Page 1

Date: Apr. 21, 1993

COPIER : SF-2022

1. CHANGING THE TRIAC HOLDING SCREW TO ENHANCE PRODUCTIVITY

2. CHANGING THE TAKEUP GEARWHEEL TO ENHANCE PRODUCTIVITY

3. CHANGING THE MIRROR SCREW TO ENHANCE PRODUCTIVITY

1. Changing the triac holding screw to enhance productivity

1.Model name: SF-2022/2027

No. : SP-1572

2.General: Because of the reason mentioned next, change is made t o the sc rew used t o

hold the triac of t he AC circuit PWB on it s heat sink .

3.Reason: To enhance productivity.

4.Description: Change is made to the size of the screw used to install the triac (TD201) on its

heat sink (PRDAF0046FCZZ).

For TD201

XBPSD30P10K00 XBPSD30P08K00

(M3x10) ( M3x8)

For TD202

XBPSD30P10K00 (No change made)

(M3x10)

4.Action: (Factory action)

Since March 1993.

SHARP CORPORATION Reprography Division

1/3

Green

C

Page 2

2. Changing the takeup gearwheel to enhance productivity

1.Model name: SF-2022/2027

2.General: Because of the reason mentioned next, change is made to the takeup

gearwheel.

3.Reason: To enhance productivity.

4.Description: Material of the takeup gearwheel changed from Dieamid L1724K to Polyfine

MF75L.

Takeup gearwheel: changed

NGERH0860FCZZ (Material: Dieamid L1724K)

NGERH0860FCZ1 (Material: Polyfine MF75L)

5.Action: (Factory action)

Since March 1993.

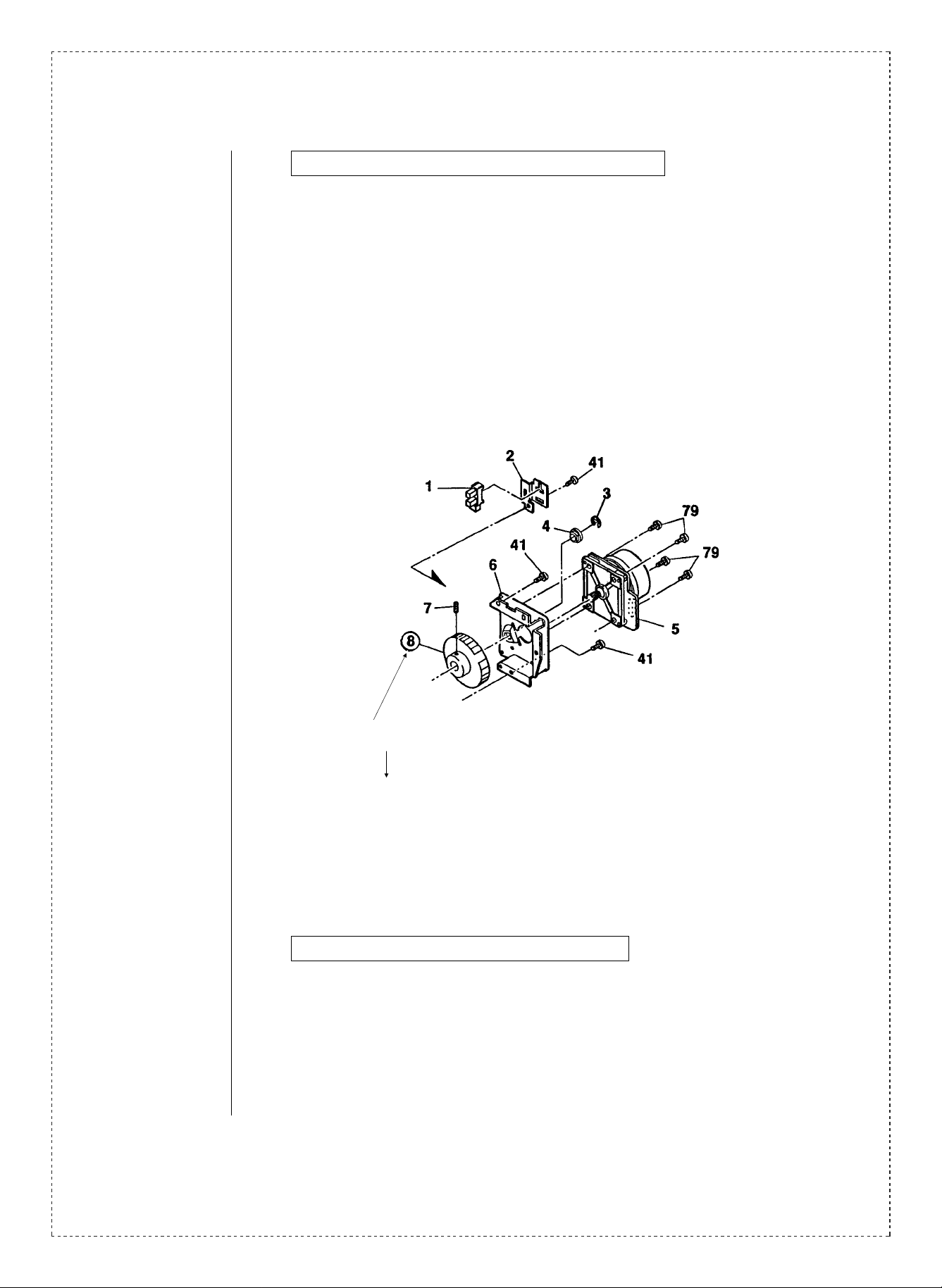

3. Changing the mirror spring to enhance productivity

1.Model name: SF-2022/2027/2035

2.General: Change is made to the structure of t he #1 mi rror holding m irror spring t o

eliminate a variance in the bent angl e as i t was bent twice.

2/3

Page 3

3.Reason: To enhance productivity at the l ine.

4.Description: Change is made to the structure of the mirror screw as illustrated below.

Mirror spring: changed

Mirror spring: changed

MSPRP1591FCZZ MSPRP2101FCZZ

5.Action: (Factory action)

Since mid-Jan 1993.

Ref.

Model

No.

1

SF-2022

2 12 -8 NGERH0860FCZZ NGERH0860FCZ1 AP

SF-2022

3

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. C urr e nt t y pe c a n be u s ed i n place of n ew type.

New ty pe cann ot be us ed in place of curr ent type .

3. C urr e nt type c a nn ot b e us e d in p l ac e o f ne w ty p e.

New t y pe c a n be u s ed i n pl a ce of cur ren t ty p e.

Parts m ar ke d wi th “ ” is im p ort an t fo r m ain ta in ing the sa fe ty of the s e t. B e sur e t o rep l ace these pa rts wi th

specified ones for maintaining the safety and performance of the set.

name

2027

2027

2035

Version P/G No.

All

Changed

Current parts New parts

Parts code Parts code

34 -47 XBPSD30P10K00 Quantity change AA Screw (M3x10)

34 — XBPSD30P08K00 AA Screw (M3x8) — Q’ty: 1

10 -10 MSPRP1591FCZZ MSPRP2101FCZZ AC Mirror spring

!

Price

rank

5. Interc ha ng ea ble i f r ep l ace d wi th s a m e typ es of

relate d pa r ts in us e.

6. Others.

Parts name

Takeup

gearwheel

Effective

time

’93/3

MidJan.

1991

Interchangeability

—

1

1 Q’ty: 2

Note

Qty:

2 to 1

3/3

Loading...

Loading...