Page 1

Date: Apr. 8, 1994

COPIER : Z-20

No. : SP-1717

1. TROUBLE SHOOTING STACKING TROUBLE.

2. CHANGE IN BRACKET C

(FOR 200 V SERIES MACHINES ONLY).

1. Trouble shooting stacking trouble.

1.Model name: Z-20 / 23 / 25 / 27

2.General: The position of the pressure roller has been moved 1.2 mm towards the paper feeding

side as a trouble shooting measure to alleviate the problem of copy paper stacking in

the delivery section of the machine.

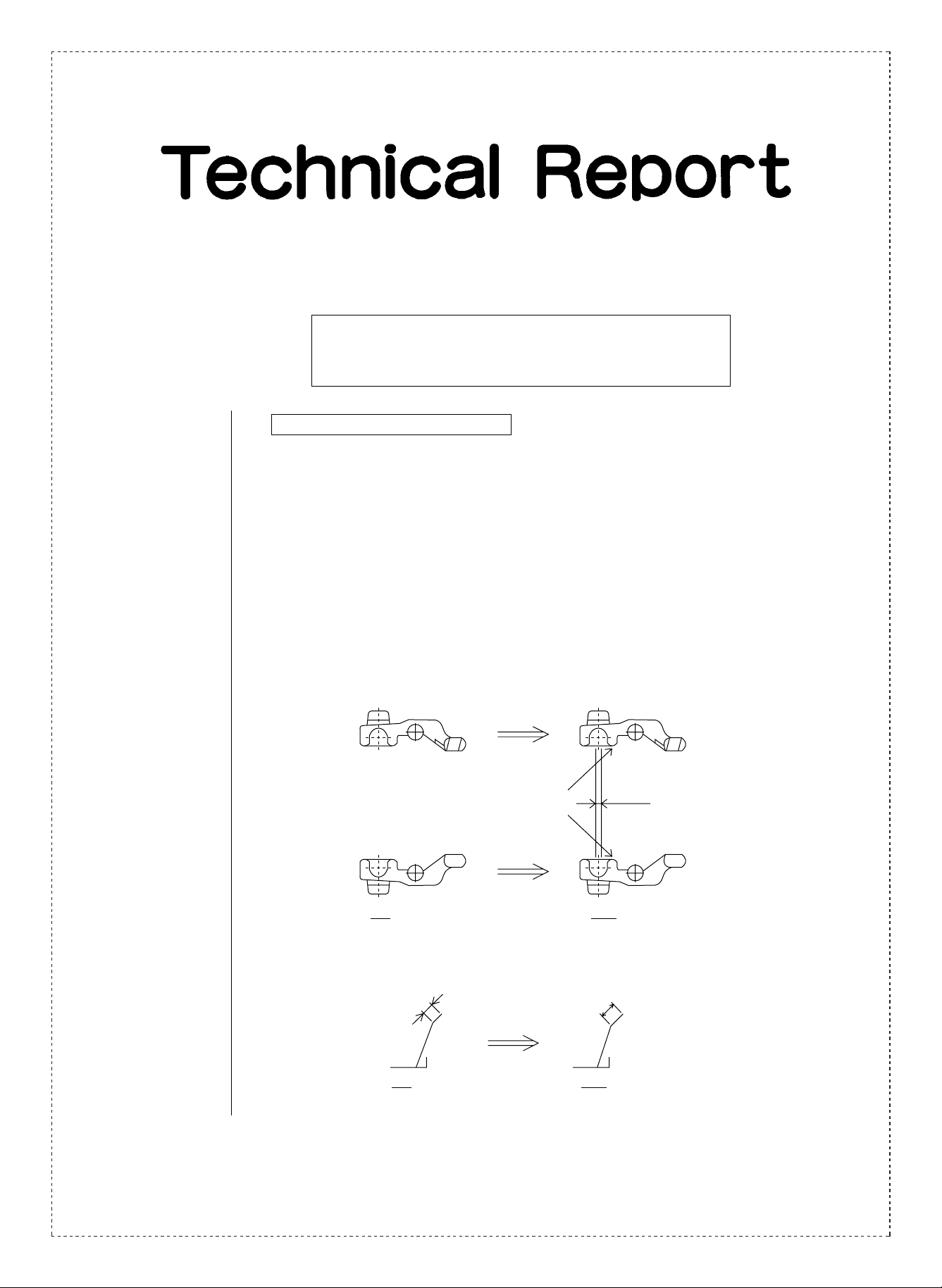

3.Description: The shapes of PF lever F, PF lever R, the fusing scraper, the fusing front paper guide

and the fusing actuator have been changed in accordance with the change in position

of the pressure roller.

Changed PF lever F, PF lever R.

PR LEVER F

PR LEVER R

Old New

R 0.5

1.2

R 0.5

Changed fusing scraper.

3

6

Old New

SHARP CORPORATION Reprography Division

1/4

Green

C

Page 2

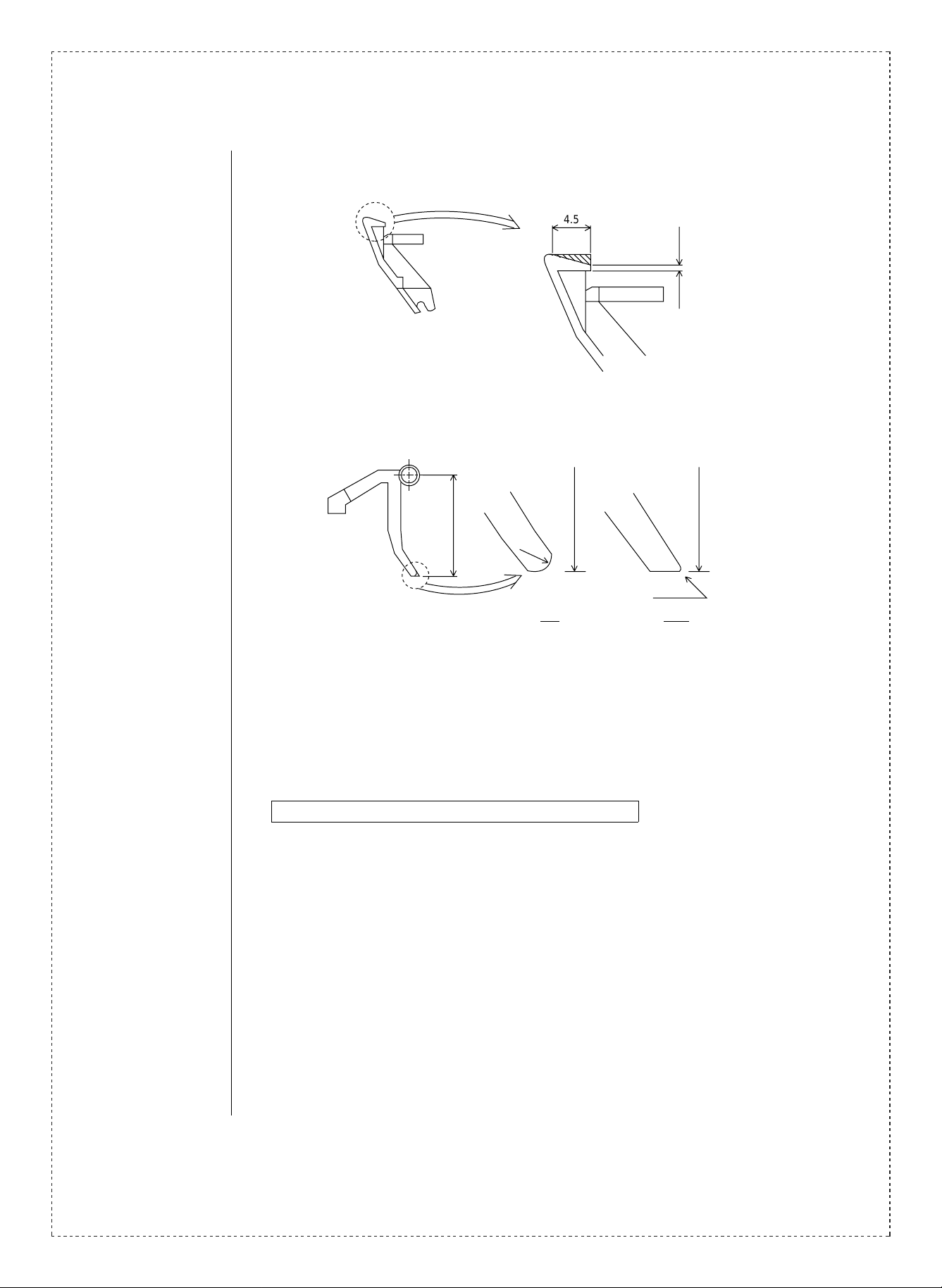

Changed fusing front paper guide.

Changed fusing actuator.

4.5

0

+0.2

A

R1

A = 33.5

Old New

Diagonal cut

R0.3

0

+0.2

A = 33.7

4.Action: (Factory action)

Z-20: From 1994 Mid January production.

Z-23 / 25: From the start of mass production.

2. Change in bracket C (For 200V series machines only).

1.Model name: Z-20 / 23 / 25

2.General: The C bracket unit has been changed in the 200V series machines bound for SEEG,

Great Britain, Australia and South Africa to alleviate the problem of electrical noise in

compliance with standards.

Note: The C bracket unit change has been carried out in the 200V series machines

bound for all OEM destinations.

3.Description: The noise reduction capacitor (0.47µF) forking from the CL harness in the C bracket

unit has been moved as close as possible to the AC cord and noise filter circuit in the

main power PWB as a trouble shooting measure to improve noise reduction efficiency.

2/4

Page 3

AC Cord side AC Cord side

ABAB

0.47µF

0.47µF

In accordance with the change described above the parts code of the C bracket unit

has been changed as shown below . The changed C bracket unit, however, is used only

in machines bound for SEEG, Great Britain, Australia and South Africa, as described

above. The old C bracket unit is still in use in the 200V series machines bound for all

other destinations.

Note: The C bracket change has been carried out in the 200 V series machines bound

for all OEM destinations.

(Changed C bracket)

4.Action: (Factory action)

From the start of mass production.

3/4

Page 4

Ref.

Model

No.

1

Z- 20

2

<Interchange>

1. Intercha ng ea bl e. 4. N ot i nt er ch an ge ab l e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

sp eci fi e d on es fo r m ai n ta in i ng t he s a fe ty an d pe rformance o f the s et .

name

23

25

Version P/G No.

5 -36

5 -38

5 -33

All

2-3

7 -32

SEEG,

U.K,

Australia,

South

Africa

3

!

Current parts New parts

Parts name

Parts code Parts code

MLEVP0642FCZZ MLEVP0642FCZ1 AE PF Lever F 1st lot.

MLEVP0643FCZZ MLEVP0643FCZ1 AE PF Lever R

LPLTM4500FCZZ LPLTM4500FCZ1 AB Fusing scraper

PGIDM1473FCZZ PGIDM1473FCZ1 AN

MLEVP0638FCZZ MLEVP0638FCZ1 AC Fusing actuator

CBRC-0056FC5A CBRC-0056FC5B AS C Bracket unit 1st lot. —

Price

rank

Fusing front

paper guide

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others.

Effec-

tive

time

Z-20:

Mid-

Jan.’94

Other:

1st lot.

change-

* The old C bracket unit is in use in all 200 V series machines bound for destinations

other than those listed at left.

Inter-

Note

ability

3

*

4/4

Loading...

Loading...