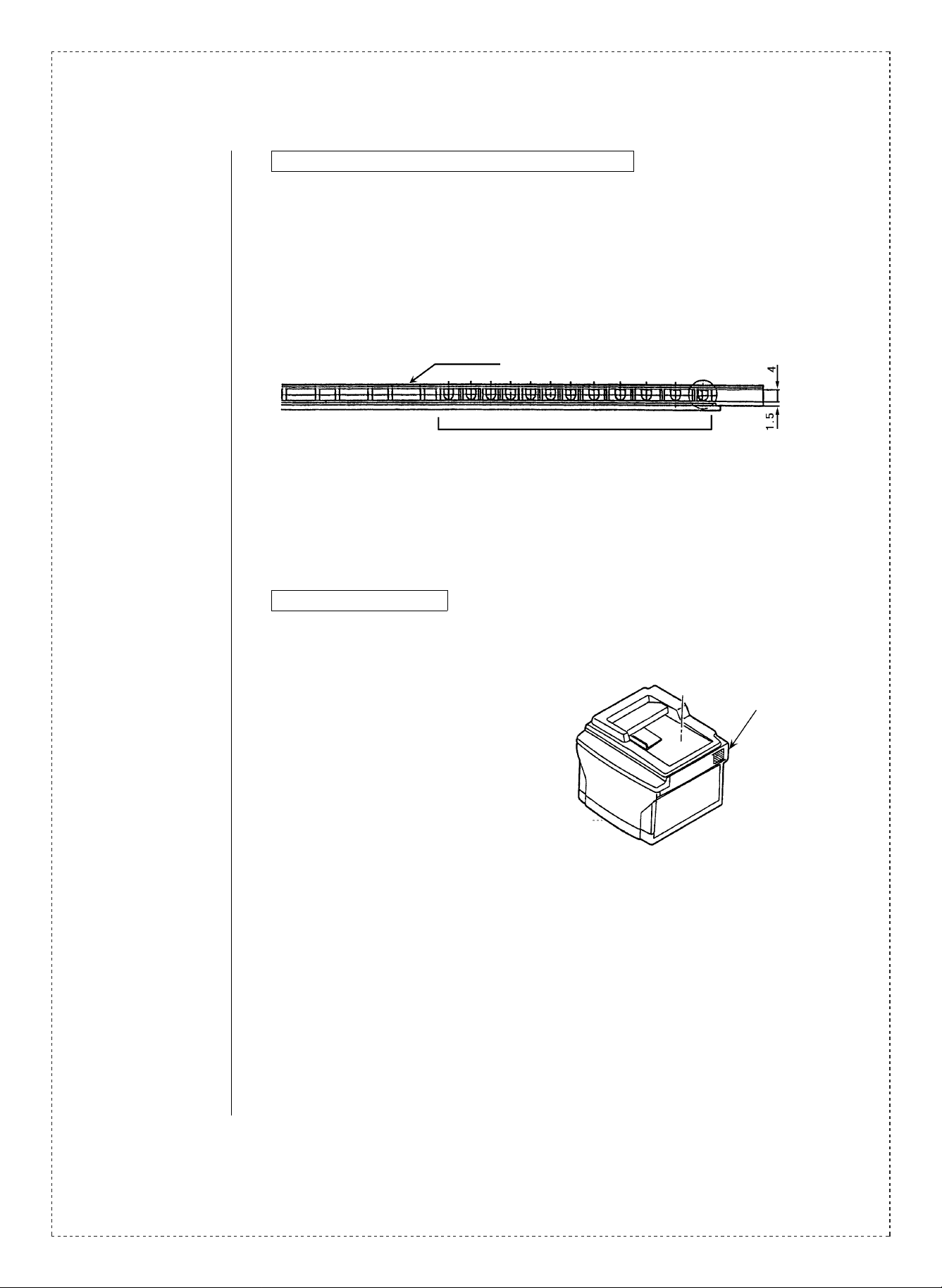

2. Discontinuance of black paint in the BL holder section

1.Model name: SF-2014/21 14/2214

Z-800, SN-1420/1430 (USA only)

2.General: Matted black paint had been applied to the LED attachment section (on the inner wall

side) of the BL holder, but discontinued of the paint has no effect on copying or other

operations, and has therefore been discontinued.

3.Description:

Matted black paint on inner wall section - discontinued

BL Holder N2

4.Action: From the start of 1995 March production

3. Attachment of BSI label

1.Model name: SF-2014/2114/2214 (for UK only)

2.General: The BSI standards have been passed, and

in accordance, a BSI label has been

attached in the location as shown in the

figure to the right to machines produced

domestically which are bound for the UK.

BSI label has

been attached

3.Action: From the start of 1995 March production

2/3

Page 3

Ref.

No.

Model

name

SF-2014

SF-2114

SF-2214

Version P/G No.

14

All

14 — XBPSD30P08K00 AA Screw (M3x8)

14 — XWHSD30-05070 AA Washer

Current parts New parts

Parts code Parts code

XBPSD30P06K00

(Q’ty: 6)

Q’ty change

6 → 5

Price

Parts name

rank

AA Screw (M3x6)

Effec-

tive

time

Inter-

change-

ability

Note

USA

only

All

USA

only

12

13

13

13

5 -23

4 -23

5 -23

!

XBPSD30P06K00

(Q’ty: 6)

— XBPSD30P08K00 AA Screw (M3x8)

— XWHSD30-05070 AA Washer

LHLDZ1198FCZ1 LHLDZ1198FCZ2 AL BL holder

Q’ty change

6 → 5

AA Screw (M3x6)

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others.

See

text.

1st lot

’95/3

Z-800

1

SN-1420

SN-1430

Z-800 12

SN-1420

SN-1430

Z-800 12

SN-1420

SN-1430

SF-2014

SF-2114

SF-2214

2

Z-800

SN-1420

SN-1430

<Interchange>

1. Interc ha ng ea bl e. 4. N ot i nt er ch an ge ab l e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

speci fied ones for mai n ta in i ng t he safety an d perfor ma nc e o f th e s et .

—

1

3/3

Loading...

Loading...