Page 1

q

SERVICE MANUAL

CODE : 00Z

AREB9//A1E

DIGITAL LASER COPIER

PRINTER OPTION

DUAL FUNCTION BOARD

MODEL

CONTENTS

AR-EB9

[1] SYSTEM CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

[2] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

[3] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . 5

[4] ELECTRICAL SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

[5] USER PROGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

[6] FLASH ROM VERSION UP PROCEDURE . . . . . . . . . . . . . . . . . 8

[7] CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 3

Parts mark ed w ith "!" are important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

This document has been pub lished to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

Page 3

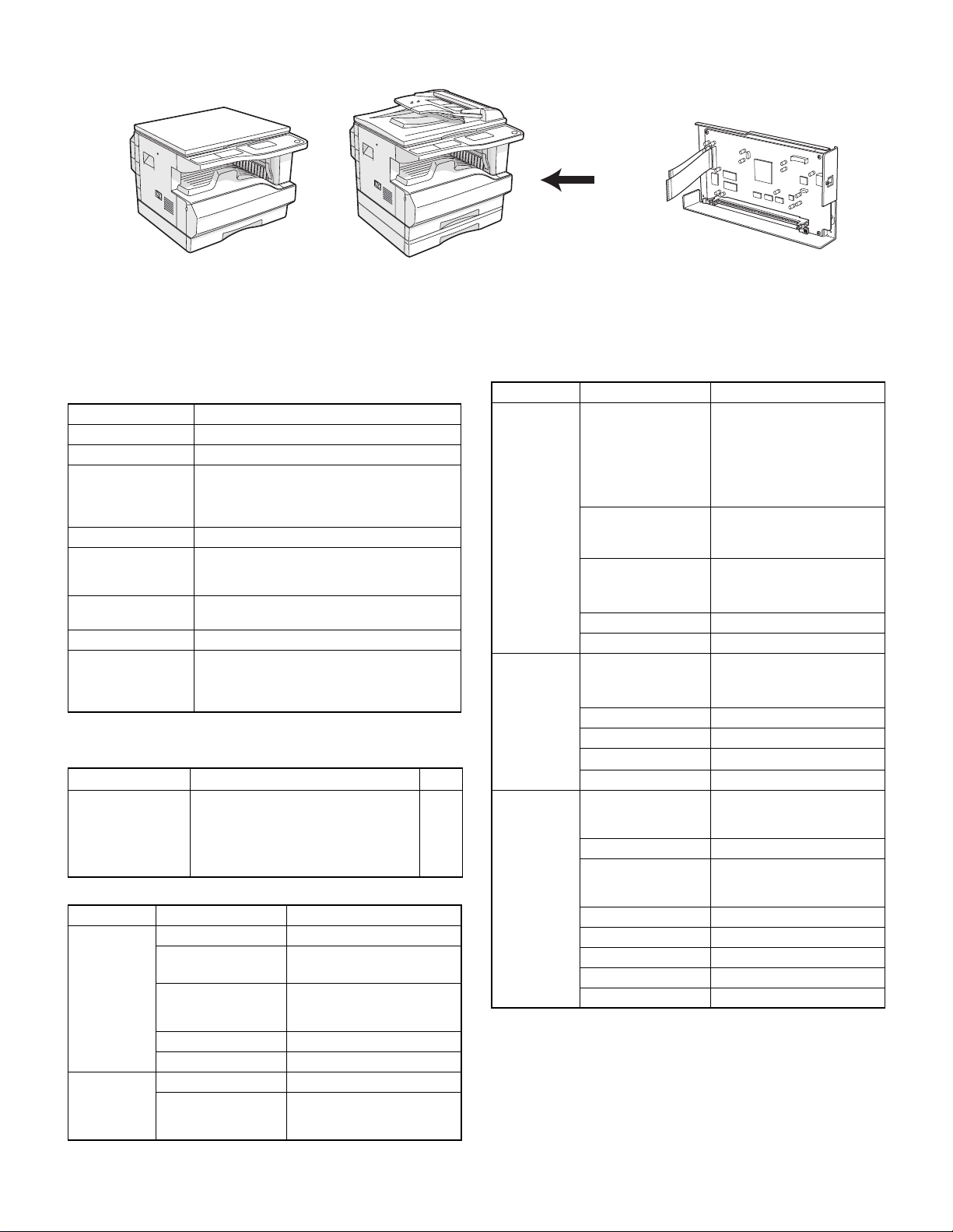

[1] SYSTEM CONFIGURATION

[2] SPECIFICATIONS

1. “Sharp Printer Language with Compression (SPLC)” Printer mode

(AR-EB9)

A. Basic specification

Item Detail

Print Speed AR-M162/M165(16ppm)/AR-M207(20ppm)

Data resolution 300/600dpi

Input tray 4 Multi size tray

Option memory

Printer driver Two drivers for the case when the AR-EB9 is

AR-EB9 Manual

(Online manual)

Platform IBM PC/AT (Include compatible machine)

Support OS

(Printer Driver)

1 Multi Bypass tray

(Depending on conditions of the machine and

option installation.)

AR-SM5 (256MB) c an be added to the AR-EB9.

installed and when it is not are automatically

installed by plug & play.

Standard

Windows 95/98/Me

Windows NT4.0 Workstation (SP5 or later)

Windows 2000 Professional

Windows XP Home/Professional Edition

B. Printer driver specification

(1) System

Machine OS GDI

IBM PC/AT

(Include compatible

machine)

(2) Printing function specification

Main Copies 1-999

Main

Windows 95/98/Me

Windows NT4.0 Workstation

(SP5 or later)

Windows 2000 Professional

Windows XP Home/Professional Edition

Function GDI Driver

Collate Collate

Uncollate

Document Style 1-sided

2-sided (Book)

2-sided (Tablet)

N-up printing 2/4

N-up Order Z

N-up Border Yes/No

Duplex 1-sided

2-sided (Book)

2-sided (Tablet)

Yes

Function GDI Driver

Paper Paper Size A3/B4/A4/B5/A5/B6/A6/

Custom Paper Size 1 size

Paper Selection • Auto Select

Fit to Page Yes/No

Image Orientation Portrait/Landscape

Advanced Print Quality Normal

Image Adjustment Yes/No

Brightness 0 to 100

Contrast

Pure Black Print Yes/No

Water-marks Watermark (None)/TOP SECRET/

User setting Add/Update/Delete

Position Center

Size 6 to 300

Angle

Gray Scale 0 to 255

Edit Font Yes

On first page only Yes/No

Ledger(11x17)/Legal

(8.5 x 14)/Foolscap (8.5 x 13)/

Letter (8.5 x 11)/Invoice

(5.5 x 8.5)/Folio/Executive/

COM-10/DL/C5/8K/16K/

Custom

100 - 297mm(W)

148 - 431.8mm(H)

• Bypass

• Tray 1/2

Draft

Photo (without Win9x, Me)

0 to 100

CONFIDENTIAL/DRAFT/

ORIGINAL/COPY

50

m

X:

50

m

Y:

90

m

AR-EB9 SYSTEM CONFIGURATION

– 1 –

Page 4

(3) Scanner function specification

Type Flat bed color scanner

Scan system Document table/document feed unit

Light source White CCFL

Resolution Basic 600 x 600dpi

Set range: 50 ~ 9600dpi

Document Sheet/Book

Effective

OC/SPF: Approx.297(V) x 431(H)

scan range

Scan speed OC/SPF: 2.8mm sec/line

(Color/BW (at the light source selection) 0.96msec/

Line (Gray scal/BW))

Input data 1bit or 12bit

Output data 1bit or 8bit

Scan color Black and white binary/Gray scale/Full color

Protocol TWAIN/WIA (XP only)/STI

Interface USB1.1

USB2.0 (It can be used according to conditions.)

(Option support: High speed mode)

(Supported when E-sort is installed)

Scanner utility Sharp Desk/Button Manager

Duplex scan Provided

Supported OS W indows 98/M E/2000/XP

Void area Top/End (2.5mm) on the driver side

Left/right: 3.0mm

Memory storage

JPEG-compression by hardware.

method

(4) Print quality

Resolution 600dpi Print quality is selected from

Pure Black Print On Pure Black print function is ON.

*

Off

Default

*

*

/Draft/Photo.

Normal

Pure Black print function is OFF.

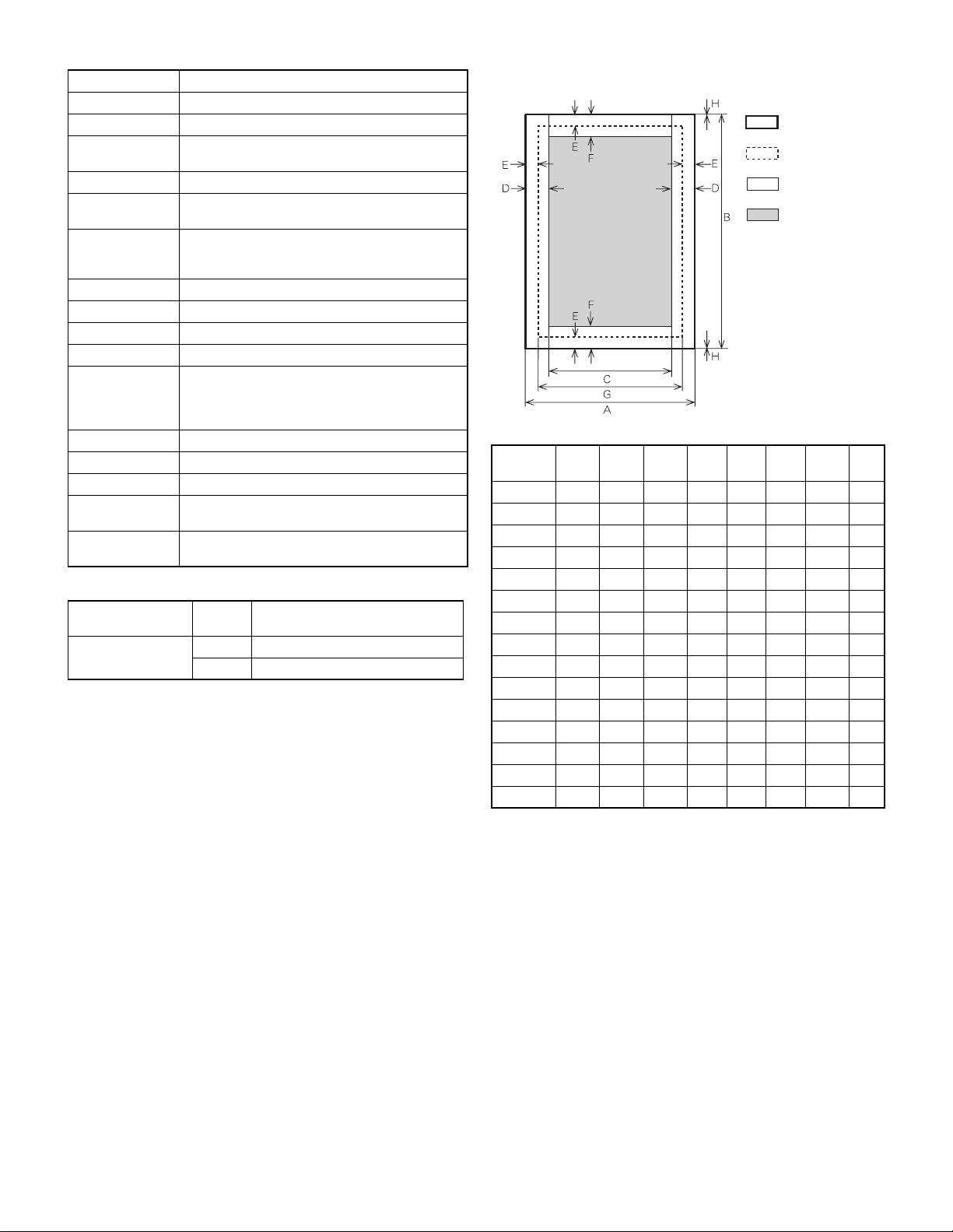

(5) Print area

Actual page size

Print area

Logic paper size

HP/GL

picture frame

Paper

Size

A3 7014 9920 6730 142 100 300 6814 0

B4 6070 8597 5786 142 100 300 5870 0

A4 4960 7014 4676 142 100 300 4760 0

B5 4298 6070 4014 142 100 300 4098 0

A5 3508 4960 3224 142 100 300 3308 0

Ledger 6600 10200 6300 150 100 300 6400 0

Legal 5100 8400 4800 150 100 300 4900 0

Letter 5100 6600 4800 150 100 300 4900 0

Invoice 3300 5100 3000 150 100 300 3100 0

Foolscap 5100 7800 4800 150 100 300 4900 0

Folio 4980 7800 4680 15 0 100 300 4780 0

Executive 4350 6300 4050 150 100 300 4150 0

COM-10 2474 5700 2174 150 100 300 2274 0

C5 3826 5408 3542 142 100 300 3626 0

DL 2598 5196 2314 142 100 300 2398 0

ABCDEFGH

AR-EB9 SPECIFICATIONS

– 2 –

Page 5

Actual page

size

Print area

Logic paper

size

HP/GL

picture

frame

Top margin

*

The set value is received from the digital copier, and d ata are made

according to the set value.

Left margin

*

Since the paper size sensor is not set, the digital copier cannot recognize the size and direction of paper which is actually inserted.

Therefore, the left margin is set according to the paper size specified

in the print data sent from the computer, and print process is performed.

If the computer does not specify the paper size, or in the case of the

custom size, the left margin is set according to the default paper size.

(6) Print reference

Paper

Size

A3 9920 7014 9684 118 100 300 9720 0

B4 8597 6070 8361 118 100 300 8397 0

A4 7014 4960 6778 118 100 300 6814 0

B5 6070 4298 5834 118 100 300 5870 0

A5 4960 3508 4724 118 100 300 4760 0

Ledger 8400 5100 8160 120 100 300 8200 0

Legal 8400 5100 8160 120 100 300 8200 0

Letter 6600 5100 6360 120 100 300 6400 0

Invoice 5100 3300 2860 120 100 300 4900 0

Foolscap 7800 5100 7560 120 100 300 7600 0

Folio 7800 4980 7560 120 100 300 7600 0

Executive 6300 4350 6060 120 100 300 6100 0

COM-10 5700 2474 5460 120 100 300 5500 0

C5 5408 3826 5172 118 100 300 5208 0

DL 5196 2598 4960 118 100 300 4996 0

ABCDEFGH

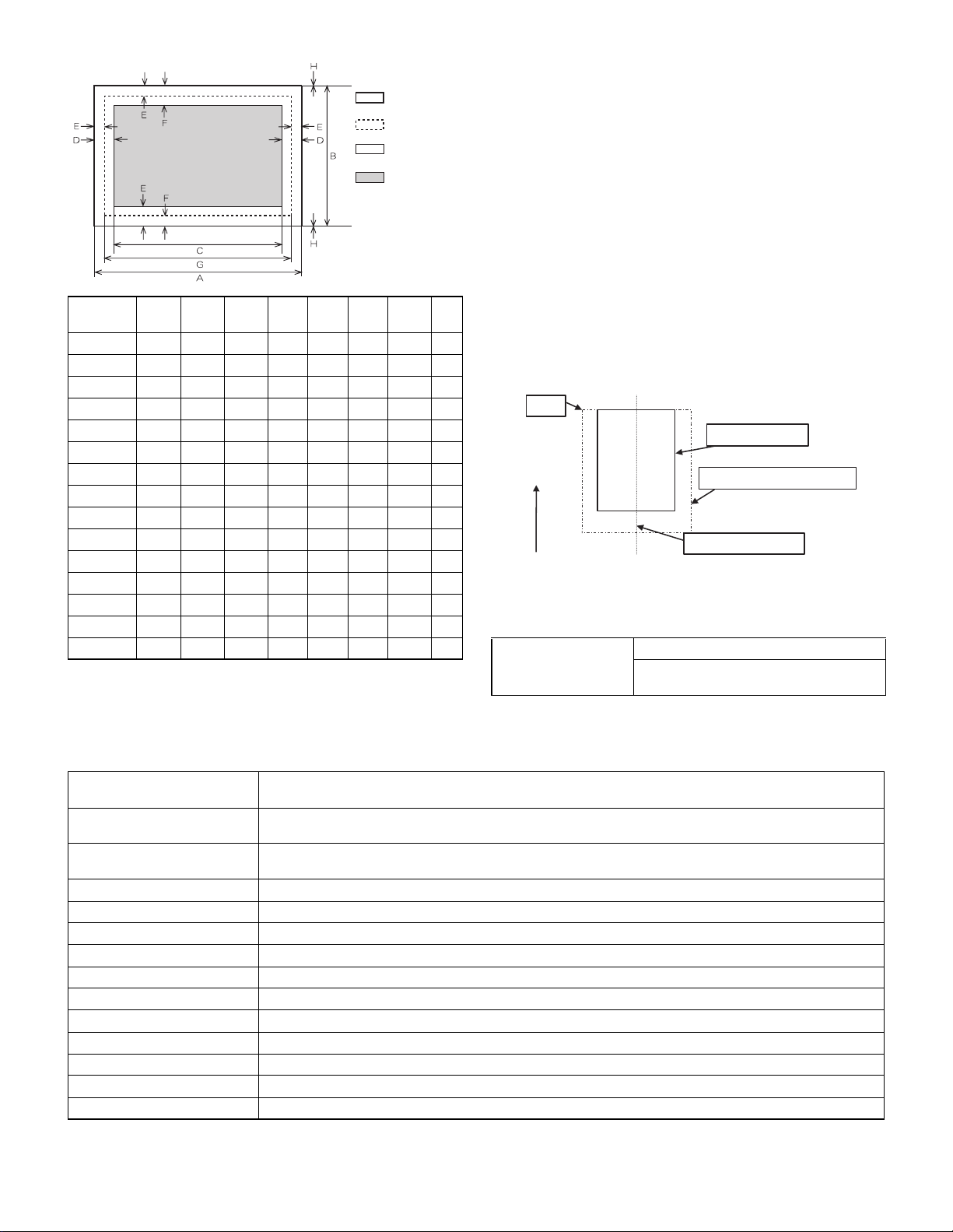

2. IMC2 board functions

This machine employs the center reference system.

Since the digital copier is not provided with the tray size detection feature, formatting and center distribution are performed not by the actual

paper size but by the paper size specified by the computer.

Origin

Actual paper size

Size specified by the HOST

Paper feed direction

Center reference line

D. Interface

Interface USB 1.1 (Standard)

USB 2.0 High speed

(With the AR-EB9 installed))

Sort function (Electronic sort) 100 sheets (max. 765 sheets) <copy mode> with A4 standard documents at 600dpi.

*

Non sort function (Electronic sort)

*

Rotation copy If there is paper of the same size as the docu ment , the imag e is rot ated to cop y even tho ugh the pa per is se t in

2 in 1, 4 in 1 Copies of 2 pages or 4 pa ges a re i ntegra ted i nto one su rface. Divid ed b y sol id li nes. (Sel ectab le by the u ser pr ogra m.)

Edge erase Images surrounding the document are erased when copying. (Adjustable in 0 ~ 20mm by the user program.)

Center erase The image at the center is erased when copying. (Adjustable in 0 ~ 20mm by the user program.)

Margin shift Binding margin is made at the left edge of the set documents. (Adjustable in 5 ~ 20mm by the user program.)

Memory for electronic sort 16MB

Memory read capacity 600dpi:100 sheets (Max. 765 sheets) <copy mode> of A4 standard documents (Sharp A4 standard document)

*

Memory expansion DIMM memory slot x 1, max. 256MB (With AR-SM5) x 1 slot + 16MB (Max. 272MB in total)

USB2.0 USB2.0 compat ib le (Check syste m by key operation)

SPLC (JBIG-GDI) Supported when Dual function Board (AR-EB9) is installed.

ROPM Supported when Dual function Board (AR-EB9) is installed.

Card Shot This function creates 2 in 1 images of the front and back side of the card and centers them on the paper.

Caution: The number of sheets for the columns marked with “*” is calculated supposing that the same quantity is assigned to the ROPM memory and

the copy expansion memory.

Offset paper exit by the shifter function

100 sheets (max. 765 sheets) <copy mode> with A4 standard documents at 600dpi.

Offset paper exit by the shifter function

the different direction from the document direction.

AR-EB9 SPECIFICATIONS

– 3 –

Page 6

Page 7

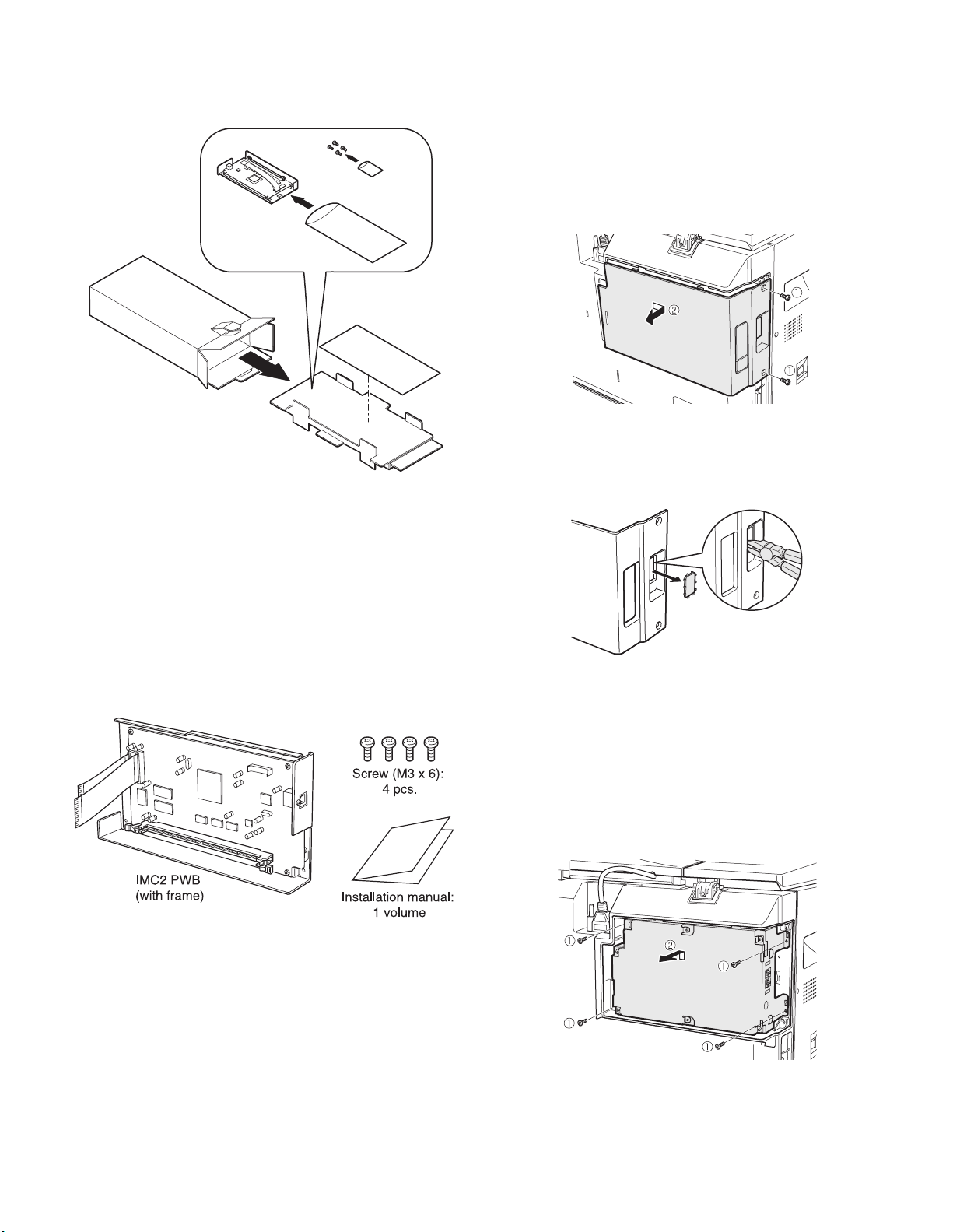

[3] UNPACKING AND INSTALLATION

1. Unpacking

3. Installation procedure

Turn the main switch of the main unit to the "OFF" po sition and

then remove the power plug of the main unit from the outlet.

1) Remove the rear cover.

Remove the two screws.

1

Slide the cover to the right to remove it.

2

2) Cut out the cut-out portion of the rear cover.

Cut out the cut-out portion with nippers or the like.

At this time, be careful about the orientation of the nippers so that

the cut plane of the rear cover is flat.

<Before installation>

For improvement of workability, part of the description in this

manual may be modified without prior notice.

In this case, refer to the service manual.

2. Parts included

• If the machine is equipped with a fax expansion kit, proceed to

the next step.

• If the machine is not equipped with a fax expansion kit, carry out

steps 4, 5, 7, and later.

3) Remove the fax expansion unit.

Remove the four screws.

1

While lifting the fax expansion kit, remove it.

2

AR-EB9 UNPACKING AND INSTALLATION

– 4 –

Page 8

4) Attach the IMC2 PWB.

Fit the two pawls of the IMC2 PWB frame to the mounting por-

1

tions of the main unit.

Secure the PWB with the four supplied gold en scre ws (M3 x 6).

2

7) Attach the rear cover.

Fit the two pawls of the rear cover to the main unit and slide the

1

cover to the left until it is locked.

Secure the cover with the two screws.

2

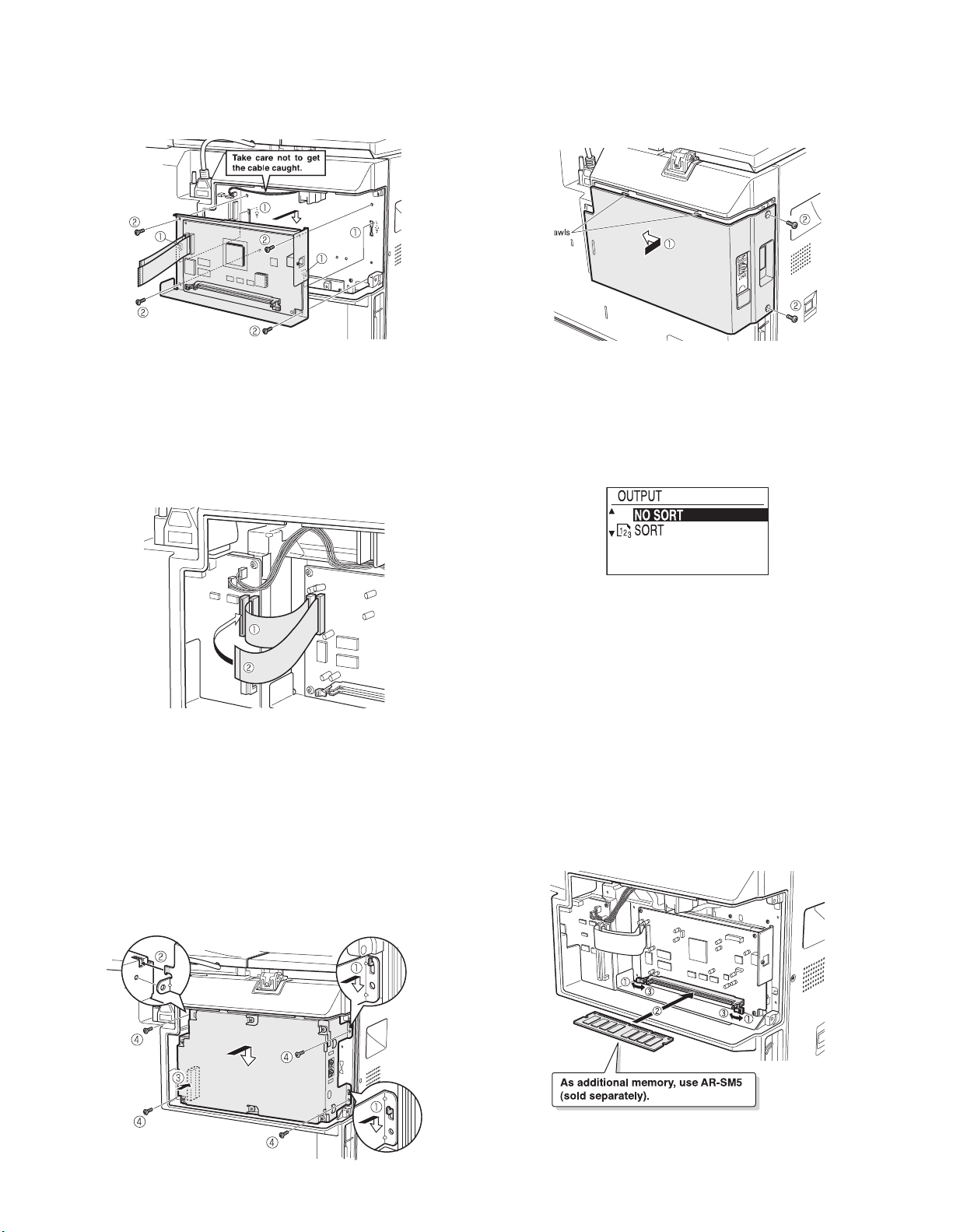

5) Connect the IMC2 PWB to the MCU PWB of the main unit.

Connect the PWB so that the shorter flat cable comes inside.

1

Connect the PWB So that the longer flat cable comes outside.

2

Note: Be careful about the orientation of the flat cable insertion and

check that both ends of each cable are securely inserted into the

connector. (The terminal surface of each flat cable must have

contact with the connector terminals.)

6) Attach the fax expansion unit.

Fit the two mounting portions (upper and lower) located at the

1

right side of the fax expansion unit to the pawls of the frame of

the main unit.

Fit the left pawl located at the left side of the fax expansion unit

2

to the frame of the main unit.

Push the lower left part of the fax expansion unit to connect

3

securely the connector of the fax expansion unit to the co nnector of the main unit.

Secure the unit with the supplied four screws (M3 x 6).

4

Insert the power plug of the main unit to the outlet and turn on the

power switch. Then, carry out the following procedure.

8) Check the IMC2 PWB.

Select the [COPY] mode on the operation panel and press the

[OUTPUT] key.

Check that the following screen is displayed.

9) Check printing.

For installation of the driver software on the computer, see the operation manual supplied with the main unit.

Connect the USB cable, carry out printing from the computer, and

check that printing can be performed normally.

4. Mounting of additional memory

(After installation, proceed to 3-5) )

Open the two locking clips of the socket.

1

Insert the memory matching the orientation of its notches.

2

Close the locking clips of the socket.

3

Q Notice for Users in Canada

This Class A digital apparatus complies with Canadian ICES-003.

AR-EB9 UNPACKING AND INSTALLATION

– 5 –

Page 9

[4] ELECTRIC A L SE C TION

The OA982 board mounted on the IMC2 board inputs and outputs image data to and from the MCU board, controls SDRAM memory, and communicates with USB2.0 devices.

SDRAM memory is used to store programs and image data as well as for a working area.

USB 2.0 devices communicate with a PC through a USB2.0 cable at a rate of 480 Mbps.

SDRAM memory can be expanded by using 1BANK SDRAM DIMM (AR-SM5).

Communications between the OA982 and the AR-SM5 is held using an ASIC-controlled BUFFER IC (74VCX16244/16245).

1. Block diagram

CN6 168PIN DIMM SOCKET

(For 1BANK SNR SDRAM DIMM)

CONTROL BUS ADDRESS BUS

IC28 BUFFER

74VCX16244

CONTROL SIGNAL (/CS,/RAS,/CAS,/WE etc.)

ADDRESS BUS

DATA BUS

IC29 BUFFER

74VCX16244

DATA BUS

IC26 BUFFER

74VCX16245

/OE,/DIR

SDRAM CLK

81.2376MHz

IC6

ZeroDelayBuffer

CY2305

IC35

BUFFER

ASIC

USB2.0

Connector

USB2.0

High/Full

Speed

IC8

USB2.0Driver

ISP1581

Y1 XTAL

12.0000MHz

Peripheral

BUS(DMA)

8bit ADBUS

IC1

OA982

X1 XTAL

20.3094MHz

2. Pin arrangement

The table below shows connector pin arrangement between the MCU to IMC2 PWB.

• IMC2 side

Interface-1 CN2 (22FE-BT-VK-N)

Pin

No.

Signal

name

Processing of

connection

Pattern = “direct”

Pin

No.

Signal

name

Processing of

connection

Pattern = “direct”

1 DGND (MCU 3 IMC) 12 PI_DATA2 MCU 3 IMC

MCU 13 PI_DATA1 MCU 3 IMC

2ESCMD IMC

3 /ESCRDY MCU

4 PI_WR MCU

5 PI_ACK MCU

6PI_REQ IMC

7 PI_DATA7 MCU

8 PI_DATA6 MCU

9 PI_DATA5 MCU

10 PI_DATA4 MCU

11 PI_DATA3 MCU

3

IMC 14 PI_DATA0 MCU 3 IMC

3

IMC 15 /HSYNC MCU 3 IMC

3

IMC 16 /ESPAGE IMC 3 MCU

3

MCU 17 /PRLINE MCU 3 IMC

3

IMC 18 /RESET MCU 3 IMC

3

IMC 19 3.3V (MCU 3 IMC)

3

IMC 20 3.3V (MCU 3 IMC)

3

IMC 21 DGND (MCU 3 IMC)

3

IMC 22 DGND (MCU 3 IMC)

3

Interface-2 CN3 (22FE-BT-VK-N)

Pin

No.

1 DGND (MCU 3 IMC) 12

2 ESSTS MCU

3 /ESSRDY IMC

4 (PO_CS) NOT USE 15 /READY MCU

5PO_ACK IMC

6 PO_REQ MCU

7

8

9

10

11

IC2

8Mbit

FlashROM

SDRAM CLK 81.2376MHz

Signal

name

PO_DATA7

PO_DATA6

PO_DATA5

PO_DATA4

PO_DATA3

Pattern = “direct”

IMC 3 MCU 18 5V (MCU 3 IMC)

IMC 3 MCU 19 3.3V (MCU 3 IMC)

IMC 3 MCU 20 3.3V (MCU 3 IMC)

IMC 3 MCU 21 DGND (MCU 3 IMC)

IMC 3 MCU 22 DGND (MCU 3 IMC)

IC3

256Mbit SDRAM

IC4

256Mbit SDRAM

Pixel Output BUS (8bit DMA)

Pixel Input BUS (8bit DMA)

3.3V

Processing of

connection

Pin

No.

Signal

name

PO_DATA2

IMC 13

3

MCU 14

3

MCU 16 /SCLINE MCU 3 IMC

3

IMC 17 /ESDET IMC (GND)

3

PO_DATA1

PO_DATA0

2pinFFC (To MCU)

CN2 2

CN3 22pinFFC (To MCU)

Processing of

connection

Pattern = “direct”

IMC 3 MCU

IMC 3 MCU

IMC 3 MCU

IMC

3

MCU

3

AR-EB9 ELECTRICAL SECTION

– 6 –

Page 10

[5] USER PROGRAMS

1. Feature

With the AR-EB9, the following user settings can be made:

Special function

• Edge erase copy

• 2 in 1 copy

• 4 in 1 copy

• Card s hot

Copy setting (Key operator)

• Margin default

• Erase adjust

• Card s hot default

• Rotation copy

• Sort auto select

Device control (Key operator)

• Memory for printer

• USB2.0 mode

2. Driver Installation procedure

Note: When the driver for the AR-M205/M160 is already installed,

there is no need to install the driver.

A. USB joint maintenance program installation

The driver is installed by plug and play.

B. Installation procedure on Windows XP

1) Machine side:

Executable by performing the Service Simulation No. 49-01 (Flash

Rom program-writing mode).

(A word “Download mode.” appears on the operation panel to

denote the download mode status. )

2) Connect the machine and the PC with a USB cable.

(Be sure to connect the USB cab le to the main un it si de. C onnect ion t o

the optional dual fun ction board cannot e xecute t his funct ion. )

[6] FLASH ROM VERSION UP

PROCEDURE

1. Preparation

Write the download data (the file with the extension dwl) to the main

body of AR-M207/M162/M165.

Necessary files for download

• Maintenance.exe ( Maintenance software)

• ProcModelH.mdl

• ProcModelH.fmt

• ProcModelH.ini

Driver

• Drivers\2kXP\Mainte.inf (For XP/2000)

• Drivers\Win9xME\Mainte.inf (For ME/98)

• Drivers\Win9xME\UsbScan.s ys (For ME/98)

Download File

• Download F ile:***.dwl

<Note>

• When creating a folder for a maintenance tool in the PC, be sure that

no lengthy folder name is included in the path.

(Example)

Incorrect c:\Maintenance Download Tool

Correct c:\Maintenance\Downtool

3) Check that the following display is shown.

Select "Install from a list or the specific location" and press

the [NEXT] button.

4) Select "Include this location in the search". If the retrieval area does

not include the folder which includes the maintenance tool driver

(Mainte.inf), select "Browse".

If the folder path is properly shown, press the [NEXT] button to go to

procedure (7).

AR-EB9 USER PROGRAMS

– 7 –

Page 11

5) Select the folder which includes the maintenance tool driver

(Mainte.inf), and press the OK button. (When the driver is included

in the “C:\Maintenance Tool\Divers\2kxp” folder:)

6) Check that the path to the folder which includes the maintenance

tool driver (Mainte.inf) is shown, and press the [NEXT] button.

C. Installation procedure on Windows 2000

1) Machine side:

Executable by performing the Service Simulation No. 49-01 (Flash

Rom program-writing mode).

(A word “Download mode.” appears on the operation panel to

denote the download mode status. )

2) Connect the machine and the PC with a USB cable.

(Be sure to connect the USB cab le to the main un it si de. C onnect ion t o

the optional dual fun ction board cannot e xecute t his funct ion. )

3) Check that the new hardware search wizard is shown.

Press the [NEXT] button.

7) Check that the following display is shown. Press the Continue

Anyway button.

8) When installation is completed, the following display is shown.

Press the Finish button.

4) Select "Search for a suitable driver for my device" and press the

[NEXT] button.

5) Select "Specify a location" and press the [NEXT] button.

The installation procedure (on Windows XP) is completed with the

above operation.

AR-EB9 FLASH ROM VERSION UP PROCEDURE

– 8 –

Page 12

6) If the reference position is not the folder which includes the maintenance tool driver (Mainte.inf), select [Reference]. If the reference

position is the folder which includes the maintenance tool driver,

press [OK] button to go to procedure (9).

7) Specify the folder which includes the maintenance tool driver

(Mainte.inf), and press [Open] button.

8) Check to confirm that the path to the folder which includes the maintenance tool driver (Mainte.inf) is displayed, and press [OK] button.

(Supposing that the maintenance tool driver is included in the folder

of “C:\Maintenance Tool\Drivers\2kXp”.

10) When installation is completed, the following display is shown.

Press the Finish button.

11) When the indication is displayed to reboot the PC, press [YES] and

boot the PC.

The installation procedure of the joint maintenance program on

Windows 2000 is completed with the above operation.

3. Download procedure

1) Main body side:

Executable by performing the Service Simulation No. 49-01

(Flash Rom program-writing mode).

(A word “Download mode.” appears on the operation panel to

denote the download mode status. )

2) Connect the machine and the PC with a USB cable.

(Be sure to connect the USB cab le to the main un it si de. C onnect ion t o

the optional dual fun ction board cannot e xecute t his funct ion. )

9) Press the [NEXT] button, and installation is started.

3) PC side:

Boot "Maintenance.exe" and select [AR-M207/M162/M165 Series]

on the model selection menu.

<Sample display>

AR-EB9 FLASH ROM VERSION UP PROCEDURE

– 9 –

Page 13

4) PC side:

Check to confirm that "Simulation Command List" tree is displayed

on the integrated maintenance program.

8) PC side:

Specify the download file (*.dwl).

5) PC side:

If "The copier is off." is displayed on the left lower side after booting

the integrated maintenance program, select [File] and then [Reconnect] on the menu bar.

6) PC side:

Check to confirm that the tree is displayed on [Special (MCU/IMC2/

Panel/ Facsimile)] of the integrated maintenance program. If the

tree is not displayed, check that the USB is properly connected and

select [Reconnect] again in the previous procedure of (5).

9) PC side:

When the DWL data file is specified, the DWL data file is transferred

from the PC to the machine. Downl oading is proce eded aut omati cally.

10) PC side:

When the message below is displayed, download is completed.

Completion message:

Download is completed. Do not turn the copier power off until

“Processing finished. Turn off the p ower.” i s disp layed on t he copi er.

7) PC side:

Double click [Special (MCU//IMC2/Panel/ Facsimile)] on the main

tree items to extend the sub tree items, and select [DWL Data Area

Download].

AR-EB9 FLASH ROM VERSION UP PROCEDURE

NOTE (Important):

• Be sure that the power is not turned off and the USB cable is not

removed until the word "OFF" appears.

11) Main body side:

Wait until the word “Processing finished.Turn off the power.”

appears on the operation panel.

The appearance of “Processing finished.Turn off the power.”

indicates the completion of the download (writing into ROM).

Turn the power off and the USB cable can be removed at this point.

– 10 –

Page 14

12) Terminate the maintenance program, and turn on the power of the

main body.

NOTE:

• For making a second connection with another machine, se lect the

"File" and "Reconnect" in the menu bar on the maintenance program at the time of the USB being re-connec ted. Repe at the previous procedures from the above 5).

Forbidden actions while downloading (Important)

*

Failure in the download concerned may not allow you to conduct the

subsequent download procedures. Added care should be taken to

avoid having the situation below arise while downloading.

• Switching off the main body of AR-M207/M162.

• Disconnecting the download cable (USB cable).

If the above inhibit item occurs during downloading:

*

Turn OFF and ON the power.

1) If “Download mode.” (which means downloading) is displayed on

the operation panel of the machine, perform downloading again.

4. Version confirming procedure

1) Machine side:

Execute the service simulation No. 49-01 (Flash ROM program

writing mode).

(A word “Download mode.” appears on the operation panel to

denote the download mode status.)

2) Connect the main unit and the PC with a USB cable.

(Be sure to connect the USB cab le to the main un it si de. C onnect ion t o

the optional dual fun ction board cannot e xecute t his funct ion. )

3) PC side:

Boot "Maintenance.exe" and select [AR-M207/M162/M165 Series]

on the model selection menu.

4) PC side:

Check to confirm that "Simulation Command List" tree is displayed

on the integrated maintenance program.

2) If “Download mode.” (which means downloading) is not displayed

on the operation panel of the machine, turn OFF the power, and

press and hold the 4 key and the CA key and turn ON the power.

If, then, “Download mode.” (which means downloading) is

displayed on the operation panel LED of the machine, perform

downloading again. If “Download mode.” is still not displayed, the

MCU/Panel/IMC2/Fax must be replaced.

5) PC side:

If "The copier is off." is displayed on the left lower side after booting

the integrated maintenance program, select [File] and then

[Reconnect] on the menu bar.

AR-EB9 FLASH ROM VERSION UP PROCEDURE

– 11 –

Page 15

6) PC side:

Check to confirm that the tree is displayed on [Special (MCU/IMC2/

Panel/ Facsimile)] of the integrated maintenance program. If the

tree is not displayed, check that the USB is properly connected and

select [Reconnect] again in the previous procedure of (5).

7) PC side:

Double click [Special (MCU//IMC2/Panel/ Facsimile)] on the main tree

items to extend the sub tree items, and se lect [ Confi rm version] .

8) Check to confirm that the display below is indicated.

Version confirming is completed with the following procedures:

• In version confirming, "

**.**.**

" means that connection is not

made with the MCU PWB or that download is not performed.

(The above figure shows the case where the FAX PWB is not

installed.)

• When download is completed, the version number is displayed

such as the MCU boot version and the MCU program version.

• The CPM and the SD-RAM size are displayed when the MCU/

Panel PWB is installed and the boot section operates normally.

AR-EB9 FLASH ROM VERSION UP PROCEDURE

– 12 –

Page 16

B

B

B

C10

VDDQ

NM

_SDRAM_CKE

3943

VDDQ

VDDQ

CLK

CKE

37

B

C21

10U/16V

+

3.3V

C25

0.1U

K4S560832D

_SDRAM_DATA[15:0]

_SDRAM_DATA9

_SDRAM_DATA11

_SDRAM_DATA8

_SDRAM_DATA10

245781011

DQ0NCDQ1NCDQ2NCDQ3

A0A1A2A3A4A5A6A7A8A9A10

IC4

2324252629303132333422

_SDRAM_DATA15

_SDRAM_DATA14SDRAM_ADDR6

_SDRAM_DATA13

DQ4NCDQ5NCDQ6NCDQ7

BA0

BA1

A11

A12

20

21

35

36

C24

0.1U

C23

0.1U

C22

0.1U

11427

54

41

28

61246

52

VSS

VSS

VSS

VDD

VDD

VDD

VSSQ

VSSQ

VSSQ

VSSQ

NC

NC

NC

DQM

391938

NC

13

424445474850515315

40

D

D

D

D

C1

1/4

12345678

12345678

12345678

12345678

_SDRAM_DATA[15:0]

_SDRAM_DATA0

_SDRAM_DATA1

293133353840424430323436394143

IO0

IO1

IC2

A0A1A2A3A4A5A6A7A8A9A10

25242322212019

_SDRAM_DATA3

_SDRAM_DATA5

_SDRAM_DATA6

_SDRAM_DATA4

_SDRAM_DATA2

IO2

IO3

IO4

IO5

_SDRAM_DATA7

IO6

IO7

IO8

IO9

8765432

18

3.3V

IO10

IO11

IO12

A11

A12

R4

0J

SDRAM_ADDR[12:0]

TP894 TP

SDRAM_ADDR0

45

IO13

IO14

IO15/A-1

A13

A14

A15

A16

A17

A18NCWE

1

481716131112472628

NM

C2

0.1U

3.3V

VCC

CEOERY/BY

A19

A20

15910

C

C

C

C

274637

GND

GND

RESET

BYTE

WP/ACC

14

MBM29LV160B-90PFTN or LH28F800BJE-PBTL90

_SDRAM_DATA2

_SDRAM_DATA1

_SDRAM_DATA4

_SDRAM_DATA3

_SDRAM_DATA0

245781011

DQ0NCDQ1NCDQ2NCDQ3

A0A1A2A3A4A5A6A7A8A9A10

IC3

2324252629303132333422

_SDRAM_DATA7

_SDRAM_DATA5

_SDRAM_DATA6

DQ4NCDQ5NCDQ6NCDQ7

C9

NM

_SDRAM_CS0_L

3.3V

49

VDDQ

RAS

BA0

BA1

A11

CS

WE

CAS

A12

181617

20

21

35

36

A

C45

10U/16V

+

3.3V

C49

0.1U

C48

0.1U

C47

0.1U

C46

0.1U

3.3V

54

41

28

11427

3943

49

VDDQ

VDDQ

VDDQ

RAS

CS

WE

CAS

CLK

181617

61246

52

VSS

VSS

VSS

VDD

VDD

VDD

VSSQ

VSSQ

VSSQ

VSSQ

VDDQ

NC

NC

NC

DQM

CKE

13

424445474850515315

391938

37

40

21

21

21

21

K4S560832D

NC

_SDRAM_DATA[15:0]

TP885 TP

_SDRAM_DATA0

123

BR1 10JX4

TP2 SDRAM_DATA0

SDRAM_DATA0

74

IC1

119

SDRAM_ADDR[12:0]

TP886 TP

_SDRAM_DATA4

_SDRAM_DATA6

_SDRAM_DATA5

_SDRAM_DATA2

_SDRAM_DATA7

_SDRAM_DATA3

_SDRAM_DATA1

678

678

4 5

123

BR2 10JX4

TP12 SDRAM_DATA5

TP16 SDRAM_DATA7

TP4 SDRAM_DATA1

TP10 SDRAM_DATA4

TP8 SDRAM_DATA3

TP6 SDRAM_DATA2

TP14 SDRAM_DATA6

SDRAM_DATA3

SDRAM_DATA7

SDRAM_DATA5

SDRAM_DATA6

SDRAM_DATA4

SDRAM_DATA1

SDRAM_DATA2

SDRAM_DATA6

SDRAM_DATA5

SDRAM_DATA4

SDRAM_DATA3

SDRAM_DATA2

SDRAM_DATA1

SDRAM_DATA0

PI_LINE_SYNC/GP_D6

PI_TR_TGEN

PI_TGEN6

PI_TGEN5

PI_TGEN4

PI_TGEN3

PI_TGEN2

120

124

125

126

127

128

SDRAM_ADDR1

SDRAM_ADDR2

TP887 TP

_SDRAM_DATA8

_SDRAM_DATA10

_SDRAM_DATA9

678

123

4 5

BR3 10JX4

TP20 SDRAM_DATA9

TP22 SDRAM_DATA10

TP18 SDRAM_DATA8

SDRAM_DATA8

SDRAM_DATA9

SDRAM_DATA10

SDRAM_DATA9

SDRAM_DATA8

SDRAM_DATA7

SDRAM_DATA10

PI_TGEN1

PI_TGEN0

PI_DATA7

PI_DATA6

129

131

132

133

SDRAM_ADDR3

SDRAM_ADDR7

SDRAM_ADDR6

SDRAM_ADDR5

SDRAM_ADDR4

TP888 TP

_SDRAM_DATA12

_SDRAM_DATA11

_SDRAM_DATA13

_SDRAM_DATA14

_SDRAM_DATA15

678

4 5

123

4 5

BR4 10JX4

TP28 SDRAM_DATA13

TP26 SDRAM_DATA12

TP30 SDRAM_DATA14

TP32 SDRAM_DATA15

TP24 SDRAM_DATA11

SDRAM_DATA11

SDRAM_DATA15

SDRAM_DATA13

SDRAM_DATA14

SDRAM_DATA12

535556575860616263656667687273

SDRAM_DATA15

SDRAM_DATA14

SDRAM_DATA13

SDRAM_DATA12

SDRAM_DATA11

PI_DATA5

PI_DATA4

PI_DATA3

PI_DATA2

PI_DATA1

134

135

137

138

141

SDRAM_ADDR11

SDRAM_ADDR10

SDRAM_ADDR9

SDRAM_BANK0

SDRAM_ADDR8

SDRAM_ADDR12

SDRAM_BANK[1:0]

_SDRAM_DQMA0

_SDRAM_DQMB1

_SDRAM_DQMB0

_SDRAM_DQMA1

TP889 TP

_SDRAM_DQMB1

_SDRAM_DQMA1

_SDRAM_DQMB0

_SDRAM_DQMA0

678

123

4 5

BR5 10JX4

TP40 SDRAM_DQMB1

TP34 SDRAM_DQMA0

TP38 SDRAM_DQMA1

TP36 SDRAM_DQMB0

SDRAM_DQMB1

SDRAM_DQMB0

SDRAM_DQMA0

SDRAM_DQMA1

105

106

107

109

SDRAM_DQMB1

SDRAM_DQMA1

SDRAM_DQMB0

SDRAM_DQMA0

PP_HIDRIVE/USART1_RX

PP_DRIVE/USART1_TX

PP_NINIT

PI_DATA0

143

145

146

142

SDRAM_BANK1

SDRAM_RAS_L

SDRAM_CAS_L

SDRAM_WE_L

_SDRAM_DATA[15:0]

_SDRAM_CS1A_L

_SDRAM_CS1B_L

_SDRAM_CS0_L

TP891 TP

TP892 TP

TP890 TP

_SDRAM_CS0_L

_SDRAM_CS1A_L

_SDRAM_CS1B_L

ROM_CS_L

R3 10J

R1 10J

R2 10J

TP49 ROM_CS_L

TP43 SDRAM_CS0_L

TP47 SDRAM_CS1B_L

TP45 SDRAM_CS1A_L

SDRAM_CS0_L

SDRAM_CS1B_L

SDRAM_CS1A_L

77

102

104

SDRAM_CS0_L

SDRAM_CS1A_L

SDRAM_CS1B_L

PP_NFAULT

PP_NSELECTIN

PP_NAUTOFD

PP_SELECT

147

151

152

153

_SDRAM_DQMB1

_SDRAM_DQMB0

_SDRAM_DATA8

_SDRAM_DATA9

3.3V

ROM_CS_L

SDRAM_WE_L

SDRAM_CAS_L

TP54 SDRAM_CAS_L

TP52 SDRAM_WE_L

TP56 SDRAM_RAS_L

SDRAM_WE_L

SDRAM_RAS_L

SDRAM_CAS_L

75

110

111

ROM_CS_L

SDRAM_WE_L

SDRAM_CAS_L

PP_PERROR

PP_BUSY

PP_NACK

PP_DATA7

154

155

156

157

ROM_CS_L

_SDRAM_DQMA1

_SDRAM_DQMA0

10KJ

R417

SDRAM_ADDR[12:0]

SDRAM_RAS_L

TP65 SDRAM_ADDR3

TP63 SDRAM_ADDR2

TP61 SDRAM_ADDR1

TP59 SDRAM_ADDR0

SDRAM_ADDR3

SDRAM_ADDR0

SDRAM_ADDR2

SDRAM_ADDR1

101

SDRAM_RAS_L

SDRAM_ADDR3

SDRAM_ADDR2

SDRAM_ADDR1

SDRAM_ADDR0

PP_DATA6

PP_DATA5

PP_DATA4

PP_DATA3

PP_DATA2

PP_DATA1/USART1_CK

159

160

161

162

163

165

3.3V

RY_BY

TP69 SDRAM_ADDR5

TP67 SDRAM_ADDR4

TP70 SDRAM_ADDR6

TP72 SDRAM_ADDR7

SDRAM_ADDR7

SDRAM_ADDR6

SDRAM_ADDR5

SDRAM_ADDR4

SDRAM_ADDR7

SDRAM_ADDR6

SDRAM_ADDR5

SDRAM_ADDR4

BASE_CLK/GP_PWM1

PP_DATA0

PP_NSTROBE

168

166

167

TP893 TP

R5

4.7KJ

TP883

CLK

TP81 SDRAM_ADDR12

TP76 SDRAM_ADDR9

TP74 SDRAM_ADDR8

TP77 SDRAM_ADDR10

TP79 SDRAM_ADDR11

SDRAM_ADDR8

SDRAM_ADDR11

SDRAM_ADDR9

SDRAM_ADDR10

SDRAM_ADDR12

80

SDRAM_ADDR9

SDRAM_ADDR8

SDRAM_ADDR12

SDRAM_ADDR11

SDRAM_ADDR10

REG_A9/PB_NCS1

REG_A8/PB_NCS2

MAIN_CLK/GP_PWM0

CLK_EXT/GP_PWM2

178

180

170

169

*change-1(2003.3.17)

RESET_L

_SDRAM_CLK

_SDRAM_CKE

_SDRAM_CLK

_SDRAM_CKE

TP884

CKE

SDRAM_BANK[1:0]

R9 10J

R8 10J

TP89 SDRAM_CLK

TP86 SDRAM_BANK1

TP84 SDRAM_BANK0

TP91 SDRAM_CKE

SDRAM_CKE

SDRAM_BANK0

SDRAM_BANK1

SDRAM_CLK

78

7982838485899091929495969799100

SDRAM_CLK

SDRAM_CKE

SDRAM_BANK1

SDRAM_BANK0

REG_AD2/PB_DATA2

REG_AD3/PB_DATA3

REG_AD4/PB_DATA4

REG_AD5/PB_DATA5

REG_AD6/PB_DATA6

REG_AD7/PB_DATA7

187

186

185

183

182

181

R10 4.7KJ

3.3V

R11

+

TP881

VDD7

7

PLLCS_VDDA

REG_AD0/PB_DATA0

REG_AD1/PB_DATA1

REG_ADDR_VALID/PB_NCS0

REG_RD_L/PB_NCS3

REG_WR_L/PB_NAE0

REG_CS_L/PB_NAE1

REG_RDY/PB_NWE

189

188

190

194

195

196

197

SDRAM_ADDR1

SDRAM_ADDR0

SDRAM_ADDR2

SDRAM_ADDR[12:0] _SDRAM_DATA[15:0]

1J

C3

47U/16V

TP882

VDD149

C5

1U

C4

0.01U

6

PLLCS_VSSA

GP_C0/PB_ADDR0

GP_C1/PB_ADDR1

GP_C2/PB_ADDR2

GP_C3/PB_ADDR3

INTERRUPT_L/PB_NOE

199

201

202

203

204

198

SDRAM_ADDR7

SDRAM_ADDR6

SDRAM_ADDR5

SDRAM_ADDR3

SDRAM_ADDR4

R14

+

149

PLLSS_VDDA

GP_C4/PB_ADDR4

GP_C5/PB_ADDR5

GP_C6/PB_ADDR6

GP_C7/PB_ADDR7

GP_B0/USART0_TX

128

205

207

208

SDRAM_ADDR9

SDRAM_ADDR10

SDRAM_ADDR11

SDRAM_ADDR12

SDRAM_ADDR8

SDRAM_BANK[1:0]

1J

C6

47U/16V

C8

1U

C7

0.01U

148

PLLSS_VSSA

GP_B1/USART0_RX

GP_B2/USART0_CK

GP_B3/ANA_SD1

GP_B4/DT_ACKB

GP_B5/DT_REQB

9

11121314151619

SDRAM_BANK0

SDRAM_BANK1

_SDRAM_CS0_L

3.3V

VDD_IO

VDD_IO

GP_B6/DT_ACKA

GP_B7/DT_REQA

GP_D0/ADC_A0

SDRAM_RAS_L

SDRAM_CAS_L

SDRAM_WE_L

25

VDD_IO

VDD_IO

VDD_IO

GP_D1/ADC_A1

GP_D2/ADC_A2

GP_D3/ADC_CLK

21

22

_SDRAM_CLK

_SDRAM_DQMA0

_SDRAM_CKE

_SDRAM_CLK

+

3.3V

115

103

VDD_IO

VDD_IO

VDD_IO

VDD_IO

VDD_IO

VDD_IO

GP_D4/ADC_DATA

GP_D5/ADC_NCS

GP_A1

GP_A2/DC_CHY1

GP_A0

26282930313224

23

C11

10U/16V

C20

0.1U

C19

0.1U

C18

0.1U

C17

0.1U

C16

0.1U

C15

0.1U

C14

0.1U

C13

0.1U

C12

0.1U

144

130

VDD_IO

VDD_IO

VDD_IO

VDD_IO

GP_A3/DC_CHX1

GP_A4/DC_PWM1

GP_A5/DC_CHY0

GP_A6/DC_CHX0

34

+

3.3V

VDD_IO

TP135

3.3V

12293888170713659184620033184201713158

VDD_IO

VDD_IO

VDD_CORE

VDD_CORE

VDD_CORE

VDD_CORE

VDD_CORE

GP_A7/DC_PWM0

PO_LINE_SYNC/ANA_SCLK

PO_PAGE_SYNC/ANA_NCS

PO_REQ/ANA_SD0

PO_ACK/PDATA0/PDS0

PO_DONE/PDATA2/PDS2

PO_WR/PDATA1/PDS1

PO_DATA7/LHEAT/PAS_M

PO_DATA6/LCTRL/CFIRE2

37383940424344454748495051

SDRAM_ADDR[12:0]

C26

10U/16V

C34

0.1U

C33

0.1U

C32

0.1U

C31

0.1U

C30

0.1U

C29

0.1U

C28

0.1U

C27

0.1U

TP147

27

10

192

174

140

VSS_IO

VSS_IO

VDD_CORE

VDD_CORE

VDD_CORE

USB_DM

PO_DATA5/AGATE/CFIRE1

PO_DATA4/ACLK/MFIRE2

PO_DATA3/PENABLE/MFIRE1

PO_DATA2/PLOAD

PO_DATA1/PCLK

PO_DATA0/PDATA3/PAS_C

52

175

SDRAM_ADDR0

SDRAM_ADDR2

SDRAM_ADDR3

SDRAM_ADDR1

3.3V

VDD_CORE

VSS_IO

VSS_IO

VSS_IO

VSS_IO

USB_DP

176

SDRAM_ADDR7

SDRAM_ADDR8

SDRAM_ADDR4 _SDRAM_DATA12

SDRAM_ADDR5

C35

10U/16V

+

C43

0.1U

C42

0.1U

C41

0.1U

C40

0.1U

C39

0.1U

C38

0.1U

C37

0.1U

C36

0.1U

136

123

1086998358617766454

VSS_IO

VSS_IO

VSS_IO

VSS_IO

RESET_L

112

113

SDRAM_ADDR12

SDRAM_ADDR9

SDRAM_ADDR11

SDRAM_ADDR10

150

179

164

VSS_IO

VSS_IO

VSS_IO

VSS_IO

TCK

TMS

TDI

TDO

114

116

117

_SDRAM_CS0_L

SDRAM_BANK1

SDRAM_CAS_L

SDRAM_BANK0

SDRAM_WE_L

SDRAM_BANK[1:0]

20641193

VSS_IO

VSS_IO

VSS_CORE

TEST_MODE1

TRST_L

TEST_MODE0

172

177

118

_SDRAM_CLK

SDRAM_RAS_L

CLK_EXT_OUT

TP156

R19

CLK_EXT

CLK_EXT

121

87

VSS_CORE

VSS_CORE

VSS_CORE

_SDRAM_CKE

_SDRAM_DQMA1

_SDRAM_CLK

4.7KJ

191

173

139

VSS_CORE

VSS_CORE

VSS_CORE

VSS_CORE

XIN

XOUT

5

4

OA-982

X2

3.3V

1

2

GND

/CONT

OUT

VDD

3

4

SG8002JC (20or56MHz)

22000P(NM)

C53

0.1U(NM)

C52

12P(NM)

C51

3

3

3

3

TP7 PI_WR

TP5 PI_TGEN6

TP1 PI_LINE_SYNC

TP3 PI_TGEN7

1. IMC2 PWB

[7] CIRCUIT DIAGRAM

PI_WR

D

D

D

D

TP11 PI_ACK

TP9 PI_TGEN4

PI_ACK

TP13 PI_REQ

TP15 PI_TGEN1

PI_REQ

TP19 PI_DATA7

TP17 PI_TGEN0

TP21 PI_DATA6

PI_DATA6

PI_DATA7

TP23 PI_DATA5

TP25 PI_DATA4

PI_DATA5

TP27 PI_DATA3

PI_DATA4

PI_DATA3

TP29 PI_DATA2

TP31 PI_DATA1

PI_DATA2

TP33 PI_DATA0

PI_DATA0

PI_DATA1

TP35 PP_HIDRIVE

TP37 PP_DRIVE

TP39 PP_NINIT

RY_BY

USART1_ TX

USART1_RX

TP51 PP_NACK

TP46 PP_SELECT

TP42 PP_NSELECTIN

TP50 PP_BUSY

TP44 PP_NAUTOFD

TP48 PP_PERROR

TP41 PP_NFAULT

USB_FUNC

CN11

3.3V

UART-1 (TP or Connector)

TP53 PP_DATA7

123

TP55 PP_DATA6

USART1_RX

USART1_TX

TP57 PP_DATA5

TP58 PP_DATA4

4

TP66 PP_DATA0

TP64 PP_DATA1

TP62 PP_DATA2

TP60 PP_DATA3

B4B-PH-K-S(NM)

TP71 BASE_CLK

TP73 CLK_EXT

TP68 PP_NSTROBE

BASE_CLK

TP75 MAIN_CLK

CLK_EXT

TP80 PB_NCS2

TP78 PB_NCS1

TP83 PB_DATA6

TP97 PB_NAE1

TP95 PB_NCS3

TP92 PB_DATA1

TP85 PB_DATA5

TP82 PB_DATA7

TP93 PB_DATA0

TP96 PB_NAE0

TP94 PB_NCS0

TP90 PB_DATA2

TP98 PB_ NWE

TP87 PB_DATA4

TP88 PB_DATA3

PB_DATA3

PB_DATA7

PB_DATA0

PB_DATA1

PB_DATA4

PB_DATA5

PB_DATA6

PB_DATA2

PB_NAE0

PB_NWE

PB_NCS3

PB_DATA[7:0]

C

C

C

C

AR-EB9 CIRCUIT DIAGRAM

TP99 PB_NOE

PB_NOE

TP101 PB_ADDR1

TP100 PB_ADDR0

TP102 PB_ADDR2

PB_ADDR1

PB_ADDR0

PB_ADDR2

PB_ADDR[7:0]

TP106 PB_ADDR6

TP103 PB_ADDR3

TP104 PB_ADDR4

TP105 PB_ADDR5

PB_ADDR4

PB_ADDR5

PB_ADDR3

PB_ADDR6

– 13 –

TP107 PB_ADDR7

PB_ADDR7

TP109 USART0_RX

TP108 USART0_TX

ESCMD

TP110 USART0_CK

TP111 GP_B3

ESSTS

TP113 DT_REQB

TP112 DT_ACKB

DT_ACKB

TP114 DT_ACKA

DT_REQB

TP115 DT_REQA

TP116 GP_D0

TP117 GP_D1

/ESPAGE

/ESCRDY

TP118 GP_D2

TP119 GP_D3

/ESSRDY

WAKEUP

USBVBUS

TP120 GP_D4

USB_DM

USB_DP

TP145

TP127 GP_A5

INT_USBD

TP128 GP_A6

TP129 GP_A7

/PRLINE

R402

C400

B

B

B

B

TP131 PO_PAGE_SYNC

TP132 PO_REQ

TP130 /HSYNC

/HSYNC

4.7KJ

NC

TP133 PO_ACK

PO_REQ

TP134 PO_DONE

PO_ACK

TP137 PO_DATA7

TP136 PO_WR

TP139 PO_DATA5

TP138 PO_DATA6

PO_DATA6

PO_DATA7

TP140 PO_DATA4

TP141 PO_DATA3

PO_DATA4

PO_DATA5

TP142 PO_DATA2

TP143 PO_DATA1

PO_DATA3

PO_DATA2

TP144 /PCLPRD

PO_DATA0

PO_DATA1

TP146

TP126 GP_A4

TP123 GP_A1

TP125 GP_A3

TP121 GP_D5

TP124 GP_A2

TP122 GP_A0

/SCLINE

/READY

SCL

SDA

SUSPEND

R401

3.9KJ

TP148 RESET_L

TP149 TDO

RESET_L

TP152 TDI

TP151 TMS

TP153 TRST_L

TP150 TCK

TMS

TCK

TDO

TDI

TRST_L

JTAGSCAN0

JTAGSCAN1

TP157

TP955

TP

TP155 TEST_MODE1

TP154 TEST_MODE0

R17 4.7KJ

R18 4.7KJ

XIN

X1

C44

XOUT

XIN

R20 0J

20.3094MHz

12P

A A

A A

A A

A

BASE_CLK

TP880

XOUT

C50

12P

87654

87654

87654

87654

Page 17

C70

C80

C79

C78

C77

C76

C75

C74

C73

C72

C71

157

168

VCC

VCC

CB6

CB7

136

137

TP232 NC

+

47U/16V

0.1U

0.1U

0.1U

0.1U

0.1U

0.1U

0.1U

0.1U

0.1U

0.1U

+

C69

112233243546468788596

47U/16V

VSS

VSS

NCNCNCNCNCNCNC

24253144485051

TP237 NC

TP234 NC

TP233 NC

TP236 NC

TP235 NC

A

107

116

127

138

148

152

162

21

21

21

VSS

VSS

VSS

VSS

VSS

VSS

VSS

VSS

VSS

VSS

VSS

VSS

VSS

NCNCNC

NC

NC

NCNCNC

NCNCNC

616280

108

109

132

134

135

145

146

TP239 NC

TP240 NC

TP242 NC

TP244 NC

TP245 NC

TP246 NC

TP247 NC

TP241 NC

TP249 NC

TP248 NC

TP243 NC

TP238 NC

21

VSS

VSS

VSS

NC

147

164

DIMM168pinConnector MO-161

TP250 NC

TP251 NC

3

3

3

3

B

B

B

JTAGSCAN0

JTAGSCAN1

EPSONTEST

EPSONINP1

8

1012141618

USB_FUNC

20

B20B-PHDSS-B

19

C

C

C

C

A_SDRAM_ADDR[12:0]

A_SDRAM_BANK[1:0]

A_SDRAM_BANK1

A_SDRAM_BANK0

A_SDRAM_ADDR10

A_SDRAM_ADDR9

A_SDRAM_ADDR11

A_SDRAM_ADDR12

126

A10

A11

A12

BA1

BA0

CN6

DQ58

DQ59

DQ60

DQ61

DQ62

DQ63

155

156

158

159

160

161

A_SDRAM_DATA14

A_SDRAM_DATA15

A_SDRAM_DATA10

A_SDRAM_DATA9

A_SDRAM_DATA13

A_SDRAM_DATA11

A_SDRAM_DATA12

A_SDRAM_DATA[15:0]

A_SDRAM_ADDR8

A_SDRAM_ADDR6

A_SDRAM_ADDR7

A_SDRAM_ADDR5

A_SDRAM_ADDR4

A9

DQ53

DQ54

DQ55

DQ56

DQ57

144

149

150

151

153

154

A_SDRAM_DATA6

A_SDRAM_DATA8

A_SDRAM_DATA5

A_SDRAM_DATA4

A_SDRAM_DATA7

A_SDRAM_RAS_L

A_SDRAM_RAS_L

A_SDRAM_ADDR3

A_SDRAM_ADDR0

A_SDRAM_ADDR2

A_SDRAM_ADDR1

33

117341183511936120371213812339122

115271113011445129

A0A1A2A3A4A5A6A7A8

/RAS

DQ46

DQ47

DQ48

DQ49

DQ50

DQ51

DQ52

103

104

139

140

141

142

A_SDRAM_DATA2

A_SDRAM_DATA3

A_SDRAM_DATA0

A_SDRAM_DATA1

A_SDRAM_DATA0

A_SDRAM_DATA1

TP208 /CS3

TP209 /CS1

A_SDRAM_WE_L

A_SDRAM_CAS_L

A_SDRAM_CS1B_L

A_SDRAM_CAS_L

A_SDRAM_WE_L

A_SDRAM_CS1B_L

/WE

/CS2

/CS3

/CAS

DQ40

DQ41

DQ42

DQ43

DQ44

DQ45

100

101

A_SDRAM_DATA6

A_SDRAM_DATA8

A_SDRAM_DATA3

A_SDRAM_DATA2

A_SDRAM_DATA5

A_SDRAM_DATA4

A_SDRAM_DATA7

A_SDRAM_CS1A_L

A_SDRAM_DQMB1

A_SDRAM_CS1A_L

/CS0

/CS1

DQ36

DQ37

DQ38

DQ39

A_SDRAM_DATA12

A_SDRAM_DATA11

A_SDRAM_DATA10

A_SDRAM_DATA9

D

D

D

D

R419

10KJ

C59

C58

3.3V 3.3V

0.01U

0.01U

RESET_L

R48 0J

/RESET

TP193

TP957

TP

C60

R41 68J

R52

10KJ(NM)

PST597KNR(NM)

IC5

3.3V

3.3V

100P

R64

RESET_IC_OUT

45

VoutVcc

M/RSUBGND

C63

NM

NM

MACHINESET

ONLY

0.1U(NM)

1 2 3

C61

0.1U(NM)

246

CN1

1357911131517

2/4

12345678

12345678

12345678

12345678

3.3V

R26 10KJ

R25 10KJ

R24 10KJ

R23 NM

R22 10KJ

R21 10KJ

TDO

TCK

TRST_L

TMS

TDI

TP166

TP161

TP164

TP162

TP163

678

123

4 5

BR11 33JX4

TCK

TDI

TMS

TDO

TRST_L

3.3V

A_SDRAM_DQMB1

A_SDRAM_DQMB0

A_SDRAM_DQMA0

A_SDRAM_DQMA0

A_SDRAM_DQMB0

113

130

131

DQMB2

DQMB3

DQMB4

DQMB5

DQMB6

DQMB7

DQ30

DQ31

DQ32

DQ33

DQ34

DQ35

A_SDRAM_DATA15

A_SDRAM_DATA14

A_SDRAM_DATA13

A_SDRAM_DATA14

A_SDRAM_DATA15

A_SDRAM_DATA13

B

SDA

10KJ

R420

SCL

A_SDRAM_DQMA1

A_SDRAM_DQMA1

_SDRAM_CLK_3

_SDRAM_CLK_2

_SDRAM_CLK_1

28294647112

42

1257916363128838281167

CK1

CK2

CK3

DQMB0

DQMB1

DQ23

DQ24

DQ25

DQ26

DQ27

DQ28

DQ29

A_SDRAM_DATA7

A_SDRAM_DATA9

A_SDRAM_DATA6

A_SDRAM_DATA11

A_SDRAM_DATA8

A_SDRAM_DATA10

A_SDRAM_DATA12

R71 0J

_SDRAM_CKE

_SDRAM_CLK_0

_SDRAM_CKE

CK0

CKE1

CKE0

DQ17

DQ18

DQ19

DQ20

DQ21

DQ22

A_SDRAM_DATA3

A_SDRAM_DATA2

A_SDRAM_DATA5

A_SDRAM_DATA4

A_SDRAM_DATA0

A_SDRAM_DATA1

3.3V

TP212 NC

TP210 NC

TP211 NC

R78 10KJ(NM)

R76 10KJ(NM)

R74 10KJ(NM)

166

165

WP

SA2

SA1

SA0

SCL

SDA

DQ10

DQ11

DQ12

DQ13

DQ14

DQ15

DQ16

A_SDRAM_DATA1

A_SDRAM_DATA0

A_SDRAM_DATA4

A_SDRAM_DATA5

A_SDRAM_DATA2

A_SDRAM_DATA3

A_SDRAM_DATA6

0J

0J

0J

3.3V

6182640414959738490102

VCC

VCC

VCC

VCC

DQ3

DQ4

DQ5

DQ6

DQ7

DQ8

DQ9

10111314151617192055565758606566676970717274757677868788899192939495979899

A_SDRAM_DATA10

A_SDRAM_DATA13

A_SDRAM_DATA12

A_SDRAM_DATA8

A_SDRAM_DATA11

A_SDRAM_DATA7

A_SDRAM_DATA9

R85

R84

R83

VCC

VCC

VCC

VCC

VCC

VCC

VCC

DQ0

DQ1

DQ2

CB0

CB1

2345789

21

22

TP222 NC

TP219 NC

A_SDRAM_DATA15

A_SDRAM_DATA14

110

124

133

143

VCC

VCC

VCC

VCC

CB2

CB3

CB4

CB5

52

53

105

106

TP226 NC

TP229 NC

TP225 NC

TP230 NC

TP227 NC

DEBUG ONLY

PO_DATA2

/READY

PO_DATA0

PO_DATA1

3.3V3.3V

C57

0.1U

R409

10KJ

R407

TP160

NM

C56

47U/16V

5V

NM

C55

0.1U

47U/16V

10KJ

R408

10KJ

R410

10KJ

R414

10KJ

R412

10KJ

R411

10KJ

R413

10KJ

TP159 3.3V

5V

3.3V

R28

R27

3.3V

TP158 3.3V

C54

/SCLINE

R36 0J

R32 0J

R34 0J

R40 0J

R38 0J

/ESDET

PO_DATA1

PO_DATA0

PO_DATA2

/SCLINE

/READY

TP176

TP170

TP172

TP168

TP174

TP178

22

CN3

CN2

/ESPAGE

/RESET

/PRLINE C62

/HSYNC

PI_DATA0

PI_DATA1

PI_DATA2

TP167

TP173

TP175

TP177

TP169

TP165

TP171

R30 0J

R39 0J

R31 0J

R29 0J

R33 0J

R35 0J

R37 0J

PO_DATA3

PO_DATA4

R47 0J

R45 0J

R43 0J

PO_DATA3

PO_DATA4

PO_DATA5

TP180

TP182

TP184

10111213141516171819202122

PI_DATA3

PI_DATA4

PI_DATA5

TP183

TP179

TP181

R46 0J

R42 0J

R44 0J

PO_DATA5

PO_DATA7

PO_DATA6

R56 10J

R54 0J

R51 0J

PO_REQ

PO_DATA6

PO_DATA7

TP186

TP192

TP190

PI_REQ

PI_DATA6

PI_DATA7

TP191

TP189

TP185

R50 0J

R53 0J

R55 0J

PO_REQ

PO_ACK

R58 0J

(PO_CS)

PO_ACK

TP197

TP195

PI_WR

PI_ACK

TP196

TP194

R59 10J

R57 10J

ESSTS

/ESSRDY

R63 10J

R61 0J

S

ESST

/ESSRDY

TP199

TP201

ESCMD

/ESCRDY

TP200

TP198

R62 0J

R60 10J

123456789101112131415161718192021

123456789

C402

68P

C401

68P

22FE-BT-VK-N

From For DC2-BUS

Connector

22FE-BT-VK-N

C404

C403

68P

_SDRAM_CLK_2

_SDRAM_CLK_0

_SDRAM_CLK_3

R65 0J

R67 0J

R69 0J

C66

39PF

C65

2200P

TP897 TP

TP898 TP

TP899 TP

C64

CLK4

CLKOUT

REF

CLK2

123

TP896 TP

TP895 TP

R66 0J

_SDRAM_CLK

_SDRAM_CLK

_SDRAM_CLK_1

C405

68P

0.1U

678

VDD

CY2305

CLK1

GND CLK3

4 5

CLK1

TP207

R70 0J

_SDRAM_CLK_0

87654

87654

87654

87654

3.3V

IC6

68P

PI_DATA2

PI_DATA3

PI_DATA4

PI_DATA5

PI_DATA6

PI_DATA7

PI_REQ

PI_ACK

PI_WR

ESCMD

/ESCRDY

B

B

B

C

C

C

C

B

A A

A A

A A

A

/ESPAGE

PI_DATA1

PI_DATA0

/HSYNC

/PRLINE

/RESET

D

D

D

D

AR-EB9 CIRCUIT DIAGRAM

– 14 –

Page 18

B

B

B

B

A_SDRAM_BANK[1:0]

A_SDRAM_BANK0

4 5

3.3V3.3V

TP908 TP

235689111213141617192022

42

31

18

7

IC29

SDRAM_BANK0

A_SDRAM_ADDR[12:0]

SDRAM_BANK[1:0]

BD

A_SDRAM_CS1A_L

A_SDRAM_CS1B_L

A_SDRAM_CAS_L

A_SDRAM_RAS_L

A_SDRAM_WE_L

TP875

A_SDRAM_BANK1

BR403

0JX4

BR404

0JX4

1 8

2 7

3 6

1 8

2 7

3 6

4 5

TP909 TP

1Y1

1Y2

1Y3

1Y4

2Y1

2Y2

2Y3

2Y4

VCC

VCC

VCC

VCC

1A4

1A3

1A2

1A1

2A4

2A3

2A2

2A1

434446473738404132333536262729

SDRAM_BANK1

SDRAM_CAS_L

SDRAM_RAS_L

AD

TP868

SDRAM_WE_L

SDRAM_CAS_L

SDRAM_RAS_L

_SDRAM_CS1B_L

_SDRAM_CS1A_L

A_SDRAM_DQMB0

A_SDRAM_DQMB1

A_SDRAM_DQMA0

A_SDRAM_DQMA1

BR405

0JX4

1 8

2 7

3 6

4 5

TP910 TP

3Y1

3Y2

3Y3

3Y4

3A4

3A3

3A2

3A1

_SDRAM_DQMA1

_SDRAM_DQMB0

_SDRAM_DQMA0

_SDRAM_DQMB1

TP876

30

AD

BD

4Y1

4A1

TP869

TP877

AD

BD

BD

BD

TP879

TP878

C131

C130

23

4Y2

4Y3

4Y4

4A4

4A3

4A2

1OE

3OE

2OE

1

242548

AD

AD

OE

OE

TP870

TP871

TP872

TP873

A_SDRAM_DATA13

A_SDRAM_DATA14

A_SDRAM_DATA12

A_SDRAM_DATA10

A_SDRAM_DATA11

A_SDRAM_DATA9

BR38

0JX4

BR37

0JX4

2 7

3 6

4 5

1 8

2 7

3 6

TP

TP901

1B1

1B2

1B3

1B4

1B5

1B6

1B7

VCC

VCC

VCC

VCC

1A1

1A2

1A3

1A4

1A5

1A6

1A7

C

C

C

C

A_SDRAM_DATA8

A_SDRAM_DATA6

A_SDRAM_DATA5

A_SDRAM_DATA4

A_SDRAM_DATA7

BR36

0JX4

1 8

2 7

3 6

4 5

1 8

TP

TP902

12

13141617192022

2B1

2B2

2B3

1B8

1A8

2A1

2A2

2A3

37

36353332302927

A_SDRAM_DATA1

A_SDRAM_DATA2

A_SDRAM_DATA3

A_SDRAM_DATA0

BR42

0JX4

1 8

2 7

3 6

4 5

TP

TP903

23

2B4

2B5

2B6

2B7

2B8

2A4

2A5

2A6

2A7

2A8

26

1

1DIR

2DIR

244825

C125

C124

GND

GND

GND

GND

GND

GND

GND

GND

1OE

2OE

A_SDRAM_DATA[15:0]

0.1U

0.1U

45

39

34

28

21

15

10

4

74VCX16245

D

D

D

D

3/4

12345678

12345678

12345678

12345678

A_SDRAM_DATA14

A_SDRAM_DATA15

A_SDRAM_DATA13

BR39

10KJX4

1 8

2 7

3 6

3.3V

A_SDRAM_DATA11

A_SDRAM_DATA8

A_SDRAM_DATA12

A_SDRAM_DATA10

A_SDRAM_DATA9

BR43

10KJX4

1 8

2 7

3 6

4 5

4 5

A_SDRAM_DATA7

A_SDRAM_DATA4

A_SDRAM_DATA2

A_SDRAM_DATA5

A_SDRAM_DATA3

A_SDRAM_DATA6

BR40

BR41

10KJX4

1 8

2 7

1 8

2 7

3 6

4 5

A_SDRAM_DATA1

10KJX4

3 6

A_SDRAM_DATA0

4 5

A_SDRAM_DATA15

4 5

TP

TP900

23568911

42

31

18

7

47464443414038

IC26

4OE

TP874

GND

GND

GND

GND

GND

GND

GND

GND

0.1U

0.1U

45

39

34

28

21

15

10

4

74VCX16244

A

21

21

21

21

3

3

3

3

_SDRAM_CS1B_L_SDRAM_CLK

SDRAM_RAS_L

RESET_L

_SDRAM_DATA7

_SDRAM_DATA8

_SDRAM_DATA6

_SDRAM_DATA5

_SDRAM_DATA0

_SDRAM_DATA2

_SDRAM_DATA3

_SDRAM_DATA4

TP947

TP856

NA2_IN2

TP948

NA2_IN1

TP857

DIR

EPSONTEST

OE

TP953 USB_ALE

TP954 USB_CS

R418

USB_ALE

4.7KJ

USB_CS

PB_NCS3

PB_NAE0

TP865 BD

235689111213141617192022

42

31

18

7

IC28

TP860 AD

SDRAM_ADDR[12:0]

A_SDRAM_ADDR8

A_SDRAM_ADDR9

A_SDRAM_ADDR11

A_SDRAM_ADDR10

A_SDRAM_ADDR12

BR400

0JX4

1 8

2 7

3 6

4 5

R400 0J

TP867 BD

TP866 BD

TP904 TP

TP905 TP

1Y1

1Y2

1Y3

1Y4

2Y1

2Y2

2Y3

2Y4

VCC

VCC

VCC

VCC

1A4

1A3

1A2

1A1

2A4

2A3

2A2

2A1

434446473738404132333536262729

SDRAM_ADDR11

SDRAM_ADDR8

SDRAM_ADDR9

SDRAM_ADDR10

SDRAM_ADDR12

TP862 AD

TP861 AD

A_SDRAM_ADDR4

A_SDRAM_ADDR6

A_SDRAM_ADDR5

A_SDRAM_ADDR7

A_SDRAM_ADDR3

BR401

0JX4

1 8

2 7

3 6

4 5

4 5

TP906 TP

3Y1

3Y2

3Y3

3Y4

3A4

3A3

3A2

3A1

30

SDRAM_ADDR5

SDRAM_ADDR3

SDRAM_ADDR6

SDRAM_ADDR7

SDRAM_ADDR4

A_SDRAM_ADDR2

A_SDRAM_ADDR0

A_SDRAM_ADDR1

BR402

0JX4

1 8

2 7

3 6

TP907 TP

23

4Y1

4Y2

4Y3

4Y4

4A4

4A3

4A2

4A1

1OE

1

SDRAM_ADDR1

SDRAM_ADDR0

SDRAM_ADDR2

C129

0.1U

C128

0.1U

GND

45

GND

39

GND

34

GND

28

GND

21

GND

15

GND

10

GND

4

4OE

3OE

2OE

242548

74VCX16244

OE

OE

TP864

TP863

_SDRAM_DATA15

_SDRAM_DATA14

_SDRAM_DATA12

_SDRAM_DATA11

_SDRAM_DATA9

_SDRAM_DATA13

_SDRAM_DATA10

_SDRAM_DATA[15:0]

_SDRAM_CS1A_L

SDRAM_CAS_L

SDRAM_WE_L

EPSONINP1

VSS

VDD

INP0

_SDRAM_CLK

TEST_OUT1

VSS

NA1_IN1

TP951 TEST_OU T1

TP949 NA1_IN1

VDD

NA1_IN2

TP950 NA1_IN2

INP2

INP1

VDD

NA2_OUT

NA2_OUT

TP943

VSS

CAS_L

VSS

TEST_OUT2

TEST_OUT2

TP952

WE_L

VDD

3738394041424344454647

VDD

VSS

24

ASIC(RH-IX0026QSZZQ)

VSS

36

PB_NAE0

35

PB_NCS3

34

USB_CS

33

USB_ALE

32

TEST_IN

31

VDD

30

VSS

29

TSTEN

28

NA2_IN2

27

NA2_IN1

26

VDD

25

48

VSS

VDD

1

CS1A_L

RAS_L

2

CS1B_L

3

VSS

4

5

VSS

6

RESET_L

7

VDD

8

VSS

9

DIR

10

OE

11

VSS

12

VDD

NA1_OUT

1314151617181920212223

OE

DIR

IC35

NA1_OUT

TP942

DIR

OE

_SDRAM_DATA1

3.3V

D

D

D

D

C119

10U/16V

C120

0.1U

*change-1(2003.3.17)

C121

0.1U

C123

0.1U

C122

0.1U

B

B

B

C

C

C

C

B

A A

A A

A A

A

87654

87654

87654

87654

AR-EB9 CIRCUIT DIAGRAM

– 15 –

Page 19

B

B

B

D

D

D

D

4/4

12345678

12345678

12345678

12345678

C

C

C

C

FGND_UD1

AG

FG

B

A

0J(1608)

L2

3.3V

C86

0.01U

3.3V

C85

0.01U

C84

0.01U

C83

0.01U

C82

0.01U

0J(1608)

L3

SUSPEND

R127 10KJ

R126 NC

TP

TP931

MODE1

BUS_CONF

AD3

AD4

BR13

TP913 TP

1827364

PB_DATA5

PB_DATA4

TP252 /CS1

AD5

AD6

0JX4

5

PB_DATA6

PB_DATA7

/CS1

AD7

TP253 /CS0

R128 10KJ

TP932 TP

/CS0

NC

R130

R129 10KJ

TP254

TP933 TP

21

22

DA2

INTRQ

READY

DATA0

DATA1

BR14

TP914 TP

1827364

PB_DATA1

PB_DATA0

WAKEUP

DA2

62

63

WAKEUP

SUSPEND

DATA2

DATA3

0JX4

TP915 TP

5

1827364

PB_DATA2

PB_DATA4

PB_DATA3

R132

R131

DATA4

DATA5

DATA6

0JX4

BR15

PB_DATA6

PB_DATA5

10KJ

10KJ

GND

C96 15P

DATA7

DATA8

BR16

TP916 TP

5

1827364

PB_DATA7

PB_ADDR1

PB_ADDR0

TP

TP934

60

XTAL1

DATA9

DATA10

DATA11

0JX4

5

PB_ADDR3

PB_ADDR2

TP941

TP

GND

GND

USBVBUS

12MHz

Y1

TP935 TP

59

XTAL2

DATA12

DATA13

0JX4

BR17

TP917 TP

1827364

PB_ADDR5

PB_ADDR4

PB_ADDR6

BLM21PG600SN1

L4

C97 15P

R134

TP

TP936

4

Vreg(3.3)

/RESET

DATA14

DATA15

10

57

TP918 TP

5

R133 0J

PB_ADDR7

-D+DSHIELD

+5V

CN8

23541

GND

TP

1.5KJ

TP

TP

TP939

TP938

TP937

567

D-

D+

RPU

DREQ

DACK

/CS

/RD

/WR

INT

2526272829

TP

TP

TP

TP

TP

TP

TP919

TP924

TP923

TP921

TP922

TP920

0J

0J

0J

0J

0J

R135 NM

R138

R140

R139

R136

R137

UBR23(ACON)

GND

USB2.0 DEV1

R142 NM

DLW21SN900SQ2

L5

R143

TP

TP940

8

RREF

AGND

23

AGND

3

DGND

61

DGND

42

DGND

36

DGND

1

EOT

ALE

ISP1581

111213

TP

TP926

TP925 TP

0.01U

C98

12KF

R144

R141

L6

BLM21PG600SN1

R145 NM

0J

NM

FGND_UD2

FG

AGND_UD2

AG

TP956

AGND

AGND_UD2

AG

GND

GND

21

21

21

21

3

3

3

3

10U/16V

10U/16V

0.1U

0.1U

0.1U

0.1U

0.1U

*change-1(2003.3.17)

AG

GND

GND

GND

3.3V

PB_NOE

PB_NWE

R415 0J

R416 0J

R123 10KJ

R124 10KJ

R122 10KJ

R125 10KJ

*change-1(2003.3.17)

TPTPTP

TP930

TP928

TP929

TP927 TP

9

14

1516171819

20

DIOR

DIOW

MODE0

VCC(3.3)

58

VCC(3.3)

24

VCC(5.0)

64

VCC(5.0)

43

VCC(5.0)

37

VCC(5.0)

2

AD0

AD1

AD2

IC8

3031323334353839404144454647484950515253545556

0JX4

BR12

TP912 TP

5

1827364

PB_DATA1

PB_DATA0

PB_DATA3

PB_DATA2

GND

C89

+

C88

0.1U

TP911 TP

L1

0J(1608)

+

C87

C95

3.3V

C94

C93

C92

C91

C81

0.01U

3.3V

C176

NM

C189

NM

C190

NM

C184

C165

C153

C156

C151

C158

C152

C159

C154

D

D

D

D

NM

NM

NM

NM

NM

NM

NM

NM

NM

C180

C178

C173

C174

C175

C172

C177

C185

NM

NM

C179

NM

NM

C183

NM

NM

C186

NM

C182

NM

NM

NM

C187

NM

NM

C181

NM

C188

NM

NM

GND

C90

0.1U

GND

C

C

C

C

GND

PB_DATA[7:0]

PB_DATA[7:0]

PB_ADDR[7:0]

B

B

B

B

RESET_L

PB_NCS3

R405 0J

USB_CS

DT_REQB

DT_ACKB

INT_USBD

PB_NWE

PB_NOE

R406 0J

USB_ALE

87654

87654

87654

87654

A A

A A

A A

A

AR-EB9 CIRCUIT DIAGRAM

– 16 –

Page 20

LEAD-FREE SOLDER

The PWB’s of this model employs lead-free solder. The “LF” marks indicated on the PWB’s and the Service Manual mean “Lead-Free” solder. The

alphabet following the LF mark shows the kind of lead-free solder.

Example:

<Solder composition code of lead-free solder>

Solder composition

Sn-Ag-Cu

Sn-Ag-Bi

Sn-Ag-Bi-Cu

Sn-Zn-Bi

Sn-In-Ag-Bi

Sn-Cu-Ni

Sn-Ag-Sb

Bi-Sn-Ag-P

Bi-Sn-Ag

5mm

Lead-Free

Solder composition

code (Refer to the

table at the right.)

a

(1) NOTE FOR THE USE OF LEAD-FREE SOLDER THREAD

When repairing a lead-free solder PWB, use lead-free solder thread. Never use conventional lead solder thread, which may cause a breakdown or an

accident.

Since the melting point of lead-free solder t hread is about 40°C higher than that of conventional lead solder thread, the use of the exclusive-use soldering iron is recommendable.

Solder composition code

a

b

z

i

n

s

p

(2) NOTE FOR SOLDERING WORK

Since the melting point of lead-free solder is about 220°C, which is about 40°C higher than that of conventional lead solder, a nd its soldering capacity

is inferior to conventional one, it is apt to keep the soldering iron in contact with the PWB for longer time. Th is may cause land separation or may

exceed the heat-resistive temperature of components. Use enough care to separate the soldering iron from the PWB when completion of soldering is

confirmed.

Since lead-free solder includes a greater quantity of tin, the iron tip may corrode easily. Turn ON/OFF the soldering iron power frequently.

If different-kind solder remains on the soldering iron tip, it is melted together with lead-free solder. To avoid this, clean t he soldering iron t ip after com-

pletion of soldering work.

If the soldering iron tip is discolored black during soldering work, clean and file the tip with steel wool or a fine filer.

Page 21

q

PARTS GUIDE

CODE:00ZAREB9//P1/

DIGITAL COPIER OPTION

DUAL FUNCTION BOARD

1

Packing material & Accessories

MODEL

CONTENTS

AR-EB9

Because parts marked with "!" is indispensable for the machine safety maintenance and poeration, it must

Be replaced with the parts specific to the product specification.

This document has been published to be used for

SHARP CORPORATION

after sales service only.

The contents are subject to change without ontice.

Page 22

DEFINITION

The definition of each Rank is as follows and also noted in the list

Rank A : Maintenance parts, and consumable parts which are not included in but closely related to maintenance parts

Rank B : Performance/function parts (sensors, clutches, and other electrical parts), consumable parts

Rank E : Unit parts including PWB

Rank D : Preparation parts (External fitting, packing, parts packed together)

Rank C : Parts other than the above (excluding sub components of PWB)

Because parts marked with "!" is indispensable for the machine safety maintenance and operation, it must be replaced with

the parts specific to the product specification.

F Other than this Parts Guide, please refer to documents Service Manual(including Circuit Diagram)of this model.

F Please use the 13 digit code described in the right hand corner of front cover of the document, when you place an order.

F For U.S. only-Use order codes provided in advertising literature. Do not order from parts department.

Packing material & Accessories

1

PRICE

NEW

NO. PARTS CODE

1 CPWBX0130QS33 CF N E IMC2 PWB

2 DHAI-0330QSZZ AD C IMC OUT harness

3 DHAI-0329QSZZ AD C IMC IN harness

4 LX-BZ0705FCPZ AC N C Screw(3×6)

5 LPLTM0315QSZZ AL C PWB fixing plate

8 XHBS730P06000 AC C Screw(3×6)

9 SSAKA0006UCZZ AA D Vinyl bag(50×60mm)

101 TLABZ0530QSZZ AB N C USB 2.0 display label

RANK

MARK

PART

RANK

DESCRIPTION

Packing material & Accessories

1

4

4

1

4

2

3

8

8

4

4

9

5

PRP02442

– 1 –

Page 23

CAUTION FOR BATTERY REPLACEMENT

(Danish) ADVARSEL !

Lithiumbatteri - Eksplosionsfare ved fejlagtig håndtering.

(English) Caution !

Dispose of used batteries according to manufacturer's instructions.

(Finnish) VAROITUS

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan

(French) ATTENTION

ll y a danger d'explosion s'il y a remplacement incorrect

de la batterie. Remplacer uniquement avec une batterie du

Mettre au rébut les batteries usagées conformément aux

Udskiftning må kun ske med batteri

Levér det brugte batteri tilbage til leverandoren.

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

Paristo voi räjähtää,jos se on virheellisesti asennettu.

tyyppiin. Hävitä käytetty paristo valmistajan ohjeiden

même type on d'un type équivalent recommandé par

af samme fabrikat og type.

recommended by the manufacturer.

mukaisesti.

le constructeur.

instructions du fabricant.

(Swedish) VARNING

(German) Achtung

Als Ersatzbatterien dürfen nur Batterien vom gleichen Typ oder

(For USA,CANADA)

(MANGANESS DIOXIDE) MEMORY BACK-UP BATTERY

THAT MUST BE DISPOSED OF PROPERLY. REMOVE THE

BATTERY FROM THE PRODUCT AND CONTACT YOUR

LOCAL ENVIRONMENTAL AGENCIES FOR INFORMATION

CE PRODUIT CONTIENT UNE PILE DE SAUVEGARDE DE

MÉMOIRE LITHIUM PRIMAIRE (DIOXYDE DE MANGANESE)

QUI DOIT ÊTRE TRAITÉE CORRECTEMENT. ENLEVEZ LA

PILE DU PRODUIT ET PRENEZ CONTACT AVEC VOTRE

AGENCE ENVIRONNEMENTALE LOCALE POUR DES

INFORMATIONS SUR LES MÉTHODES DE RECYCLAGE ET

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent

typ som rekornmenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens

Explosionsgefahr bei Verwendung inkorrekter Batterien.

vom Hersteller empfohlene Batterien verwendet werden.

Entsorgung der gebrauchten Batterien nur nach den vom

Hersteller angegebenen Anwerisugen.

CAUTION FOR BATTERY DISPOSAL

THIS PRODUCT CONTAINS A LITHIUM PRIMARY

ON RECYCLING AND DISPOSAL OPTIONS.

"TRAITEMENT DES PILES USAGÉES"

Instruktion.

"BATTERY DISPOSAL"

DE TRAITEMENT.

Page 24

q

COPYRIGHT2004 BY SHARP CORPORATION

All rights reserved.

Printed in Japan.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted.

In any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise,

without prior written permission of the publisher.

Trademark acknowledgments

Microsoft and Windows are trademarks of Microsoft Corporation in the U.S.A and other

countries.

IBM and PC/AT are trademarks of International Business Machines Corporation.

Adobe and Acrobat are trademarks of Adobe Systems Incorporated.

All other trademarks and copyrights are the property of their respective owners.

SHARP CORPORATION

Digital Document Systems Group

QUALITY ENHANCEMENT CENTER

Yamatokoriyama, Nara 639-1186, Japan

2004 November Printed in Japan

t

Loading...

Loading...