Page 1

Date: Dec. 7, 1993

COPIER : SF-7850

1. REVOLVING CASSETE LOCK MALFUNCTION DUE TO

W-BASE PLATE LOCK SCRAPING.

2. ELIMINA TION OF IRREGULAR NOISE FROM THE DRUM UNIT.

No. : SP-1653

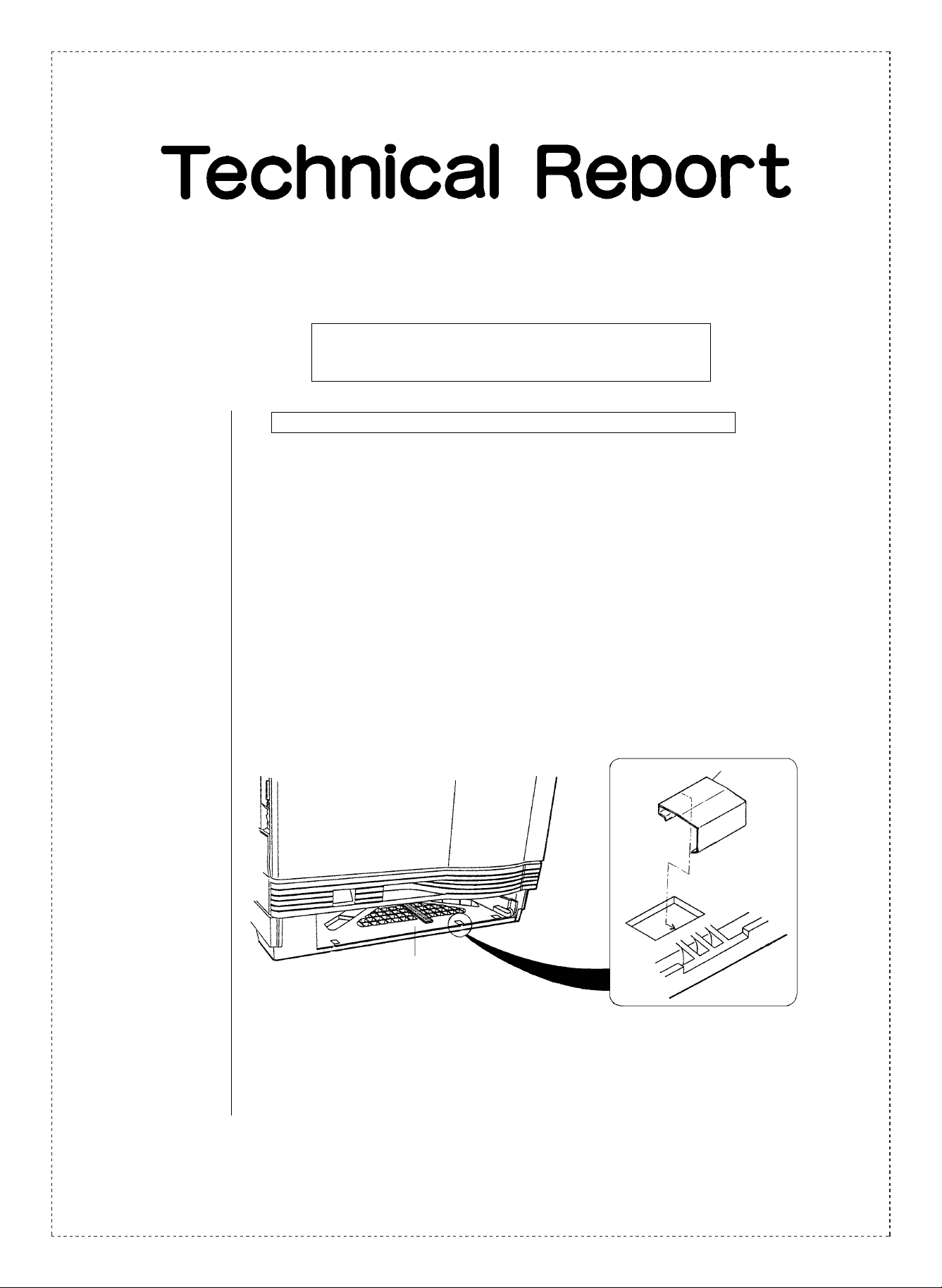

1. Revolving cassete lock malfunction due to w-base plate lock scraping.

1.Model name: SF-7850

2.General: As reported in T/R SP-1505, a holding claw reinforcement plate (CPLTM4403FC01)

had been added to the R-Base plate to alleviate the problem of wear on the holding

claws of the revolving drum lock. This reinforcement plate has caused scraping of the

W-base plate lock, causing the lock to malfunction and not work. A lock plate has

therefore been added to the W-base plate to alleviate the problem.

3.Reason: Revolving cassette lock malfunction due to scraping of the W-base plate lock.

4.Description: A lock plate has been added to the W-base plate cassette lock (right side only).

Added lock plate.

W-base plate.

SHARP CORPORATION Reprography Division

1/4

Green

C

Page 2

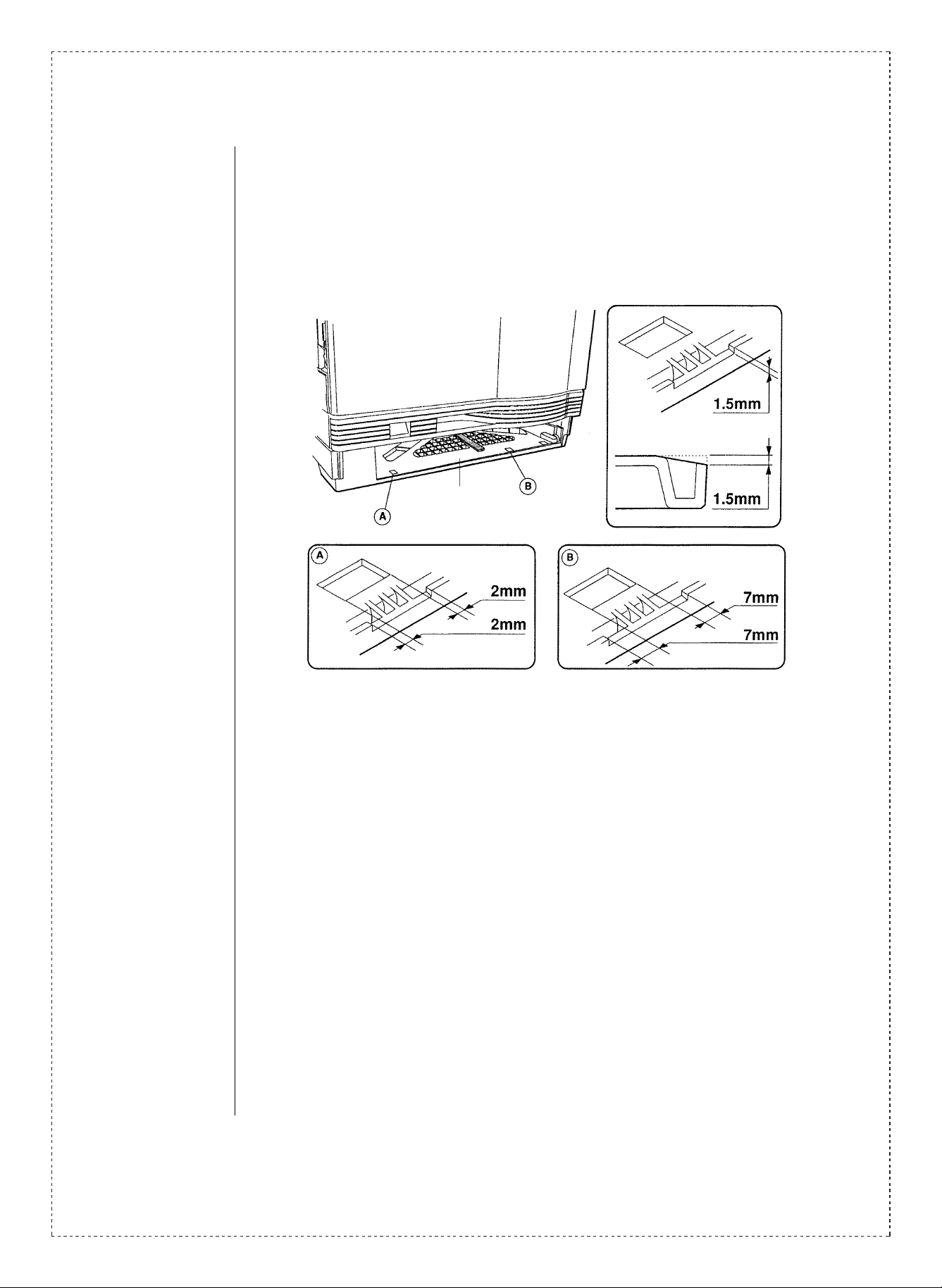

Note: 1. When adding the lock plate, check to make sure that the cassette lock of the

W-base plate has been scraped and worn away as shown below.If it is not worn

down, it should be ground down (T/R SP-1507). Refer to diagram below.

2. It is necessary to remove the revolving cassette when installing the lock plate.

W-base plate.

★ The SF-7850 was located in the direction that the revolving cassette was pushed out

by the RM drive unit, but the holding claws of the cassette were scraped and lock

malfunctions occurred. In the case of the new SF-7855 / 7830, the cassette is pushed

out by only two springs that are located behind the cassette. Even if the claws are

scraped and worn down, it will not affect the power used to push out the cassette

enough to cause a lock malfunction. Therefore, the lock plate and reinforcement plate

have not been added to the SF-7855 / 7830 models.

5.Action (Factory action)

From 1993 November production.

2/4

Page 3

2. Elimination of irregular noise from the drum unit. (Overseas only)

1.Model name: SF-7800 / 7850 / 7855 / 7830

2.General: Irregular noise has occurred between the drum and the drum cleaning blade, caused

primarily by environmental factors such as high temperatures and high humidity. To

remedy this problem, the drum cleaning blade has been changed.

3.Reason: The blade has been hardening and changing due to environmental factors (high

temperature and high humidity), causing it to jump during drum revolution, and causing

irregular noise.

4.Description: In order to prevent the irregular noise from occurring, the material composing the blade

has been changed to a more suitable substance which is resistant to environmental

stress caused by high temperature and high humidity. In accordance with this change,

the color of the blade lot number has been changed from blue to black.

Drum unit.

5.Action: (Factory action)

From 1993 November production.

Changed blade.

UCLEZ0108FCZZ

UCLEZ0108FCZ1

3/4

Page 4

Ref.

No.

Model

name

Version P/G No.

Current parts New parts

Parts code Parts code

Price

rank

Parts name

Effec-

tive

time

Inter-

change-

ability

Note

1 SF-7850

SF-7800

7850

2

7870

7855

7830

<Interchange>

1. In te rc ha ng ea bl e. 4. Not i nt er ch an ge ab l e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

speci fi e d on es fo r m ain ta in i ng t he s a fe ty an d pe rf o rma nc e o f th e s et .

10

All

6-1

!

— LPLTM4592FCZZ AE Lock plate. ’93/11 —

UCLEZ0108FCZZ UCLEZ0108FCZ1 AV Cleaning blade. ’93/11 3

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Ot he rs .

4/4

Loading...

Loading...