Page 1

Date: Oct. 14, 1993

COPIER : SF-2035

1.CHANGES IN MATERI ALS TO IMPROVE THE TAKE- UP

DRIVING SHAFT DURING RETURN

2.CHANGES TO THE MANUAL P APER FEED SECTI ON

TO IMPROVE PRODUCTIVITY

No. : SP-1632

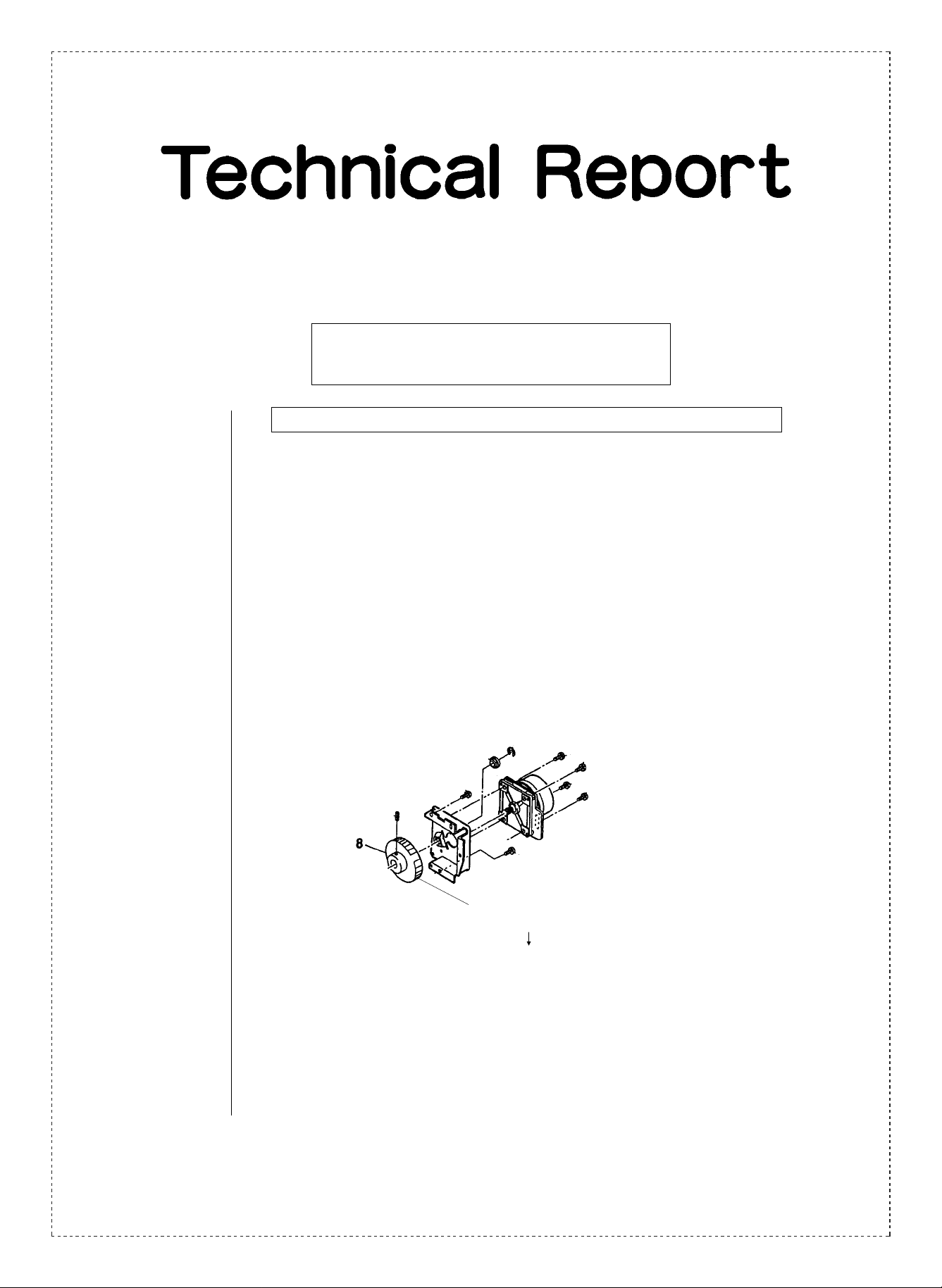

1.Changes in materials to improve the take-up driving shaft during return function

1.Model name: SF-2035

2.General: During mirror-based return, the home position sensor malfunctioned. This caused the

gear cogs in the take-up driving shaft to break under shock leading to unwanted

movements.

A material change was made to strengthen the take-up driving shaft gear and to

prevent further damages.

3.Reason: Strengthening of the materials used for the take-up driving shaft gear to prevent gear

damages.

4.Description: Materials used for the gear will be changed from polyphane to 12 nylon.

Material change for take-up driving shaft gear

NGERH0944FCZZ (polyphane)

NGERH0944FCZ1 (12 nylon)

5.Action: For production : Normal replacement as of mid-September 1993.

SHARP CORPORATION Reprography Division

1/2

Green

C

Page 2

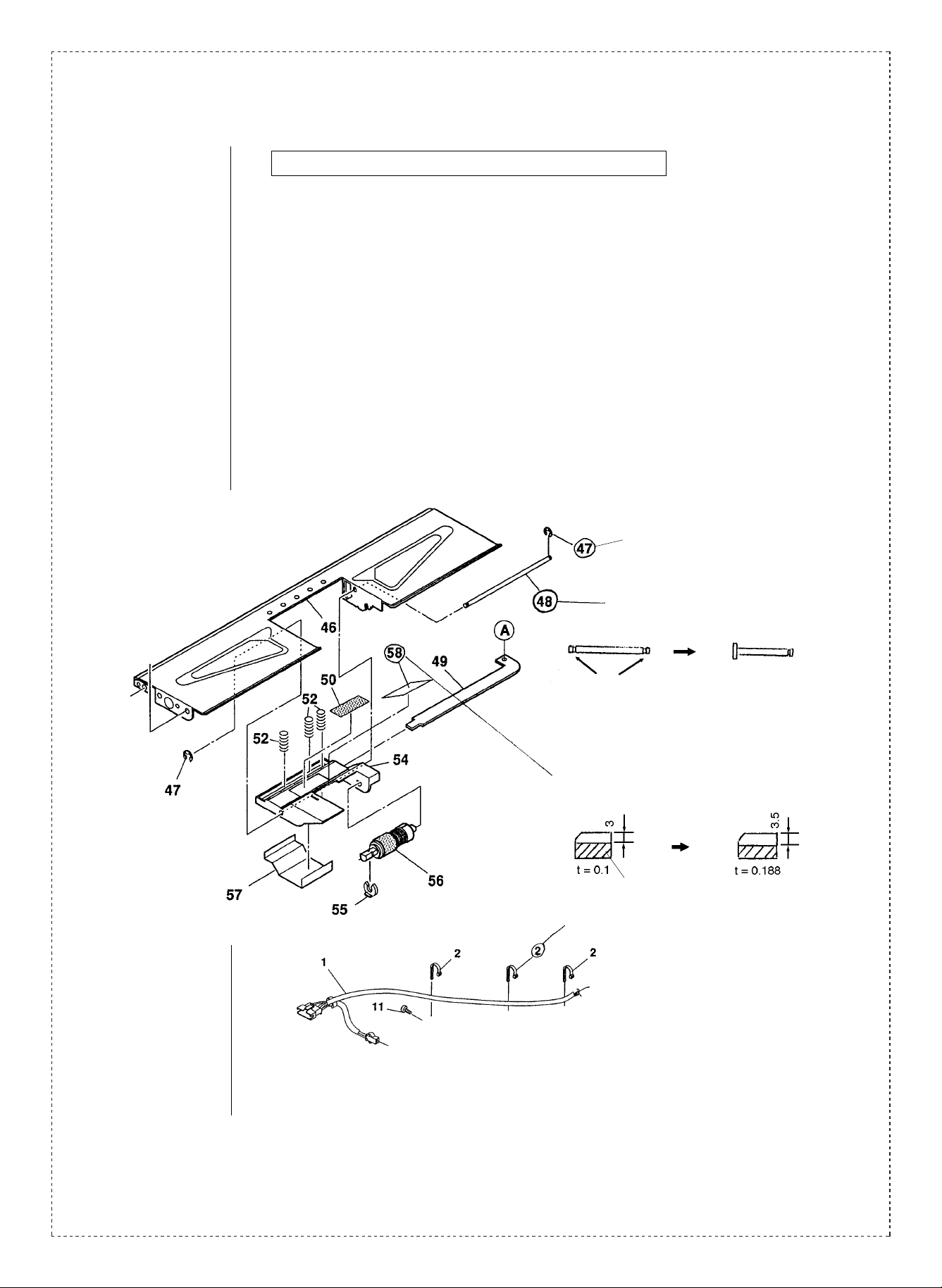

2. Changes to the manual paper feed to improve productivity .

1.Model name: SF-2035 / 2037 / 2022 / 2018

2.General: Changes to the pressure welded shaft of the manual multi-unit and the manual mylar;

and discontinuance of one wire hand in the suspension harness were made due to the

following reasons.

3.Reason: Improvement of productivity

4.Description: 1. Structural changes were made to the pressure welded shaft as shown in the

illustration. Only one E ring will be used as a stopper instead of two.

2. Structural changes were made to the manual mylar to improve productivity and

rebound during manual paper supply. (3F-2 will not be used.)

3. Discontinuance of the central wire hand in the manual multi-suspension harness

Discontinued E ring

Changes to the

pressure welded shaft

Old (E ring stoppers

in two places)

Changes to manual mylar

(SF-2018 does not have a manual mylar)

Double-sided tape

Discontinuance of additional hand

New (Hender

processed, single

E ring stopper)

5.Action: For production: Normal replacement from October 1993.

2\3

Page 3

Ref.

Model

No.

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. C urr e nt t y pe c a n be u s ed i n p la ce of new t y pe .

New ty pe cann ot be us ed i n place of curr ent type .

3. C urre nt ty pe cann ot be used i n place of new ty pe.

New t y pe c a n be u sed in p la c e of c u rr en t ty p e.

Parts m ar ke d wi t h “ ” is i mp ort an t fo r m a inta i ni ng t he sa fe ty of t he s e t. B e su r e to re pl ac e t he se pa r ts wi t h

specified ones for maintaining the safety and performance of the set.

name

Version P/G No.

Current parts New parts

Parts code Parts code

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others .

Price

rank

Parts name

Effec-

tive

time

Inter-

change-

ability

Note

Loading...

Loading...