Page 1

Date: Oct. 27, 1993

COPIER : Z-88

1. PREVENTION OF COPY LAMP DISLOCATION DURING TRANSPORT

2. PREVENTION OF 4/5 MIRROR ADJUSTMENT PLATE CONTACT

3. TROUBLE SHOOTING L5 ERRORS THAT OCCUR WHEN MAKING

REDUCED-SIZE COPIES (70%)

1. Prevention of copy lamp dislocation during transport

1.Model name: Z-88 / SF-2010 / Z-85 / Z-85II

2.General: A support plate has been added to lamp contact plate F in order to prevent dislocation

of the copy lamp caused by shock during transport.

No. : SP-1645

3.Cause: Copy lamps are often dislocated due to shocks caused by severe drops during

transport.

* Since models Z-88 are wire-driven, they are especially susceptible to the

above-mentioned trouble.

4.Description: A support plate will be installed next to the lamp spring as shown in the diagram below.

New support plate installed next to the lamp spring. (LPLTM4534FCZZ).

5.Effective time: (Production)

Z-85/85II ................................September, 1993.

Z-88/SF-2010 (100V units)..... December, 1993.

Z-88/SF-2010 (200V units) ..... January, 1994. (including SMF).

SHARP CORPORATION Reprography Division

1/3

Green

C

Page 2

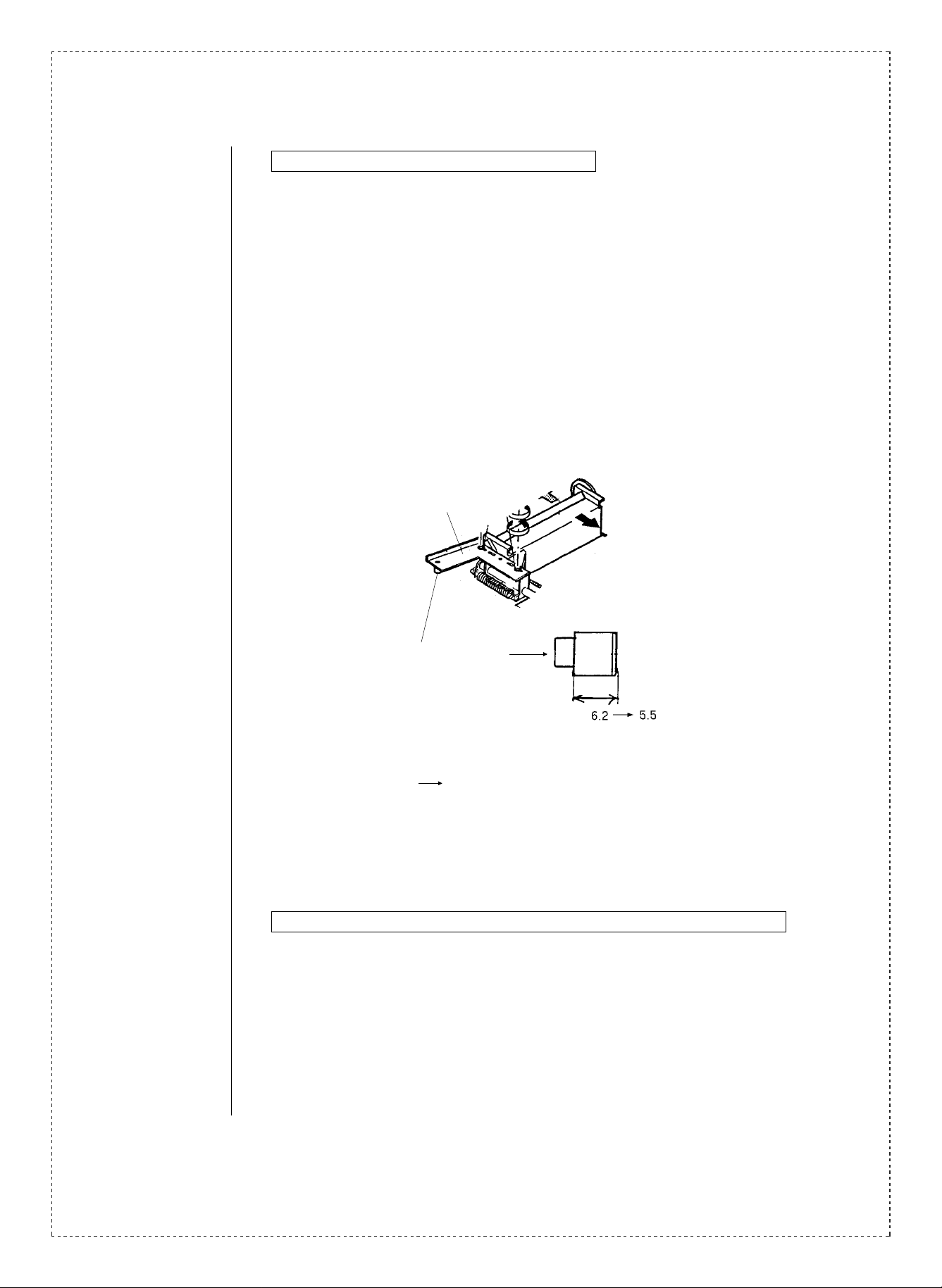

2. Prvention of 4/5 mirror adjustment plate contact

1.Model name: Z-88 / SF-2010

2.General: The tip of the boss extending from the 4/5 mirror adjustment comes into contact with

the magnifying cam when making enlarged copies. T o prevent this, the boss will be

shortened. (Though models Z-85/85II also use a 4/5 mirror, the position of the

magnifying cam is 1 mm lower than that on the Z-88 series, so the above problem does

not occur. For this reason, the Z-85/85II series will not be changed.)

3.Cause: Prevention of contact between the adjustment plate boss and the magnifying cam.

4.Description: The length of the adjustment plate boss of the 4/5 mirror has been changed from 6.2

mm to 5.5 mm.

4/5 mirror adjustment plate.

Change in boss length.

The parts code for the changed 4/5 mirror adjustment plate has been changed as

follows:

CPLT M4006FC01 CPLTM4006FC02

5.Effective time: (Production):

December, 1993 (including SMF).

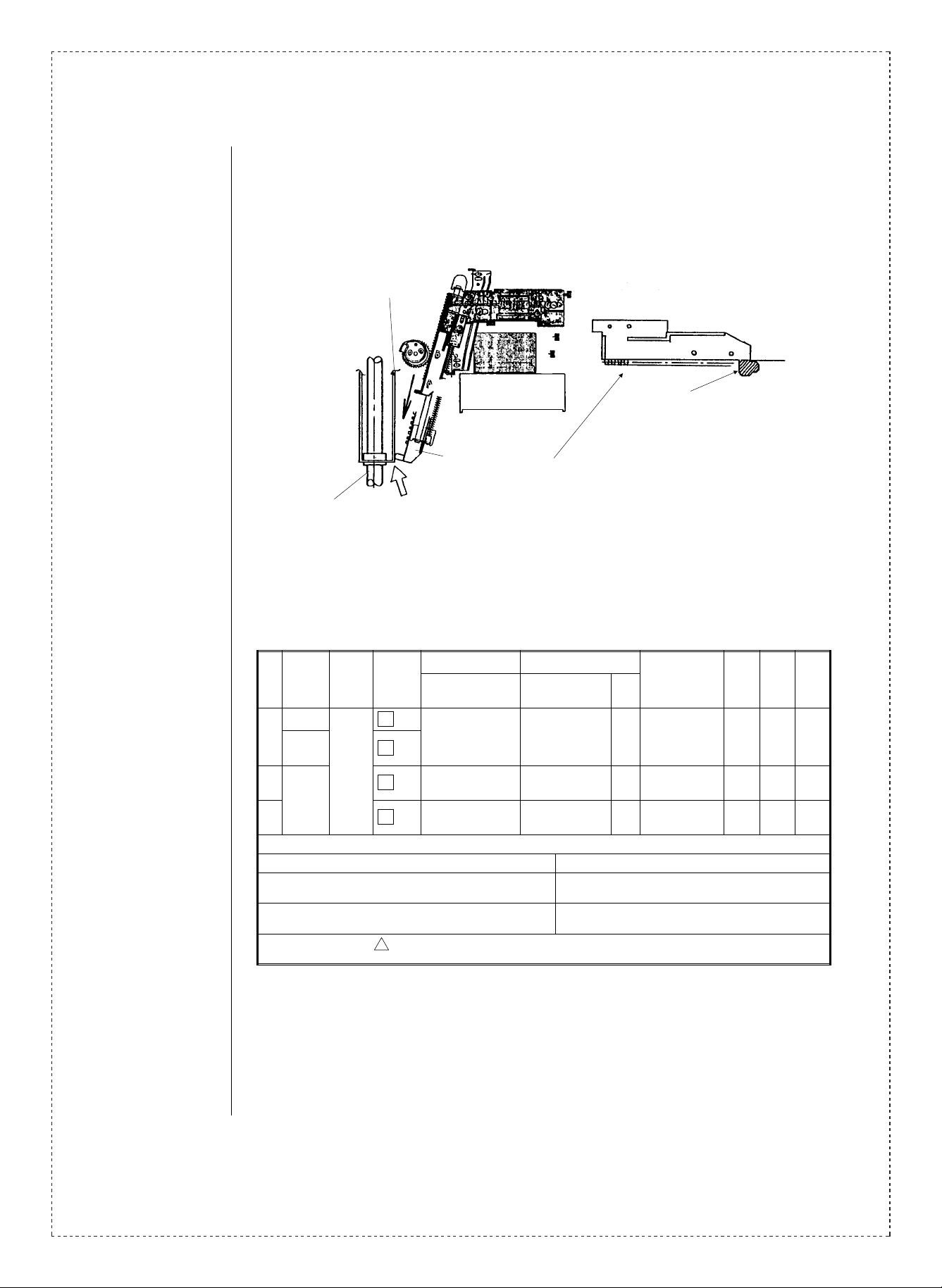

3. Tr ouble shooting L5 errors that occur when making reduced-size copies (70%)

1.Model name: Z-88 /SF-2010

2.General: When the lens magnification is set at 70%, the lens shaft holder comes into contact with

the side panel of the 2/3 mirror, and an L5 error (lens motor lock) sometimes occurs

when the lens is unable to return from 70% to 100%. To alleviate this problem, the

shape of the lens shaft holder has been changed.

2/3

Page 3

3.Cause: Preventing L5 errors that occur when making reduced-size copies (70%).

4.Description: The portion of the lens shaft holder which comes in contact with the side panel of the

2/3 mirror will be cut off as shown below.

Side panel of the 2/3 mirror.

Lens shaft holder.

Portion of the lens shaft

holder to be cut off.

Lens shaft holder.

MB Shaft.

5.Effective time: (Production):

June, 1993 (including SMF).

Ref.

Model

No.

Z-85/850

1

Z-88

SF-2010

2

Z-88

SF-2010

3

<Inter change>

1. Interchangeable. 4. Not interchangeable.

2. Cur re nt type can be u s ed i n p lac e of n ew type .

New ty pe cann ot be us ed i n place of curr ent type .

3. Cur rent type cann ot be us ed in pl ace of new typ e.

New t y pe c a n be u sed in p lac e of c u r ren t ty p e.

Parts m ar ke d wi t h “ ” is imp or t an t fo r m a in ta ini ng t he s a fe ty of the set. B e s u re to r e plac e t he s e pa rts wi t h

specified ones for maintaining the safety and performance of the set.

name

Version P/G No.

Portion of the lens shaft holder

which comes in contact with the

side panel of the 2/3 mirror.

Current parts New parts

Parts code Parts code

4

3

All

5 -27

5 -50

!

— LPLTM4534FCZZ AA

CPLTM4006FC01 CPLTM4006FC02 AH

LHLDZ1075FCZ1 LHLDZ1075FCZ2 AQ

Price

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Ot he r s.

Parts name

rank

Lamp spring

support plate

4/5 mirror

adjustment plate

Lens shaft

holder Z-88

Effec-

Inter-

tive

change-

time

ability

See

text.

’93/12 3

’93/6 3

Note

—

3/3

Loading...

Loading...