Page 1

Date: Mar. 31, 1994

OPTION: SF-S52

No. : SP-1725

SF-S52

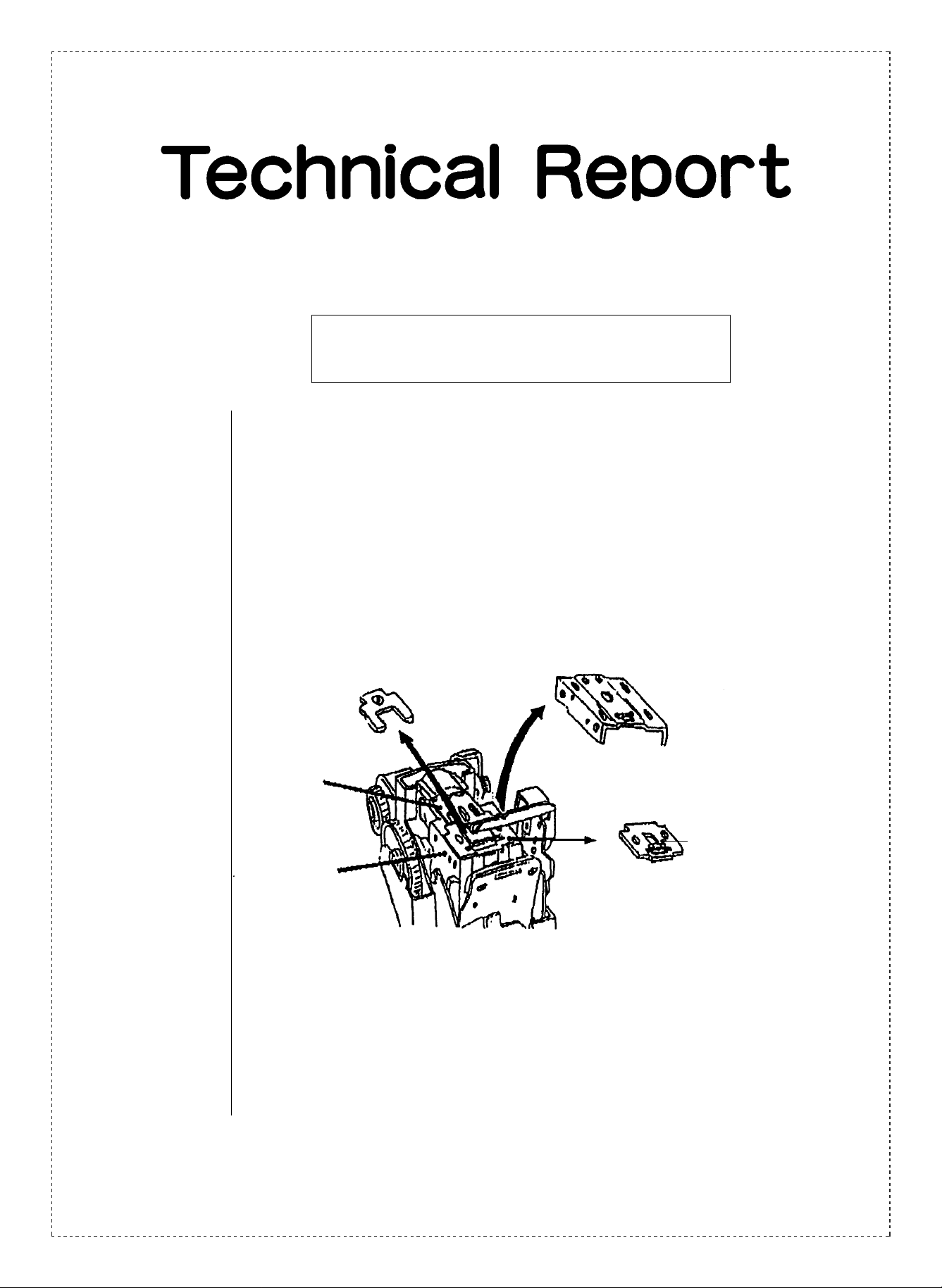

TROUBLE SHOOTING STAPLE FEEDING TROUBLE IN

THE STAPLE UNIT.

The problem of staple feeding in the staple unit of model SF-S51 was reported in

technical report no. SP-1660, but the same problem has occurred in model SF-S52 and

is hereby reported.

1.General: The staple opening of the face plate was too small, and staples sometimes could not

pass through during staple mode operations (staple sort, and manual staple

operations). The trouble shooting measures described below are requested.

2.Cause: Due to staple unit face plate parts irregularities, the staple opening was too small,

causing the resistance during staple feeding to be too strong for the staples to pass

through (A change in the face plate metal pattern was carried out in 1993 March, but

dimension variance in the metal pattern occurred).

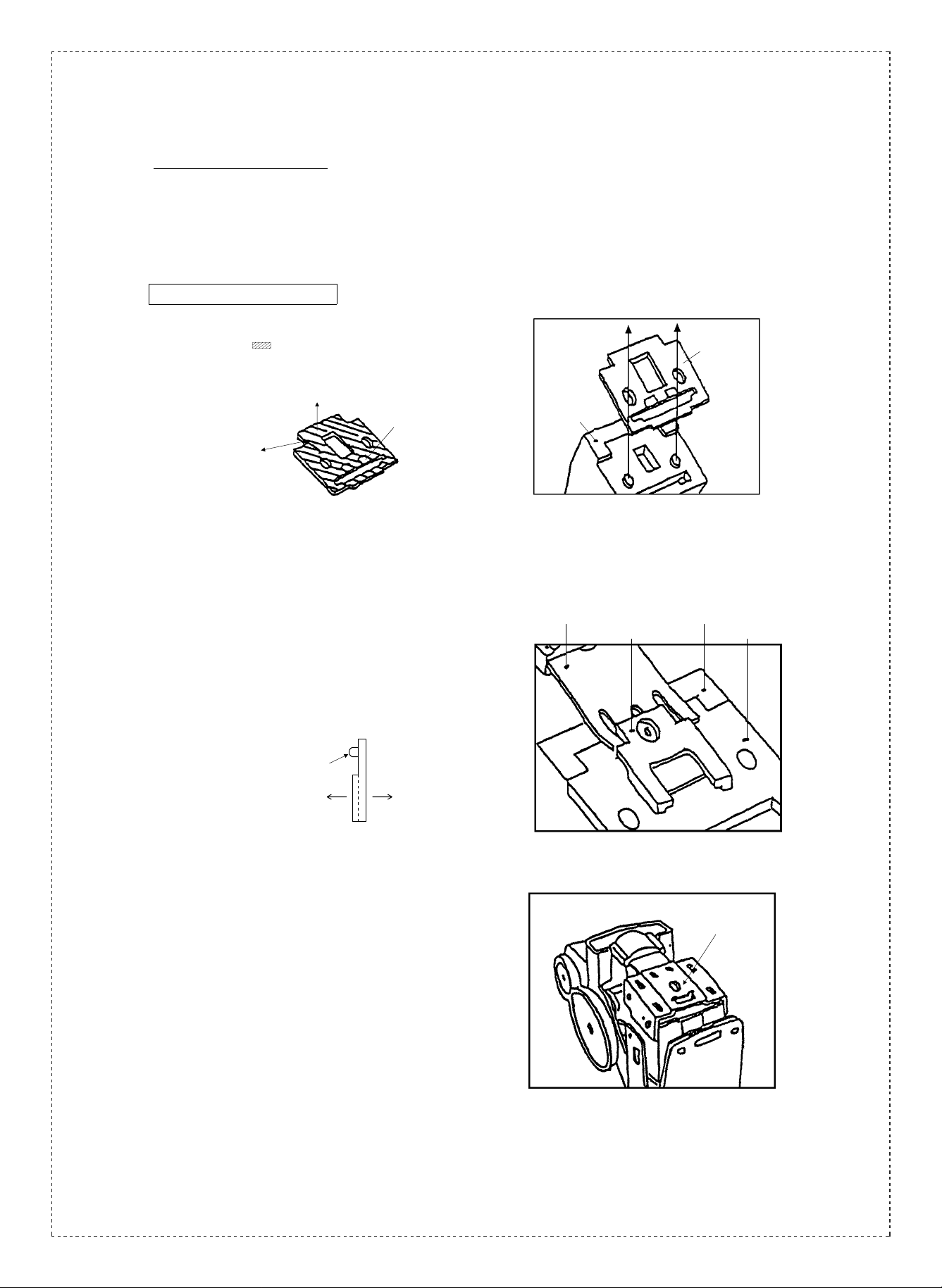

Former

Driver plunger

Body

Front sheath

Face plate

Location where the

dimension variance

occurred in the staple

opening.

3.Description:

SHARP CORPORATION Reprography Division

In order to maintain the proper staple opening dimensions in the face plate, finishing

(polishing) of the metal pattern has been added.

Note: The feeder of model SF-S52 is different in shape from the feeder used in model

SF-S51. The driving power is about the same as the new type of feeder used in

model SF-S51, but for interchangeability with the SF-S51, the feeder of model

SF-S52 has been changed to the new type of feeder used in the SF-S51.

1/7

Green

C

Page 2

4.Action: (Factory action)

From 1993 December production.

How to read the manufacturing number of model SF-S52.

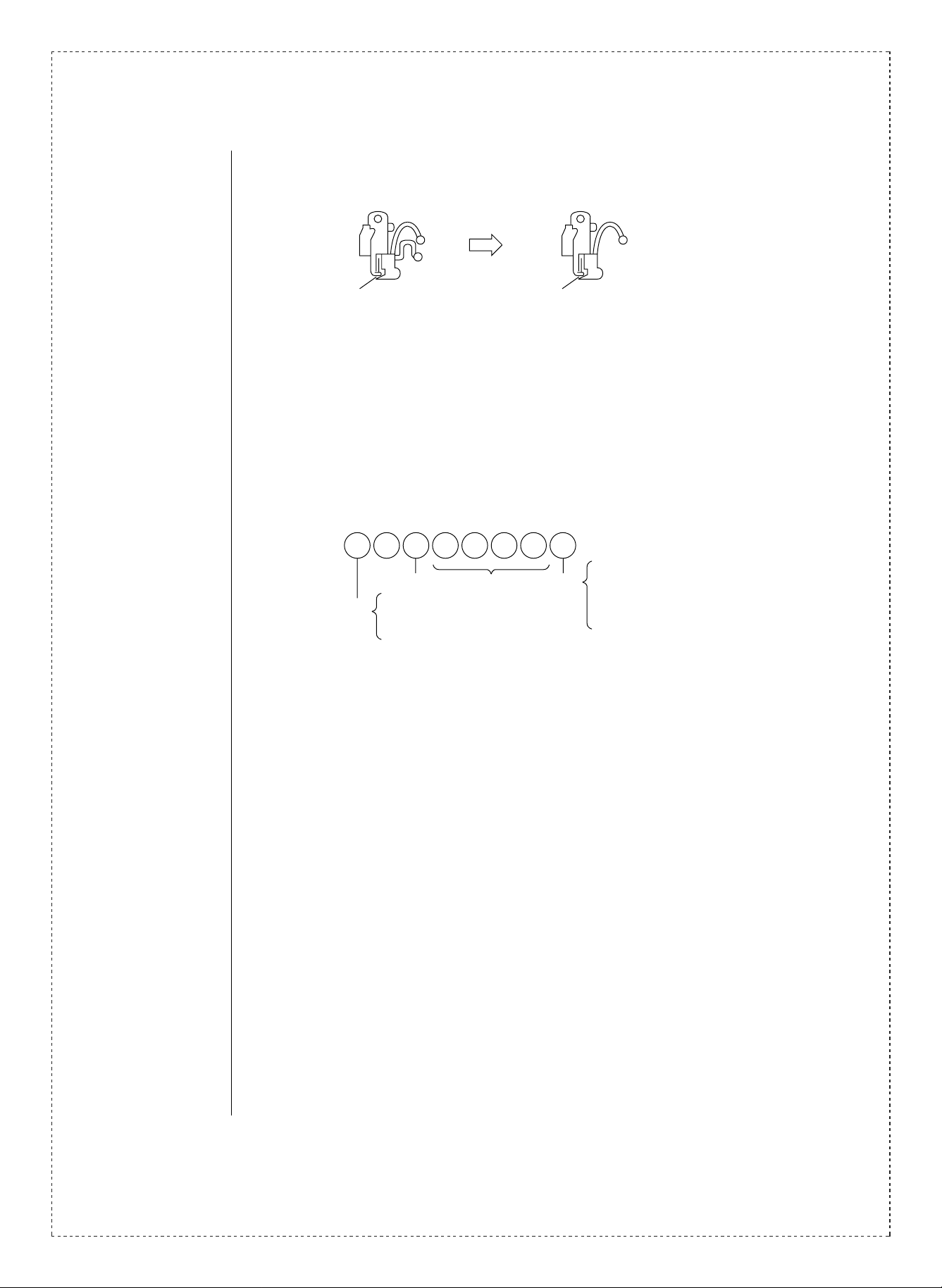

???

Old New

DC

Maker code Date

=

2 1992

=

3 1993

=

4 1994

Serial number

(Interchangeable with model SF-S51)

=

1 to 9 January to September

=

0 October

=

X November

=

Y December

2/7

(Field action)

When the trouble described above occurs, The face plate and M shaped spring should

be replaced.

(Replacement parts).

• Face plate (polished).

• M shaped spring (once removed, the spring may become deformed and so a new

spring should also be replaced).

* As previously explained, the driving power of the feeder is the same for both old and

new models, and it is therefore not necessary to replace it.

Questions concerning replacement parts should be directed to the Product Quality

Control Section of the Copier Operations Division.

Page 3

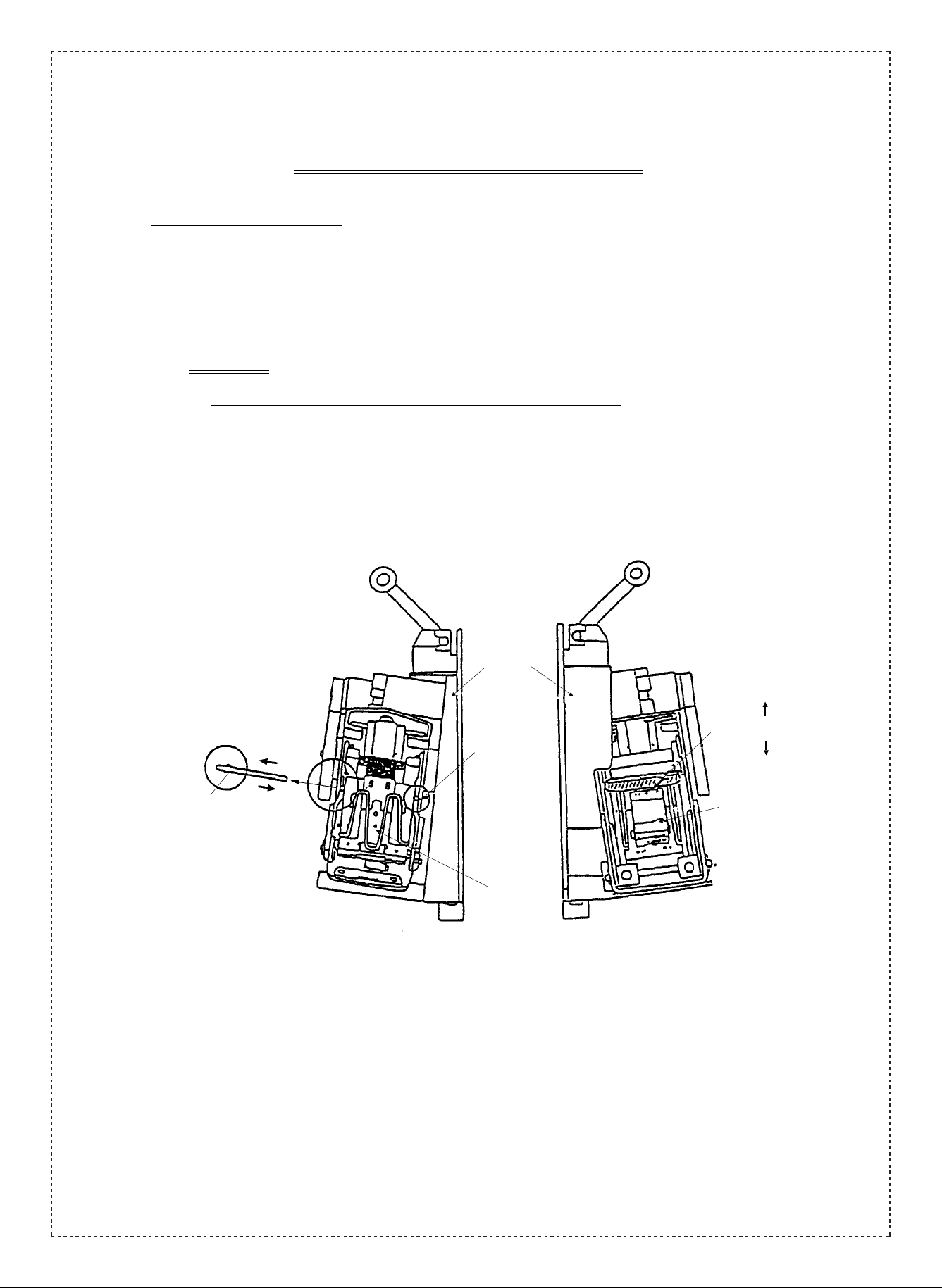

How to replace the face plate and the M-spring

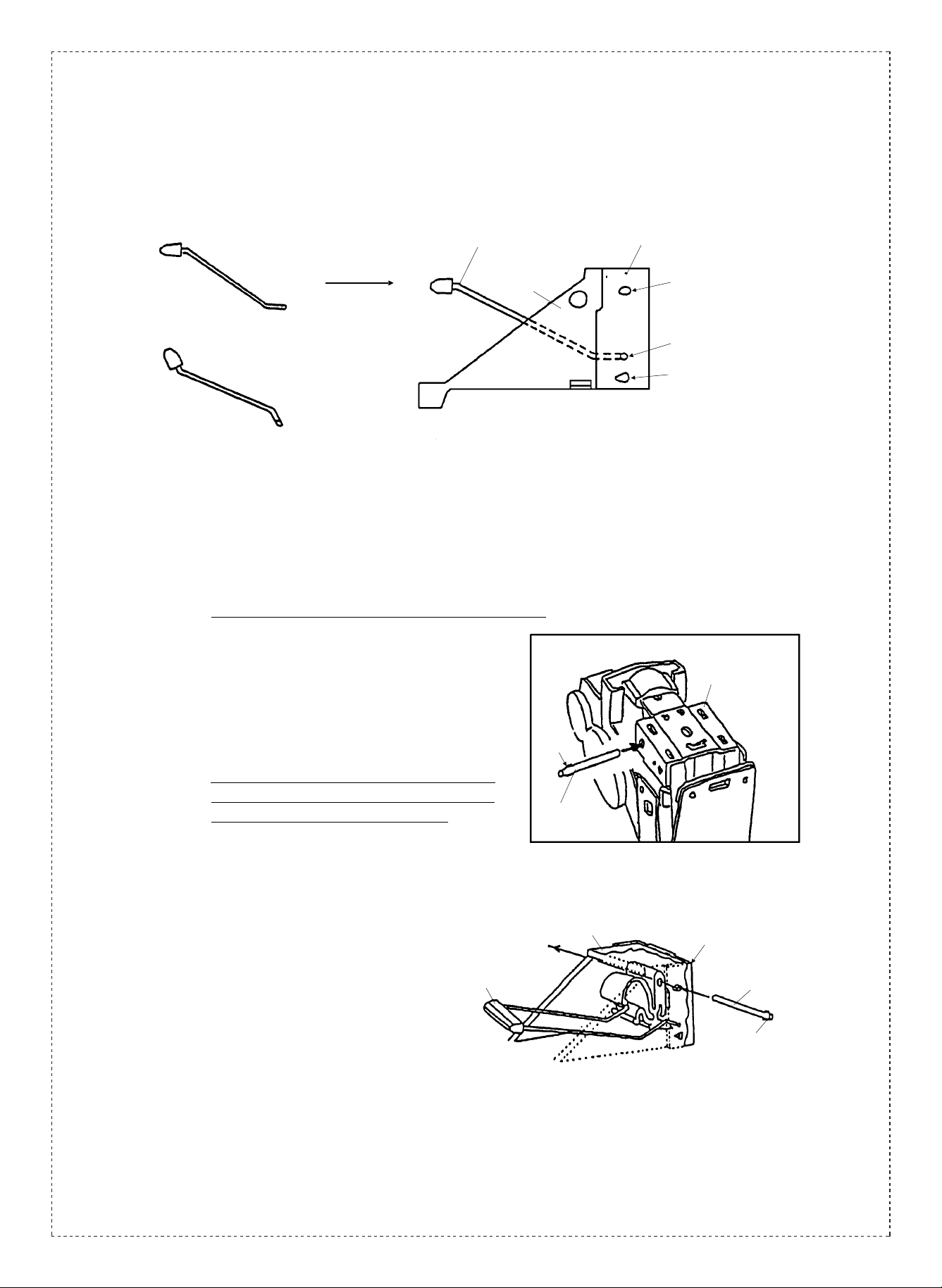

When disassemble the stapler

1. Remove the stapler from the sorter.

2. Raise the cartridge spring (cf. Fig. 1), and remove the staple cartridge.

3. Pull out the body pin, and remove the feeder.

It has set direction.

Caution: The body pin has to be pulled out in one direction only as follows.

Lay down the stapler, and pat the body pin on the right side. Pull out the body pin in direction A as Fig. 1.

Using the plier (or the minus screwdriver), hold head of the body pin.)

And pat the plier (or the minus screwdriver).

body pin

rib

direction of pulling

B

cover

A

head of

body pin

(pat here)

anvil guard

remove the staple

cartridge upward

cartridge spring

install the staple

cartridge lower

feeder

Fig.1.

3/7

Page 4

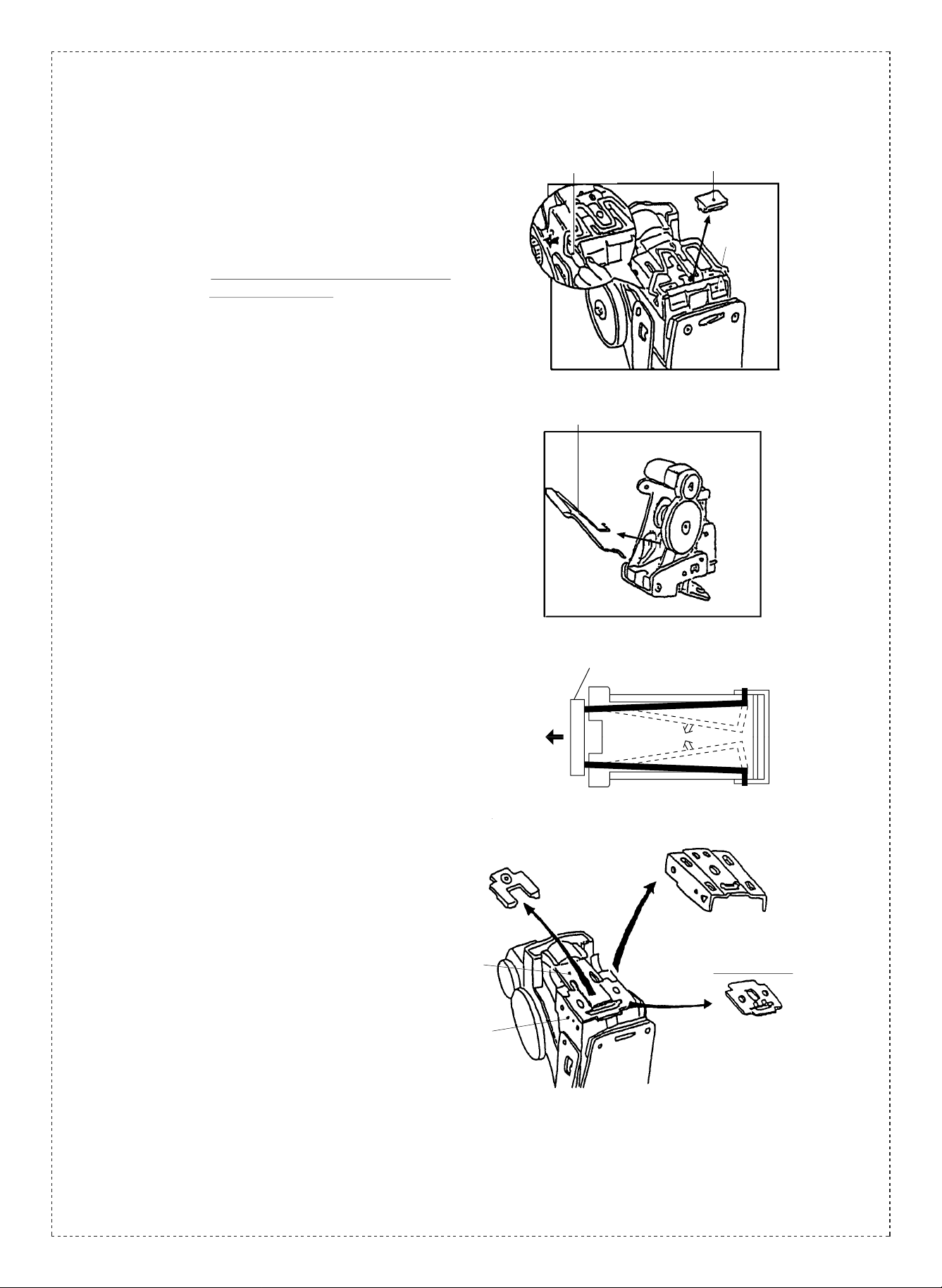

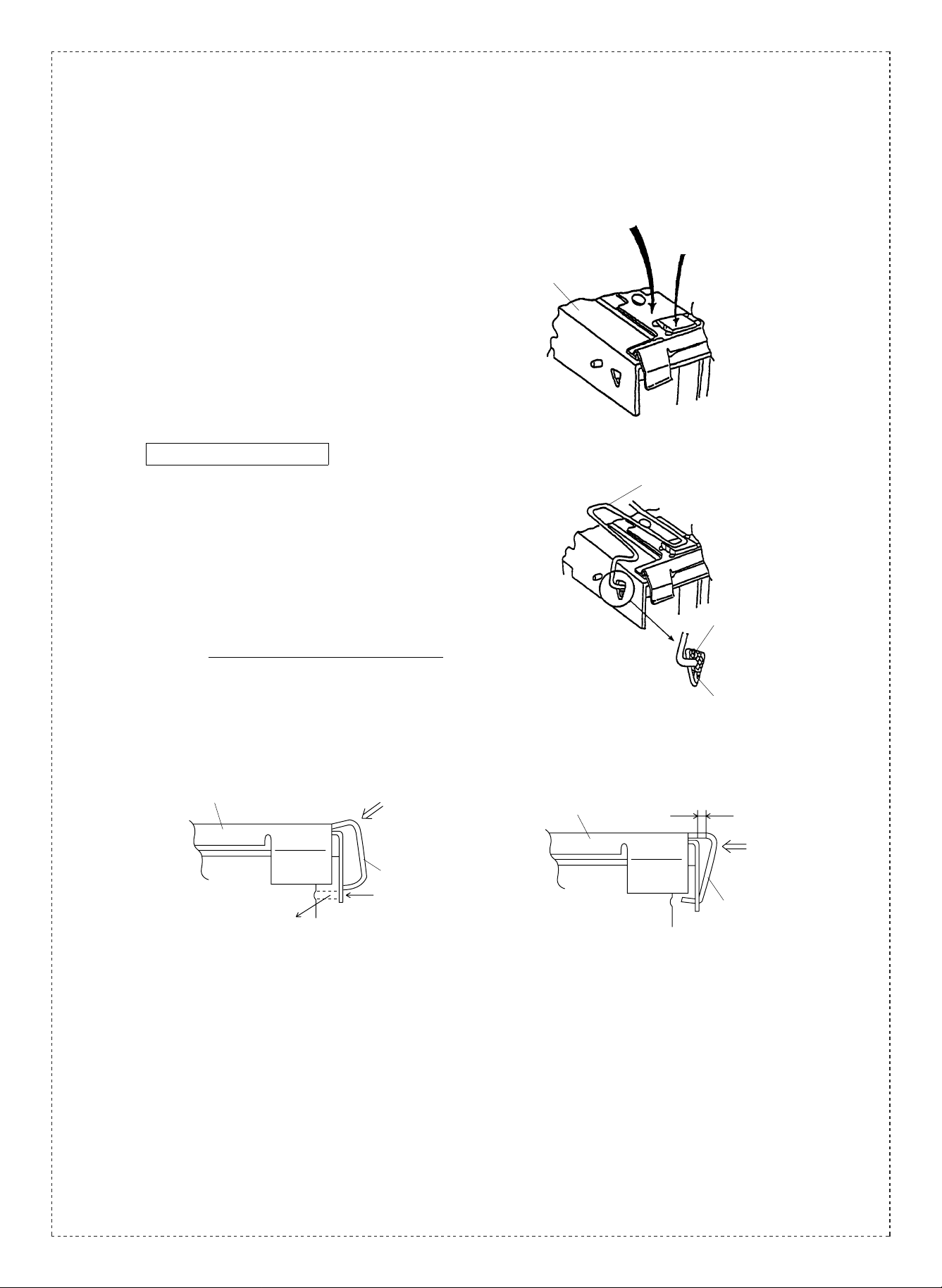

4. Remove the bending block and the anvil guard.

And using the minus screwdriver as Fig. 2,

remove the M-spring pulling up the right and

left side of it.

Caution: Don’t use the removed M-spring again,

due to deformation.

5. Remove the cartridge spring from back of the

stapler. Removing the cartridge spring, push the

cartridge spring from the outside to inside.

minus screwdriver

cartridge spring

bending block

anvil guard

Fig.2.

6. Remove the front sheath and the former from the

stapler as Fig.5. And remove the face plate under

the driver plunger. Removed face plate should be

replaced into new one.

driver pluger

body

former

cartridge spring

2

2

Fig.3.

1

Fig.4.

front sheath

1

new face plate

4/7

Fig.5.

Page 5

When assemble the stapler

1. Install the new face plate into bosses of the body as Fig.6 and 7.

At that time, take care not to put the face plate front side back.

When replace the face plate

Coat the designated grease on the surface of the

new face plate ( ) thinly.

(About one-half grain of cone)

surface

bosses of

the body

new face

plate

body

Fig.6.

Grease: LUBRIPLATE #105

Maker : FISKE BROTHERS REFINING CO.,

(New Jersey, Oh10)

2. Install the former on the driver plunger, to put the

projection of the former in the long hole of the driver

plunger as Fig.9.

side of the former

projection

under side

(back)

Fig.8.

upper side

(front)

3. Install the front sheath as Fig.10.

driver plunger

Fig.7.

former

body

face plate

Fig.9.

Fig.10.

front sheath

5/7

Page 6

4. Holding the front sheath by hand, and install the cartridge spring as Fig.11 and 12.

In case of installing the cartridge spring to the hole, push the cartridge spring to the inside. (cf.Fig.12)

front sheath

right

wrong

Fig.11.

cartridge spring

body

install position

Fig.12.

5. After installed the cartridge spring, install the feeder inside of the body by the body pin.

Caution: Install the feeder after the cartridge spring without fail.

insert the body pin

insert the cartridge spring

insert the M-spring

Install the feeder inside of the body as Fig.14. And

insert the body pin in a direction indicated by an

arrow as Fig.13 and 14.

Caution: Push the body pin through into the hole of the

feeder without fail. In case of it, don’t damage

the entrance of the hole of the feeder.

After the body pin inserted, pat the body pin to stick

out both ends of it from the body equally.

cartridge spring

rib

body pin

body

front sheath

Fig.13.

front sheath

body pin

rib

6/7

Fig.14.

Page 7

6. Install the bending block, the anvil guard and the M-spring.

➀ Install the bending block into the hole of the front

sheath.

It has no set direction.

➁ And then, install the anvil guard as Fig.15.

When replace the M-spring

➂ Hang both sides of the new M-spring on the holes

of the front sheath as Fig.16. (Don’t use the

removed M-spring.)

Using the plastic hammer, pat both sides of the

M-spring, and push the M-spring into the hole as

Fig.18.

Caution: Push the M-spring closely as Fig.18.

➁ anvil guard

➀ bending block

front sheath

Fig.15.

➂ M-spring

hole of the

front sheath

Replace of new parts is completed.

anvil guard

body

hole

Fig.17.

M-spring

anvil guard

body

Fig.18.

Fig.16.

insert the M-spring

push the M-spring closelypat here

push

M-spring

7/7

Loading...

Loading...