Page 1

Date: Feb. 18, 1994

COPIER : Z-88

PARTS CHANGES

(Z - 88, 85, 70 SERI ES, 50 SERIES).

1.Model name: Z-88 / SF-2010 / Z-85 (II) / 70 series / 50 series

2.General: The following parts have been changed in the models lis ted above.

Item. Model. Change.

1. Z-85 Change in No. 6 mirror parts in the optical unit.

2. Z-85, 52 Addition of noise reduction sheet, wave washer and

packing mylar in the lower frame area.

3. Z-88, 85 Change in table cushion in the optical unit.

4. Z-88, 85 (II) Change in the OC mat.

5. Z-88, 85 (II) Change in copy lamp unit parts.

6. Z-88 / 85 Change in MSW holder in the upper frame area.

7. Z-85 (II) / 52 Change in lower frame F, R.

8. Z-85 / 52 (II) Change in the noise reduction sheet of paper guide C.

9. Z-88 / 85 (II) Change in the roller width of paper guide C.

10. Z-88 / 85 (II) Addition of insulation sheet to the AE sensor in the copy

lamp unit.

1 1. Z-88 Change in shape of the lower frame.

12. Z-85 (II) / 52 (II) Change in the pressure bearing socket of the fixing unit.

13. Z-88 / 85 (II) Change in the 26 T gear of the lower frame R area.

14. Z-80 series, 70 series,

50 series Change in HIC in the CLR cir c uit board.

15. Z-88 Addition of sheet in the manual paper feeding unit.

16. Z-88 Addition of 4th mirror s hield sheet in the optical unit.

17. Z-50 series, 70 series Change in installation position of the copy paper feeding

unit. (Fig. 9)

No. : SP-1671

SHARP CORPORATION Reprography Division

1/7

Green

C

Page 2

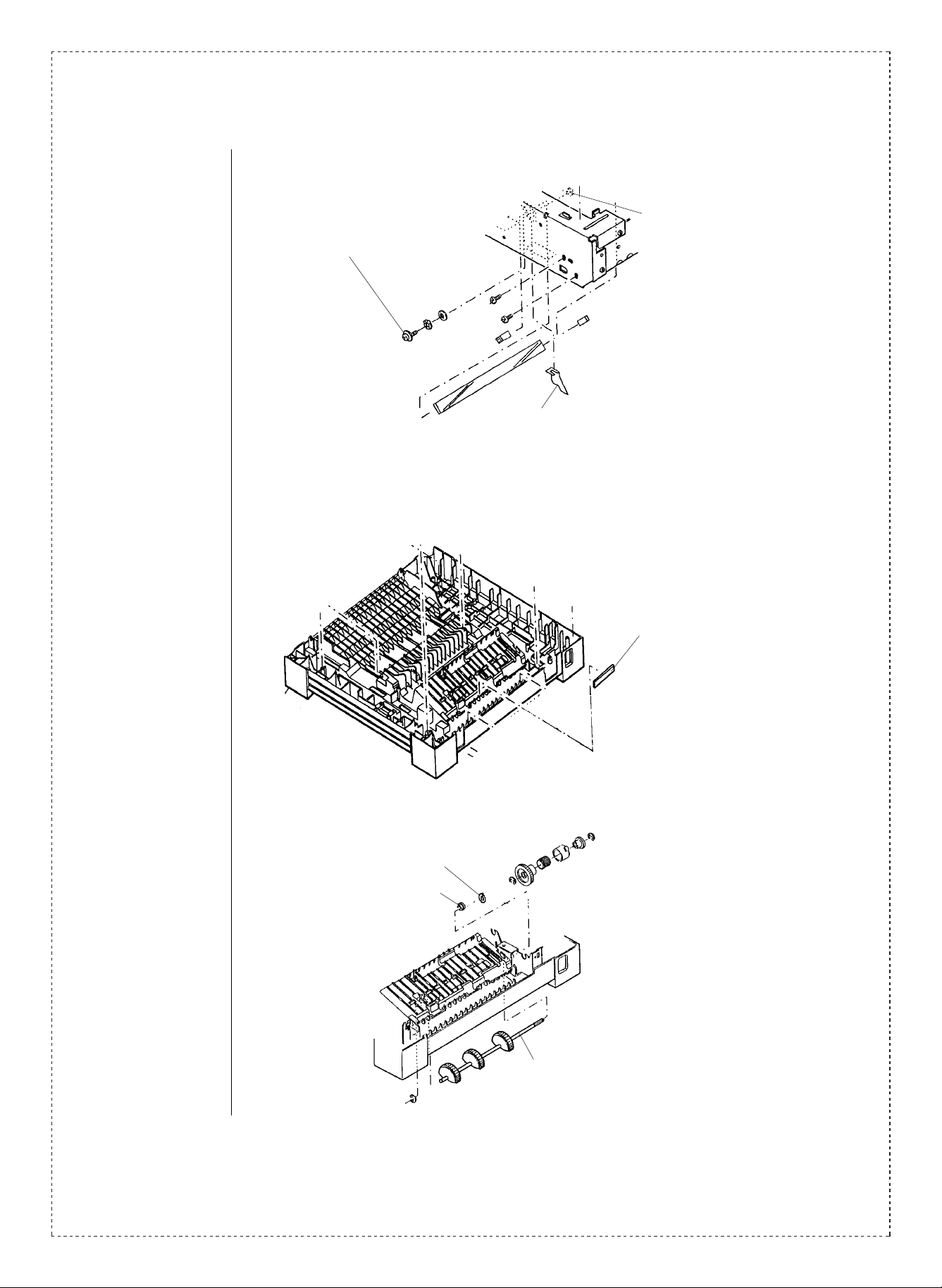

Item 1: Change in No. 6 mirror parts in the optic al unit (Z-85).

Changed nut.

Changed adjustment

screw for the no. 6 mirror.

Changed screw sheet for the no. 6 mirror.

Fig. 1

Item 2: Addition of noise reduction sheet, wave washer and packing mylar in t he lower

frame area.

Added wave washer.

Shaft holder.

Frame noise reduction sheet.

Fig. 2

Fig. 3

Copy paper feeder roller A.

5/7

Page 3

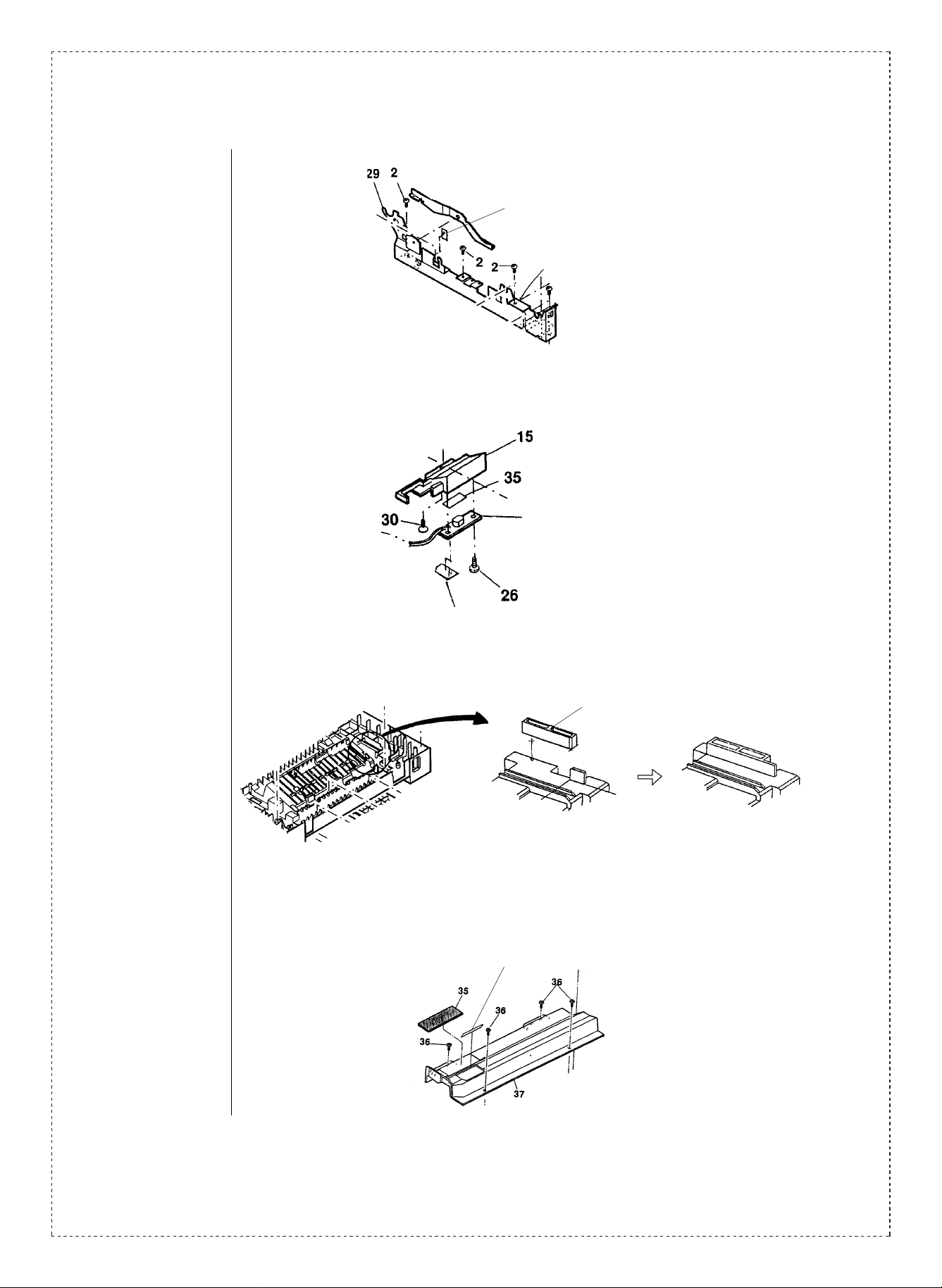

Added packing mylar.

Lower frame R.

Fig. 4

Item 10: Addition of insulation sheet to the AE sensor in the copy lamp unit.

AE sensor circuit board.

Added AE insulation sheet.

Fig. 5

Temporary: Plate block attached.

Old. New.

Fig. 6

Item 15: Addition of sheet in the manual paper feeding unit.

Added MF sheet B9. (PSHEP3283FCZZ)

(Z-88/SF-2010)

6/7

Fig. 7

Page 4

Item 16: Addition of 4th mirror shield sheet in the optical unit.

No.4 mirror shiel sheet.

(PSHEP3370FCZZ)

No.4 mirror

Fig. 8

Item 17: Change in installation position of the copy paper feeding unit.

The installation position of the copy paper feeding unit has been changed to

prevent jams from occurring when MS - 3 catches on the cut portion of the copy

paper feeding unit (From 1993 April production).

Models: Z-55, 75, 76, 72, 77, SF-6100

M4x10 (S tight)

(XHBSE40P10000)

Copy paper feeding UN

moved to the right side.

[Front side.]

Extended.

Copy paper

feeding UN.

Lower frame F.

(LFRM-0410FCZZ)

[Front side.]

Lower frame plate.

Fig. 9

Copy paper feeding UN.

[Right side.]

Lower frame R.

(LFRM-0415FCZZ)

[Manual feeding side]

The extension of the front side is aligned so that it is almost centered in the long hole of

the copy paper feeding UN. The copy paper feeding UN is attached by screws while

pressing it in place from behind.

7/7

Page 5

2/7

Ref.

Model name Subject P/G No. Version Current New

No.

1 Z-85

Change in No. 6 mirror parts

in the optical unit.

3

3 -55 LX-BZ0637FCZZ LX-BZ0691FCZZ AD

PSHEP3222FCZZ CSHEZ3322FC01 AD

3 -36 XNESF40-32000 XNGSF40-24000 AA Nut M4. E 1 ’92/11

Z-85

8

— PSHEZ3196FCZZ AB Frame noise reduction sheet. G —

Z-52/57

7

Addition of noise reduction

2

3

Z-85

Z-52/57

Z-85

Z-85

Z-88

SF-2010

sheet, wave washer and

packing mylar in the lower

frame area.

Change in table cushion in

the optical unit.

8

— LX-BZ0214FCZZ AC Wave washer. G —

7 ’92/9

8 — PSHEP3221FCZZ AC Packing mylar. A —

3 -58

All

PCUSG0190FCZZ PCUSG0190FCZ1 AB Table glass cushion. B 1

5 -58

3 -58 PCUSG0190FCZZ PCUSG0190FCZ1 AB Table glass cushion. B 1 X

Z-88

4

Z-85II

Change in the OC mat.

2-3

PSHEZ3087FCZZ PSHEZ3087FCZ1 AV OC mat. B 1 ’93/4 X

SF-2010

Z-88

3-5

LDAIU0444FCZZ LDAIU0444FCZ1 AD Lamp connection housing R. G 1

Z-85, 85II

4-5 ’93/1

Price

rank

Parts name Cause

No 6 mirror adjustment screw

sheet AS.

No. 6 mirror adjustment

screws.

Effec-

Inter-

tive

change-

time

ability

E 1 ’92/11

E 1 ’92/11

1st lot.

’92/9

1st lot.

1992

Mid-Sep.

Running

change

from

1993

July.

1st lot.

Discription

The addition of this sheet was reported in

Technical Report SP-1491.

The sheet has been changed.

To establish compatibility with model Z - 88

(SF-2010).

To establish compatibility with model Z - 88

(SF-2010).

Mylar has been added to prevent the pressure

fixing roller from slipping in the direction of the

slide.

Figure

availability

Fig. 1

Fig. 2

Fig. 3

Fig. 4

X

X

SF-2010 4 -5 LDAIU0444FCZZ LDAIU0444FCZ1 AD Lamp connection housing R. G 1 1st lot. X

5

Change in copy lamp unit

parts.

3 -10

Z-88

CDAIU0443FC01 LDAIU0443FCZ1 AK Lamp connection housing F G 1 1st lot. X

4 -10

6

SF-2010

Z-88

SF-2010

Z-85

Change in MSW holder in the

upper frame area.

4 -10 CDAIU0443FC01 LDAIU0443FCZ1 AK G 1 1st lot. X

6 -60

LHLDZ0758FCZZ LHLDZ0758FCZ1 AH MSW holder. G 1 1st lot. X

5 -21

Page 6

Ref.

Model name Subject P/G No. Version Current New

No.

6 OWL1, 2, 3

Z-85/85II

Z-52/57

(II include)

7

Z-85/85II

Change in MSW holder in the

upper frame area.

Change in lower frame F, R.

7 -60

8 -34

7 -34

8 -29

LHLDZ0758FCZZ LHLDZ0758FCZ1 AM MSW holder. G 1 1sr lot. X

CFRM-0719FC01 CFRM-0719FC02 AS Lower frame front assembly. E 1

CFRM-0721FC01 CFRM-0721FC02 AS Lower frame right assembly. E 1 X

Z-52/57(II)

7 -29

Price

rank

Parts name Cause

Inter-

change-

ability

Effective

time

Natural

conversion

from 1993

January.

Discription

Changed to the lower frame F, R used in

model Z-88.

Figure

availability

X

Z-85

8

Z-52(II)/57(II) 6 -68 ’92/12

Z-85/85II

9

Z-85/85II

Z-88

10

Z-85/85II

Change in the noise reduction

sheet of paper guide C.

Change in the roller width of

paper guide C.

Addition of insulation sheet to

the AE sensor in the copy

lamp unit.

SF-2010

7 -68

PCUSF0165FCZZ PSHEZ3224FCZZ AA

Paper guide C noise

reduction sheet.

B1

7 -71 NROLP0924FCZZ NROLP0924FCZ1 AC Roller.

B 5 ’93/9

7 -72 XWHSD40-08100 Discontinued —

3

All

— PSHEP3468FCZZ AE AE insulation sheet. A — ’93/6

Washer.

4

4 — PSHEP3468FCZZ AE AE insulation sheet. A — ’93/6

8 -50 LFRM-0718FCZ1 LFRM-0718FCZ3 BC Lower frame plate (gray). C 1

11

Z-88

SF-2010

Change in shape of the lower

frame.

8 -50 LFRM-0718FCK1 LFRM-0718FCK3 BC

Lower frame plate (calm

gray).

C1

8 -50 LFRM-0718FCN1 LFRM-0718FCN3 BC Lower frame plate (OA gray). C 1 ’93/5

Change in the pressure

12 Z-85(II)

bearing socket of the fixing

8 -30 NBRGP0260FCZZ NBRGP0260FCZ1 AD Pressure bearing socket. E 1

unit.

13

14

Z-88/85II

SF-2010

Z-52(II)

57(II)

Z-88

70 series

60 series

Change in the 26 T gear of

the lower frame R area.

Change in HIC in the CLR

circuit board.

7 -23 NGERH0383FCZZ NGERH0383FCZ1 AD Gear 26 T. A 1

7 -23 NGERH0383FCZZ NGERH0383FCZ1 AD Gear 26 T. A 1 X

13 -19 VHIMHIK-1//-1 VHIMHIK-1//-2 AX HIC A 3 ’93/9

Change in thickness of the noise reduction

’92/5

sheet (t 2 → t0.5). The following models have

also been changed: Z-50, 55, 70, 72, 75, 76,

77, SF-6100.

The washer has been eliminated in

accordance with the change in the width of

the roller (4 locations). (roller width: 10m →

11.8).

The sheet has been added to insulate the

dark box from the edge of the AE sensor

circuit board.

A block was attached to the lower frame plate

Mid-Jul.

of model Z-88 from the first production lot, but

1993.

it has been eliminated in the total

Mid-Jul.

manufacturing change. Consideration was

1993.

also given to metal pattern compatibility with

models Z-52 / 85, and the same changes

were carried out, but the parts codes have not

been changed.

To establish compatibility with model Z-88,

the following models have also been

changed: Z-52 (II) / 57 (II), Z-50 series, 70

series, SF-6100.

Running

A change has been made to a softer material,

change

to prevent other parts from being damaged

from 1993

when the roller locks. Refer to Technical

February.

Report SP-1532.

A diode has been added in the HIC to prevent

it from being damaged by static electricity,

etc.

X

X

X

Fig. 5

Fig. 6

X

X

X

3/7

Page 7

4/7

Ref.

Model name Subject P/G No. Version Current New

No.

Z-88

15

SF-2010

16 Z-88

Reason for cause

A : Quality improvement

B : Productivity improvement

C : Operability improvement

D : Convenience of parts procurement

E : Standardization

F : Serviceability improvement

G : Correction to parts guide

Addition of sheet in the

manual paper feeding unit.

Addition of No.4 mirror shield

sheet in the optical unit.

9

3

5 — PSHEP3370FCZZ AB No. 4 mirror shield sheet G — 1st lot. Fig. 8

All

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. Current type can be used in place of new type. New type cannot be used in place of current type. 5. Interchangeable if replaced with same types of related parts in use.

3. Current type cannot be used in place of new type. New type can be used in place of current type. 6. Others.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the safety and performance of the set.

— PSHEP3283FCZZ AB MF sheet B9 G — 1st lot. Fig. 7

!

Price

rank

Parts name Cause

Inter-

change-

ability

Effective

time

Discription

Figure

availability

Loading...

Loading...