Page 1

Date: Jun. 16, 1994

COPIER : Z-20

1.PREVENTION OF TRANSFER ELE CTRODE HOLDER DEFORMATION

2.PREVENTION OF PAPER SUPPLY JAM AND DOUBLE FEEDING

3.IMPROVEMENT OF HALF TONE STRIPES

4.IMPROVEMENT OF WHITE STRIPED IMAGES

1. Prevention of transfer electrode holder deformation

1.Model name: Z-20, 25, 27

2.General: The shape of the transfer electrode holder T has been changed. This is to prevent the

holder from bending from torque when securing the transfer electrode holder T.

No. : SP-1760

3.Description: <Temporary measure> Mass production, 1st lot only (November 1993 production)

Enforcement of three spacer mountings.

Spacer Spacer Spacer

<Permanent measure> From December 1993 production agram

Addition of ribs in the six positions shown below.

Rib PRib P Rib PRib P Rib PRib P

Current and new parts are interchangeable. Parts code remain unchanged.

4.Action: Mass production, 1st unit.

SHARP CORPORATION Reprography Division

1/3

Green

C

Page 2

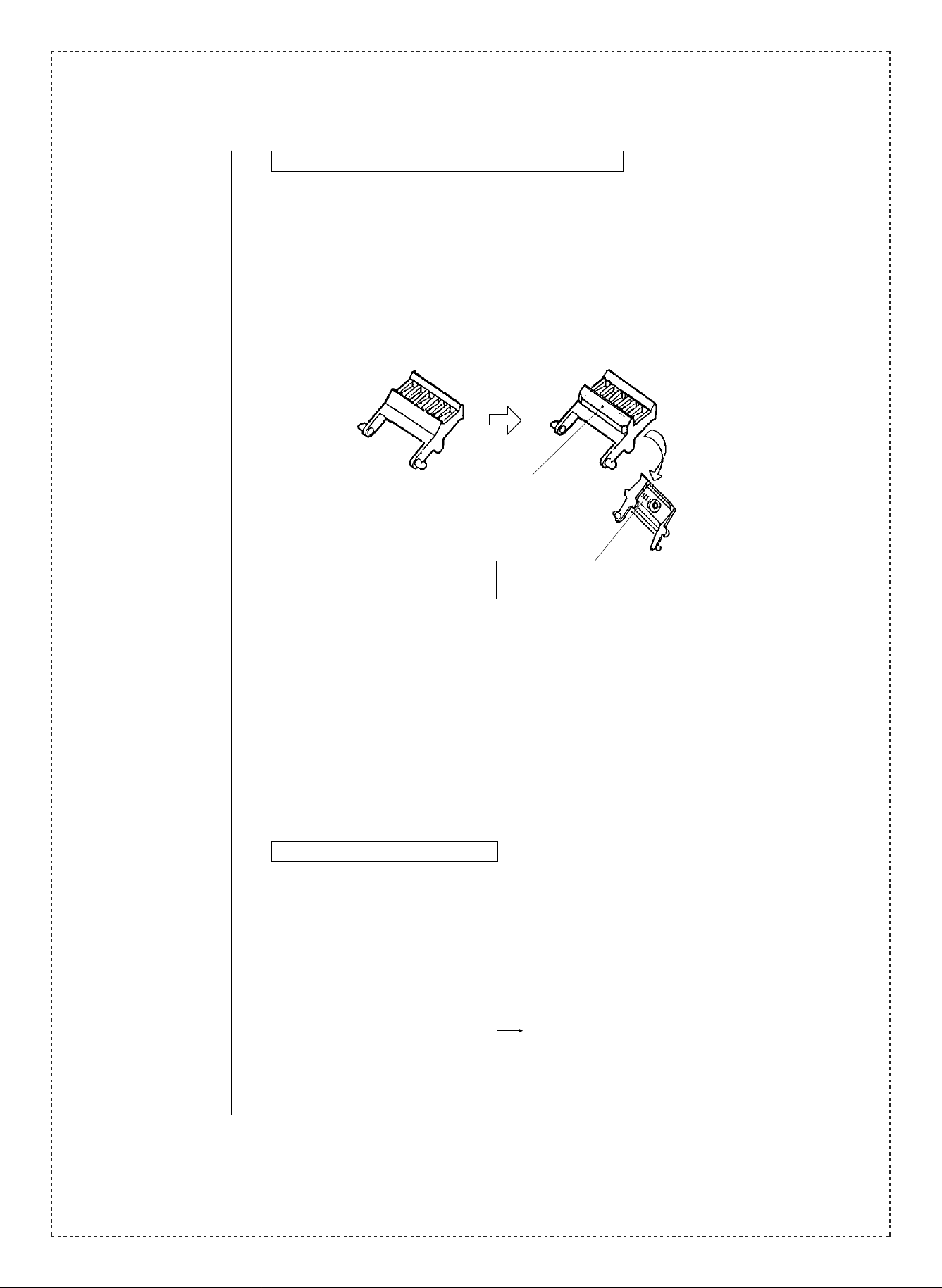

2. Prevention of paper supply JAM and double feeding

1.Model name: Z-23, 25, 27

2.General: The surface shape of the paper pass for the pressure holder has been changed. This is

to prevent paper supply jams and double feeding in the multi-paper supply unit.

3.Description:

(Current)

Changed surface shape

Addition of “HI” engraving on the

back surface of new parts.

(New)

As temporary measures, separate parts (PH guide) were adhered to the pressure

holder. (From mass production, 1st unit) As permanent measures, the mold has been

changed. (From February 1994 production)

Current and new parts are interchangeable. Parts code remain unchanged.

4.Action: Mass production, 1st unit.

3. Improvement of halftone stripes

1.Model name: Z-20, 23, 25, 27

2.General: The reflective mylar 2 in the light source unit has been replaced with reflective plates 2

(aluminum). This is to soften the halftone stripes for more uniformity in halftone copies.

3.Description: Current New

Reflective mylar (t = 0.05mm mylar) Reflective plate 2 (t = 0.5mm aluminum plate)

4.Action: From mid-February 1994 production

2/3

Page 3

4. Improvement of white lines on images

1.Model name: Z-20, 25, 27

2.General: Application of grease and changes to the spring weight were made. This is to prevent

white lines from appearing on images when the coupler in the drive unit escaped and

caused the MG roller to stop for a few seconds.

3.Description: MG roller spring weight 70g (silver) Weight 140g (gold)

Gear 18A

NGERH0966FCZZ

MG roller SP

MSPRC2132FCZZ

MG coupler

NCPL-0021FCZZ

Apply grease to shaded areas

(Quantity: 3mg/area, in two places)

4.Action: April 1994 production, 1st unit. (Grease application has already been enforced as a

temporary measure for mass production, 1st unit.)

Ref.

Model

No.

Z-20

Z-23

3

Z-25

Z-27

Z-20

4

Z-25

Z-27

<Interchange>

1. Interc ha ng ea bl e. 4. Not int erc h an ge ab l e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

specifi e d on es fo r m ai n ta in i ng t he s a fe ty and perfo rma nc e o f th e s et .

name

Version P/G No.

6-7

ALL

4 -14

!

Current parts New parts

Parts code Parts code

PSHEP3441FCZZ LPLTM4600FCZZ AD Reflective plate 2

MSPRC2132FCZZ MSPRC2132FCZ1 AA MG roller SP

Price

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others.

Parts name

rank

Effec-

tive

time

Mid-

’94/2

1st lot

’94/4

Inter-

change-

ability

3

3

Note

3/3

Loading...

Loading...