Page 1

Date: Dec. 28, 1993

OPTION : SF-S51

No. : SP-1660

SF - S51

TROUBLE SHOOTING THE STAPLE DRIVE OF

THE STAPLE UNIT (BLANK SHOTS)

1.General: The opening in the faceplate for the staples is sometimes a little small, preventing the

staples from being driven properly when using staple modes (staple sort and manual

staple modes). By changing the shape of the feeder the staple driving force is

increased sufficiently so that the staples can be driven, even if the opening in the

faceplate should be a little small.

2.Cause: The opening for the staples is sometimes too small, due to manufacturing irregularities

in the parts of the staple unit face plate. This increases friction resistance, which

prevents the staples from being driven. (irregularities in the dimensions of the mold for

the faceplate occurred when it was renewed in March of 1993.)

Burrs (unpolished edges) sometimes remain on the staple openings of the faceplate

after manufacturing. The trouble mentioned above also occurs when the staples get

caught on these burrs.

* Dimension irregularities are the main cause of stapling trouble. Only a small

percentage of the stapling trouble is caused by burrs remaining on the staple opening

of the faceplates.

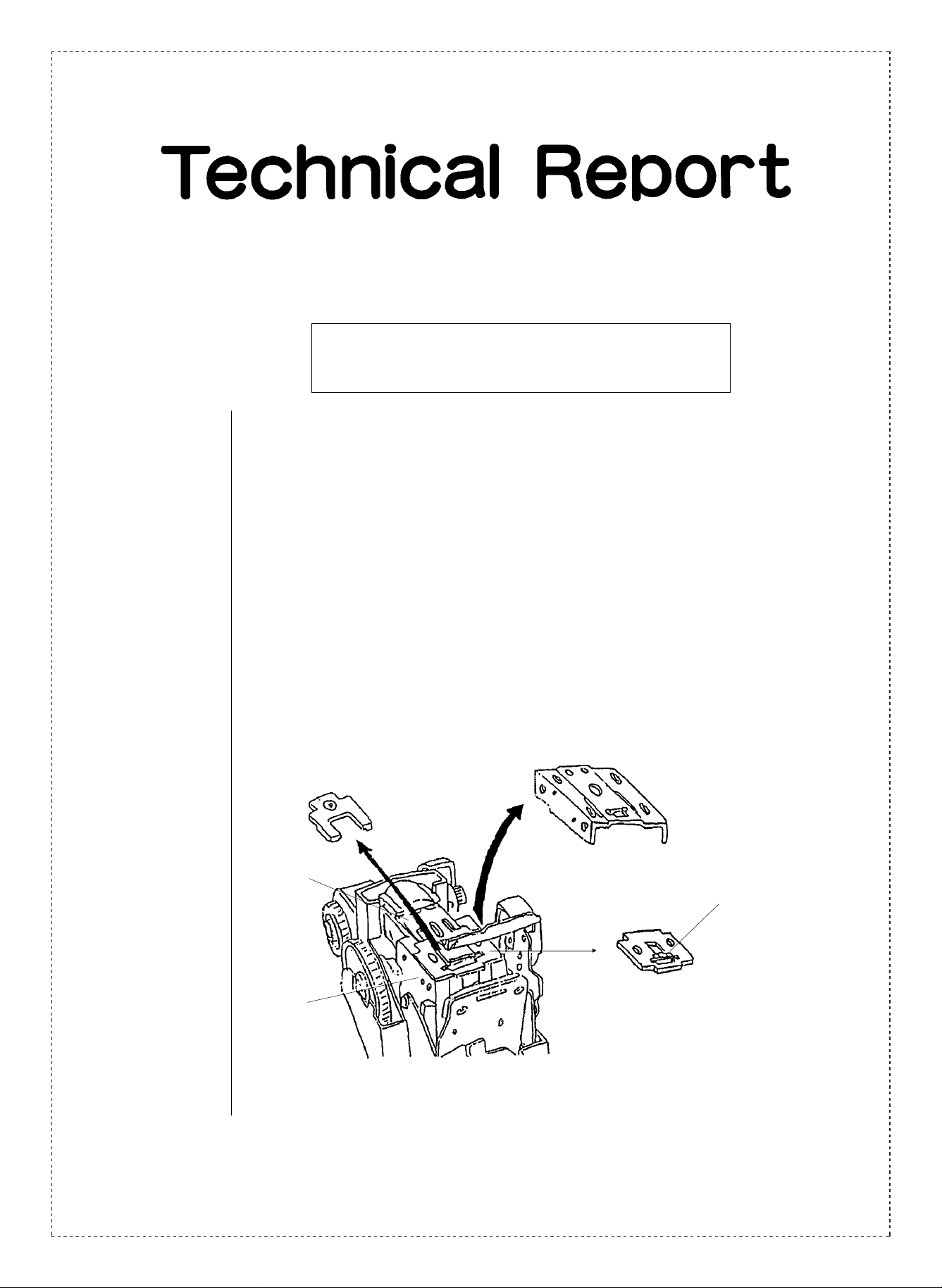

FRONT SHEATH

FORMER

DRIVER PLUNGER

FACE PLATE

Location of the staple opening

dimension irregularities.

BODY

SHARP CORPORATION Reprography Division

1/7

Green

C

Page 2

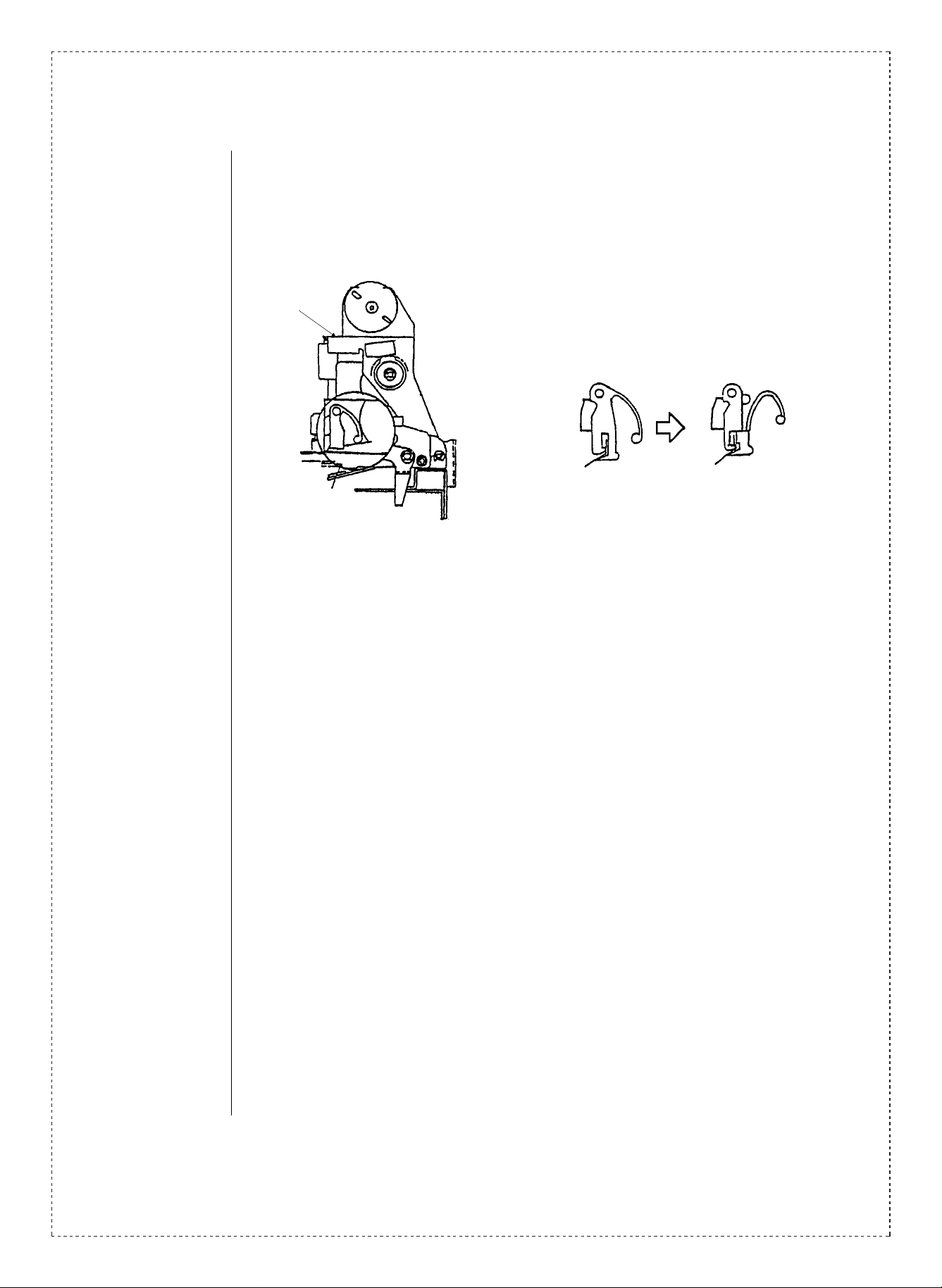

3.Description: ➀ The shape of the feeder spring has been changed. This has improved the driving

power applied to the staples, enabling them to be driven with no problem, even if the

dimensions of the staple opening in the faceplate is small.

➁ Burr removal and rechecks of the faceplate.

* φ0.5 blue seal.

(Old type.) (New type.)

* To distingusish which units have had

these changes carried out, a blue seal

has been affixed.

4.Action: (Factory action)

From 1993 October production.

(Field action)

When trouble occurs, the feeder, faceplate and M-spring should be replaced.

(Replacement parts).

• Feeder (new type).

• Faceplate (properly finished, with burrs removed).

• M-spring (The spring may become deformed when removed, and should therefore be

replaced.)

In regard to the supply of these replacement parts, please contact PQA, Reprographic

Division.

2/7

Page 3

of Countermeasure Parts for Staple Misfeeding Defect

replacemen t parts:

• FEEDER (a part to feed staple belt)

• FACE PLATE (a metal sheet attached to the body)

• M-SHAPED SPRING (a M-shaped wire spring)

Replacement Procedure

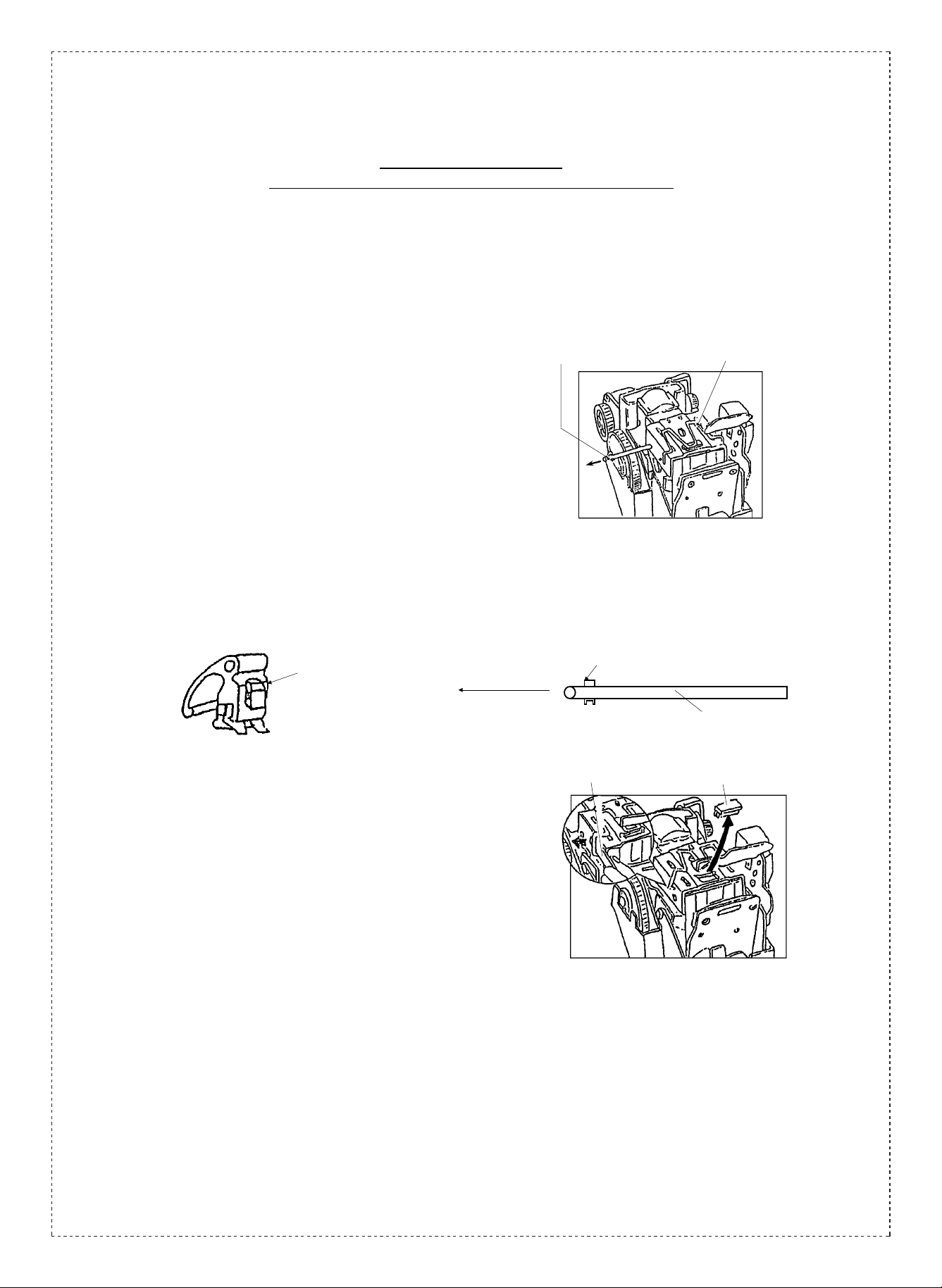

1. Disassemble of Stapler Unit

➀ Pull out BODY PIN toward the arrow mark direction in

Fig.1.

(If you try to pull it to revers e dir ection , it wi ll be s tuck

with ribs.)

• It mak es this operat io n easy to ta p the bot tom of

BODY PIN slight ly wit h any tool such as s crew

driver.

FEEDER is now rem ova ble from the st apler uni t.

FEEDER (current)

pulling direction

BODY PIN

M-SHAPED SPRING

Fig.1

rib

BODY PIN

➁ Remove M-SHAPED SPRING pulling both sides with

any tool such as flat s crew dri ver. (See Fi g.2.)

Also remove BENDING BLOCK at the same time.

•CAUTION!

Do not re-use this M-SHAPED SPRING since it might

be deformed for t his oper ati on.

flat screw driver

BENDING BLOCK

Fig.2

3/7

Page 4

➂ Remove CAR TRIDGE SPRING pu shin g both sid es

from behind th e unit. ( See Fig. 3.)

stapler unit

CARTRIDGE SPRING

CARTRIDGE SPRING

1

2

➃ Remove FRON T SHEAT H and FORMER from th e unit.

➄ Remove curre nt FACE PLATE under DR IVER

PLUNGER.

FRONT SHEATH

FORMER

DRIVER PLUNGER

Fig.3

FACE PLATE (current)

BODY

2.Assemble of Stapler Unit

➀ Put new FACE PLATE on bosses of BODY. (See

Fig.4.)

Make sure the embos sed s ide is up.

NOTE)

Deburring is appl ie d to the entranc e of st aple of new

FACE PLATEs.

4/7

FACE

PLATE

BODY

Fig.4

Page 5

➁ Put FORMER on DRIVER PLUNGER to be the side

having a boss do wn.(See F ig.5. )

side view of FORMER

boss

DRIVER PLUNGER

FORMER

BODY

FACE PLATE

down (back)

up (face)

➂ Put FRONT SHEATH.

➃ Push FRONT S HEATH and assembl e CART RIDGE

SPRING pushin g both s ides .

See figures bel ow as t o loca tion an d dire ction f or

assembly.

((insert direction))

Fig.5

FRONT SHEATH

Fig.6

front

CARTRIDGE SPRING

BODY

((location))

FRONT SHEATH

a hole for cartridge spring

a hole for body pin

a hole for M-shaped spring

5/7

Page 6

➄ Assemble new FEEDER into BODY with BODY PIN

after assembly of CART RIDG E SPRIN G. (It is

impossibl e to assemble FEEDE R before CARTRIDGE

SPRING.)

NOTE)

New FEEDERs have impr oved feed for ce with ne w

configurat ion giv en on it s spr ing. )

1) Put new FEEDER in BODY.

rib

Fig.7

insert direction of body pin

(Adjust the direction of ribs to a hole of body.)

2) Ins ert BODY P IN to hole s of BO DY through

FEEDER. (See Fig.7.)

• It m akes t his op eratio n easy to tu rn the s taple r unit

up side down and hol d FEED ER when insert ing

BODY PIN.

Do not hit BODY P IN hard dur ing i nsert ion, or the

edge of holes mig ht be def ormed.

➅ Assemble BENDING BLOCK and new M-SHAPED

SPRING.

1) Insert BENDING BLOCK into holes of F RONT

SHEATH.

2) Tap the corner of M-SHAPED SPRING with a plastic

hammer af ter insert ing its both sides into holes of

BASE.

BODY

new FEEDER

BODY PIN

a hole for cartridge spring

M-SHAPED SPRING

6/7

3) Insert M-SHAPED SPRING into h oles o f BO DY.

Fig.8

Page 7

Make sure not to ma ke any gap between the si de of

FRONT SHEATH and M-SHAPED SPRING.

Insert correctly

FRONT SHEATH

to make no gap.

• Pleas e use new M -SHAPED SPRING although it does

not have any modif ica tion si nce ol d one mig ht be

deformed for t his oper atio n.

example of deformation

Edge is deformed

(out of use)

Tap here!

BENDING BLOCK

BASE

a hole for M-shaped spring

Angle of corner is deformed.

(out of use)

- end of procedure -

7/7

Loading...

Loading...