Page 1

Date: Jun. 16, 1994

COPIER : SF-2022

1. PREVENTION OF BOSS BREAKAGE IN THE LENS CARRIAGE

2. CHANGES TO AC PWB PAT TERNS FOR 20 0V SERIES

3. DESIGNATION OF SERVICE PARTS FOR PAPER DISPENSER

CABINET SPACER AND BEARING

1. Prevention of boss breakage in the lens carriage

1.Model name: SF-2022, 2027, 1025 SF-7800, 7850, 7855, 7830

2.General: Breakage was found to occur in the boss for the lens drive wire spring in the optical unit

lens carriage. An ’R’ has been attached to the base of the boss to strengthen it.

No. : SP-1757

3.Action: 100V series: SF-2022, 2022H, 2027, 2027H, 1025 : From May 1994 production

200V series: SF-2022, 2027, 1025 : From mid-April 1994 production

SF-7800, 7850, 7855, 7830 : From May 1994 production

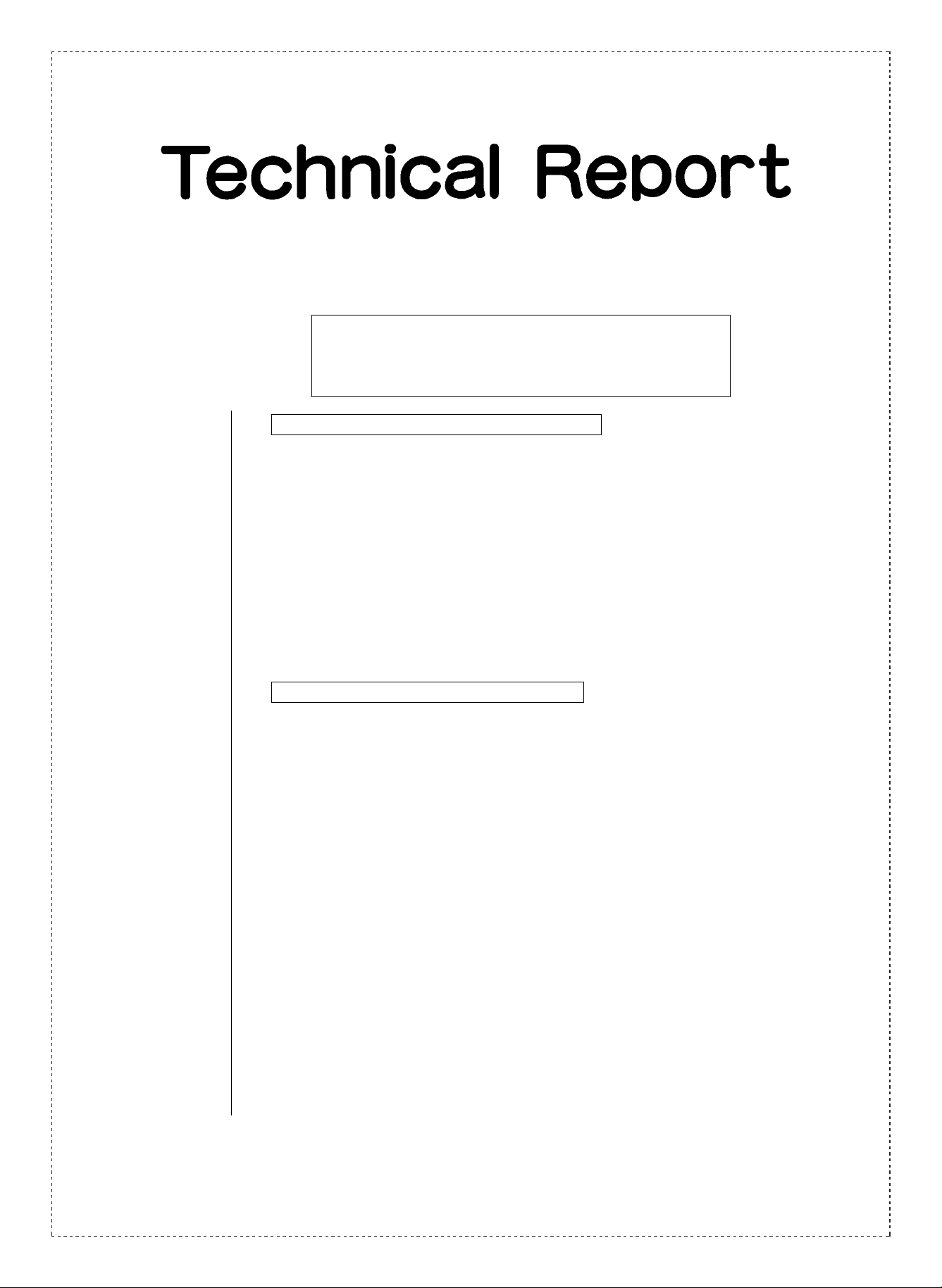

2. Changes to AC PWB patterns for 200V series

1.Model name: SF-2035, 200V series only

2.General: Changes were made to the AC PWB patterns in accordance with safety standards for

the UK. However, these changes were made only for units bound for the UK and other

limited destinations. On units bound for all other destinations, current patterns were

redeemed and then changed. Redemption of all current PWB patterns has been

completed. Therefore, new patterns have been made for units bound for the remaining

200V destinations.

SHARP CORPORATION Reprography Division

1/3

Green

C

Page 2

3.Description:

4.Action: From mid-April 1994 production.

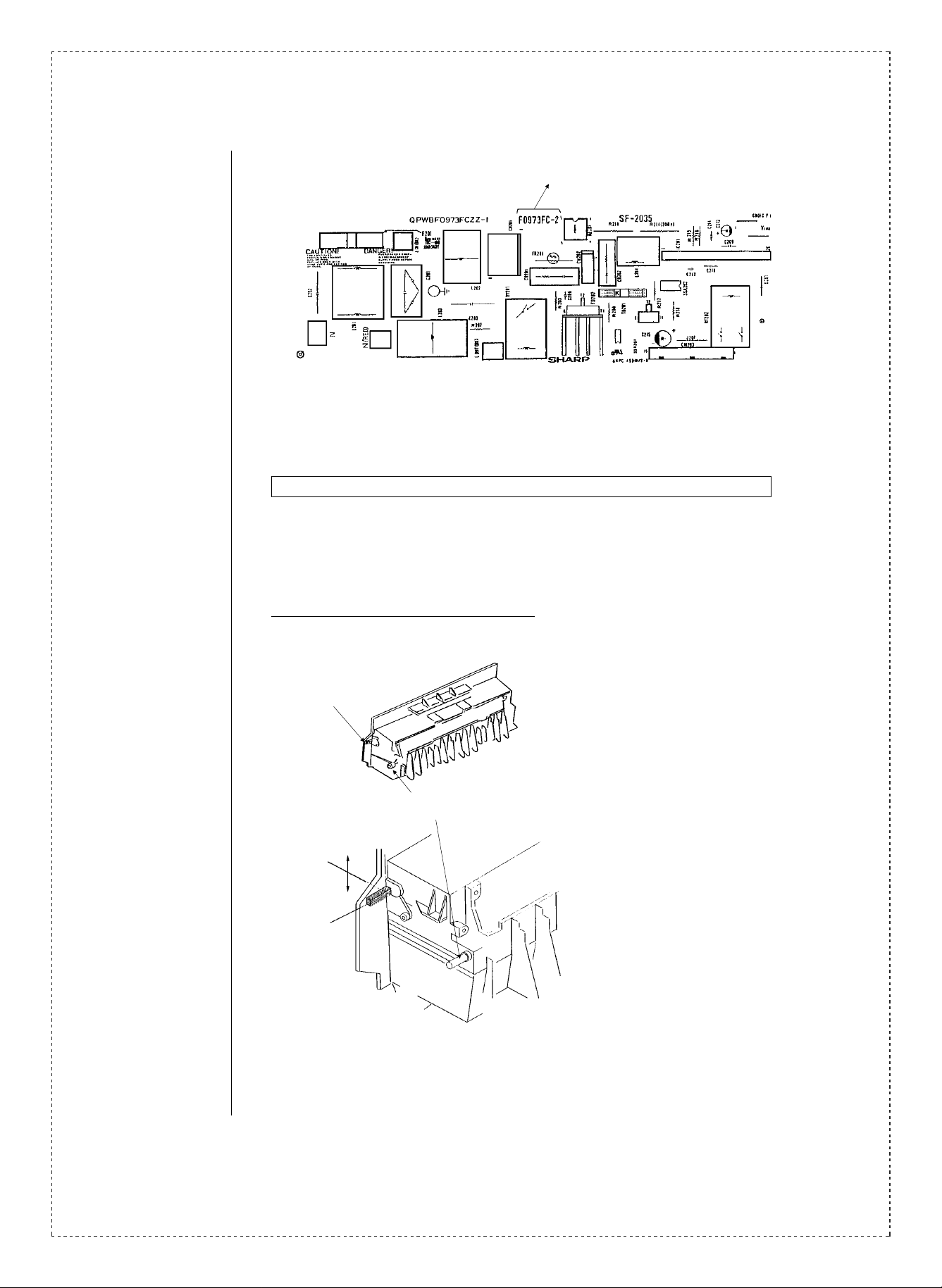

3. Designation of service parts for paper dispenser cabinet spacer and bearing

1.Model name: SF-2022, 2027, 2035/2035H, 1025

Changed maintenance silk

Changed from F0973FC-2 to F0973FC-3

2.General: The following service parts have been designated to prevent boss breakage in the

paper dispenser cabinet of reversal units.

Note: Designation is for service parts only.

3.Description:

L/R symmetrical

positions

Spacer mounting

0~+2mm

➀

Reference

Surface reference

➁

General view

Exchanged both L/ R bear ings

L/R symmetrical positions

0

(Bearing Exchange)

(1) Remove screw and washer

(2) Remove current bearing

(3) Insert new bearing

(4) Mount screw and washer

(Dispenser Cabinet Spacer Mounting)

(1) Cleanse the mounting surface with alcohol.

(2) Confirm mounting position using reference

Place the spacer against the surface.

Then mount spacer in line with surface

reference ➁.

➀.

2/3

Note: Please be sure to confirm that reference ➀ does not extrude from the main body.

If Reference ➀ extrudes from the main body, it will come in contact with the F/R

support plate during opening/closing of the dispenser cabinet.

Page 3

Ref.

No.

1

Model

name

SF-2022

2027

1025

SF-2022

2027

1025

Version P/G No.

100V

series

200V

series

12 -58 PLNS-0043FCZZ PLNS-0043FCZ1 BK Lens

Current parts New parts

Parts code Parts code

Price

rank

Parts name

Effec-

tive

time

’94/5

MidApr.

1994

SF-7800

7850

7855

All ’94/5

7830

7870

2027

2035

1025

200V

35 -901 CPWBF0973FC51 CPWBF0973FC52 BQ AC circuit PWB ’94/4 3

series

6

—

All

6

—

PSPAZ0654FCZZ

(Q’ty: 2)

NBRGY2111SCZZ

(Q’ty: 2)

Paper dispenser

AF

cabinet spacer

AB Bearing — —

——

2 SF-2035

SF-2022

3

<Interchange>

1. Interc ha ng ea bl e. 4. N ot i nt er ch an ge ab l e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

s p ec i fi e d on es for mai n ta in i ng t he s a fe ty and pe r fo rma nc e o f th e set.

!

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others.

Inter-

change-

ability

3

Note

Designated

as service

parts only

3/3

Loading...

Loading...