Page 1

Date: Apr. 3, 1995

COPIER : SF-2014

1. COUNTER MEASURES FOR BLAC K STRE AKING DURING REDUCED COPIES

2. PREVENTION OF DOUBLE FEEDING

3. COUNTER MEASURES FOR BARKE R RO LL ER RETURN M ALF UNCTIONING IN THE PAPER FEEDING UNIT

4. PREVENTION OF SKIPPING (ABNORMAL NOISE) OF THE PS CONNECTION GEAR IN THE FEEDING UNIT

5. PREVENTION OF TRANSFER MISALIGNMENT DURING COPY OPERATIONS

No. : SP-1868

1. Counter measures for black streaking during reduced copies

1.Model name: SF-2014/21 14/2214

Z-800, SN-1420/1430 (USA only)

2.General: Rib cuts have been carried out on the BL holder to alleviate problems of black streaks

which had been occurring during reduced copy operations of the SPF mounted machines.

3.Description:

The rib cuts mentioned above were carried out by hand from the start of mass

production to 1994 October production, of the SF-2214, SN-1430 models, which are

SPF mounted machines. From 1994 November production, the rib cuts have been

carried out on all models in the metal molding stage.

4.Action: From the start of 1994 November production

2. Prevention of double feeding

1.Model name: SF-2014/21 14/2214

Z-800, SN-1420/1430 (USA only)

Rib cuts carried out at these locations.

2.General: When the pressure springs of the separator roller in the bottom frame were attached

diagonally to the boss on the base plate side, double feeds were occasionally caused

by increases in the pressure of the spring. The changes described below have been

carried out to alleviate this problem.

Green

C

SHARP CORPORATION Reprography Division

1/5

Page 2

3.Description: The diameter of one side of the separator pressure springs has been increased so that

it doesnUt move up the boss.

(Old)

±0.2

φ7

Attached: 3 Attached: 3 Attached: 1

NG OK

Moved up the boss

+0.1

4.Action: Running change from 1994 Mid-October production

-0.2

φ7

(New)

0

+0.2

φ7.3

Attached: 3

Attached: 1

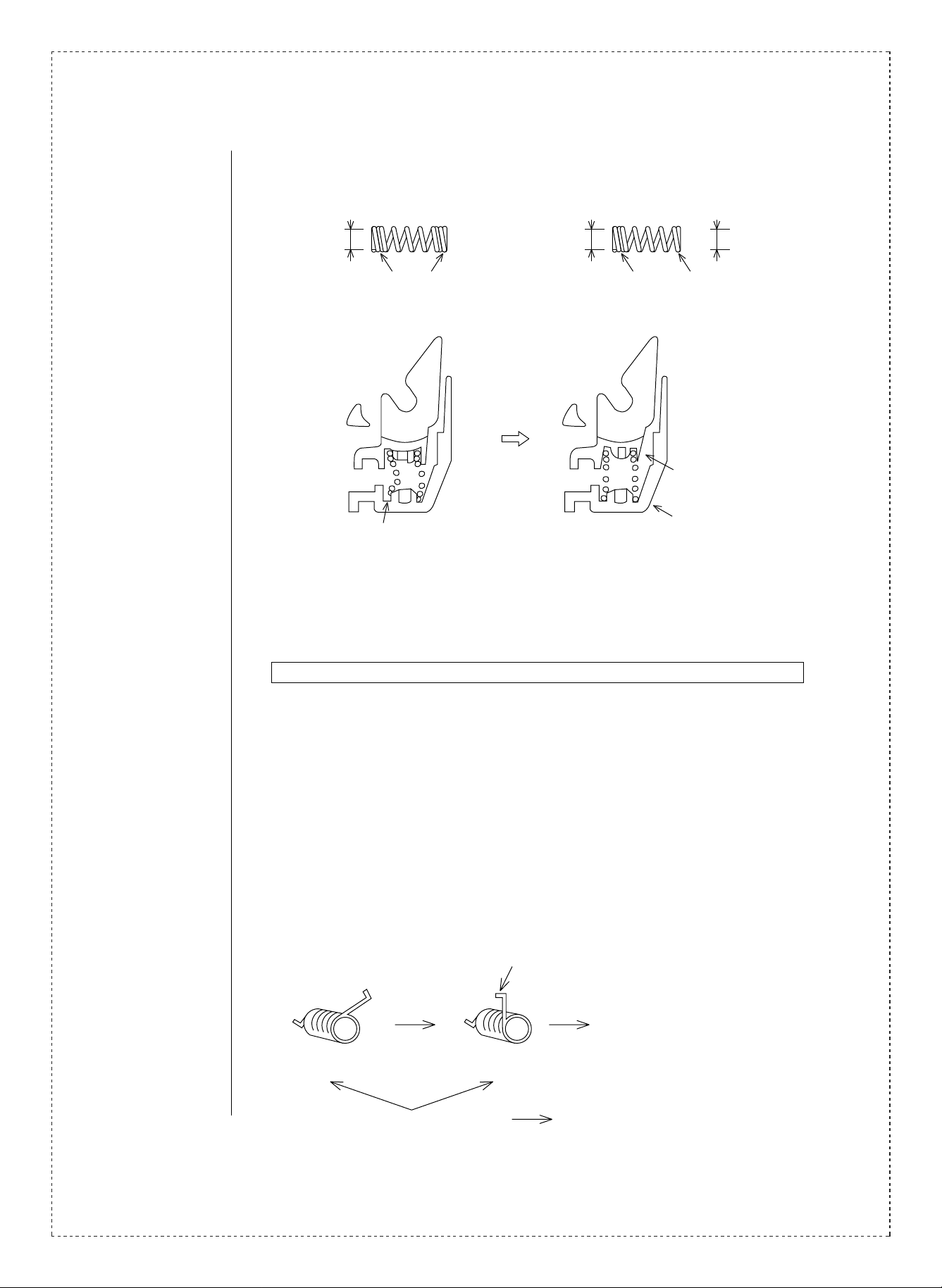

3. Counter measures for barker roller return malfunctioning in the paper feeding unit

1.Model name: SF-2014/21 14/2214

Z-800, SN-1420/1430 (USA only)

2.General: To prevent the barker roller in the 250 cassette unit from malfunctioning (the roller

sometimes becomes jammed and remains in the lowered position instead of raising

back up, in some cases preventing the cassette from being withdrawn), the spring load

of roller release arm spring 250 had been changed by altering the shape of the already

installed springs, but now the springs are being changed in the metal moulding stage as

a permanent measure.

3.Description: Change in spring load by coiling

Change in spring load by coiling

(Permanent measure)

Shaped by metal mould, the

(Old spring)

(Temporary measure)

Reshaped spring

shape is the same as the

temporary springs.

2/5

MSPRC2201FCZZ MSPRC2201FCZ1

Page 3

4.Action: Temporary action: From the start of mass production to 1994 mid-October production

Permanent action: From 1994 mid October production

4. Prevention of skipping (Abnormal noise) of the PS connection gear in the feeding unit

1.Model name: SF-2014/2114/2214, Z-800

SN-1420/1430 (USA only)

2.General: The connection arm occasionally became loose and the one way clutch gear slipped

due to idling torque when the transport roller in the feeding unit rotated during

production, causing abnormal noise. To alleviate this problem, the measures described

below were carried out.

3.Description: The spring load of the paper guide front spring was increased to prevent the gear from

slipping.

Diameter: φ 0.4 → φ 0.55

Spring load: 18 mm — 104 g → 18 mm — 350 g

Spring

PS Connection arm

Transport roller

One way clutch gear

The interlocking of this gear slips.

4.Action: Running change from 1994 mid-October production

5. Prevention of transfer misalignment during copy operations

1.Model name: SF-2014/21 14/2214

Z-800, SN-1420/1430 (USA only)

2.General: A change in shape has been carried out on the TC case unit to prevent transfer

misalignment problems during copy operations.

3/5

Page 4

3.Description: (1)Change in angle of the transfer front guide

A

Transfer front guide

(2)Thickening of the installment location of the TC holder for the transfer front guide

Attach TC holder spacers (4 locations).

Front side Rear side

(Old)

32°

+2°

0

(New)

47°

+2°

0

<Temporary measure>

0 0.5

0 0.5

0 0.5

0 0.5

0 0.5

TC Holder spacers

Change by metal mould.

Front side Rear side

<Permanent measure>

(3)• Thickening of the upper surface of the JAM prevention ribs (9 locations)

• Addition of paper curling transfer misalignment prevention ribs (2 locations)

Added rib

Thickened location

(9 locations)

0 0.5

4.Action: (1), (2) From the start of mass production

(3) Running change from 1994 mid-October production

4/5

Added rib

TC Holder

Page 5

Ref.

No.

1

Model

name

SF-2014

SF-2114

SF-2214

Z-800

SN-1420

SN-1430

Version P/G No.

5 -23

All

only

4 -23

5 -23

USA

Current parts New parts

Parts code Parts code

LHLDZ1198FCZZ LHLDZ1198FCZ1 AP BL holder

Price

Parts name

rank

Effec-

tive

time

1st lot

’94/11

Inter-

change-

ability

Note

SF-2014

SF-2114

SF-2214

2

Z-800

SN-1420

SN-1430

SF-2014

SF-2114

SF-2214

3

Z-800

SN-1420

SN-1430

SF-2014

SF-2114

SF-2214

4

Z-800

SN-1420

SN-1430

SF-2014

SF-2114

SF-2214

5

Z-800

SN-1420

SN-1430

<Interchange>

1. Interc ha ng ea bl e. 4. N ot i nt er ch an ge ab l e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

s p ec i fie d ones fo r m ai n ta in i ng t he s a fe ty and pe r fo rma nc e o f th e s et .

All

USA

only

All

USA

only

All

USA

only

All

USA

only

13 -40

51 -17

13 -40

14 -40

51 -17

18 -28

52 -16

16 -28

17 -28

52 -16

18 -6

16 -6

17 -6

15 -7

14 -7

15 -7

!

MSPRC2189FCZZ MSPRC2189FCZ1 AC

MSPRC2201FCZZ MSPRC2201FCZ1 AC

MSPRC1120FCZ1 MSPRC2346FCZZ AB

LHLDZ1205FCZZ LHLDZ1205FCZ1 AL TC Holder N

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others.

Separator roller

pressure spring

Roller release

arm spring 250

PS Connection

arm

Mid-

’94/10

1st lot

’94/9

1st lot —

3

5/5

Loading...

Loading...