Page 1

Date: Dec. 8, 1993

COPIER : Z-72

PREVENTING DEFORMATION IN THE PRESSURE

ROLLER DUE TO A LONG PERIOD STORAGE

1.Model name: Z-50, 55, 70, 75, 72, 76, 77, SF-6100

2.General: To avert dent on the tension roller owing to a long storage, the tension roller protective

sheet is inserted between the upper heat roller and the tension roller. Notwithstanding,

as it is probable to cause a dent to appear on the tension roller if stored for a long time

under a hot and dampen location with the action taken, change is made to the

mechanism to avoid tension on the roller while it is being stored.

No. : SP-1673

3.Reason: To avert dent on the tension roller when stored for a long period.

4.Description: A cut is provided in the fuser frames F and R, respectively, to stretch the upper fuser

unit to the front when packed, which engages the upper fuser unit pressed part with the

cut to avoid the tension. When the machine is unpacked, the upper fuser unit is pushed

towards the rear side with a spring to added the tension to the fuser roller. With change,

the use of the tension roller protective sheet is discontinued, with change also made in

the unpacking instruction label and the description in the operation manual.

SHARP CORPORATION Reprography Division

1/5

Green

C

Page 2

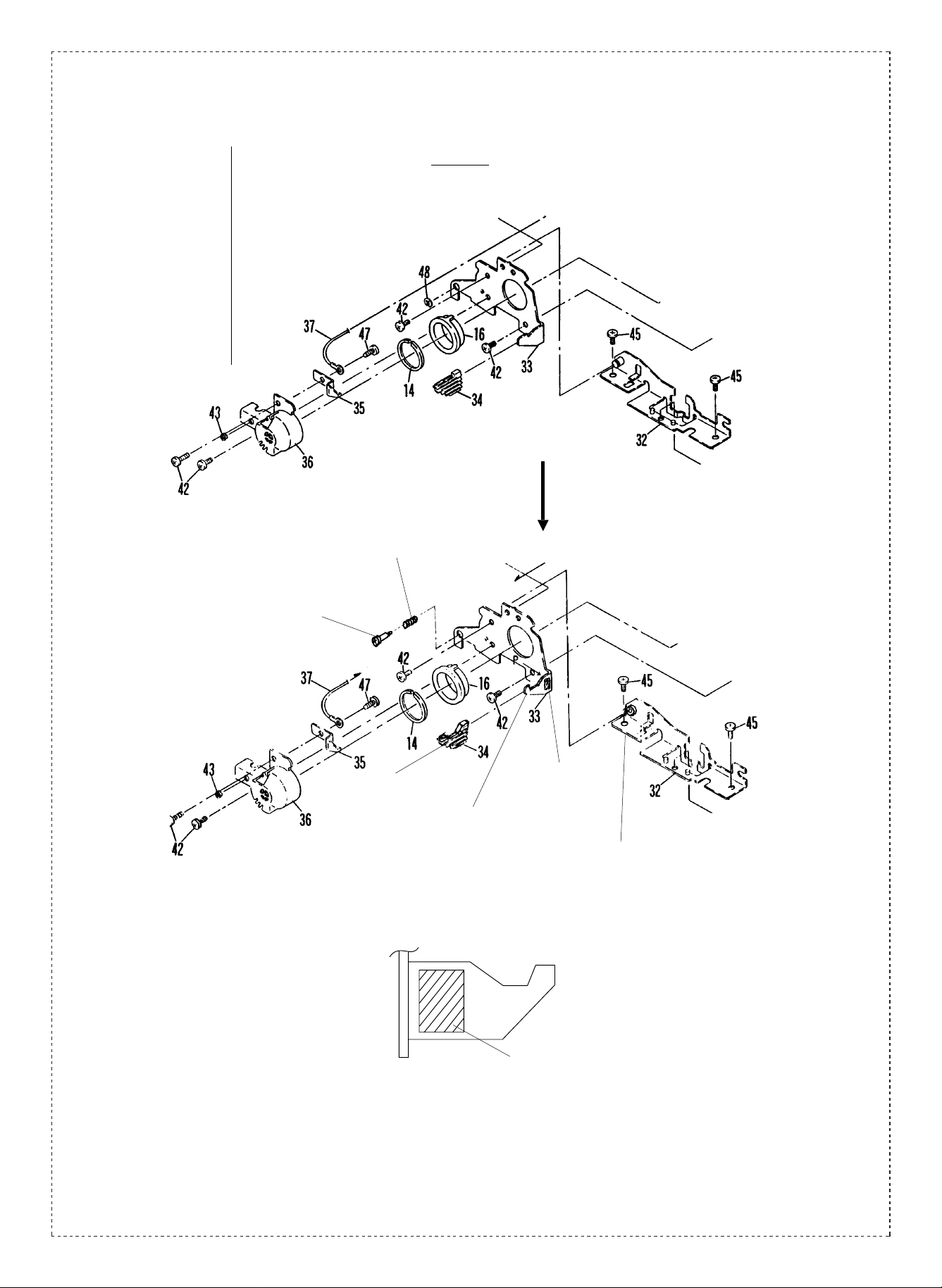

Changed in the fuser unit front side

Spring added

Changed to

Cup screw added

Arrow view P

On the opposite side where the fuser tape pasted, a 0.5 thick fuser tape B is pasted

Change in the fuser handle

(cut added)

Change in the fuser frame F

(cut and fuser tape added)

Fuser tape

pasted

Change in the fuser baseplate F

Stud (E-ring discontinued to use and

M4 tapping screw added)

2/5

Fuser tape B (0.5 thick) pasted

Page 3

Changed in the fuser unit rear side

Changed to

Fuser frame R (cut added)

3/5

Page 4

Change in the tension roller

Washer added

Changed to

Washer added

* To prevent crack to appear in the tension roller bearing caused by impact, a washer is

added on both sides of the tension roller, respectively, to hold the roller rigid. The

washer is inserted between the tension roller and the bushing.

5.Action: (Factory action)

From April 1993.

From May 1993 for the SMF production.

4/5

Page 5

Ref.

Model

No.

Z-50

SF-6100

<Int er change>

1. Interchangeable. 4. Not interchangeable.

2. Curre nt t y pe can be u sed i n p la c e of n ew t y pe .

New ty pe cann ot be us ed i n place of curr ent type .

3. Curre nt ty pe cann ot be us ed i n place of new ty pe.

New t y pe c a n be u sed in pla c e of c u rr en t ty p e.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

s p ec if ie d on es fo r maintaining the safe ty an d pe rfo r m an c e of t he s e t.

name

55

70

75

72

76

77

Version P/G No.

5 -17

5 -32

5 -33

5 -34

All

5 -48

5

5

5

— SPAKA3603FCZZ Discontinued —

!

Current parts New parts

Parts code Parts code

LFRM-0417FCZZ LFRM-0417FCZ1 AE

CDAIU0265FC01 CDAIU0265FC02 AG

LFRM-0416FCZZ LFRM-0416FCZ1 AE

JHNDP0071FCZZ JHNDP0071FCZ1 AB

XRESP50-06000 Discontinued —

— LX-WZ0313FCZZ

— MSPRC2157FCZZ AB

— LX-BZ0489FCZZ AB

5. Interchangeable if replaced with same types of

6. Others.

Price

rank

AA Washer

relate d parts in use .

Parts name

Fusing frame R

Fusing base

plate F

Fusing frame F

Fusing handle

E-ring (5E)

Spring

Sholder screw

Unpacking

instruction sheet

Effective

time

’93/4

Interchangeability

3

3

3

3

—

— Q’ty: 2

—

—

—

Note

5/5

Loading...

Loading...