Page 1

Date: Oct. 27, 1993

COPIER : SF-2035

No. : SP-1637

[ Parts change information ]

1. 500 CASSETTE PAPER FEEDER UNITS CHANGE TO

IMPROVE PRODUCTIVITY.

2. PREVENTION OF INSPECTION AND MAINTENANCE

LABEL PEELING.

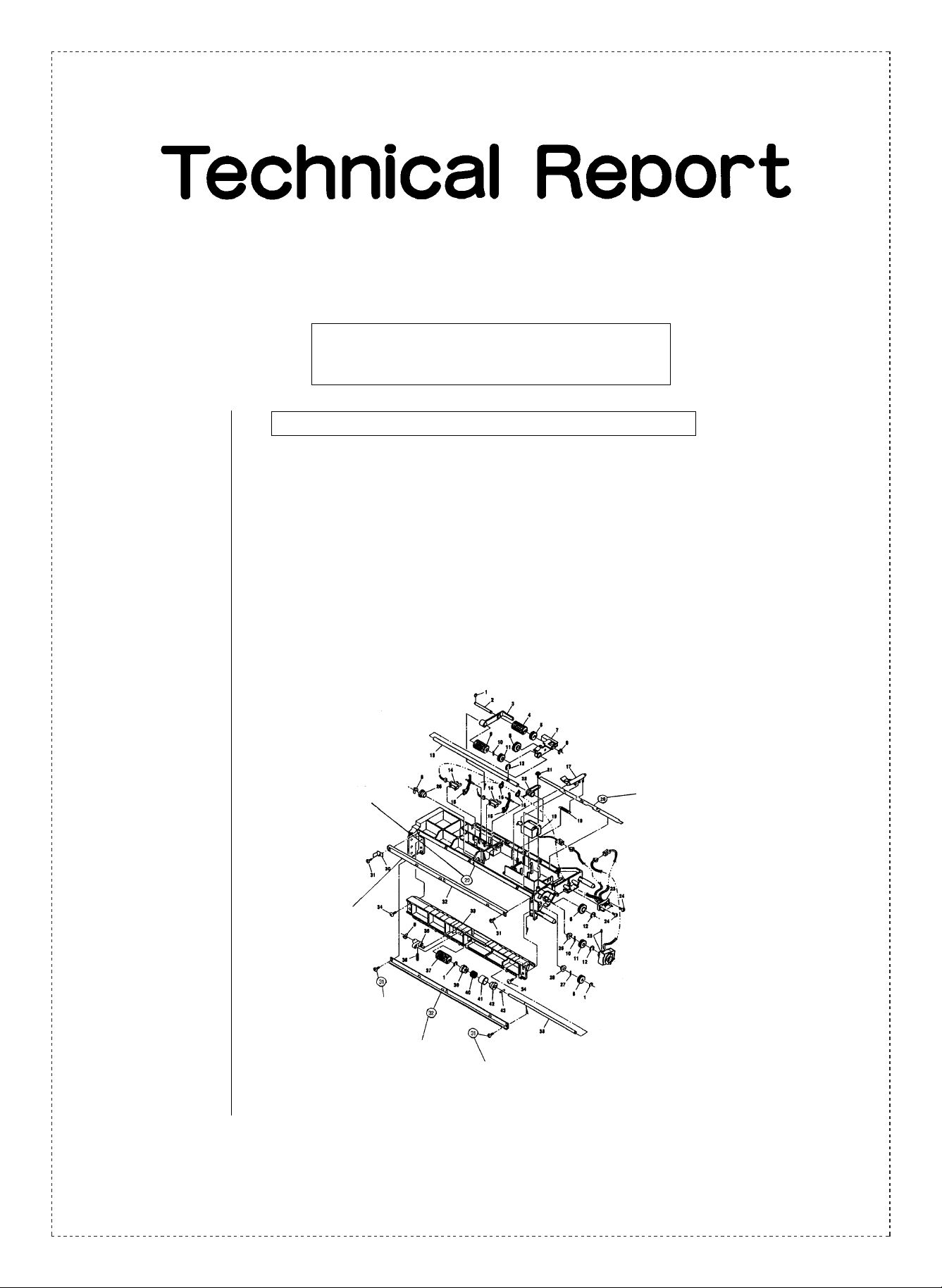

1. 500 cassette paper feeder units change to improve productivity.

1.Model name: SF-2035 / 2027 / 2022 / 2018

2.General: The internal parts of the 500 cassette paper feeder units have been changed for the

reasons described below.

3.Cause: To improve productivity.

4.Description: 1. Main bracket change.

2. Cable cover elimination.

3. Change in number of reinforcement plates.

Main bracket change. Eliminated cable cover.

Upper reinforcement

plate inserted.

Eliminated.

Eliminated reinforcement plate.

Eliminated.

SHARP CORPORATION Reprography Division

1/4

Green

C

Page 2

5.Effective time: (Factory action)

Ranning change from August, 1993.

USA, CANADA : From ’93/8 production.

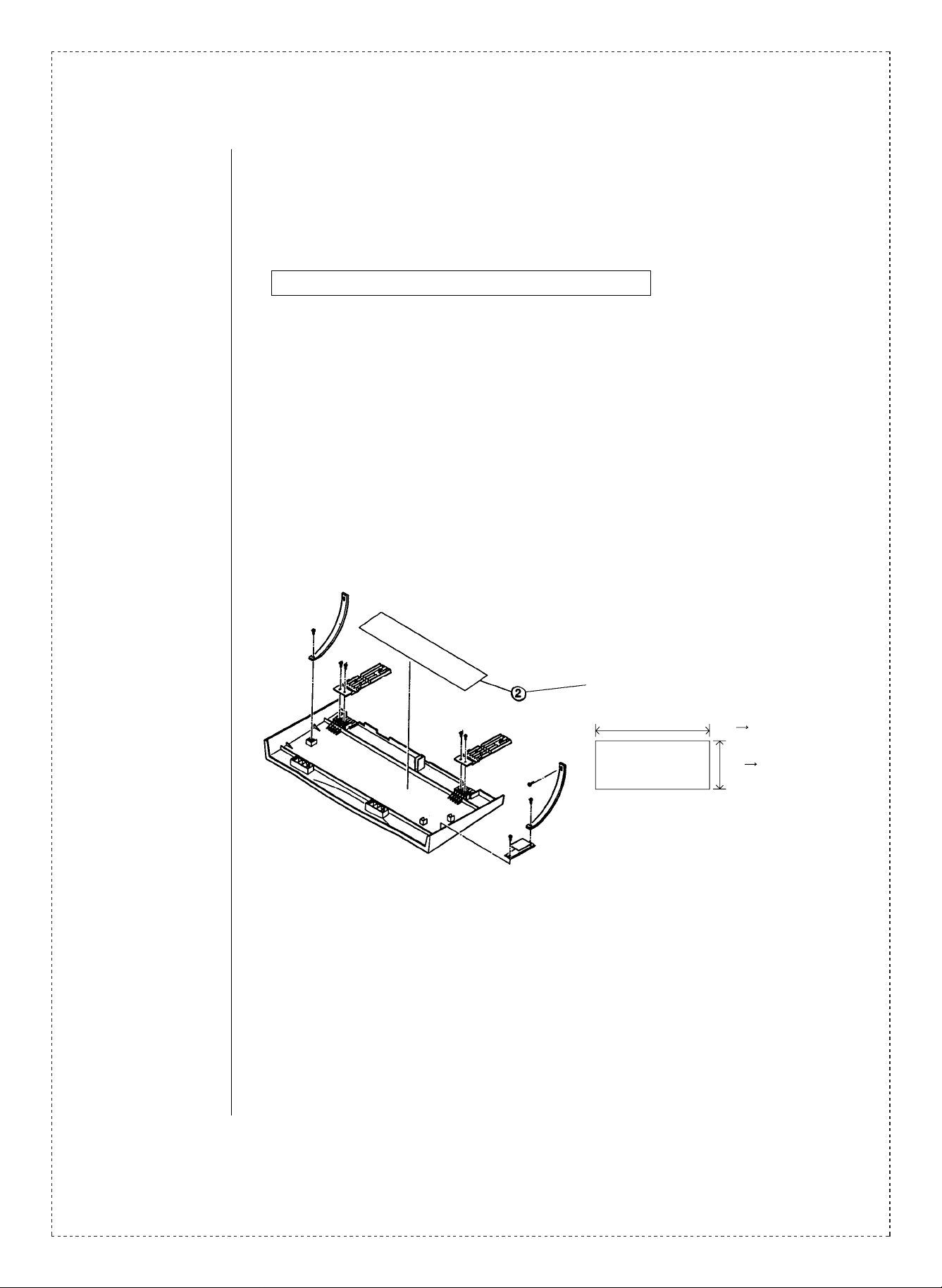

2. Prevention of inspection and maintenance label peeling.

1.Model name: SF-2022 / 2027 / 2018

2.General: The inspection and maintenance label pasted on the inside of the front cabinet of the

machine was positioned partially in the ejector pin contact area of the front cabinet.

The rubbing of the ejector pin was causing the label to peel in that area, and the label

size was changed to prevent the problem from continuing.

3.Cause: To prevent peeling of the inspection and maintenance label.

4.Description: The dimensions of the inspection and maintenance labels were decreased so that the

ejector pin does not come in contact with them. (The content of the labels has remained

the same as before.)

Inspection and maintenance

label change.

400 394

140 120

The front cabinet assy parts code has been changed in accordance with the change in

the inspection and maintenance label size.

2/4

Page 3

* USA

• Inspection and maintenance labels ( Common to SF-2022 / 2027)

TLABH3084FCZZ → TLABH3477FCZZ

• Front cabinet assy (for SF-2022) CCAB-0751FC03 → CCAB-0751FC20

• Front cabinet assy (for SF-2027) CCAB-0751FC07 → CCAB-0751FC25

* England / Australia

• Inspection and maintenance labels ( Common to SF-2022 / 2027)

TLABH3084FCZZ → TLABH3477FCZZ

• Front cabinet assy (for SF-2022) CCAB-0751FC04 → CCAB-0751FC21

• Front cabinet assy (for SF-2027) CCAB-0751FC08 → CCAB-0751FC26

* SEEG / Canada / Other (4 languages)

• Inspection and maintenance labels ( Common to SF-2022 / 2027)

TLABH3085FCZZ → TLABH3478FCZZ

• Front cabinet assy (for SF-2022) CCAB-0751FC05 → CCAB-0751FC22

• Front cabinet assy (for SF-2027) CCAB-0751FC09 → CCAB-0751FC27

* Indonesia

• Inspection and maintenance labels ( Common to SF-2022 / 2027)

TLABH3085FCZZ → TLABH3478FCZZ

• Front cabinet assy (for SF-2022) CCAB-0751FC06 → CCAB-0751FC23

• Front cabinet assy (for SF-2027) CCAB-0751FC10 → CCAB-0751FC28

5.Effective time: (Factory action)

From August, 1993.

3/4

Page 4

Ref.

No.

Model

name

Version P/G No.

Current parts New parts

Parts code Parts code

Price

rank

Parts name

Effec-

tive

time

Inter-

change-

ability

Note

26 -29

SF-2035

2027

1

SF-2022

SF-2022 USA

SF-2027 USA

2

SF-2022

SF-2027

SF-2022

SF-2027

SF-2022

SF-2027

<Inter ch ange>

1. Interchangeable. 4. Not interchangeable.

2. C urr e nt t y pe c a n be u s ed i n p la ce of new t ype.

3. C urre nt ty pe cann ot be used i n place of new ty pe.

Parts m ar ke d wi t h “ ” is i mp ort an t fo r m a inta i ni ng t he sa fe ty of t he s e t. B e su r e to re pl ace these pa r ts wi t h

specified ones for maintaining the safety and performance of the set.

All

2022

2018

USA

UK

Austraria

2027

Other

UK

Australia

UK

Australia

SEEG

Canada

Other

Indonesia

Indonesia

New ty pe cann ot be us ed i n place of curr ent type .

New t y pe c a n be u sed in p la c e of c u rr en t ty p e.

26 -20 PCOVP1154FCZ1 Discontinued — Cable cover —

26 -32 LPLTM4057FCZZ Quantity change AF

26 -31 XEBSD30P08000 Quantity change AA

1-2

1-2

1-1

1-1

1-1

1-1

1-1

1-1

1-1

1-1

!

CBRC-0048FC01 CBRC-0048FC02 AU Main bracket

Reinforcement

plate

Screw

(M3x8P tight)

TLABH3084FCZZ TLABH3477FCZZ AG

TLABH3085FCZZ TLABH3478FCZZ AG

CCAB-0751FC03 CCAB-0751FC20 BE

CCAB-0751FC07 CCAB-0751FC25 BE

CCAB-0751FC04 CCAB-0751FC21 BE

CCAB-0751FC08 CCAB-0751FC26 BE

CCAB-0751FC05 CCAB-0751FC22 BE

CCAB-0751FC09 CCAB-0751FC27 BE

CCAB-0751FC06 CCAB-0751FC23 BE

CCAB-0751FC10 CCAB-0751F28 BE

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others .

Inspection and

maintenance

labels

Inspection and

maintenance

labels

Front cabinet

assy

Front cabinet

assy

Front cabinet

assy

Front cabinet

assy

Front cabinet

assy

Front cabinet

assy

Front cabinet

assy

Front cabinet

assy

See

text.

’93/8 1

’93/8 1

’93/8 1

’93/8 1

’93/8 1

’93/8 1

’93/8 1

’93/8 1

’93/8 1

’93/8 1

1

Q’ty;

—

2 to 1

Q’ty:

—

4 to 2

4/4

Loading...

Loading...