Page 1

Date: Mar. 29, 1994

COPIER : Z-20

No. : SP-1718

PREVENTION OF ABNORMAL NOISE.

1.ABNORMAL NOISE FROM THE DRIVE UNIT .

2.ABNORMAL NOISE FROM THE FUSING UNIT.

1.Model name: Z-20 / 23 / 25

2.General: Grease has been applied to prevent the occurrence of abnormal noise in the Z-20

series.

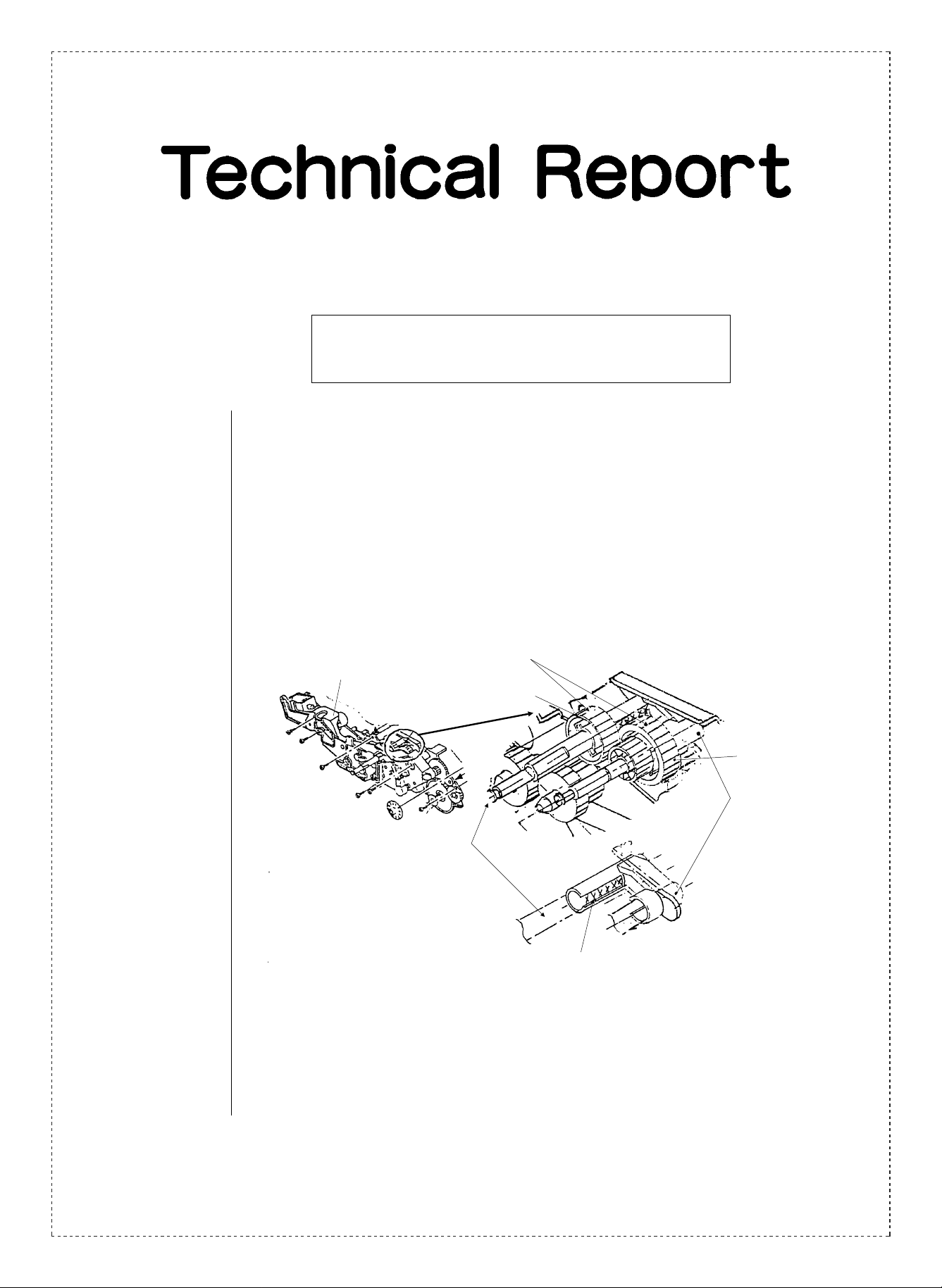

3.Description: 1. Prevention of abnormal noise occurring in the drive unit.

White grease (UKOG-0158FCZZ) has been applied to the shaft contact areas and the

gear teeth of gear 27, and gear 17 in the drive unit.

White grease (X5-6020) should be applied only to the

gear teeth in the ar eas designated by the arrows.

Drive unit

Shaft 24, 22B

(approx. 5 mg.)

Gear 24

Gear 27

Bushing A

➀ Approximately 15 mg. of white grease (X5-6020) should be

applied to the exposed areas of the XX section shaft.

The grease should be applied to the entire surfaces of

shafts 24, 22B.

SHARP CORPORATION Reprography Division

1/2

Green

C

Page 2

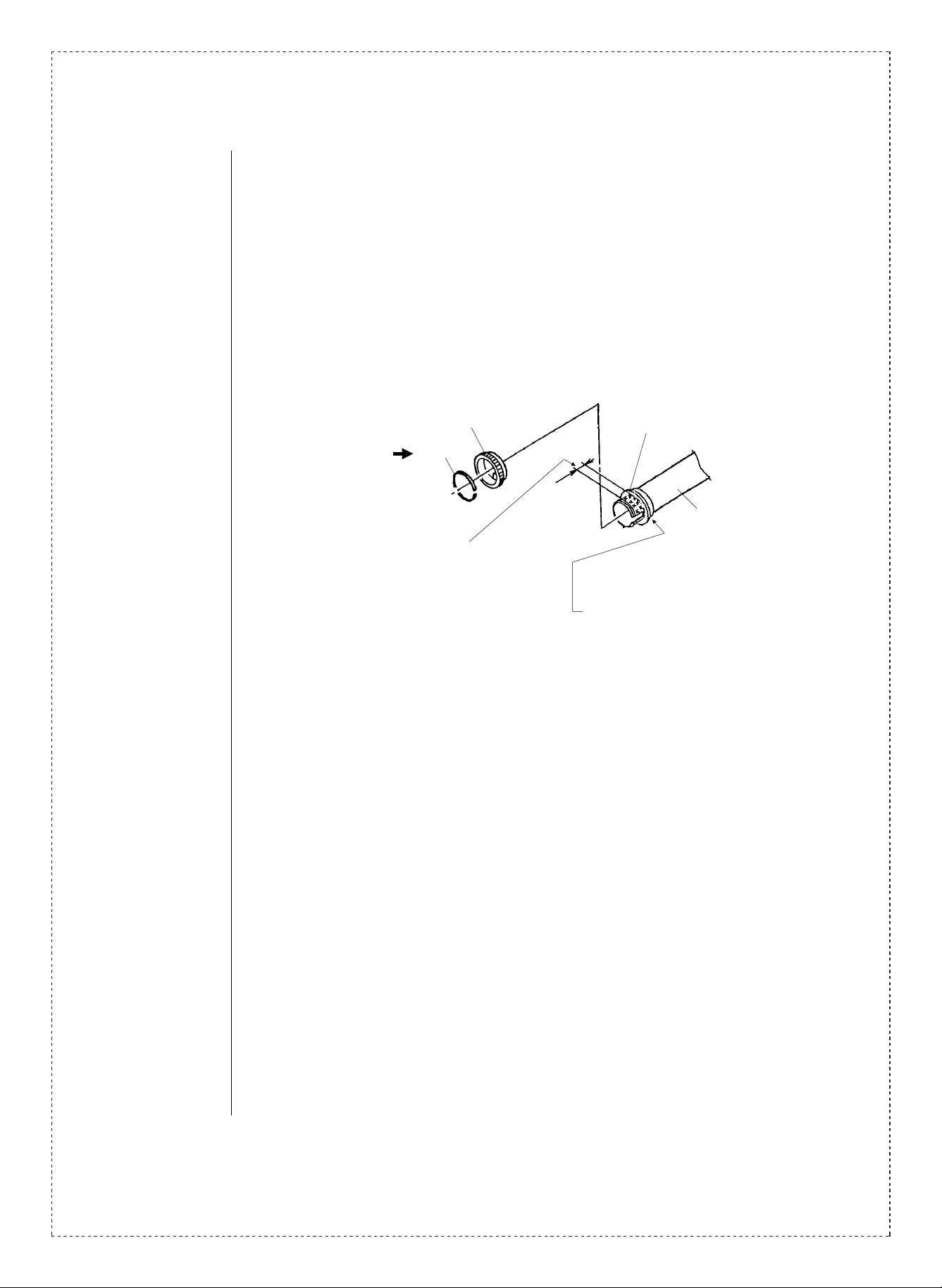

2. Prevention of abnormal noise occurring in the fusing unit.

Heat resistant grease (GU-2) has been applied to the rear side of the heat roller .

After applying approximately 15 mg of heat resistant grease to the circumference of

the right side of the heat roller the fusing gear is inserted into the heat roller and

fastened by the C ring.

Note: The heat roller ground has been removed from the static electricity discharge

brush at the end of the heat roller (Z-25). Checks should therefore be carried out

so that the static electricity discharge brush has not been coated with the

grease.

<Detailed instructions

for grease application>

[Application area]

Heat resistant grease (GU-2) is

applied to the surface of the heat

roller between the fusing bearing

and the C ring groove.

4.Action: (Factory action)

From 1993 Mid November production.

C Ring

Fusing gear

Fusing bearing

Heat roller

Caution 1: Grease should not be

applied to the end of the

heat roller.

Caution 2: Grease should not ooze

from the inside of the fixing

bearing.

2/2

Loading...

Loading...