Page 1

Date: Apr. 27, 1993

COPIER : SF-2022

1. PREVENTING A 75MM PITCH BLUR WITH A NEW PIN IN USE

2. CHANGING IN THE FABRIC SHEATH FOR PRODUCTIVITY

ENHANCEMENT

3. AVOIDING A LEEWAY IN THE DV DRIVE SHAFT

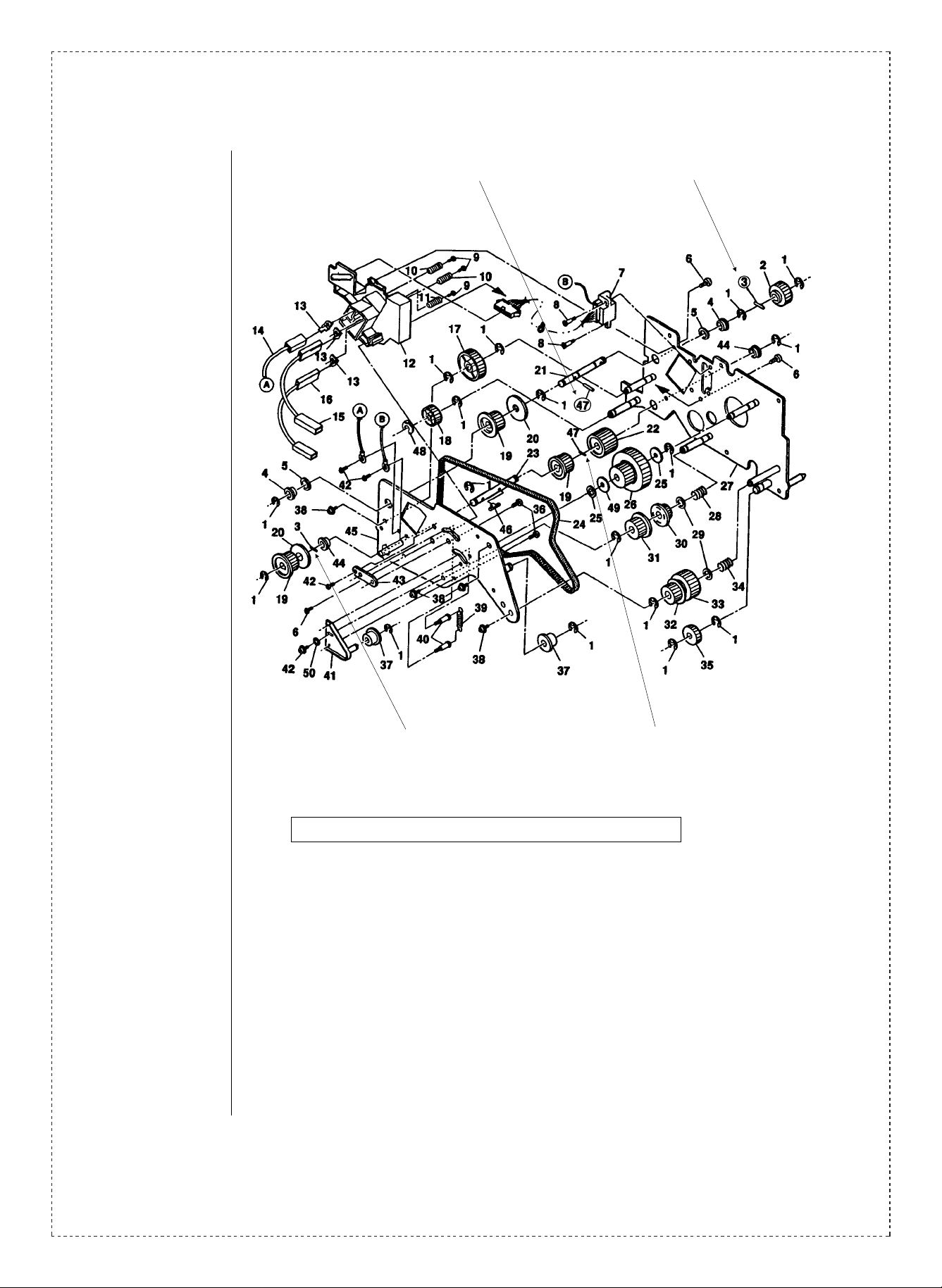

1. Preventing a 75mm pitch blur with a new pin in use

1.Model name: SF-2022/2027

No. : SP-1570

2.General: Owing to a play in the pin and the gearwheel at the drum drive block of the

main drive unit, it m ay probably c ause an occurrence of a 75mm pitc h blur

toward the paper moving direction. To avoid this, a change is made to the stop

pin.

3.Phenomenon: A 75mm pitch blur m ay occur towards the paper m oving direct ion. This would

not occur when copying normal characters, but may occur when making a copy

of an original that has grid on it.

4.Description: Change is made to the pin as described next to get rid of the play.

• φ3-10 stop pin φ3-11 waved split spr ing pin

(LPINS0155FCZZ) (LPINS0278FCZZ)

• φ3-9.5 st raight split spring pin φ3-9.5 waved s plit spring pin

(LPINS0262FCZZ) (LPINS0264FCZZ)

SHARP CORPORATION Reprography Division

1/4

Green

C

Page 2

Changed: LPINS0262FCZZ

↓

LPINS0264FCZZ

Changed: LPINS0155FCZZ

↓

LPINS0278FCZZ

5.Action: (Factory action)

This pin stays the same as is now.This pin stays the same as is now.

Since February 1993.

2. Changing in the fabric sheath for productivity enhancement

1.Model name: SF-2022/2027/2035/CM11/D19/D20/D21

2.General: Change is made to the structure of t he fabric sheath due t o the followi ng

reason.

3.Reason: To achieve productivity enhancement.

4.Description: Change is made to the fabric sheath of the paper feed unit as described next.

2/4

Page 3

5.Action: (Factory action)

Front side

Only this area

is covered.

Shape changed

The sheath is now changed to

cover entire wire area to cover

only the bent area.

Rear side

From April 1993.

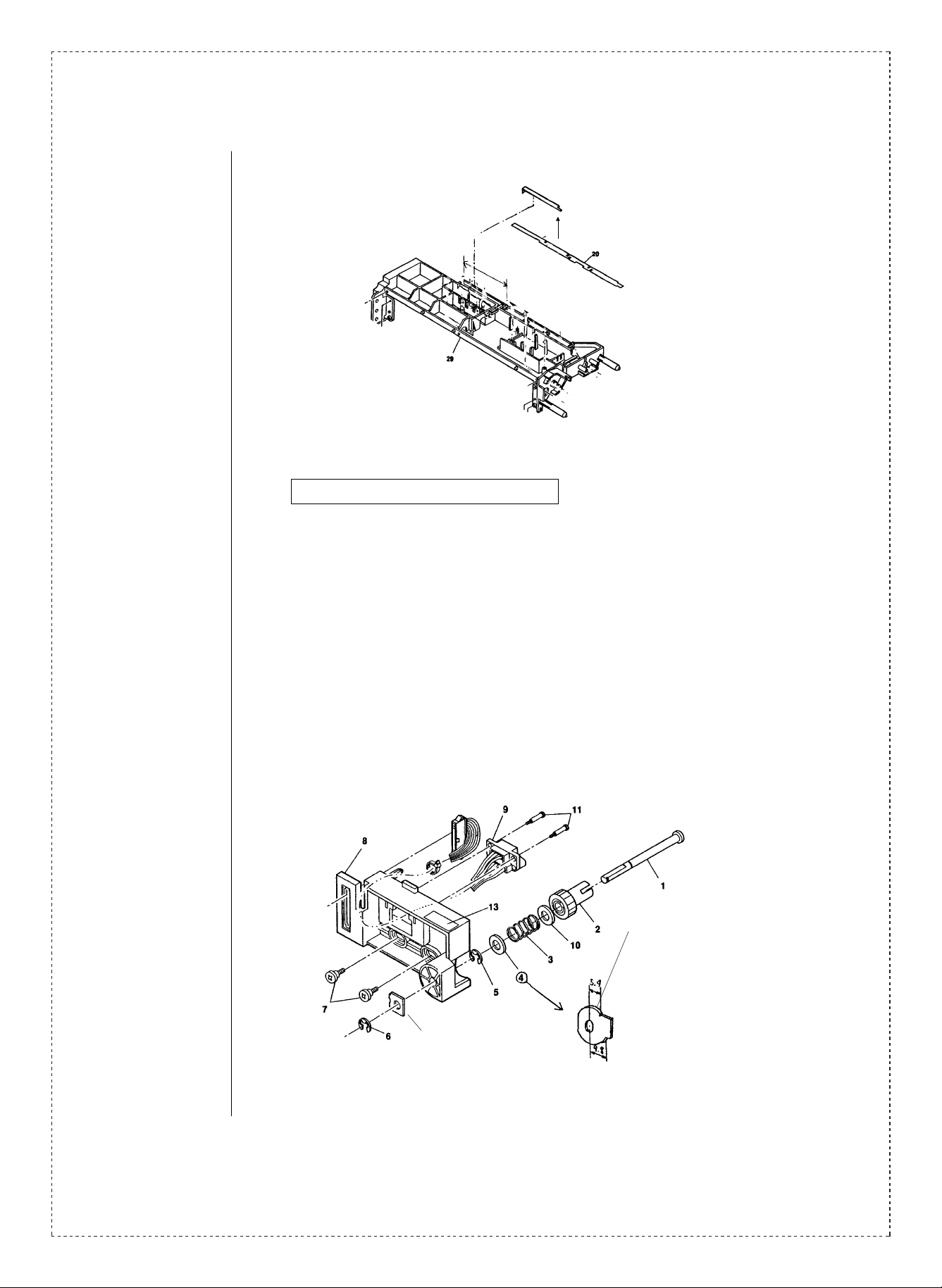

3. Avoiding a leeway in the DV drive shaft

1.Model name: SF-2022/2027/2035

2.General: Change made to the washer and a DV drive holding plate is added t o ban

leeway of the DV drive shaft.

3.Reason: To prohibit leeway of the DV drive shaft.

4.Description: The washer is replaced with a DV drive shaft holding plate-2 and a drive

holding shaft is added.

DV drive shaft holding plate-2

(LPLTM4451FCZZ)

∗Note the installing direction.

Shape changed

Add

DV driveshaft holding plate.

(LPLTM4448FCZZ)

3/4

Page 4

5.Action: (Factory action)

Since February 1993 for SF-2022 and SF-2027.

Since the first producti on unit f or SF-2035.

Ref.

Model

No.

SF-2022

1

SF-2022

2

SF-2022

3

SF-2035

SF-2022

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. C urr e nt t y pe c a n be u s ed i n place of n ew type .

New ty pe cann ot be us ed in place of curr ent type .

3. C urr e nt type c a nn ot b e us e d in p l ac e o f ne w ty p e.

New t y pe c a n be u s ed i n pl a ce of cur ren t type.

Parts m ar ke d wi th “ ” is im p ort an t fo r m ain ta in i ng t he sa fe ty of t he s e t. B e sure to rep lac e t he s e pa rts wi th

specified ones for maintaining the safety and performance of the set.

name

2027

2027

2035

CM11

D19

D20

D21

2027

2027

Version P/G No.

20 -3

20 — LPINS0278FCZZ AB

20 -47 LPINS0262FCZZ Quantity changed AB

20 — LPINS0264FCZZ AB

26 -20

40 -20

All

66 -20

22 -4

19 -4

19 — LPLTM4448FCZZ AC

!

Current parts New parts

Parts code Parts code

LPINS0155FCZZ Quantity changed AA Stop pin (φ3X10)

PCOVP1154FCZZ PCOVP1154FCZ1 AD Fabric sheath ’93/4 1

LX-WZ0031FCZZ LPLTM4451FCZZ AB

Price

rank

5. Interc ha ng ea ble i f r ep l ace d wi th s a m e typ es of

relate d pa r ts in us e.

6. Others.

Parts name

Wave split spring

pin (φ3X11)

Straight split spring

pin (φ3X9.5)

Wave split spring

pin (φ3X9.5)

DV drive shaft

holding plate-2

DV drive shaft

holding plate

Effective

time

’93/2

’93/2 3

Since

the first

production unit

’93/2 —

Inter-

changeability

—

—

—

—

1

Note

Q’ty:

2 to 1

Q’ty: 1

Q’ty:

2 to 1

Q’ty: 1

Parts

Guide

correct

on

4/4

Loading...

Loading...