Page 1

Date: Mar. 6, 1995

COPIER : SF-2014

1. CHANGE TO PE MAGNET (TO IMPROVE PRODUCTIVITY)

2. CHANGE TO IC PROGRAMMING IN MAIN PWB

3. PREVENTION OF UNSTABLENESS OF JOINT ARM OF 250 CASSETTE MODULE UNIT

4. PREVENTION OF RISING IN TEMPERATURE IN SPF MODE

5. CHAN G E TO U-TURN GUIDE MYLAR IN MANUAL PAPER FEEDI NG UNIT

No. : SP-1866

1. Change to PE magnet (to improve productivity)

1.Model name: SF-2214

SN-1430, for USA only

2.General: The single type of the unpackaging detection PE magnet used in the back side of glass

holder has been changed to the assemble with double sided tape.

3.Action: From the first unit of mass production

2. Change to IC programming in main PWB

1.Model name: Z-800, SN-1420, 1430, for USA only

2.General: The drum lamp flushing and displaying the U7 in copy numbers view occurred when the

drum life was ended. We have corrected this in the IC control program in the main PWB

to prevent them.

3.Action: From the first unit of mass production

3. Prevention of unstableness of joint arm of 250 cassette module unit

1.Model name: SF-CM14, SN-CM11

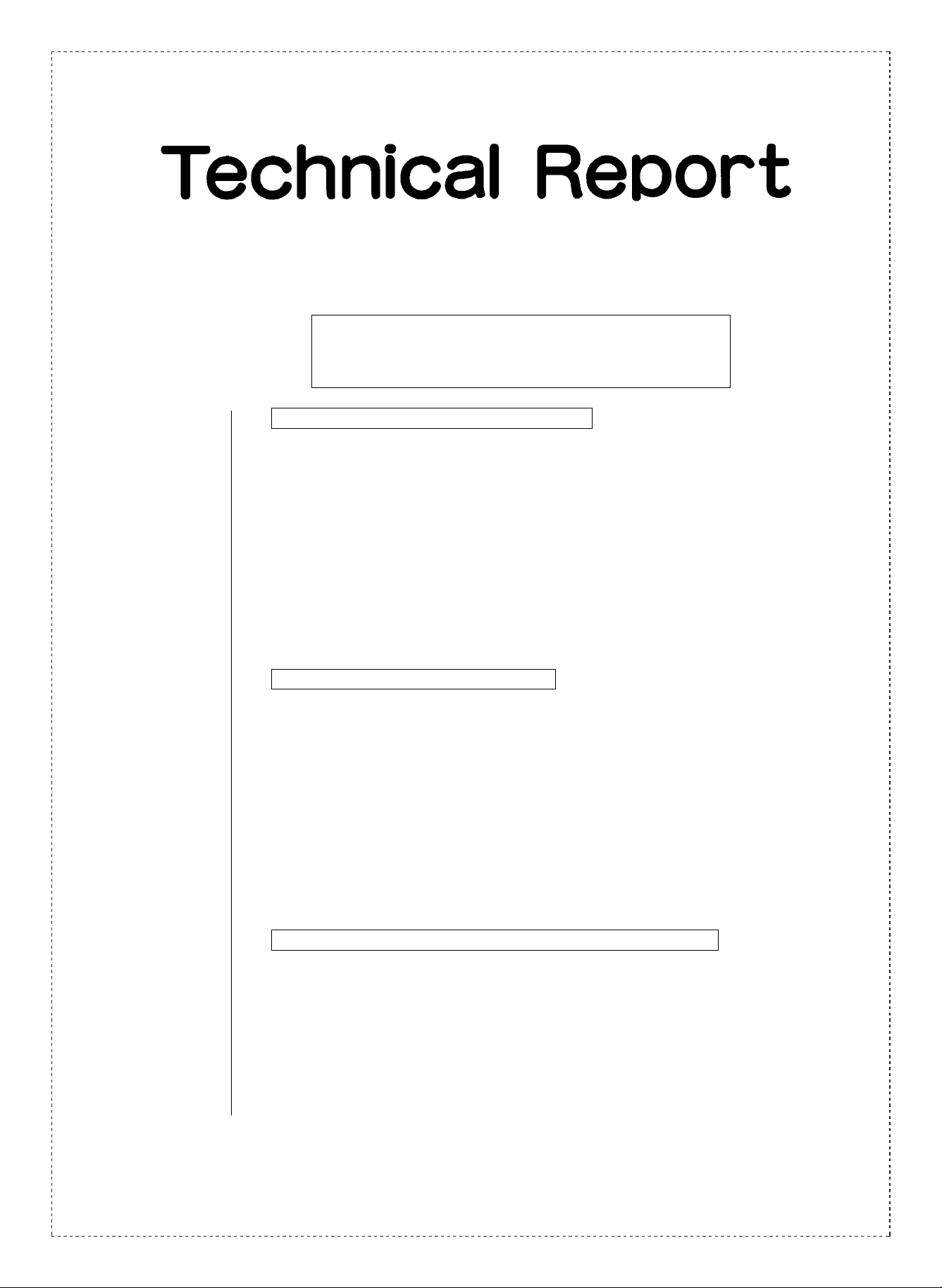

2.General: We had added two polysliders as a temporal measure to prevent unstableness of the

second joint arm. We have done a permanent measure by sliding the attachment

position of the E ring in the second idle bearing about 0.5 mm from the center.

Green

C

SHARP CORPORATION Reprography Division

1/5

Page 2

The second joint arm

The second idle bearing

The second idle bearing (current) The second idle bearing (new)

Two polysliders Interchangeable

3.Action: From the first unit of January 1995 production

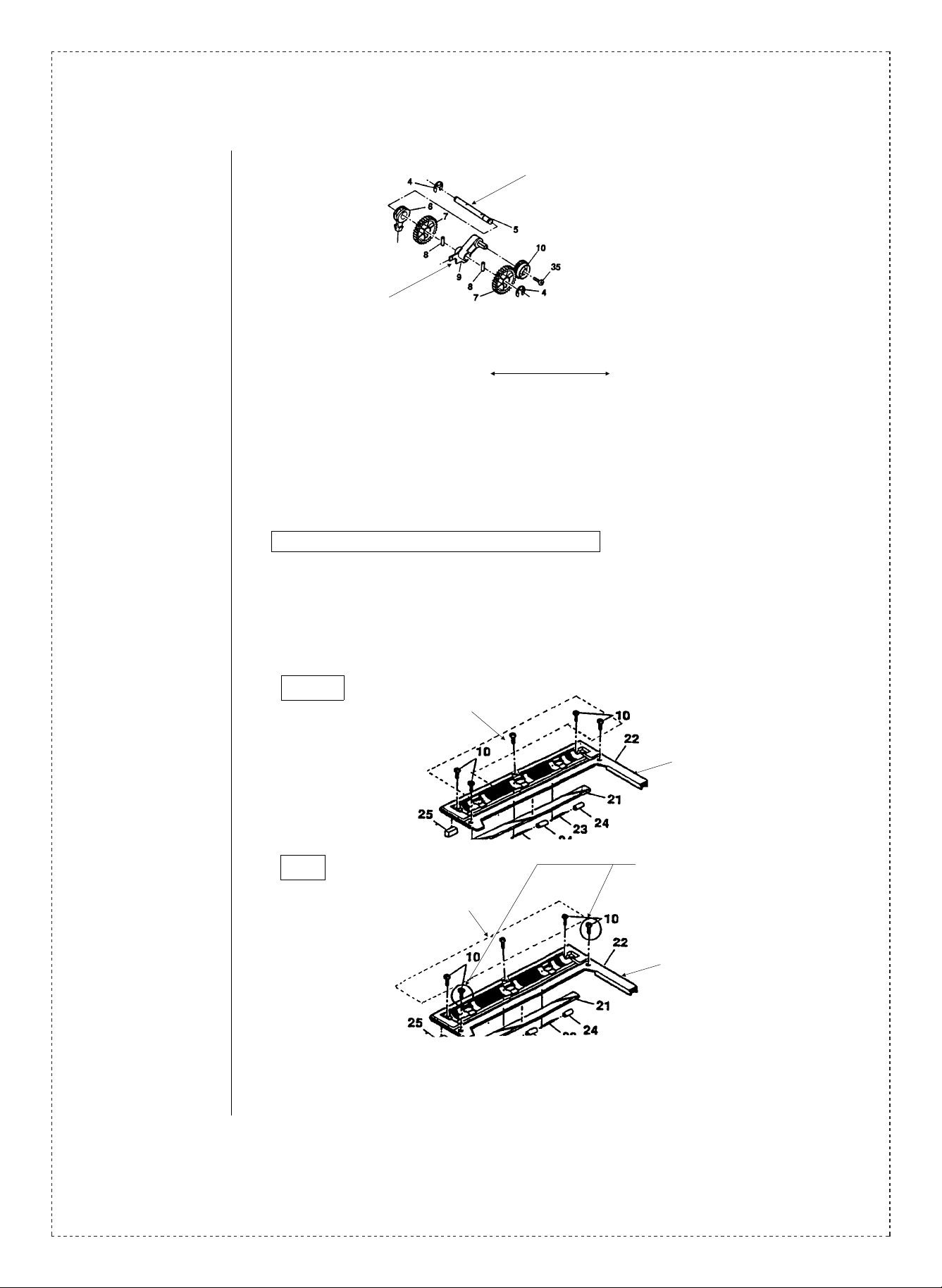

4. Prevention of rising in temperature in SPF mode

1.Model name: SF-2214, SN-1430

2.General: We have changed two of five SPF glass holder attachment screws to shoulder screws

to prevent rising in temperature in the SPF mode.

3.Description:

Current

Truss M3 X 6

LX-BZ0750FCZZ

Quantity 5

SPF glass holder

New

Truss M3 X 6

Quantity 3

4.Action: From the first unit of mass production

2/5

Screw M3

LX-BZ0759FCZZ

Quantity 2

SPF glass holder

Page 3

5. Changes to U-turn guide mylar in manual paper feeding unit

,

1.Model name: SF-2014, 2114, 2214

Z-800, SN-1420, 1430

2.General: We have changed a part of form in the U-turn guide mylar in the multi manual paper

feeder unit and the single paper feeder unit to meet the market demand.

For the destination of the inch series, we have eliminated a part of mylar in addition to

the change above.

3.Description: (Current) (New)

U-turn guide mylar

AB size series

No change in the mylar A and B.

Mylar C is changed to D and E.

Difference between the mylar C and the mylar

D and E of the U-turn guide mylar

1

60

15 15 30

U-turn guide mylar C

The shaded part is

double-sided tape.

0.5

U-turn guide mylar D U-turn guide mylar E

Inch size series

Discontinued

60

(Double-sided

tape)

Mylar A and B are eliminated.

Mylar C is changed to D and E.

60

Discontinued

(Double-sided tape)

(Current) (New)

U-turn guide mylar A PSHEP3761FCZZ Destination of AB series is as same as

U-turn guide mylar B PSHEP3762FCZZ Destination of inch series is discontinued.

the left.

U-turn guide mylar C PSHEP3763FCZZ U-turn guide mylar D PSHEP3821FCZZ

U-turn guide mylar E PSHEP3822FCZZ

4.Action: Inch size series: From the first unit of September 1994 production

AB size series: From the first unit of January 1995 production

3/5

Page 4

Ref.

Model

No.

name

SF-2214 All

1

SN-1430

Z-800

2

SN-1420

SN-1430

Version P/G No.

1 -25

1 -25

USA

18 -50

only

19 -50

Current parts New parts

Parts code Parts code

PMAGT0034FCZZ CMAGT0034FC01 AE

VHI37702E4140 VHI37702E4142 BK IC

Price

rank

Parts name

SPF glass

holder MG

Effec-

Inter-

tive

change-

time

ability

1st lot —

Note

SF-CM14 All 51 -5

3

SN-CM11

SF-2214 All

SN-1430

5

SF-2214 All

SN-1430

SF-2014

SF-2114

SF-2214

SF-CM14

Z-800

SN-1420

SN-1430

ZT-MF11 51

SN-MF11

SF-2014

SF-2114

SF-2214

SF-MF14

6

Z-800

SN-1420

SN-1430

ZT-MF11 51

USA

only

USA

only

USA

only

Inch

series

only

USA

only

Inch

series

only

USA

only

51 -5

1 -10

1 -10

1

1

16

17

15

16

53

16

17

15

16

NSFTZ2048FCZZ NSFTZ2048FCZ1 AF

LX-BZ0750FCZZ

—

PSHEP3761FCZZ

(Q’ty: 2)

PSHEP3762FCZZ Discontinued —

Q’ty change

(5 → 3)

LX-BZ0759FCZZ

(Q’ty: 2)

Discontinued —

Second idle

bearing

AB

Screw 1st lot

AB

U-turm guide

sheet A

U-turm guide

sheet B

1st lot

’95/1

1st lot

’94/9

3

—

4/5

SN-MF11

SF-2014 All

SF-2114

SF-2214

SF-MF14 All

Z-800

SN-1420

SN-1430

ZT-MF11 51

SN-MF11

EX only

USA

only

53

16

17

PSHEP3763FCZZ

15

16

53

(Q’ty: 3)

Discontinued

—

U-turm guide

sheet C

Page 5

Ref.

No.

SF-2014 All

SF-2114

SF-2214

Version P/G No.

EX only

Current parts New parts

Parts code Parts code

16

Price

rank

Parts name

Effec-

tive

time

Inter-

change-

ability

Note

USA

only

USA

only

17

15

16

53

16

17

15

16

53

!

—

— PSHEP3822FCZZ AC

PSHEP3821FCZZ

(Q’ty: 2)

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others .

AC

U-turm guide

sheet D

1st lot

’94/9

U-turm guide

sheet E

SF-MF14 All

Z-800

SN-1420

SN-1430

ZT-MF11 51

6

SN-MF11

SF-2014 All

SF-2114

SF-2214

SF-MF14 All

Z-800

SN-1420

SN-1430

ZT-MF11 51

SN-MF11

<Interchange>

1. Interc ha ng ea bl e. 4. N ot i nt er ch an ge ab l e.

2. Current type can be used in place of new type.

3. Current type cannot be used in place of new type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

specifi e d on es fo r m ai n ta in i ng t he safety an d pe r fo r ma nce o f th e set.

EX only

New type cannot be used in place of current type.

New type can be used in place of current type.

—

5/5

Loading...

Loading...