Page 1

Date: Sep. 10, 1993

COPIER : SF-2035

1. PERMANENT SOLUTION TO PREVENT A PAPER MISFEED OWING

TO A RETURN FAILURE OF THE PPD1 ACTUATOR

2. PREVENTION OF APPEARANCE OF WHITE STREAKS WITH

CHANGE IN THE MS2 ACTUATOR MATERIAL

No. : SP-1621

1. Prevention of a paper misfeed owing to a return failure of the PPD1 actuator

1.Model name: SF-2022 / 2027 / 2035

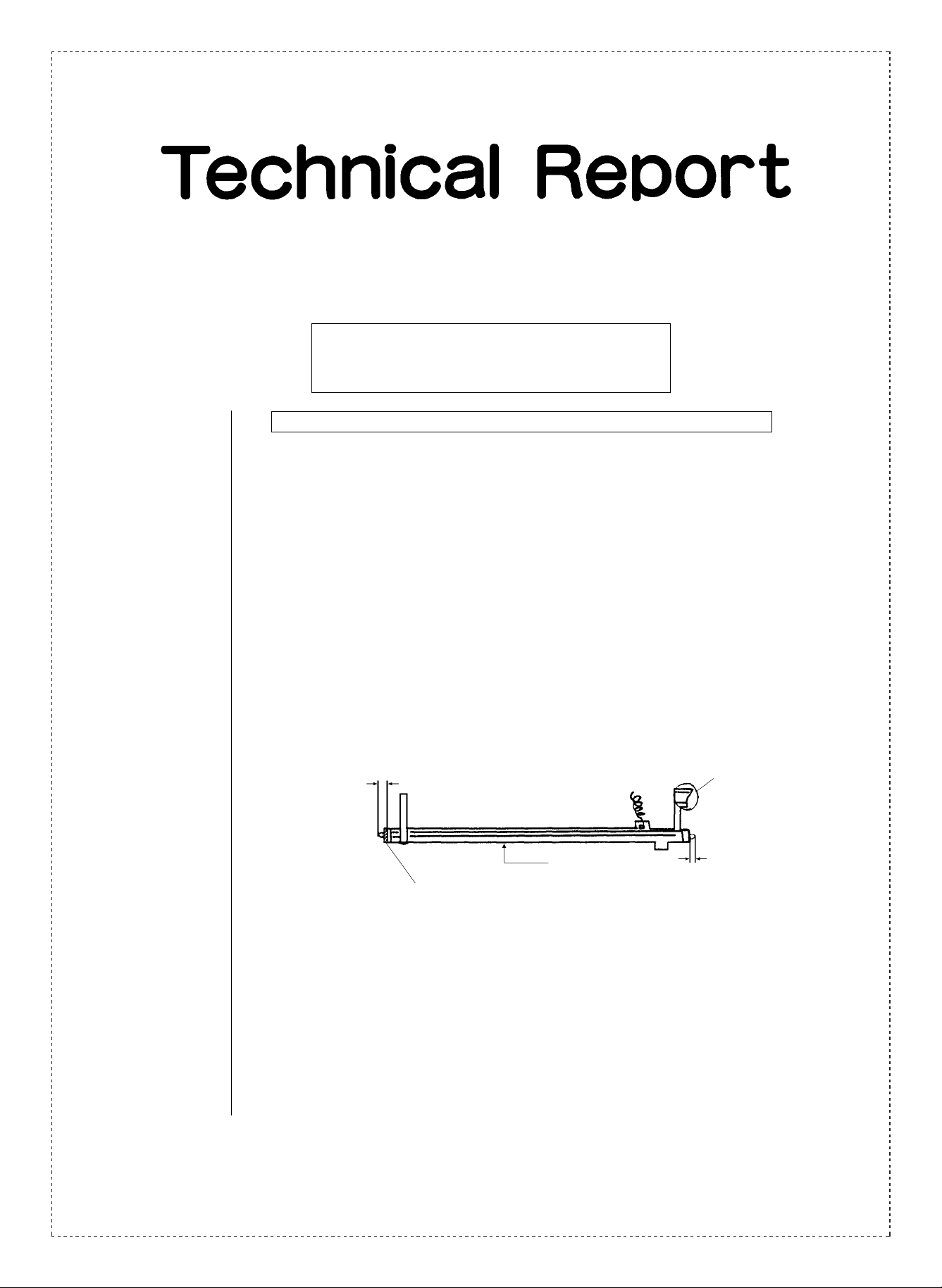

2.General: To avoid the paper misfeed caused by improper PPD1 return, change is made to the

axial distance of the PPD1 actuator.

3.Reason: To provide the thrust play against the PPD1 actuator movement.

4.Description: Change is made to the longitudinal distance as shown in the illustration to improve the

action of the PPD1 actuator.

Extended 0.7mm.

PPD1 actuator

This end (shadowed area) is cut 0.5mm.

The new item

has “A” printed.

Extended

0.5mm.

5.Action: (Factory action)

Running change Since July 1993.

SHARP CORPORATION Reprography Division

1/3

Green

C

Page 2

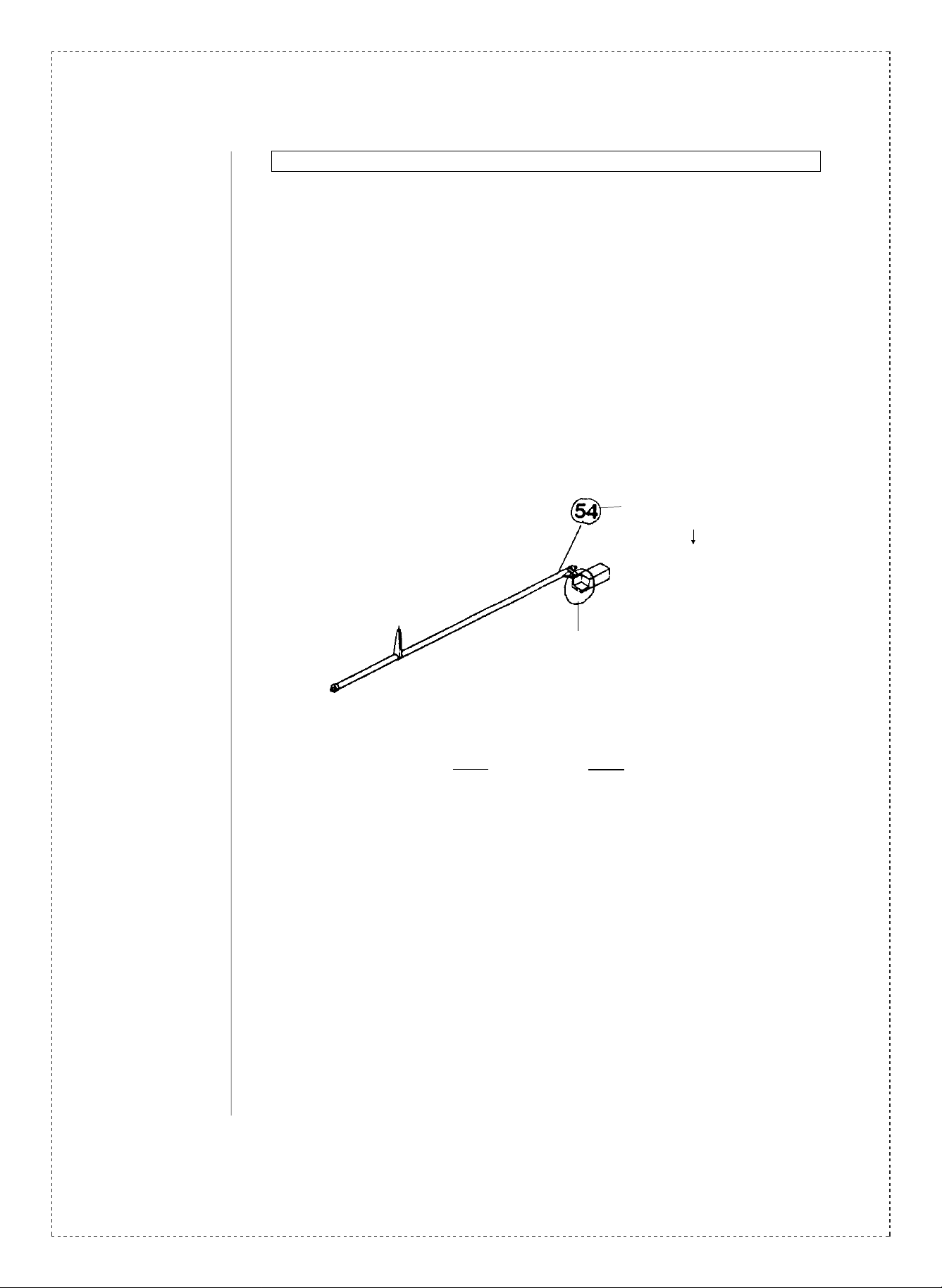

2. Prevention of appearance of white streaks with change in the MS2 actuator material

1.Model name: SF-2035 / 2027 / 2022

2.General: It is possible under a low humidity to static electricity charged as paper rubs against the

MS2 actuator, causing to produce white streaks. To avoid this to occur, change is made

to the material.This problem might occur in the halftone copy with the machine having a

large total copy count, though it depends on surrounding and paper kind.

3.Reason: This is to prevent appearance of white streaks under a low humidity producing a

halftone copy.

4.Description: A new material is used for the MS2 actuator to avoid static electricity charge against

paper.

MS2 actuator: Changed

MLEVP0583FCZ2

MLEVP0583FCZ3

Beginning from mid-January 1993 production of SF-2022 and SF-2027, a roundness

was provided at the top end of the actuator and it must be noted that its parts code was

reassigned from MLEVP0583FCZ1 to MLEVP0583FCZ2. With regard to SF-2035, the

new item (MLEVP0583FCZ2) had been used since its start of production.

5.Action: (Factory action)

From October 1993.

An “A” mark is printed on the new item.

2/3

Page 3

Ref.

Model

No.

SF-2035

1

SF-2022

SF-2035

2

SF-2022

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. C urr e nt t y pe c a n be u s ed i n p la ce of new t ype .

New ty pe cann ot be us ed i n place of curr ent type .

3. C urre nt ty pe cann ot be used i n place of new ty pe.

New t y pe c a n be u sed in p la c e of c u rr en t ty p e.

Parts m ar ke d wi t h “ ” is i mp ort an t fo r m a inta i ni ng t he sa fe ty of t he s e t. B e su r e to re pl ace t he s e pa r ts wi t h

specified ones for maintaining the safety and performance of the set.

name

2027

2027

Version P/G No.

20 -45

18 -45

All

20 -54

18 -54

!

Current parts New parts

Parts code Parts code

MLEVP0585FCZZ MLEVP0585FCZ1 AD PPD1 actuator

MLEVP0583FCZ2 MLEVP0583FCZ3 AE MS2 actuator ’93/10 1

Price

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others .

Parts name

rank

Effec-

tive

time

Running

change

since

July

1993

Inter-

change-

ability

1

Note

3/3

Loading...

Loading...