Page 1

Date: Mar. 20, 1995

COPIER : SF-2014

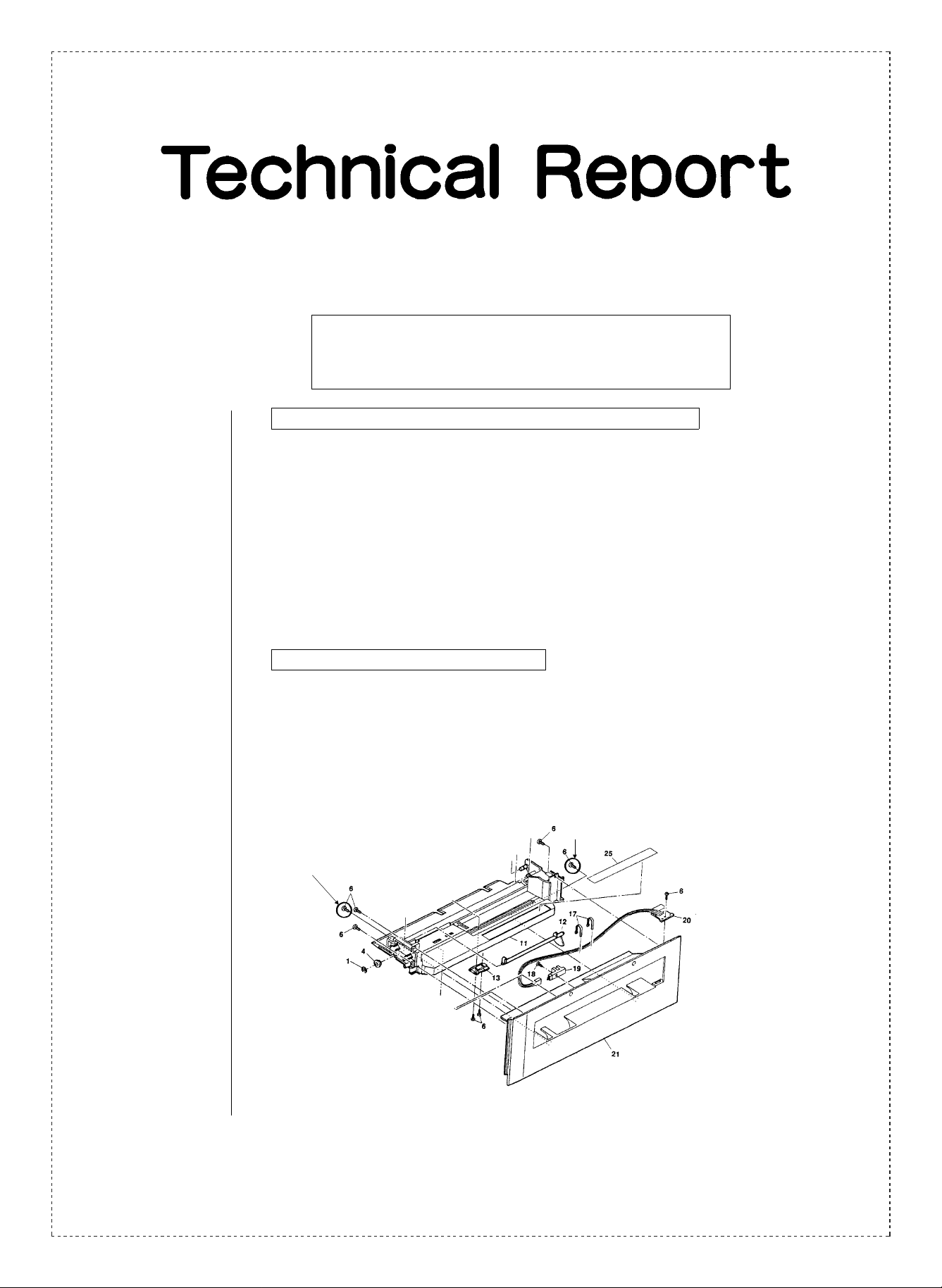

1. CHANGE OF DRIVEN ROLLER (TO IMPROVE ABILITY TO DISCHARGE PAPERS)

2. PREVENTION OF PAPER JAM IN U-TURN GUIDE

3. CHANGE OF CFM ATTACHM ENT SCREW

4. PARTS’ CODE CORRECTION IN REVERSING ROLLER UNIT

No. : SP-1851

1. Change of driven roller (to improve ability of discharging papers)

1.Model name: SF-2014, 2114, 2214

2.General: We have changed the driven roller in the fusing unit to improve ability of discharging

OHP. This has already applied from the first unit of mass production.

3.Action: From the first unit of mass production

2. Prevention of paper jam in U-turn guide

1.Model name: SF-2014, 2114, 2214

2.General: The height of the head screw which attached the manual feeding U-turn guide is so tall

that it possibly made paper jam. Therefore we changed it to the plane screw with a

short head. Also, we have added the shaft hold cushion to deal with noise.

Changed parts in the single paper feeding unit

Changed

Changed

SHARP CORPORATION Reprography Division

1/3

Green

C

Page 2

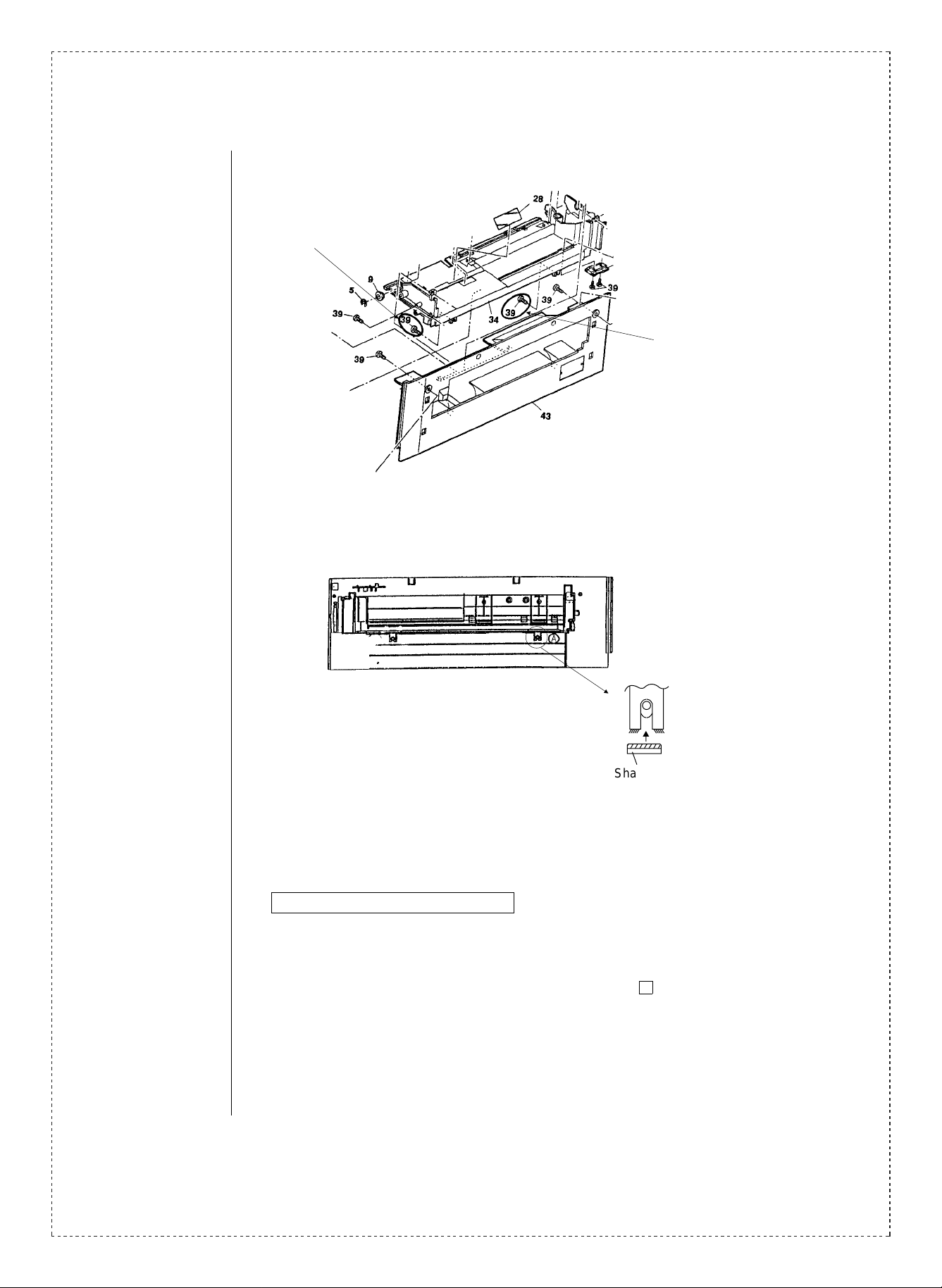

Changed parts in the multi manual paper feeding unit

Changed

Addition of shaft hold cushion

Changed

Shaft hold cushion (added)

3.Action: From the first unit of mass production

3. Change of CFM attachment screw

1.Model name: SF-2014, 2114, 2214

2.General: We have changed the CFM attachment screw (Parts guide 6 -103, quantity 2) to

longer one.

3.Action: From the first unit of mass production 1994

2/3

Page 3

4. Parts’ code correction in reversing roller unit

1.Model name: SF-2114

2.General: The part’s code of the reversing roller unit (Parts guide 3 -67) was false. This change

is only applied to the 3 -67, not for the 17 -23.

3.Action: From the first unit of mass production

Ref.

Model

No.

SF-2014

1

SF-2114

SF-2214

SF-2014

SF-2114

SF-2214

SF-2014

SF-2114

SF-2214

2

SF-MF14

SF-2014

SF-2114

SF-2214

3

4 SF-2214

<Interchange>

1. Interc ha ng ea bl e. 4. N ot i nt er ch an ge ab l e.

2. Current type can be used in place of new type.

3. Current type cannot be used in place of new type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

speci fi e d on es for mai n ta in i ng t he s a fe ty an d pe rformance o f the set .

Version P/G No.

name

11 -5

All

EX only —

New type cannot be used in place of current type.

New type can be used in place of current type.

16 -6 XEBSD30P10000

16 —

17 -39 XEBSD30P10000

17 — LX-BZ0728FCZZ AA Screw

All

16

17

6 -103

3 -67

!

Current parts New parts

Parts code Parts code

NROLP0790FCZZ

(Q’ty: 2)

— PCUSS0322FCZZ AA

XEPSD40P30000

(Q’ty: 2)

CROLR1048FC31 CROLR1048FC32 AU

PCLR-0400FCZZ

(Q’ty: 2)

Q’ty change

(8 → 6)

LX-BZ0728FCZZ

(Q’ty: 2)

Q’ty change

(10 → 8)

XEPSD40P35000

(Q’ty: 2)

Price

rank

AC

AA Screw

AA Screw

AA Screw

AA Screw —

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others.

Parts name

Discharging

paper coro A9

Shaft hold

cushion

Reversing roller

unit

Effec-

tive

time

1st lot

Inter-

change-

ability

— *

—

—

—

Note

* Please change its part’s code in the parts guide.

3/3

Loading...

Loading...