Page 1

Date: Apr. 13, 1995

COPIER : SF-2014

1. NOTIFICATION OF CHANGED PARTS AND NEW PART S ADDITIONS

2. TROUBLE SHOOTING JAMS CAUSED BY SLIPPING DURING BACK SIDE

P A PER FEEDIN G O PERA T IONS

3. COUNTER MEASURE FOR ABNORMAL NOISE IN THE OPTICAL UNIT

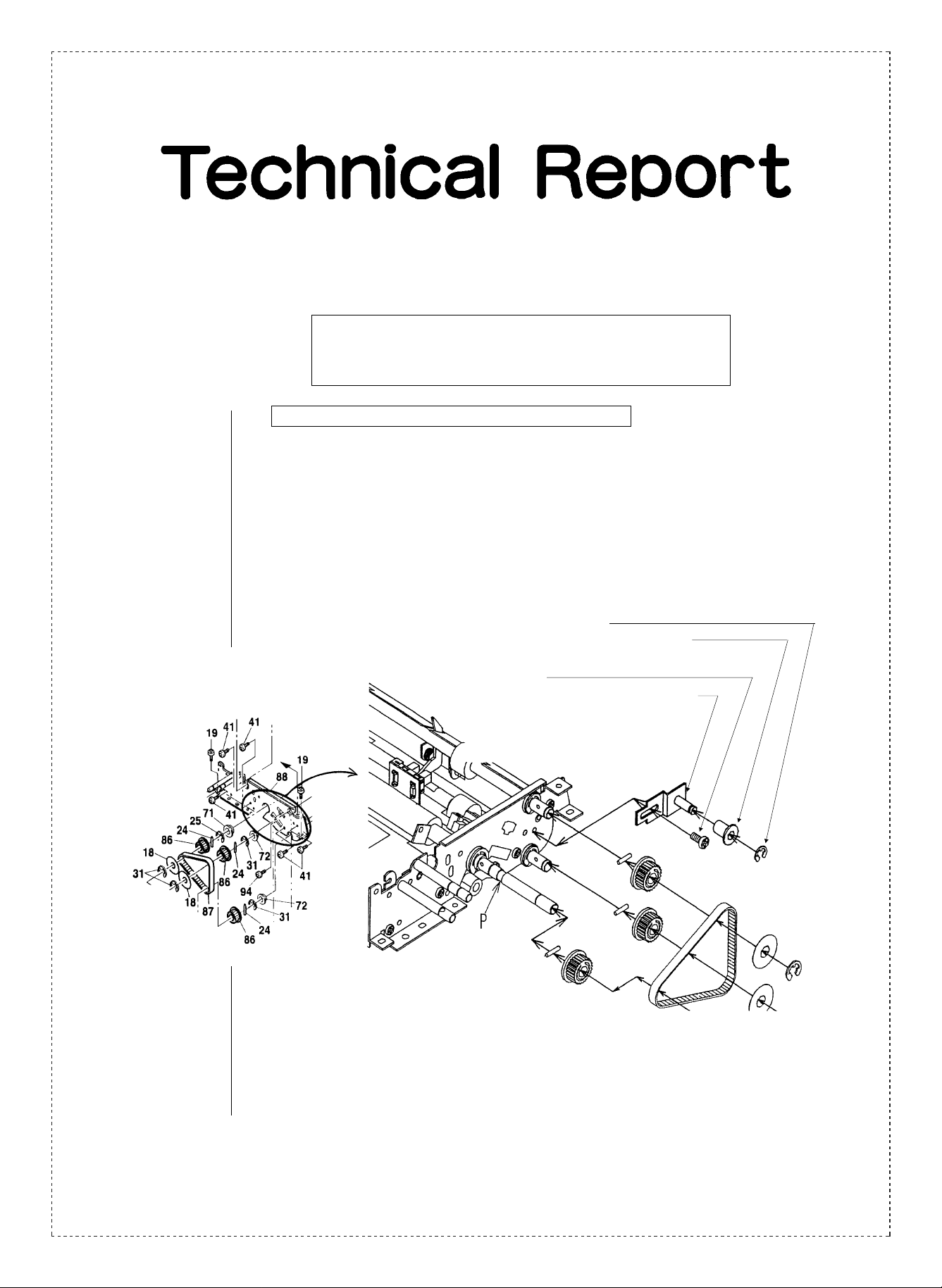

1. Notification of changed parts and new parts additions

1.Model name: SF-2214

SN-1430 (for USA only)

2.General: Changes in parts codes and the addition of new parts have been carried out in the SPF

unit from the start of mass production and are hereby reported.

No. : SP-1875

3.Description: (1) The parts listed below have been added in the SPF unit.

➀ Added: E-4 (XRESP40-0500 0)

➁ Added: PF Tension pulley (NPLYZ0139FCZZ)

➂ Added: M3 x 6 Cross recessed head mach i ne scr ew

(XBPSD30P06000)

➃ Added: Tensioner Pl at e AS (CPLTM4751FC01)

SHARP CORPORATION Reprography Division

1/6

Green

C

Page 2

Manual paper feed sheet B9

➅ Added: Sensor sheet

(PSHEZ3755FCZZ)

Attachment line standard

for the double-sided tape

➄ Added: SPF Paper

feeder lower mylar

(PSHEP3742FCZZ)

SPF Paper discharge lower PG

➆ Added: Thermistor sensor

(RDTCT0115FCZZ)

➇ Added: M3 x 6

Cross recessed head machine screw (XBPSD30P06000)

➈ Added: PS Brake spring

11

Added: Nylon washe r R (L X-WZ0048FCZZ)

(MSPRC2316FCZZ)

➉ Added: PF Washer

(LX-WZ0071FCZZ)

2/6

Page 3

(2)The parts codes changes listed below have been carried out in the SPF unit.

• A record omission has occurred

in the parts guid e, but in actuality

the part is installed.

• Changed parts code

• Changed parts code

Please refer to the parts list for parts code changes other than those listed above.

4.Action: From the start of mass production

2. Trouble shooting jams caused by slipping during back side paper feeding operations

1.Model name: SF-MF14

SN-MF1 1 (for USA only)

2.General: JAMS due to paper feed slipping have occurred in the manual multi paper feeding unit

during back side copy operations. To alleviate this problem the following change has

been carried out.

3.Description: The material of the paper feed roller has been changed to one with a higher coefficient

of friction to improve paper feeding efficiency.

(Old) (New)

Material EPDM (g ray) → Material NS (black)

3/6

Page 4

4.Aciton: Total SMF production: From the start of 1995 January production

Other than SMF production: From the start of 1995 March production

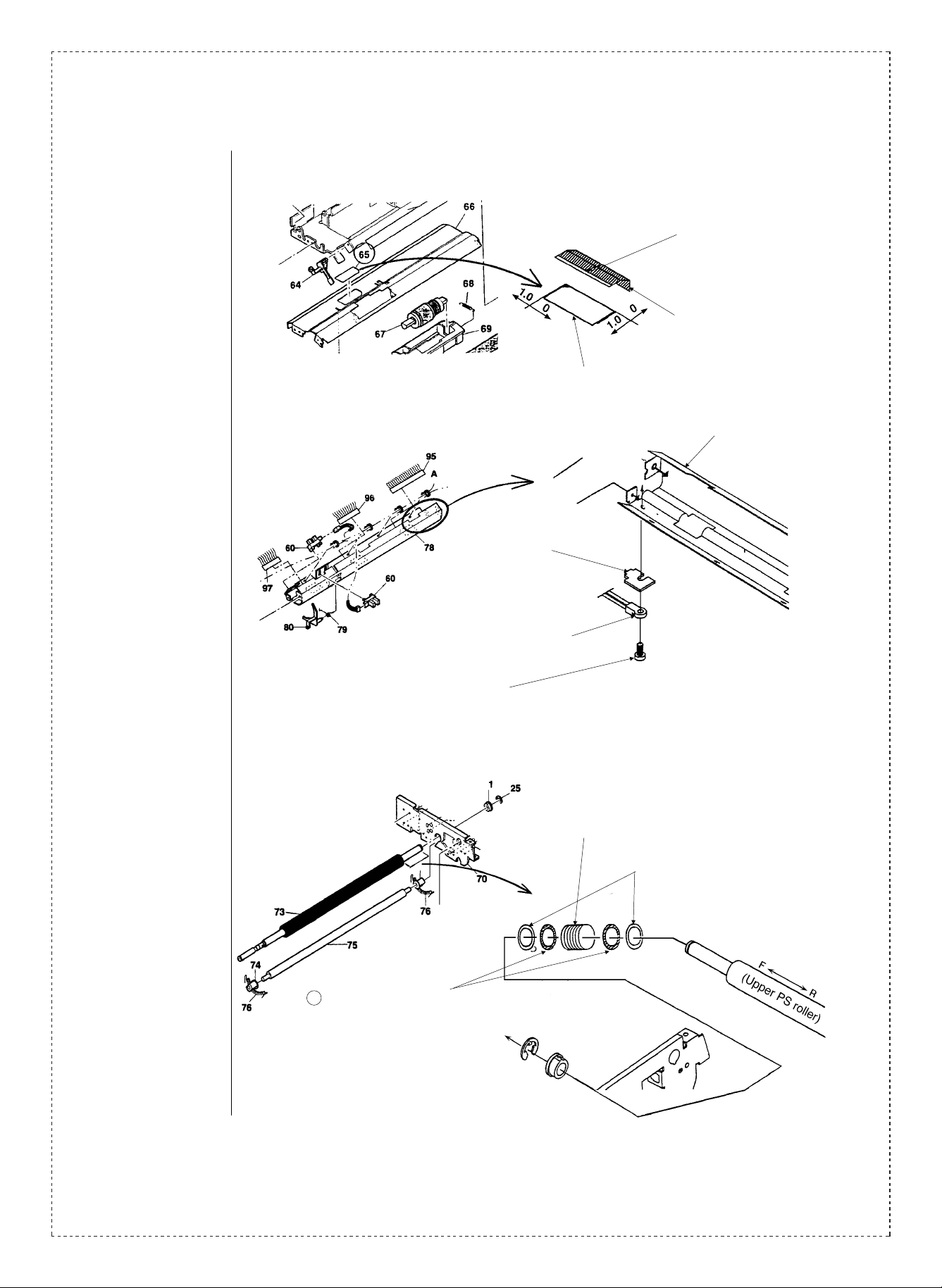

3. Counter measure for abnormal noise in the optical unit

1.Model name: SF-2014/21 14/2214

Z-800, SN-1420/1430 (for USA only)

2.General: Abnormal noise sometimes occurred when the optical unit and the no. 2 and no. 3

mirror holder units move during operations. To alleviate this problem, the changes

described below were carried out.

3.Description: White grease had been applied only to the back side cushions of the units listed above,

but it has now been added to the upper rail on the machine side of the optical unit.

<Application locations>

The white grease has been applied in four locations on the upper rail where scanning

operations of the lamp UN A , and the 2/3 mirror UN B , take place. Application points

are marked by the black dots A and B on the figure shown below.

* The amount of white grease to be applied should be approximately the size of a pea.

* Caution should be exercised so that the white grease does not come in contact with

the MB wire or other parts.

The points A and B are located in th e sam e

place on the opposite side.

4.Action: SMF production: From the start of 1995 February production

A

B

Drawing seen from P

4/6

Page 5

Ref.

Model

No.

name

SF-2214 All

1

➀

SN-1430

SF-2214 All

1

➁

SN-1430

SF-2214 All

1

➂

➇

SN-1430

SF-2214 All

1

➃

SN-1430

SF-2214 All

1

➄

SN-1430

SF-2214 All

1

➅

SN-1430

SF-2214 All

1

➆

SN-1430

SF-2214 All

1

➈

SN-1430

SF-2214 All

1

➉

SN-1430

SF-2214 All

SN-1430

SF-2214 All

SN-1430

SF-2214 All

SN-1430

1

11

SF-2214 All

SN-1430

SF-2214 All

SN-1430

SF-2214 All

SN-1430

SF-2214 All

Version P/G No.

3

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

only

only

only

only

only

only

only

only

only

only

only

only

only

only

only

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3 -72

3 -72

3 -24

3 -24

3

3

3 -73

3 -73

3 -81

3 -81

3 -77

Current parts New parts

Parts code Parts code

XRESP40-05000

(Q’ty: 10)

— NRLYZ0139FCZZ AB

XBPSD30P06000

(Q’ty: 14)

— CPLTM4751FC01 AE Tensioner Plate

— PSHEP3742FCZZ AD

— PSHEZ3755FCZZ AC Sensor sheet

— RDTCT0115FCZZ AR

— MSPRC2316FCZZ AC PS Brake spring

— LX-WZ0071FCZZ AA PF Washer

— LX-WZ0048FCZZ AA Nylon washer R

NBRGC0188FCZZ

(Q’ty: 4)

LPINS0165FCZZ

(Q’ty: 5)

—

NROLR1017FCZZ NROLR1017FCZ1 AX

NROLR1033FCZZ NROLR1033FCZ1 AR

NROLR1034FCZZ NROLR1034FCZ1 AR

Q’ty change

10 → 11

Q’ty change

14 → 16

NBRGC0529FCZZ

(Q’ty: 4)

Q’ty change

5 → 2

LPINS0089FCZZ

(Q’ty: 3)

Price

rank

AA E ring

AA Screw (M3x6)

AB SPF bearing

AB Pin

AA Spring pin

Parts name

PF Tension

pulley

SPF Paper

feeder lower

mylar

Thermistor

sensor

SPF PS roller

upper

SPF transport

roller

SPF delivery

roller

Effec-

Inter-

tive

change-

time

ability

1st lot —

Note

5/6

Page 6

Ref.

Model

No.

name

SN-1430

1

SF-2214 All

11

SN-1430

Version P/G No.

USA

USA

only

only

3 -77

3 -48

3 -48

Current parts New parts

Parts code Parts code

NROLR1034FCZZ NROLR1034FCZ1 AR

NROLR0922FCZZ NROLR1051FCZZ AT

Price

rank

Parts name

SPF delivery

roller

Manual paper

feed roller

Effec-

tive

time

1st lot

Inter-

change-

ability

—

Note

USA

only

17 -6

53 -6

!

NROLR1051FCZZ NROLR1096FCZZ AV

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others .

Manual paper

feed roller

SF-CM14 All

2

SN-MF11

<Interchange>

1. Interc ha ng ea bl e. 4. N ot i nt er ch an ge ab l e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

specifi e d on es fo r m ai n ta in i ng t he s a fe ty an d perfo r ma nce of th e set.

6/6

Loading...

Loading...