Page 1

COPIER : Z-88

CHANGES IN THE MAIN PWB

1. PREVENTING IRREGULAR NOISE GENERATION BY A SCAN MOTOR ERROR

2. PREVENTING IRREGULAR NOISE AND RADIO INTERFERENCE OCCURRENCE THAT

CAUSED BY A MAIN MOTOR ERROR

Correction the missprint in the technical report SP-1581.

1.Model name: Z-88/SF-2010.

REVISED

Date: Oct. 5, 1993

No. : SP-1581 (R)

2.General: To abate mechanical noise generated when the main motor is in operation and when

the scan motor is operating for return, some parts within the main PWB are added and

removed with a change in the CPU.

3.Phenomenon: 1. While the scan motor is reversing, its speed becomes faster then normal that hits the

paper exit side optical frame and may generate a knocking sound, therefore.

2. The main motor continues to run faster when the power is turned on.

4.Cause: 1. Owing to a lack of circuit operational margin in the circuit to detect the FG signal from

the main motor, it makes the motor to rotate faster that disables to detect the FG signal.

This causes it to return in a full power and hits with the optical frame when it stops at

the home position.

2. Counter-locomotive voltage of the main motor employed to control FET power

transistor exceeds the voltage withstanding point and damages the transistor and

makes it conductive. Although a high speed diode is used to absorb the

counter-locomotive voltage, it disables to absorb it even with this diode.

5.Description: 1. Scan motor irregular mechanical noise generation

Both the R27 resistor and the C24 capacitor of the main PWB are changed.

2. Preventing main motor control components from damage.

The diode D3 of the main PWB is removed with a capacitor newly added.

• Resistor R27 changed from 3.3KΩ to 5.1KΩ.

VRS-TS2AD332J VRS-TS2AD512J

• Capacitor C24 changed from 22,000pF to 5.600pF.

VCKYTVIHF223Z VCKYTVHB562K

• Diode (D3) replaced by a capacitor

VHDISR124200A (Q’ty: 2 to 1) VCQYNA2AM437K (Q’ty: 1)

Note: Both D3 and D4 diodes are used but only D3 diodes have been replaced by

capacitors.

1/3

SHARP CORPORATION Reprography Division

Green

C

Page 2

Besides, change is made to the CPU for the main motor control frequency.

• Change in the CPU (main motor control frequency)

4KHz 16KHz

VHI78011GC520 VHI78011GC526

VHI78011GC524

• R14 changed (4.7KΩ to 560KΩ) to abate radio interference and the use of a ferrite

core (for 100V series machine only).

VRS-TS2AD472J (Quantity: 4 to 3)

VRS-TS2AD561J (Quantity: 1 to 2)

RCORF0012FCZZ (Quantity: 1) for the 100V series machine only.

* CPU of the main PWB had been changed to VHI78011GC525 since the first

production unit must be order placed under the parts code of VHI78011GC526.

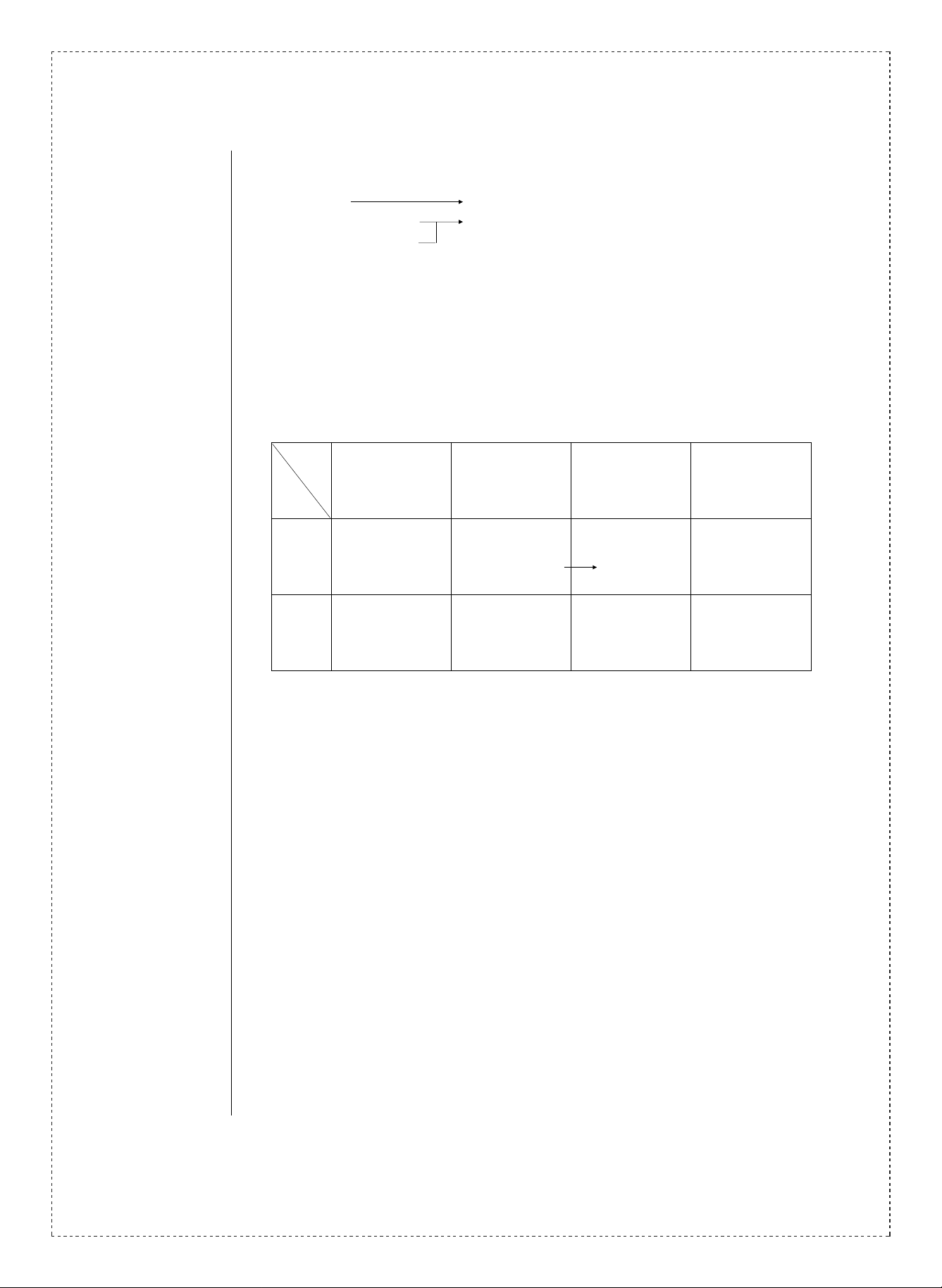

Chronological changed in the CPU and the main PWB

1st lot

AB series

CPU

Main

PWB

VHI78011GC520

inch series

VHI78011GC504

AB series

CPWBS0955FC53

inch series

CPWBS0955FC51

*1: CPWBS0955FC57 has R27 and C24 changed and the D3 replaced by a capacitor

from CPWBS0955FC55.

*2: Changed since the first production unit for the SEEG version with others made

running change from mid-March 1993.

6.Action: (Factory action)

SEEG: Since the first production unit.

Others: Running change since mid-March 1993.

From Dec/92

production unit for

all destination

excluding SEEG

All destinations,

excluding SEEG.

VHI78011GC525

(Mask CPU)

All destinations,

excluding SEEG.

CPWBS0955FC55

From

mid-December

1992 except for

SEEG.

*1

CPWBS0955FC57*2CPWBS0955FC58

Running change

from mid-March

1993.

*1

VHI78011GC526

(Mask CPU)

2/3

Page 3

Ref.

Model

No.

Z-88

SF-2010

Z-88

SF-2010

Z-88

<Inter c h an g e>

1. Interchangeable. 4. Not interchangeable.

2. Curre nt t y pe c a n be u s ed i n place of n ew type .

New ty pe cann ot be us ed in place of curr ent type .

3. Curre nt t y pe c a nn ot be use d in p l ac e o f ne w ty p e.

New t y pe c a n be u s ed i n pl a ce of cur ren t type.

Parts m ar ke d wi th “ ” is im p ort an t fo r m ain ta in i ng t he sa fe ty of t he s e t. B e sur e t o rep l ace t he s e pa r ts wi th

specified ones for maintaining the safety and performance of the set.

name

Version P/G No.

12 -38

12 -54

12 -52

12 -25

All

12

12 -58

12 -60

12 -901

100V

12

series

!

Current parts New parts

Parts code Parts code

VHI78011GC520 VHI78011GC526 AW

VRS-TS2AD332J VRS-TS2AD512J AA

VCKYTV1HF223Z VCKYTVIHB562K AA

VHD1SR124200A Quantity change AC

— VCQYNA2AM473K AB

VRS-TS2AD472J Quantity change AA

VRS-TS2AD561J Quantity change AA

CPWBS0955FC53 CPWBS0955FC58 BN

— RCORF0012FCZZ AH

Price

rank

5. Inte rc ha ng ea bl e if rep l aced with s a m e typ es of

relate d pa r ts in us e.

6. Others.

Parts name

CPU

(IC78011GC526)

Resistor, 5.1KΩ

Capacitor,

5,600pF

Diode (D3)

Capacitor,

0.047pF

Resistor, R14

Resistor, R14

Main PWB

Ferrite core

Effective

time

93/3

Inter-

change-

ability

3 *1

3

3

3

—

3

3

3

—

Note

R27

C24

Q’ty:

2 to 1

Q’ty: 1

Q’ty:

4 to 3

Q’ty:

1 to 2

100v

series

*2

*2

*1

*1Do replacement at the same time.

*2Do replacement at the same time.

3/3

Loading...

Loading...