Page 1

q

SERVICE MANUAL

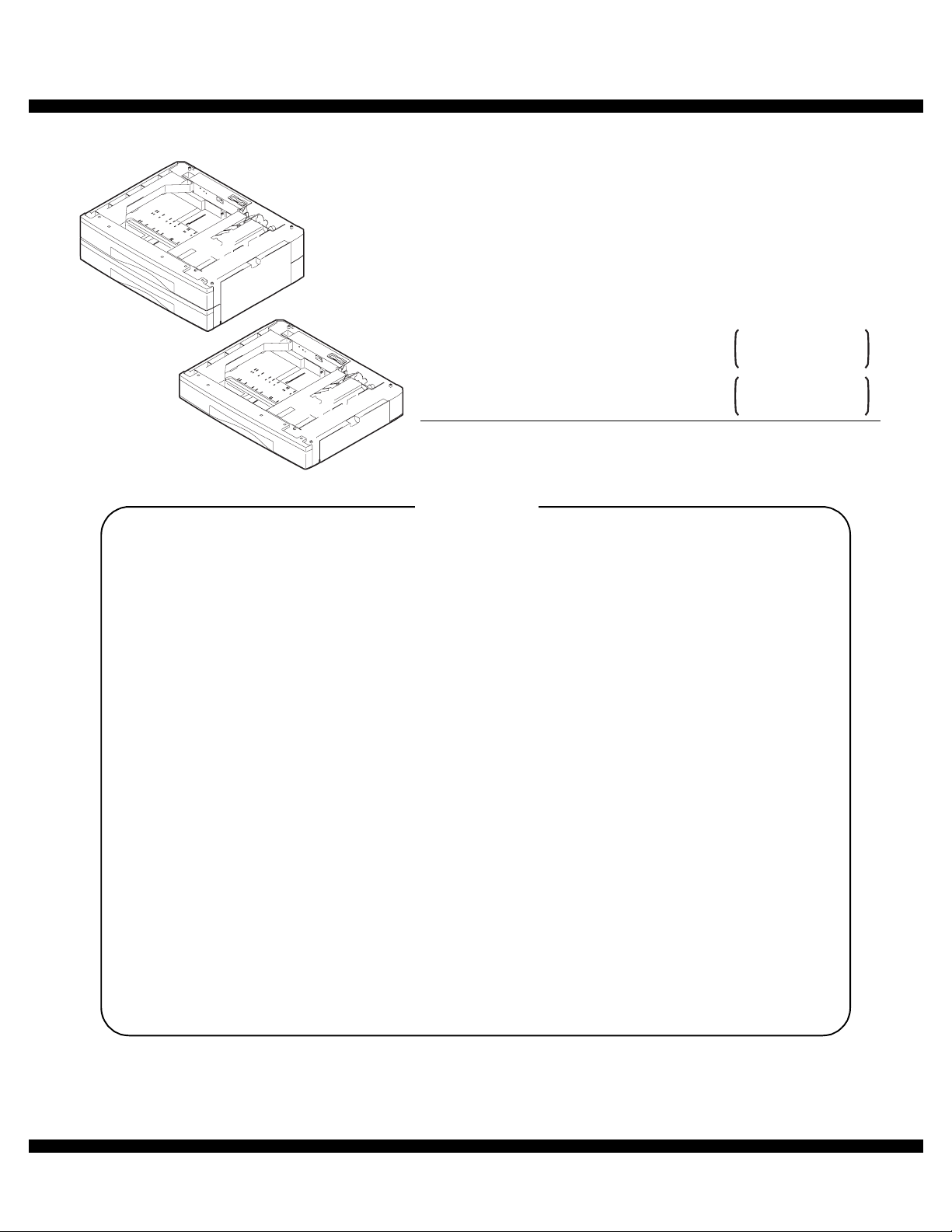

Digital copier

MODEL

CONTENTS

CODE : 00Z

ARD25//A1E

: Paper feed unit

250-sheet paper

AR-D24

AR-D25

feed unit

500-sheet paper

feed unit

[1] PRODUCT OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

[2] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

[3] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . 2

[4] EXTERNAL VIEW AND INTERNAL STRUCTURE . . . . . . . . . . . 8

[5] OPERATIONAL DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . 9

[6] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . 9

[7] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

[8] ELECTRICAL SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Parts marked with "!" are important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales servic e only.

The contents are subject to change without notice.

Page 2

Page 3

[1] PRODUCT OUTLINE

The 250-sheet paper feed unit and the 500-sheet paper feed unit are

the optional paper feed cassettes for the digital copier, and they are the

same structure as the 250-sheet cassette of the copier.

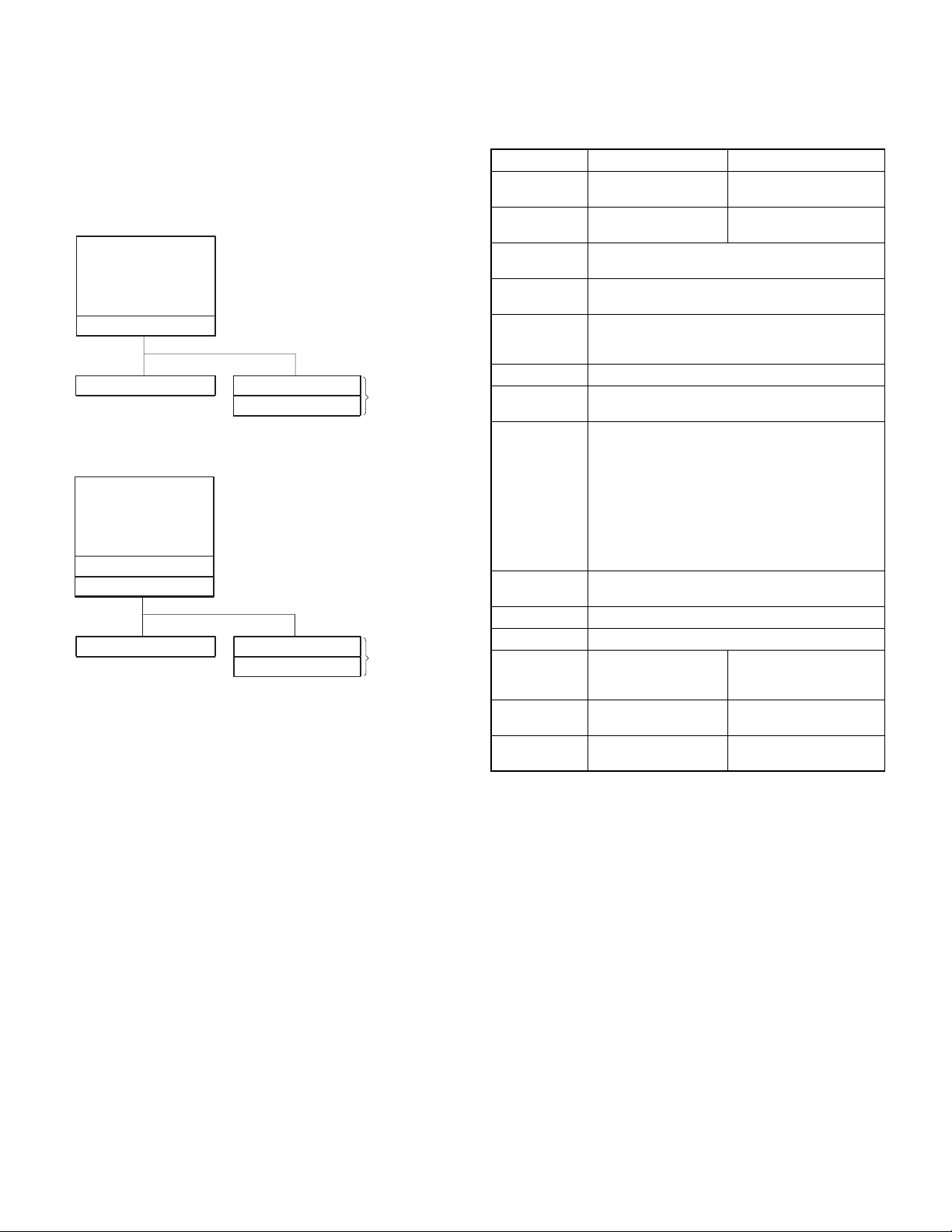

The combination of the copier and the paper feed cassette is as shown

below:

Copier

(1-Tray Model)

Standard cassette

250-sheet paper feed unit

Copier

(2-Tray Model)

Standard cassette

Standard cassette

250-sheet paper feed unit

250-sheet cassette

250-sheet cassette

250-sheet cassette

250-sheet cassette

500-sheet paper

feed unit

500-sheet paper

feed unit

[2] SPECIFICATIONS

1. Paper feed unit

AR-D24 AR-D25

Paper

feed step(s)

Paper feed

capacity

Size detection None

Paper feed

detection

Paper feed size A3, B4, A4, A4R, B5, B5R

Paper weight 56 ~ 90g/m2 (15 ~ 24lbs)

Shipping size AB series: A4

Size selection

Cassette

detachment

Heater Available only in Japan model

Power source Supplied from the machine.

External

dimension (mm)

Weight About 4.7kg

Power

consumption

1-step 2-step

250 sheets x 1 step 250 sheets x 2 steps

(The paper size is set by the user program.)

Available

11 x 17, 8.5 x 14, 8.5 x 13, 8.5 x 11, 8.5 x 11R,

8K, 16K, 16KR

Inch series: 8.5 x 11

User operation (Si ze set tin g by th e user pro gr am)

Japan: A3, B4, A4, A4R, B5, B5R

Inch series: 11 x 17, 8.5 x 14, 8.5 x 11, 8.5 x 11R

EX AB series: A3, B4, A4, A4R

Inch series foolscap area:

11 x 17, 8.5 x 14, 8.5 x 13, 8.5 x 11,

8.5 x 11R

EX AB series foolscap area:

A3, B4, A4, A4R, 8.5 x 13

Possible by the user

W: 590 x D: 471 x H: 88

(Jut portion is not

included.)

(With cassette)

5.6W 8.4W

W: 590 x D: 471 x H: 173.5

(Jut portion is not

included.)

About 10.0kg

(With cassette)

AR-D25/D24 PRODUCT OUTLINE

– 1 –

Page 4

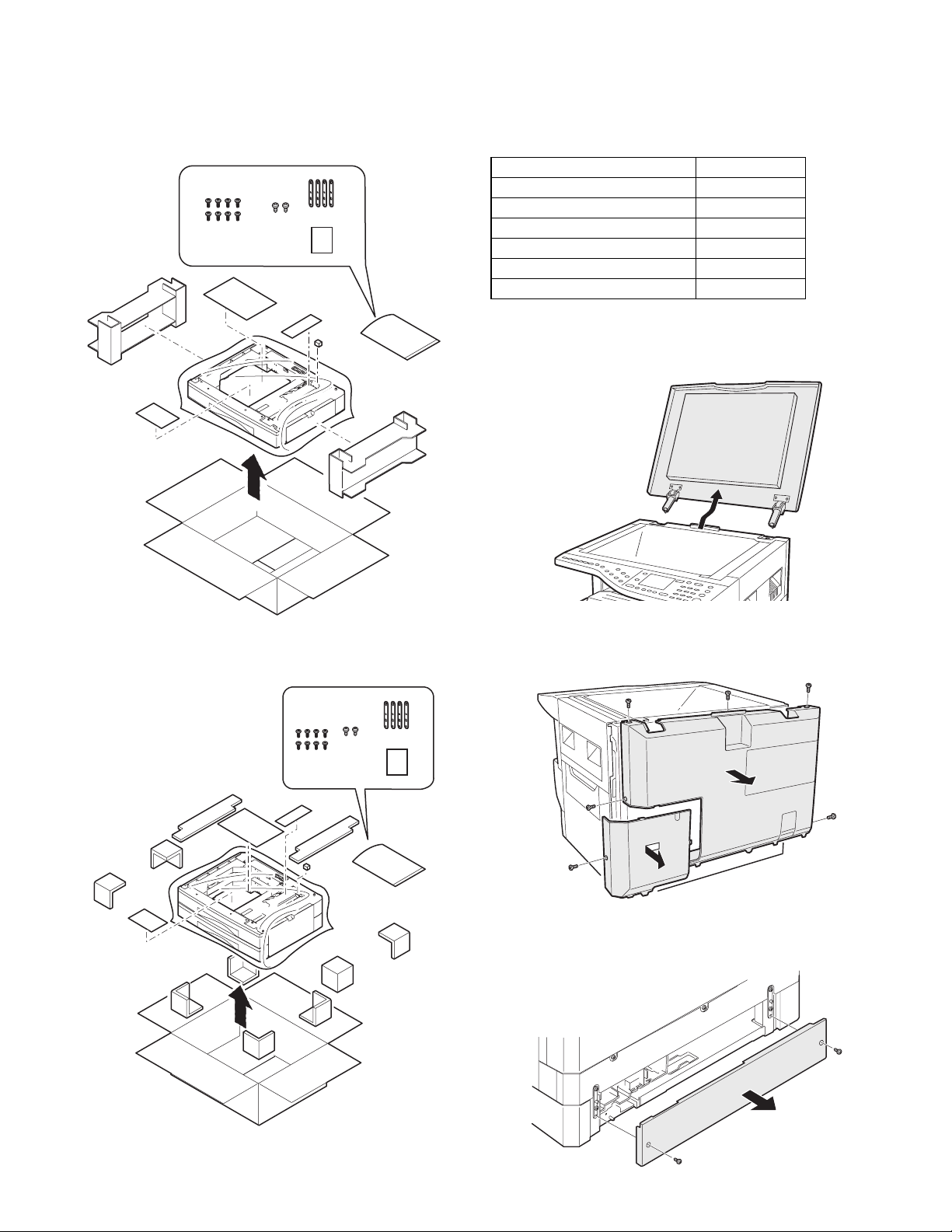

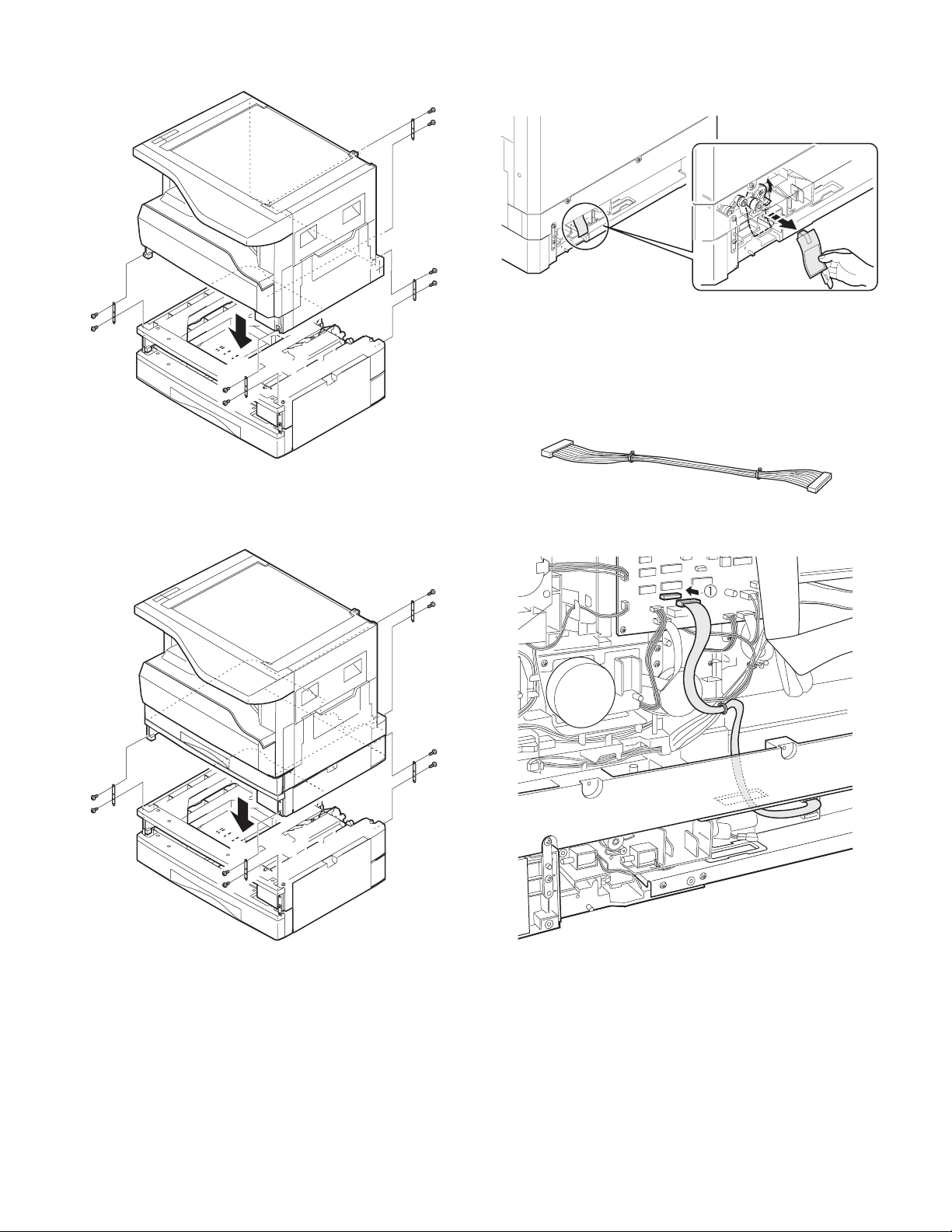

[3] UNPACKING AND INSTALLATION

1. Unpacking

(AR-D24)

2. Installation

Included parts

Part name Quantity

Screw (Fixing plate) 8

Screw 2

Screw 1

Fixing plate 3

Fixing plate 1

Connection gear 1

1) Remove the document cover.

Lift the document cover from the copier and tilt it to the rear side to

remove it.

(AR-D25)

2) Remove the rear cabinet.

Remove the screw and remove the cover. Then, remove the five screws

and remove the rear cabinet.

3) Remove the copier rear cover.

Remove the two screws and remove the rear cover.

AR-D25/D24 UNPACKING AND INSTALLATION

– 2 –

Page 5

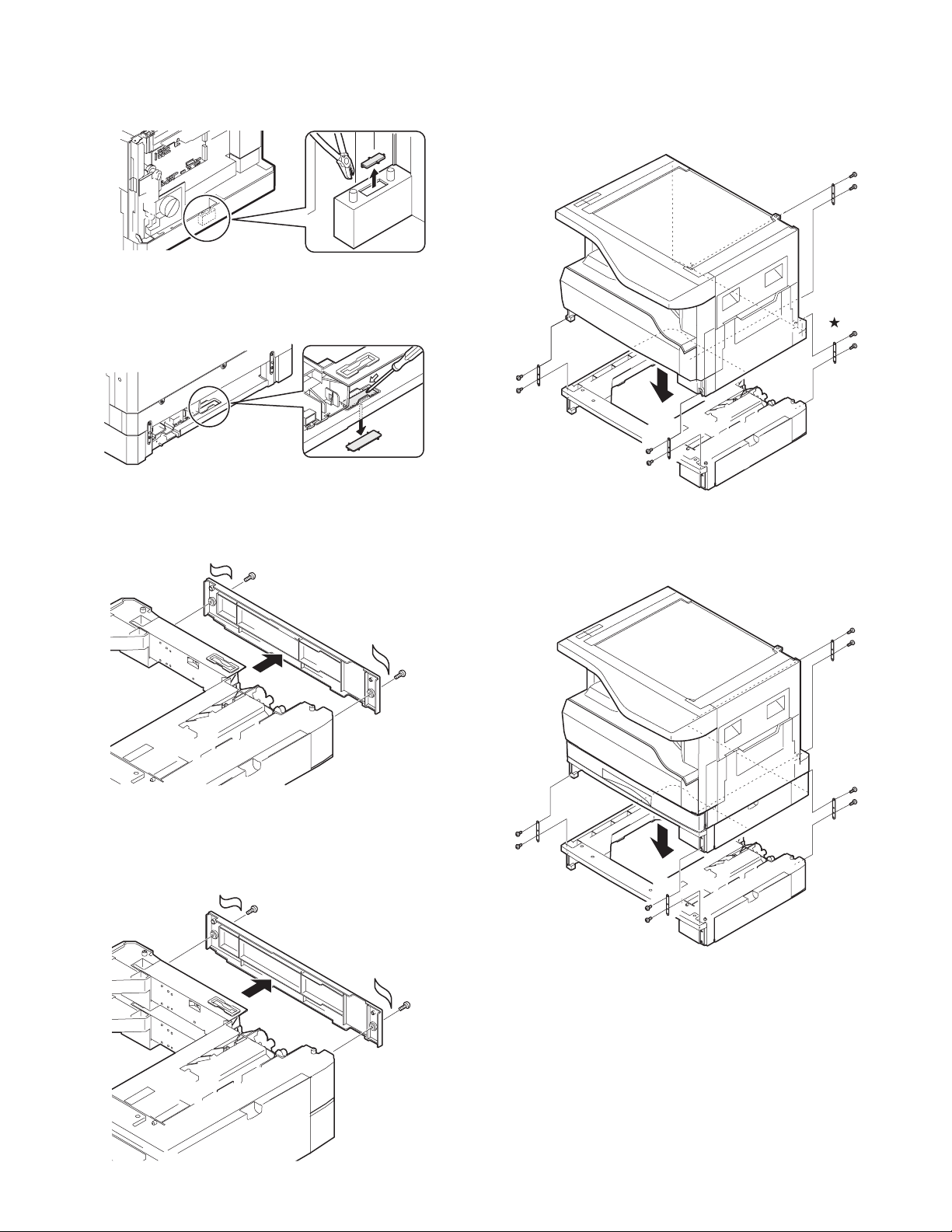

4) Make a hole for connector.

• Copier (1-tray model)

Cut out the portion shown in the illustration with nippers or the like.

• Copier (2-tray model)

Press the portion shown in the illustration with a screwdriver or the

like to remove it.

5) Remove the second cassette rear cover.

6) Install the copier onto the 250-sheet paper feed unit.

Put the copier on the 250-sheet paper feed unit, and fix with the fixing

plates and the screws.

• Copier (1-tray model) + 250-sheet paper feed unit

Remove the rear cover which is attached to the 250-sheet paper feed

unit.

Remove the rear cover (upper stage) from the 500-sheet paper feed

unit.

• Copier (2-tray model) + 250-sheet paper feed unit

AR-D25/D24 UNPACKING AND INSTALLATION

– 3 –

Page 6

• Copier (1-tray model) + 500-sheet paper feed unit

7) Remove the connection gear lock.

Remove the connection gear lock (with the red tug) after setting.

8) Connect the connector

Connect the optional relay harness contained in the 1-tray model (2-tray

model) paper feed unit to the PWB of the copier.

• Optional relay harness

• Copier (2-tray model) + 500-sheet paper feed unit

• Copier (1-tray model) + 250-sheet paper feed unit

AR-D25/D24 UNPACKING AND INSTALLATION

– 4 –

Page 7

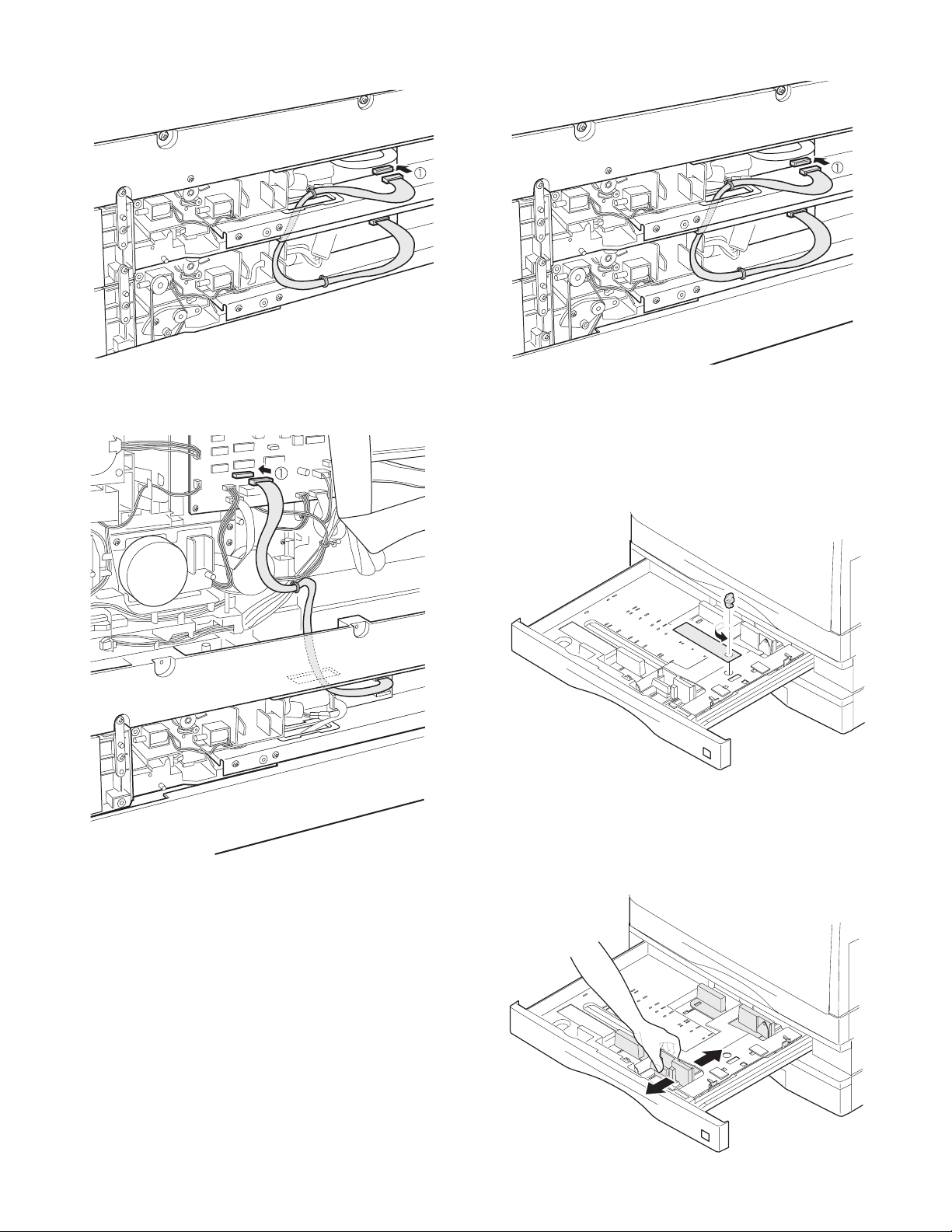

• Copier (2-tray model) + 250-sheet paper feed unit

• Copier (2-tray model) + 500-sheet paper feed unit

• Copier (1-tray model) + 500-sheet paper feed unit

9) Remove the cassette packing fixtures.

Pull the cassette until it stops.

Turn and remove the packing fixture which is fixing the paper pressure

plate inside the cassette in the direction of arrow.

10) Set the cassette side plate.

Hold the knob of the cassette side plate, slide it and set to the position

of the paper size to be used.

AR-D25/D24 UNPACKING AND INSTALLATION

– 5 –

Page 8

11) Install the cassette rear edge plate.

g

Install the cassette rear plate to the position of the paper size to be

used.

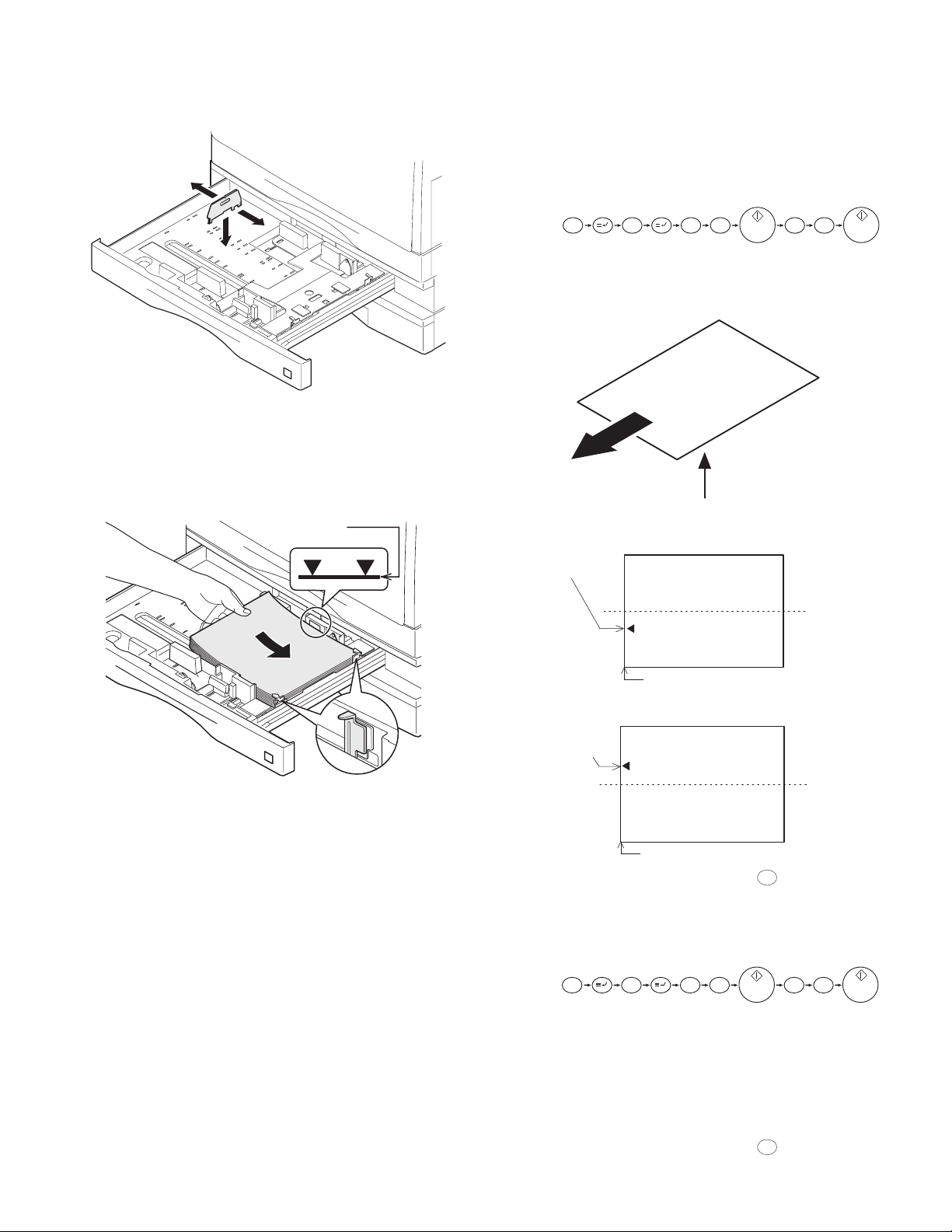

Note: To make the paper center shift adjustment and the lead edge

adjustment, insert the power plug of the copier into the

power outlet, turn on the power switch, and perform the following procedure.

13) Perform the center shift adjustment.

Set a document on the document glass and make a copy.

*If the image center is shifted, perform the following procedure.

1. Execute SIM 50-10 with the key operations on the copier.

12) Set the paper.

When setting the paper, do not exceed the height of the indication label.

cannot stack

more than this line.

[Program key]

#

C 5 0 1 0

2. Turn on the Auto lamp and the lamp of a corresponding tray by

Light and Dark key, Enter the set value with the keys on the operation panel to perform the center shift adjustment, make a copy

again, and check that the center is not shifted.

Rear side

Front side

Paper output direction

Printin

side

• When the s et value is inc reased, the image is shifted to the rear

side.

Center line of image

1

Output direction

Printing side

Center line

of paper

Leading edge

• When the set value is decreased, the image is shifted to the front

side.

Center line of image

1

Output direction

Center line

of paper

Printing side

Leading edge

After completion of the adjustment, press the key to cancel the

CA

mode.

14) Perform the lead edge adjustment.

Set a document on the document glass, and make a copy.

1. Execute SIM 50-1 with the key operations on the copier.

[Program key]

# 1

C 5 0

2. Turn on the Auto lamp and the lamp of a corresponding tray by

Light and Dark key, Enter the set value with the keys on the operation panel and make a copy to check that the lead edge is within the

specified range.

• When the set value is increased, the copy image moves forward.

• When the set value is decreased, the copy image moves backward.

After completion of the adjustment, press the key to cancel the

mode.

0

CA

AR-D25/D24 UNPACKING AND INSTALLATION

– 6 –

Page 9

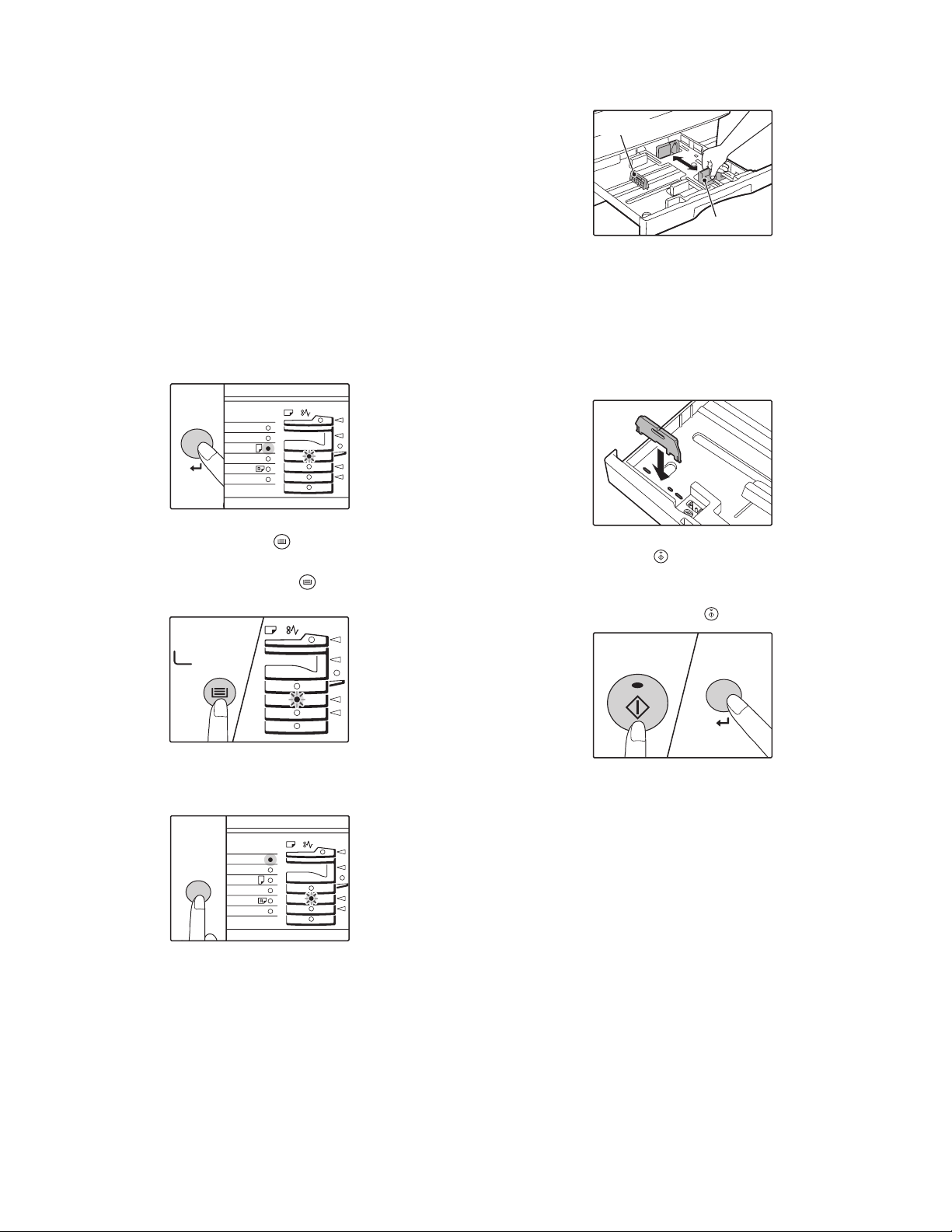

15) Changing a tray’s paper size setting

PAPER

SIZE

11X17

8½

X

14

8½

X

11

8½

X

11

8½

X

5½

EXTRA

TRAY

SELECT

ORIGINAL SIZE

ENTER

PAPER

SIZE

11X17

8½

X

14

8½

X

11

8½

X

11

8½

X

5½

EXTRA

START

Follow these steps to change a tray’s paper size setting.

Note:

• The paper size setting cannot be changed when the machine has

stopped temporarily due to running out of paper or a misfeed, or

during interrupt copying.

• During printing (even in copy mode), the paper size setting cannot

be changed.

• 5-1/2” x 8-1/2” size paper can only be selected in upper paper tray.

• Do not load paper that is a different size than the paper size setting. Copying will not be possible.

1. H old down the [PAPER SIZE ENTER] key for more than 5 seconds

to set the selected paper size.

The currently selected paper feed location indicator will blink and

the corresponding paper size (which is currently set) indicator will

light steadily. All other indicators will go out.

4. Squeeze the lock lever of the front guide and slide the front guide to

match the width of the paper, and move the left guide to the appropriate slot as marked on the tray.

Left guide

Front guide

• The front guide is a slide-type guide. Grasp the locking knob on

the guide and slide the guide to the indicator line of the paper to

be loaded.

• The left guide is an insert-type guide. Remove it and then insert it

at the indicator line of the paper to be loaded.

• Whe n using 11” x 17” sized paper store the left guide in the slot

at the left front of the paper tray.

2. Use the [TRAY SELECT] key ( ) to select the paper tray for

which you wish to change the paper size setting.

Each time the [TRAY SELECT] key ( ) is pressed, a paper tray

will be indicated with a blinking paper feed location indicator.

3. U se the [ORIGINAL SIZE ENTER] key to select the paper size.

The indicator of the selected paper size lights up.

5. Press the [START] key ( ) and then the [PAPER SIZE ENTER]

key.

To change0 the paper size setting of another tray, repeat steps 2 to

3 after pressing the [START] key ( ).

Note: Affix the paper size label for the paper size selected in step 3 to

the label position on the right end of the tray.

AR-D25/D24 UNPACKING AND INSTALLATION

– 7 –

Page 10

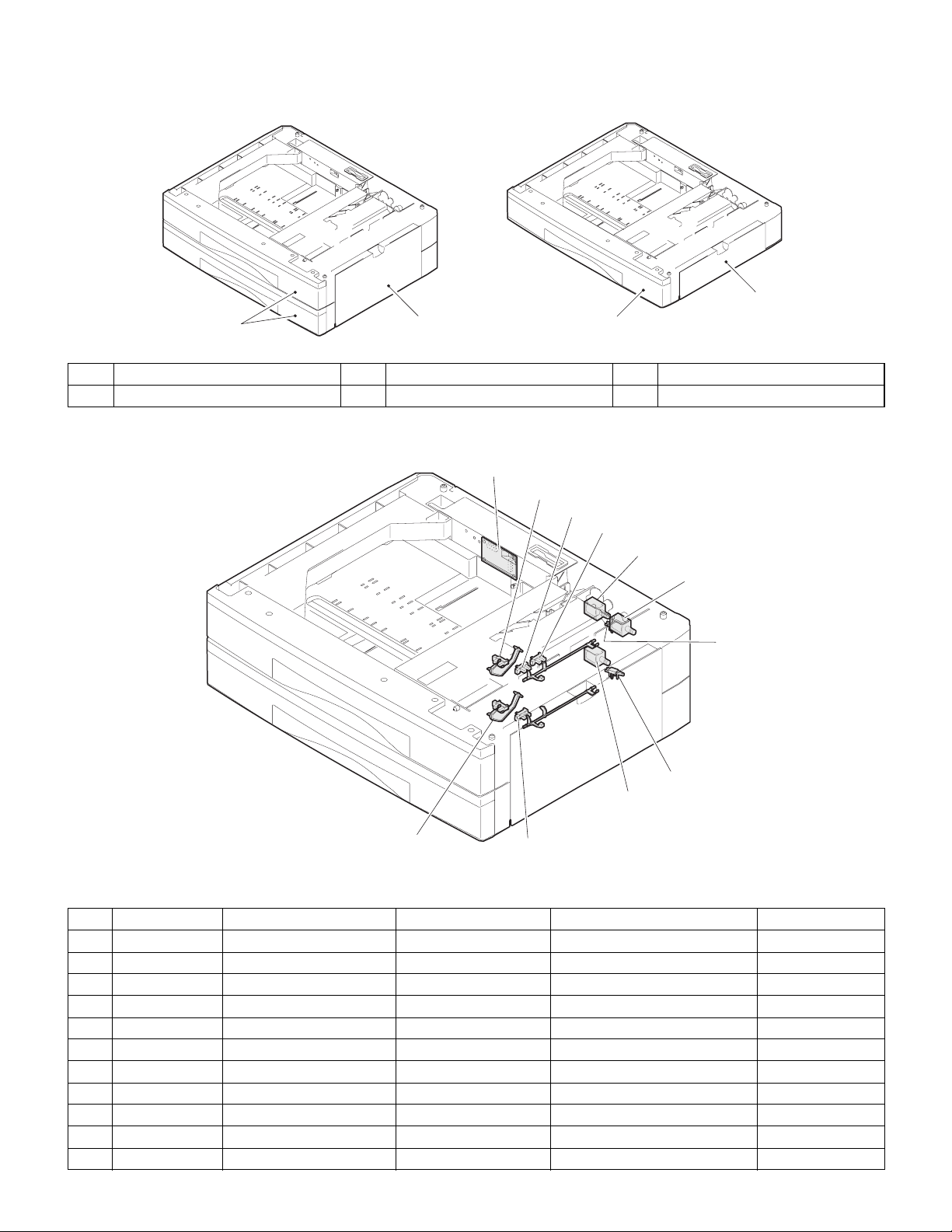

[4] EXTERNAL VIEW AND INTERNAL STRUCTURE

1. External view

3

1

No. Name No. Name No. Name

1 Paper feed tray 2 2-step paper feed right cover 3 1-step paper feed right cover

2

2. Internal structure

11

3

1

2

1

6

5

4

9

10

8

Sensors and detectors

No. Code Name Type Function, operation Remark

1 DRS1 Door open/close sensor Photo transmission Detects door open/close.

2 PPD1 Paper entry sensor Photo transmission Detects paper transport.

3 CSS1 Paper empty sensor Photo transmission Detects paper presence/empty.

4 CASS1 Cassette detection SW Contact Detects cassette installation.

5 FSOL1 Transport solenoid DC solenoid Transports paper. (for clutch)

6 PSOL1 Paper feed solenoid DC solenoid Feeds paper. (For clutch)

7 PPD2 Paper entry sensor Photo transmission Detects paper transport. AR-D25 only

8 CSS2 Paper empty sensor Photo transmission Detects paper in the cassette. AR-D25 only

9 CASS2 Cassette detection SW Contact Detects cassette installation. AR-D25 only

10 PSOL2 Paper feed solenoid DC solenoid Feeds paper. AR-D25 only

11 PWB Interface PWB — —

7

AR-D25/D24 EXTERNAL VIEW AND INTERNAL STRUCTURE

– 8 –

Page 11

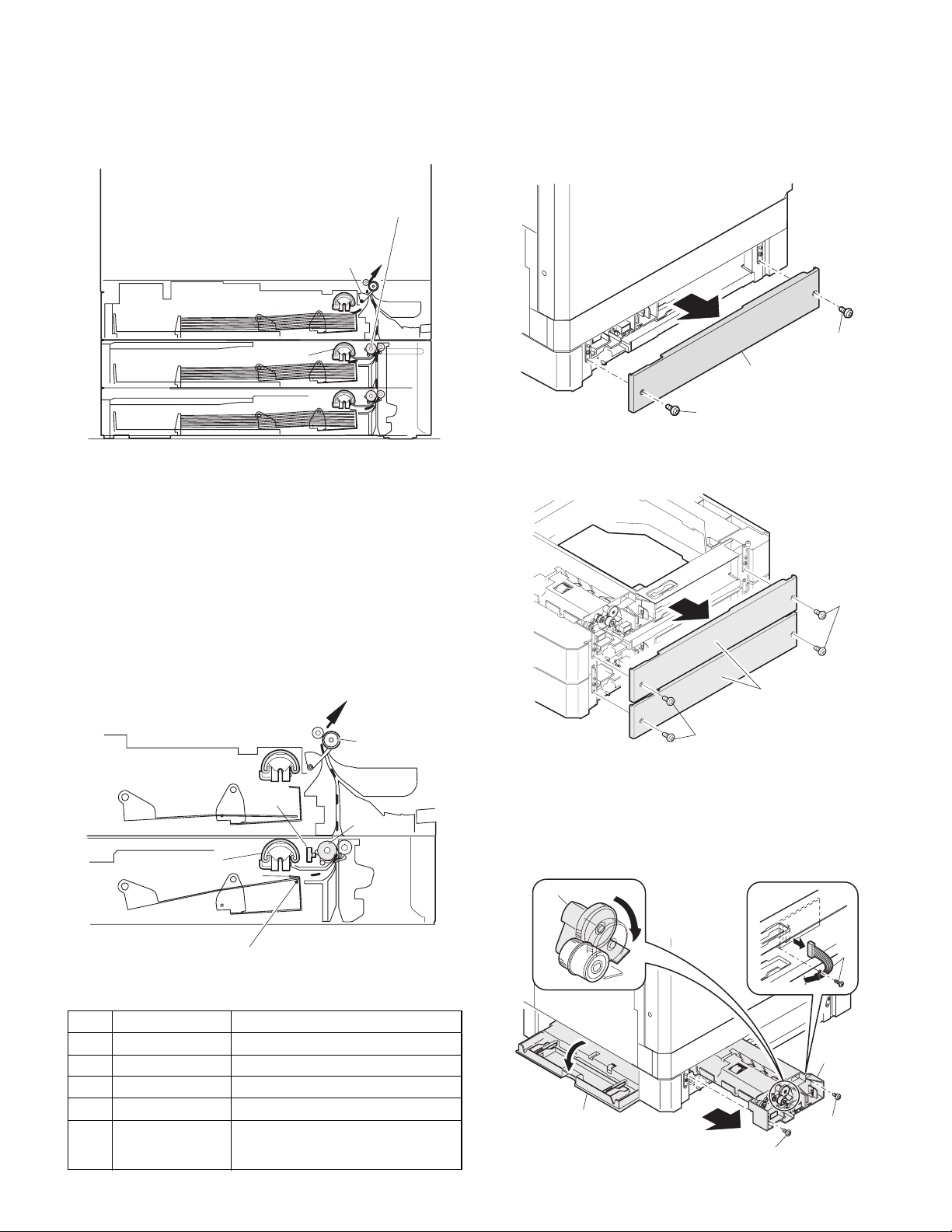

[5] OPERATIONAL DESCRIPTION

[6] DISASSEMBLY AND ASSEMBLY

1. Paper transport path

Transport roller

PF sensor

Copier

cassette

250-sheet paper

feed unit (upper)

250-sheet paper

feed unit (Lower)

Paper feed roller

2. Operational descriptions

The operations are controlled by the main body of the copier. the paper

feed roller (semi-circular roller) and the transport roller are driven by the

gear of the copier.

Paper is separated by the paper feed roller and the separation pawl,

and detected by the PF sensor, then transported to the Resist roller by

the transport roller.

1. Rear cover

[AR-D24]

1

2

1

[AR-D25]

1

To copier's PS

5

Copier

4

3

1

2

250-sheet paper feed unit

Paper lead edge

No. Name Operation

1 Paper feed roller Picks up paper.

2 Separation pawl Prevents against double feed of paper.

3 Transport roller Transports paper.

4 Paper entry sensor Detects paper transport.

5 Resist roller Makes synchronization between the

paper lead edge and the image lead

edge.

1

2. Paper feed unit section

[AR-D24]

4

2

2

1

5

3

3

AR-D25/D24 OPERATIONAL DESCRIPTION

– 9 –

Page 12

[AR-D25]

4. Transport roller gear section

5

1

1

6

3

2

6

3

4

3. Paper feed solenoid, transport solenoid

2

2

1

5. Transport roller

[AR-D24]

(3)

(2)

(1)

B

A

(1)

1

AR-D25/D24 DIS ASSEMBLY AND AS SEMBLY

– 10 –

Page 13

[Only the upper row of AR-D25]

(3)

(2)

(1)

B

A

6. Paper feed roller clutch

7. Paper feed roller

(1)

1

Note: When asembling the paper feed roller cluch, fit and insert section

A (D cut) into the shaft as shown in the figure.

A

2

1

3

2

*Be sure to rotate this part 180 degrees(It turns upward) after attach-

ment.

[7] MAINTENANCE

No. Name Work item

1 Paper feed roller PA ass’y *1 Cleaning o

2 Transport roller Cleaning o

*1 : Replace = 150K

service call

1

When

Remark

Note: For disassembly and assembly of the paper feed r oller and the

AR-D25/D24 MAINTENANCE

– 11 –

2

transport roller, refer to [6] DISASSEMBLY AND ASSEMBLY.

Page 14

D

C

B

A

1/1

12345678

2 1

24V

5V2

5V2

24V

5V2

24V

5V2

5V2

2nd/Multi step CS only

Lower connection CS

24V

5V2

5V1

CASS1

5V1

PPD1

IC1

CSS1

DRS1

Data selector

3

SELA

SELB

SELB

PSOL1

24V

IC2

FSOL1

PSOL2

CASS2

PPD2

CSS2

Multi step CS only

3

5V1

Driver array

Data selector

IC3

INTERFACE PWB

Copier body

1. BLOCK DIAGRAM

[8] ELECTRICAL SECTION

D

Y1

PSOL1

FSOL1

PSOL2

Y2

FSOL2

PSOL3

Y3

FSOL3

8 7 6 5 4

C

AR-D25/D24 ELECTRICAL SECTION

– 12 –

B

A

Page 15

D

2. ACTUAL WIRING DIAGRM

12345678

1. 2nd CS TYPE AR-D24

175778-2

1

CASS1

LGND

LGND

PPD1

5V2

LGND

DRS1

5V2

LGND

CSS1

2

DF3-3S-2C

1

2

3

DF3-3S-2C

1

2

3

DF3-3S-2C

1

2

35V2

GY

GY

OR

GY

OR

GY

OR

RD

BL

RD

BL

CASS1

PPD1

DRS1

CSS1

PSOL1

FSOL1

C

B

PHDR-20VS

TO 2ND OR MAIN BODY

(UPPER UN)

PGND

PSOL2

FSOL1

FSOL2

24VY224V

PSOL1

2

5

3

1

7

46

PSOL39FSOL3

LGND

PGND

LGND

10 16814

13

12

11

Y1

SELA

SELB

Y3

17

15

A

5V2

5V120SELC

19

18

2 1

RDRDPK

PK

GYGYGYBRPLPLPLOROR

PKPKPK

BR

GY

BR

OR

PL

LB

24V1

/PSOL1

24V1

/FSOL1

SMP-02V-NCSMR-02V-N

1

2

SMP-02V-BCSMR-02V-B

1

2

1

2

1

2

RD

BL

RD

BL

13

9

16

11

14

15

1

2

3

4

5

6

7

8

10

12

CASS1

LGND

PPD1

5V2

DRS1

CSS1

24V1

/PSOL1

24V1

/FSOL1

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

123 4 56789

CN-B

(B16B-PHDSS)

1

21 22

24V

24V

PSOL1

FSOL1

FSOL2

PSOL2

PSOL3

CS INTERFACE PWB

2ND CS

CN-C

24V

24V

FSOL3

FSOL2

PSOL2

N.C.

PSOL3

2

5

3

7

6

GY

PK

PGND

PGND

LGND

FSOL3

(B22B-PHDSS)

(B20B-PHDSS)

LGND

PGND13PGND

N.C.

10 16

8

12

11

9

LGND

CN-A

Y2

LGND

BR

1011 12 13 1415 1617 1819 20

Y3

14

BR

Y3Y2Y1

5V2

N.C.

N.C.

SELB

SELC

SELA

5V1

3

N.C.

5V2

5V1

SELB

SELA

SELC

18415

19

17

20

ELP-02V

1

AC100N

AC100L

2

FOR LOWER OPTION CS

ELR-02V

AC100N

AC100L

D

TO 2ND OR MAIN BODY

(UPPER UN)

WH

1

BK

2

ELP-02V

WH

BK

1

2

AC100N

C

ELR-02V

1

2AC100L

2nd CS UNIT

PPD1

DRS1

FSOL1

CASS1

HEATER DH1

JAPAN ONLY

PSOL1

CSS1

UNIT REAR VIEW

PWB

8 7 6 5 4

B

A

AR-D25/D24 ELECTRICAL SECTION

– 13 –

Page 16

D

2. MULTI CS TYPE AR-D25

12345678

C

B

PHDR-20VS

TO 2ND OR MAIN BODY

(UPPER UN)

A

UPPER UNIT

CASS1

CASS1

LGND

LGND

PPD1

PPD1

LGND

DRS1

DRS1

LGND

CSS1

CSS1

PSOL1

FSOL1

LOWER UNIT

CASS2

CASS2

LGND

LGND

PPD2

PPD2

5V2 3

175778-2

1

GY

2

DF3-3S-2C

GY

1

2

OR

35V2

DF3-3S-2C

GY

1

2

OR

35V2

DF3-3S-2C

GY

1

2

OR

35V2

RD

BL

RD

BL

175778-2

1

2

DF3-3S-2C

GY

1

2

OR

24VY224V

2

3

1

RDRDPK

BR

GY

BR

OR

PL

LB

1

2

1

2

SMP-02V-NCSMR-02V-N

1

24V1

2

/PSOL1

SMP-02V-BCSMR-02V-B

1

24V1

2

/FSOL1

SMR-08V-N SMP-08V-NC

BR

GY

GY

BR

OR

CASS2

1

1

LGND

2

2

LGND

3

3

PPD2

4

4

5V2

5

5

RD

BL

RD

BL

BR

BR

13

9

16

11

14

15

1

2

3

4

12

8

10

5

6

7

CASS1

LGND

PPD1

5V2

DRS1

CSS1

24V1

/PSOL1

24V1

/FSOL1

CASS2

PPD2

CSS2

24V1

/PSOL2

N.C.

123 4 56789

24V

24V

CN-B

(B16B-PHDSS)

PGND

FSOL1

PSOL1

5

46

PK

PSOL1

FSOL1

PSOL2

FSOL2

7

PKPKPK

FSOL2

PSOL2

Y1

LGND

PGND

LGND

PSOL39FSOL3

PK

21 22

PSOL3

15

10 16814

13

12

11

GYGYGYBRPLPLPLOROR

BR

GY

1011 12 13 1415 1617 1819 20

PGND

PGND

LGND

LGND

FSOL3

CN-A

(B22B-PHDSS)

CS INTERFACE PWB

MULTI CS

5V2

SELA

SELB

Y3

5V120SELC

19

17

18

BR

2 1

SELB

SELC

SELA

Y3Y2Y1

5V1

5V2

N.C.

N.C.

3

CSS2

PSOL2

PPD1

DRS1

FSOL1

CASS1

PPD2

CASS2

LGND

1

CSS2

2

5V2

3

MULTI CS UNIT

CSS1

PSOL1

CSS2

PSOL2

DF3-3S-2C

GY

OR

RD

BL

PWB

GY

LGND

6

LB

CSS2

7

OR

5V2

8

SMR-02V-N SMP-02V-NC

RD

24V1

1

BL

/PSOL2

2

UNIT REAR VIEW

UPPER UNIT

LOWER UNIT

6

7

8

1

2

LB

RD

BL

ELP-02V

1

2

TO 2ND OR MAIN BODY

(UPPER UN)

AC100N

AC100L

ELP-02V

WH

BK

1 AC100N

AC100L

2

ELR-02V

1

2

UPPER CS

HEATER DH2

LOWER CS

1

ELP-02V

1 AC100N

AC100L 2

2

ELR-02V

HEATER DH3

JAPAN ONLY

8 7 6 5 4

D

C

B

A

AR-D25/D24 ELECTRICAL SECTION

– 14 –

Page 17

D

C

B

A

12345678

2 1

3

3. INTERFACE PWB CIRCUIT DIAGRAM

D

C

AR-D25/D24 ELECTRICAL SECTION

– 15 –

8 7 6 5 4

B

A

Page 18

4. PARTS ARRANGEMENT

AR-D25 PARTS ARRANGEMENT

[PARTS SURFACE]

/PSOL1

2

B16B-PHDSS

24V1

1

CN-B

CN-C

11

13

15

17

19

1

3

5

7

9

B20B-PHDSS

24V

PSOL2

PSOL3

N.C.

PGND

LGND

Y2

N.C.

SELB

5V1

2

24V

4

FSOL2

6

FSOL3

N.C.

8

10

PGND

12

LGND

14

Y3

16

SELA

18

SELC

20

5V2

/FSOL1

4

24V1

3

/PSOL2

6

24V1

5

PPD2

8

N.C.

7

CSS2

10

LGND

9

CASS2

12

5V2

11

DRS1

14

CASS1

13

PPD1

16

CSS1

15

CN-A

1

5

7

9

11

13

15

17

19

21

B22B-PHDSS

24V

PSOL1

PGND

LGND

FSOL1

Y1

5V1

5V2

PSOL3

FSOL2

FSOL3

[SOLDER SURFACE]

2

24V

PSOL2

43

6

PGND

LGND

8

10

Y2

12

SELB

14

N.C.(5V1)

16

N.C.(5V2)

18

SELC

20

SELA

22

Y3

AR-D24 PARTS ARRANGEMENT

[PARTS SURFACE]

/PSOL1

2

B16B-PHDSS

24V1

1

CN-B

CN-C

11

13

15

17

19

1

3

5

7

9

B20B-PHDSS

24V

PSOL2

PSOL3

N.C.

PGND

LGND

Y2

N.C.

SELB

5V1

2

24V

4

FSOL2

6

FSOL3

N.C.

8

10

PGND

12

LGND

14

Y3

16

SELA

18

SELC

20

5V2

/FSOL1

4

24V1

3

/PSOL2

6

24V1

5

PPD2

8

N.C.

7

CSS2

10

LGND

9

CASS2

12

5V2

11

DRS1

14

CASS1

13

PPD1

16

CSS1

15

CN-A

1

5

7

9

11

13

15

17

19

21

B22B-PHDSS

24V

PSOL1

PGND

LGND

FSOL1

Y1

5V1

5V2

PSOL3

FSOL2

FSOL3

[SOLDER SURFACE]

2

24V

PSOL2

43

6

PGND

LGND

8

10

Y2

12

SELB

14

N.C.(5V1)

16

N.C.(5V2)

18

SELC

20

SELA

22

Y3

AR-D25/D24 ELECTRICAL SECTION

– 16 –

Page 19

q

AR-D25

PARTS GUIDE

デジタル複合機オプション

デジタル複合機オプション

デジタル複合機オプションデジタル複合機オプション

1111 段給紙デスク

段給紙デスク

段給紙デスク段給紙デスク

2222 段給紙デスク

段給紙デスク

段給紙デスク段給紙デスク

Digital Copier

Digital Copier Option

Digital CopierDigital Copier

Stand/1

Stand/1×

Stand/1Stand/1

Stand/2

Stand/2 ×××× 250 Sheet Paper Drawer

Stand/2Stand/2

× 250 Sheet Paper Drawer

250 Sheet Paper Drawer

××

250 Sheet Paper Drawer250 Sheet Paper Drawer

250 Sheet Paper Drawer

250 Sheet Paper Drawer250 Sheet Paper Drawer

Option

Option Option

AR-D24

AR-D24

CONTENTS

1

1ST トレイ外装 (1ST Tray exteriors)[AR-D24]

2

1ST トレイ給紙ユニット (1ST Tray paper feeding unit)[AR-D24]

3

2ND トレイ外装 (2ND Tray exteriors)[AR-D25]

4

2ND トレイ給紙ユニット (2ND Tray paper feeding unit)[AR-D25]

5

250 枚トレイユニット (250 sheets tray unit)

6

梱包材 & 付属品 (Packing material & Accessories)

■

索引 (Index)

MODEL

このパーツガイドに掲載されている表示価格ランクは消費税抜きです。

AR-D25

本書はサービス活動用に作成した資料です。

一部内容が製品の改良・改善等により予告

なしに変わることがあります。

SHARP CORPORATION

This document has been pub lished to be used for

after sales service only .

The contents are subject to change without notice.

Page 20

補修部品のランク付

市場における補修部品の在庫管理が、適正に運営出来る手助けとなることを、目的とします。

Aランク : メンテナンスパーツ、メンテナンスパーツには入っていないがメンテナンスパーツに近い消耗パーツ。

Bランク : 性能・機能パーツ(センサー、クラッチ等の電気パーツ)、消耗パーツ。

Eランク : 基板含むユニットパーツ。

Dランク : 整備パーツ(外装、パッキング、同梱パーツ)。

Cランク : 上記ランク以外のパーツ(基板の子部品を除いたもの)。

DEFINITION

Rank A : Maintenance parts, and consumable parts which are not included in but closely related to maintenance parts

Rank B : Performance/function parts (sensors, clutches, and other electrical parts), consumable parts

Rank E : Unit parts including PWB

Rank D : Preparation parts (External fitting, packing, parts packed together)

Rank C : Parts other than the above (excluding sub components of PWB)

安全性・信頼性確保のため部品は、必ず正規のものをご使用下さい。

! 印の商品は、安全上重要な部品です。交換をする時は、安全及び性能維持のため必ず指定の部品をご使用下さい。

Because parts marked with "!" is indispensable for the machine safety maintenance and operation, it must be replaced with

the parts specific to the product specification.

F

当モデルのサービス資料には、この資料以外にサービスマニュアル ( 回路図含む ) があります。合わせてご利用下さい。

F Other than this Parts Guide, please refer to documents Service Manual(including Circuit Diagram)of this model.

F Please use the 13 digit code described in the right hand corner of front cover of the document, when you place an order.

F For U.S. only-Use order codes provided in advertising literature. Do not order from parts department.

1

1ST トレイ外装 (1ST Tray exteriors)[AR-D24]

NO. PARTS CODE

1 GCOV-0020QSE1 AQ EQ N D

2 GGAD-0001QSZZ AE DJ C

3 GGAD-0002QSZZ AE DS C

4 LSUPP0083FCZZ AB DJ C

5 LPLTM0116QSZZ AQ EQ C

7 XEBSE40P12000 AA DD C

8 GCOV-0019QSZ2 AT EZ N D

9 PGIDM0049QSE2 BA FX N C

10 PGIDM0048QSE2 BB FX N C

11 MSPRC0141QSZZ AB DJ C

12 MLOKZ0001QSZZ AC DJ C

13 NGERH1169FCZZ AF DS C

14 PRNGP0019FCZZ AA DD C

15 DHAI-0326QSZZ AM EG C

16 CPWBF0019QSE5 AV FG E

18 MSPRD0135QSZZ AD DJ C

19 GLEGG0064FCZZ AC DJ C

21 MARMP0015QSZZ AD DJ C

22 NROLP1060FCZZ AF DS C

23 MSPRT0129QSZ1 AC DJ C

24 GCOV-0021QSE2 AP EQ N D

25 LPLTM0113QSZZ AH DX C

27 XEPSD30P08X00 AA DD C

28 XHBSE30P14000 AA DD C

30 LPLTM0135QSZZ AF DS C

31 LPLTM0138QSZZ AD DJ C

33 PSHEZ0172QSZZ AB DJ C

34 PSHEZ0173QSZZ AB DJ C

35 PSPO-0008QSZZ AC DJ C

36 PSPO-0009QSZZ AD DJ C

37 PSPO-0010QSZZ AD DJ C

38 PSPO-0011QSZZ AD DJ C

39 PSPO-0014QSZZ AG DS C

40 PSHEZ0171QSZZ AD DJ C

41 LHLDW3142KCZZ AC DD C

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

Rear cover 後カバー

Edge gard upper エッジガード 上

Edge gard lower エッジガード 下

Supporter(LCBS-3) 基板サポーター

Joint plate R 連結板 R

Screw(4×12) ビス

Front cover 前カバー

Guide L ガイド L

Guide R ガイド R

Transport PG lock spring 搬送 PG ロックスプリング

Transport PG lock 搬送 PG ロック

Joint gear 連結ギア

V ring(GTW-6) V リング

CAS harness CAS ハーネス

1ST tray interface PWB 1 段トレイ中継基板

Joint earth spring 連結アーススプリング

Rubber foot ゴム足

1ST door arm 一段ドアアーム

U-turn roller U ターンローラー

Roller spring 従動ローラースプリング

1ST right cover 一段右カバー

Guide R joint plate ガイド R 連結板

Screw(3×8X) ビス

Screw(3×14) ビス

2ND joint earth plate 2ND 連結アース板

2ND joint earth plate le ft back 2ND 連結アース板左後

Front sheet 2 (Europe) フロントシート 2

Right cover sheet (Europe) 右カバーシート

Rear cover cushion 1 (Europe) 後カバースポンジ 1

Rear cover cushion 2 (Europe) 後カバースポンジ 2

Guide R cushion F (Europe) ガイド R スポンジ F

Guide R cushion R (Europe) ガイド R スポンジ R

Right cover cushion 3 (Europe) 右カバースポンジ 3

Front sheet 1 (Europe) フロントシート 1

Cable band ケーブルバンド

DESCRIPTION

– 1 –

Page 21

1

1ST トレイ外装 (1ST Tray exteriors)[AR-D24]

36

7

7

31

19

13

21

7

4

35

7

7

14

15

41

16

21

22

23

22

23

24

7

5

27

11

27

19

12

12

20

7

34

39

9

7

10

37

8

7

7

40

33

30

7

7

11

25

1

38

2

18

3

28

34

PRP01621

– 2 –

Page 22

2

1ST トレイ給紙ユニット (1ST Tray paper feeding unit)[AR-D24]

NO. PARTS CODE

1 NGERH1207FCZZ AF DS C

2 MARMP0229FCZZ AE DS C

3 MSPRT0128QSZZ AB DJ C

4 XRESP50-06000 AA DD C

5 LBOSZ1031FCZZ AC DJ C

6 MSPRC0161QSZZ AF DS C

7 PPIPP0007QSZZ AD DJ C

8 NGERH1132FCZZ AH DX C

9 NBRGM0501FCZZ AB DJ C

10 DHAI-0075QSZ1 AR EQ C

13 NROLP0044QSZ2 AQ EQ C

15 VHPGP1A71A1-1 AG DX B

16 RPLU-0012QSZ1 AM EG N B

17 NBRGC0188FCZZ AB DD C

18 XRESP40-06000 AA DD C

19 LBOSZ1510FCZZ AF DX C

20 PPIPP0109FCZZ AB DD C

21 MSPRC1315FCZ1 AD DJ C

22 LPINS0181FCZZ AA DD C

23 LBOSZ1508FCZZ AG DX C

26 QSW-B0017QSZZ AF DS B

27 MSPRD0134QSZ2 AC DJ C

28 NGERH0041QSZZ AF DS C

29 NGERH0990FCZZ AB DJ C

30 PTME-0017QSZZ AD DJ C

31 MSPRT0130QSZ1 AB DJ C

32 PTME-0016QSZZ AD DJ C

33 RPLU-0013QSZ1 AM EG N B

34 XBBSD30P06000 AA DD C

35 MLEVP0039QSZ1 AE DS C

36 MLEVP0046QSZZ AD DJ C

38 LFRM-0031QSE3 AU EZ C

41 LPLTM0137QSZZ AD DJ C

42 LX-WZ0314FCZZ AA DD C

43 MSPRC0157QSZZ AC DJ C

44 NBRGC0529FCZZ AD DJ C

45 PPIPP0011QSZZ AC DJ C

46 XBBSE30P06000 AA DD C

47 RCORF0006QSZZ AL EB C

48 XWHSD60-10000 AA DD C

50 RHET-0011QSZZ AQ EQ E

51 XEBSE30P08000 AA DD C

52 MSPRD0156QSZZ AB DJ C

53 PSPO-0005QSZZ AA DJ C

54 PSPO-0007QSZZ AB DJ C

55 LPLTM0120QSZZ AF DS C

56 XHBSE30P08000 AA DD C

57 NSFTZ0067QSZZ AK DX C

58 LHLDR0095QSZZ AD DJ C

59 XEBSE30P12000 AA DD C

60 PCLR-0011QSZZ AC DJ C

61 LBRCR0011QSZZ AD DJ C

62 PGUMM0013QSZZ AG DX C

64 DHAI-0344QSZZ AH DX N C

501 CFRM-0031RS5C BL HL N E

502 CSFTZ0067RS52 AW FG N E

503 CGUMM0013RS51 AN EG N E

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

Joint gear(40T) 連結ギア

Joint arm 連結アーム

Joint arm spring 連結アームスプリング

E type ring Eリング

Clutch boss クラッチボス

Clutch spring クラッチスプリング

Clutch pipe クラッチスリーブ

Clutch gear(29T) クラッチギア

Metal D(B-F6-7) メタル D

1ST harness 1 ST ハーネス

1ST transport roller 一段搬送ローラー

Photo sensor(GP1 A71A1) フォトセンサー

Paper feeding solenoid 給紙ソレノイド

PF bearing PF 軸受

E type ring Eリング

Cam boss A1 カムボス A1

Pipe A 手差しクラッチスリーブ A パイプ

Clutch spring A 手差しクラッチスプリング A

Spring pin スプリングピン

Cam boss A2 カムボス A2

Tray detect switch トレイ検知スイッチ

Paper feeding earth spri ng 給紙アーススプリング

2ND gear(18T/26 T) 二段ギア

Gear(16T) ギア

Paper feeding clutch pawl 給紙クラッチ爪

Clutch pawl spring クラッチ爪スプリング

Transport clutch pawl 搬送クラッチ爪

Transport solenoid 搬送ソレノイド

Screw(3×6) ビス

PPDI actuator PPDI アクチューター

CICS actuator CICSアクチュエーター

Paper feeding frame 給紙フレーム

Boss reinforce plate ボス補強板

Poly slider ポリスライダー

Break spring ブレーキスプリング

Bearing 軸受

Break sleeve ブレーキスリーブ

Screw(3×6) ビス

Core コア

Washer ワッシャー

Heater unit (1ST tray) (Japan) 除湿ヒーター

Screw(3×8) (Japan) ビス

PPDIACT spring PPDIACT 復帰スプリング

Cluch pawl spong (Europe) クラッチ爪スポンジ

Toransport cluch paw l spong (Europe) 搬送クラッチ爪スポンジ

Heater raditate plate (Japan) ヒーター放熱板

Screw(3×8) (Japan) ビス

Paper feed rol ler shaft 給紙ローラーシャフト

Paper feed rol ler hold er 給紙ローラーホルダー

Screw(3×12) ビス

Roller color ローラーカラー

Paper feed rol ler bracke t 給紙ローラーブラケット

Paper feed rol ler gum 給紙ローラーゴム

2nd heater har ness (Japan) 2ND ヒーターハーネス

Paper feeding unit (1S T tray) (except Europe) 給紙ユニット

Paper feeding shaft 給紙シャフト

Paper feed rol ler gum 給紙ローラーゴム

DESCRIPTION

– 3 –

Page 23

2

1ST トレイ給紙ユニット (1ST Tray paper feeding unit)[AR-D24]

PRP01622

48

4

42

45

44

43

17

1

36

2

3

9

15

18

16

62

58

503

60

6

8

53

34

35

61

59

10

47

47

47

13

4

38

4

15

15

62

18

5

7

18

9

58

59

51

19

26

28

29

52

21

20

31

61

22

30

23

27

60

32

33

503

57

18

41

46

54

502

501

55

51

50

64

56

– 4 –

Page 24

3

2ND トレイ外装 (2ND Tray exteriors)[AR-D25]

NO. PARTS CODE

1 GCOV-0020QSE1 AQ EQ N D

2 GGAD-0001QSZZ AE DJ C

3 GGAD-0002QSZZ AE DS C

4 LSUPP0083FCZZ AB DJ C

5 LPLTM0116QSZZ AQ EQ C

6 LPLTM0112QSZZ AE DJ C

7 XEBSE40P12000 AA DD C

8 GCOV-0019QSZ2 AT EZ N D

9 PGIDM0049QSE2 BA FX N C

10 PGIDM0048QSE2 BB FX N C

11 MSPRC0141QSZZ AB DJ C

12 MLOKZ0001QSZZ AC DJ C

13 NGERH1169FCZZ AF DS C

14 PRNGP0019FCZZ AA DD C

15 DHAI-0326QSZZ AM EG C

16 CPWBF0019QSE6 AW FG N E

18 MSPRD0135QSZZ AD DJ C

19 GLEGG0064FCZZ AC DJ C

21 MARMM0016QSZZ AD DJ C

22 NROLP1060FCZZ AF DS C

23 MSPRT0129QSZ1 AC DJ C

24 GCOV-0022QSE2 AT EZ N D

25 LPLTM0113QSZZ AH DX C

27 XEPSD30P08X00 AA DD C

28 XHBSE30P14000 AA DD C

30 LPLTM0135QSZZ AF DS C

31 LPLTM0138QSZZ AD DJ C

32 LPLTM0115QSZZ AE DJ C

33 NPLYZ0012QSZZ AD DJ C

34 NBLTT0012QSZZ AG DX B

35 XWUSD40-04085 AA DD C

36 MSPRT0136QSZZ AB DJ C

37 LHLDW3142KCZZ AC DD C

38 PSHEZ0145QSZZ AC DJ C

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

DESCRIPTION

Rear cover 後カバー

Edge gard upper エッジガード 上

Edge gard lower エッジガード 下

Supporter(LCBS-3) 基板サポーター

Joint plate R 連結板 R

Adjustment plate 接合板

Screw(4×12) ビス

Front cover 前カバー

Guide L ガイド L

Guide R ガイド R

Transport PG lock spring 搬送 PG ロックスプリング

Transport PG lock 搬送 PG ロック

Joint gear 連結ギア

V ring(GTW-6) V リング

CAS harness CAS ハーネス

2ND tray interface PWB 2ND トレイ中継基板

Joint earth spring 連結アーススプリング

Rubber foot ゴム足

2ND door arm 2 段ドアアーム

U-turn roller U ターンローラー

Roller spring 従動ローラースプリング

2ND transport paper guide cove r 二段搬送ペーパーガイドカバー

Guide R joint plate ガイド R 連結板

Screw(3×8X) ビス

Screw(3×14) ビス

2nd joint earth plate 2ND 連結アース板

2ND joint earth plate le ft back 2ND 連結アース板左後

2ND tension plate 2ND テンショナープレート

2ND 26MXL pulley 2ND26MXL プーリー

2ND belt(B114MXL4.8) 2ND ベルト

Washer ワッシャー

2ND tension spring 2ND テンショナースプリング

Cable band ケーブルバンド

Mylar フランジマイラー

– 5 –

Page 25

3

2ND トレイ外装 (2ND Tray exteriors)[AR-D25]

B

C

A

7

1

7

31

13

7

4

7

7

2

3

14

36

15

28

7

5

27

11

9

7

10

27

12

12

11

8

7

16

37

33

34

38

7

29

7

B

C

1

35

32

7

30

7

7

31

7

7

4

29

6

7

7

9

10

19

29

7

5

6

6

7

18

7

7

2

3

6

8

7

7

7

7

20

19

23

23

21

22

6

21

7

30

7

7

25

23

23

24

– 6 –

PRP01623

Page 26

4

2ND トレイ給紙ユニット (2ND Tray paper feeding unit)[AR-D25]

NO. PARTS CODE

1 NGERH1207FCZZ AF DS C

2 MARMP0229FCZZ AE DS C

3 MSPRT0128QSZZ AB DJ C

4 XRESP50-06000 AA DD C

5 LBOSZ1031FCZZ AC DJ C

6 MSPRC0161QSZZ AF DS C

7 PPIPP0007QSZZ AD DJ C

8 NGERH1132FCZZ AH DX C

9 NBRGM0501FCZZ AB DJ C

11 DHAI-0080QSZ1 AP EQ C

12 DHAI-0081QSZ1 AK DX C

13 NROLP0045QSZ1 AR EQ C

15 VHPGP1A71A1-1 AG DX B

16 RPLU-0012QSZ1 AM EG N B

17 NBRGC0188FCZZ AB DD C

18 XRESP40-06000 AA DD C

19 LBOSZ1510FCZZ AF DX C

20 PPIPP0109FCZZ AB DD C

21 MSPRC1315FCZ1 AD DJ C

22 LPINS0181FCZZ AA DD C

23 LBOSZ1508FCZZ AG DX C

24 NPLYZ0012QSZZ AD DJ C

25 LPINS0165FCZZ AB DD C

26 QSW-B0017QSZZ AF DS B

27 MSPRD0134QSZ2 AC DJ C

28 NGERH0041QSZZ AF DS C

29 NGERH0990FCZZ AB DJ C

30 PTME-0017QSZZ AD DJ C

31 MSPRT0130QSZ1 AB DJ C

32 PTME-0016QSZZ AD DJ C

33 RPLU-0013QSZ1 AM EG N B

34 XBBSD30P06000 AA DD C

35 MLEVP0039QSZ1 AE DS C

36 MLEVP0046QSZZ AD DJ C

38 LFRM-0031QSE3 AU EZ C

41 LPLTM0137QSZZ AD DJ C

42 LX-WZ0314FCZZ AA DD C

43 MSPRC0157QSZZ AC DJ C

44 NBRGC0529FCZZ AD DJ C

45 PPIPP0011QSZZ AC DJ C

46 XBBSE30P06000 AA DD C

47 RCORF0006QSZZ AL EB C

48 XWHSD60-10000 AA DD C

50 RHET-0011QSZZ AQ EQ E

51 XEBSE30P08000 AA DD C

52 MSPRD0156QSZZ AB DJ C

55 LPLTM0120QSZZ AF DS C

56 XHBSE30P08000 AA DD C

57 NSFTZ0067QSZZ AK DX C

58 LHLDR0095QSZZ AD DJ C

59 XEBSE30P12000 AA DD C

60 PCLR-0011QSZZ AC DJ C

61 LBRCR0011QSZZ AD DJ C

62 PGUMM0013QSZZ AG DX C

64 DHAI-0344QSZZ AH DX N C

501 CFRM-0031RS69 BM HR N E

502 CFRM-0031RS6A BG GX N E

503 CSFTZ0067RS52 AW FG N E

504 CGUMM0013RS51 AN EG N E

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

Joint gear(40T) 連結ギア

Joint arm 連結アーム

Joint arm spring 連結アームスプリング

E type ring Eリング

Clutch boss クラッチボス

Clutch spring クラッチスプリング

Clutch pipe クラッチスリーブ

Clutch gear(29T) クラッチギア

Metal D(B-F6-7) メタル D

2ND harness 1 2ND ハーネス 1

2ND harness 2 2ND ハーネス 2

2ND transport roller 二段搬送ローラー

Photo sensor(GP1 A71A1) フォトセンサー

Paper feeding solenoid 給紙ソレノイド

PF bearing PF 軸受

E type ring Eリング

Cam boss A1 カムボス A1

Pipe A 手差しクラッチスリーブ A パイプ

Clutch spring A 手差しクラッチスプリング A

Spring pin スプリングピン

Cam boss A2 カムボス A2

2ND 26MXL pulley 2ND26MXL プーリー

Pin(φ2-8) 平行ピン

Tray detect switch トレイ検知スイッチ

Paper feeding earth spri ng 給紙アーススプリング

2ND gear(18T/26 T) 二段ギア

Gear(16T) ギア

Paper feeding clutch pawl 給紙クラッチ爪

Clutch pawl spring クラッチ爪スプリング

Transport clutch pawl 搬送クラッチ爪

Transport solenoid 搬送ソレノイド

Screw(3×6) ビス

PPDI actuator PPDI アクチューター

CICS actuator CICSアクチュエーター

Paper feeding frame 給紙フレーム

Boss reinforce plate ボス補強板

Poly slider ポリスライダー

Break spring ブレーキスプリング

Bearing 軸受

Break sleeve ブレーキスリーブ

Screw(3×6) ビス

Core コア

Washer ワッシャー

Heater unit (2ND tray) (Japan) 除湿ヒーター

Screw(3×8) (Japan only) ビス

PPDIACT spring PPDIACT 復帰スプリング

Heater raditate plate (Japan) ヒーター放熱板

Screw(3×8) (Japan) ビス

Paper feed rol ler shaft 給紙ローラーシャフト

Paper feed rol ler hold er 給紙ローラーホルダー

Screw(3×12) ビス

Roller color ローラーカラー

Paper feed rol ler bracke t 給紙ローラーブラケット

Paper feed rol ler gum 給紙ローラーゴム

2nd heater har ness (Japan) 2ND ヒーターハーネス

Paper feeding unit(Top) 給紙ユニット上段

Paper feeding unit(Bott om) 給紙ユニット下段

Paper feeding shaft 給紙シャフト

Paper feed rol ler gum 給紙ローラーゴム

DESCRIPTION

– 7 –

Page 27

4

2ND トレイ給紙ユニット (2ND Tray paper feeding unit)[AR-D25]

55

501

11

47

47

13

43

45

48

44

42

4

B

51

17

4

38

4

A

15

15

3

9

15

36

2

B

504

16

62

60

18

58

1

6

8

34

35

61

59

62

18

5

7

21

19

18

9

26

28

29

52

58

59

20

31

61

18

22

24

30

23

27

60

18

32

33

504

57

25

41

46

503

51

A

51

50

56

55

C

56

64

50

13

12

47

47

3

9

15

36

D

51

17

4

17

38

4

C

2

D

504

16

62

60

18

58

1

6

8

35

61

59

34

62

18

5

7

18

9

58

59

26

31

24

52

25

61

27

30

503

504

60

57

PRP01624

502

– 8 –

Page 28

5

250 枚トレイユニット (250 sheets tray unit)

NO. PARTS CODE

1 LPLTM0053QSZ1 AS EQ C

2 PSHEZ0441QSZZ AD DJ N C

3 LHLDW1226FCZZ AB DJ C

4 LPLTM2642FCG2 AD DJ C

7 XRESP40-06000 AA DD C

8 TLABH0064QSZ1 AC DJ D

11 MSPRC0334QSZZ AD DJ N C

12 XEBSD30P08000 AA DD C

13 XWHSD30-08100 AA DD C

14 NGERH0193FCZZ AB DD C

15 MSPRC0152QSZZ AB DJ C

16 MSPRC1145FCZZ AA DD C

17 LSTPP0161FCZZ AB DD C

18 GCASP0003QSE2 BD GN N D

19 TTAG-0004QSZZ AC DJ D

20 PSPAZ0022QSZZ AC DJ C

5

250 枚トレイユニット (250 sheets tray unit)

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

Rotation plate 回転板

Rotation plate sheet 回転板シート

Turn fasner ターンファスナー

Tray rear plate トレイ後端板

E type ring Eリング

Indicator label 指示線ラベル

Tray spring トレイスプリング

Screw(3×8) ビス

Washer ワッシャー

UC manual feed gear UC 手差しギア

Tray spring トレイスプリング

Stopper spring ストッパー用スプリング

Rotation plate stopper 回転板ストッパー

Tray case トレイケース

Tray rotation tag トレイ回転タグ

Rotation plate spacer 回転板スペーサー

DESCRIPTION

3

19

1

2

20

2

5

8

7

7

9

6

4

11

12

10

15

13

14

18

16

– 9 –

17

PRP01625

Page 29

6

梱包材 & 付属品 (Packing material & Accessories)

NO. PARTS CODE

6 SSAKA0302CCZZ AA DD D

7 LPLTM0112QSZZ AE DJ C

8 XEBSE40P12000 AA DD C

TCADZ0248QSZZ AQ EQ N D

9

TCADZ0249QSZZ AG DS N D

10 SPAKA0151QSZZ AR EQ D

11 SSAKH3012KCZZ AD DJ D

13 SPAKA0154QSZZ AF DS D

14 SPAKA0153QSZZ AK EB D

16 XHBSE40P10000 AA DD C

26 PGUMS0003QSZZ AC DJ C

27 TTAG-0005QSZZ AC DJ D

TLABH0116QSZ1 AN EG D

TLABH0065QSZ2 AG DX N D

28

TLABH0117QSZ1 AP EQ N D

TLABH0069QSZ2 AG DX N D

6

梱包材 & 付属品 (Packing material & Accessories)

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

Vinyl bag(160×200) ポリ袋

Adjustment plate 接合板

Screw(4×12) ビス

Inst. Card (Japan) 設置手順書

Inst. Card (Other countries) 設置手順書

OP-C packing cushion (1ST) [AR-D24] O P-C アド (1ST)

Vinyl bag(790×740mm) ポリ袋

Spacer (2ND) [AR-D25] スペーサー (2ND)

Packing cushion (2ND) [AR-D25] パット (2ND)

Screw(4×10) ビス

Joint gear lock gum 連結ギアロック

Tray rotation tag トレイ回転タグ

Cassette size label(Japan) カセットサイズ表示ラベル

Cassette size label(AB series except Japan) カセットサイズ表示ラベル

Cassette size label(Taiwan) カセットサイズ表示ラベル

Cassette size label(inch series) カセットサイズ表示ラベル

DESCRIPTION

10

28

11

8

8

16

7

16

7

8

8

13

9

27

26

6

14

9

27

13

26

6

11

28

14

14

10

14

14

12

15

PRP01626

– 10 –

Page 30

■

索引 (Index)

PARTS CODE

[C]

CFRM-0031RS5C

CFRM-0031RS69

CFRM-0031RS6A

CGUMM0013RS51

CPWBF0019QSE5

CPWBF0019QSE6

CSFTZ0067RS52

DHAI-0075QSZ1

DHAI-0080QSZ1

DHAI-0081QSZ1

DHAI-0326QSZZ

DHAI-0344QSZZ

GCASP0003QSE2

GCOV-0019QSZ2

GCOV-0020QSE1

GCOV-0021QSE2

GCOV-0022QSE2

GGAD-0001QSZZ

GGAD-0002QSZZ

GLEGG0064FCZZ

LBOSZ1031FCZZ

LBOSZ1508FCZZ

LBOSZ1510FCZZ

LBRCR0011QSZZ

LFRM-0031QSE3

LHLDR0095QSZZ

LHLDW1226FCZZ

LHLDW3142KCZZ

LPINS0165FCZZ

LPINS0181FCZZ

LPLTM0053QSZ1

LPLTM0112QSZZ

LPLTM0113QSZZ

LPLTM0115QSZZ

LPLTM0116QSZZ

LPLTM0120QSZZ

LPLTM0135QSZZ

LPLTM0137QSZZ

LPLTM0138QSZZ

LPLTM2642FCG2

LSTPP0161FCZZ

LSUPP0083FCZZ

LX-WZ0314FCZZ

MARMM0016QSZZ

MARMP0015QSZZ

MARMP0229FCZZ

MLEVP0039QSZ1

"

"

[D]

"

"

[G]

"

"

"

"

"

[L]

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

[M]

"

JAPAN ONLY

ORDER CODE

578 213 0476 2-501 BL HL N E

578 213 0478 4-501 BM HR N E

578 213 0477 4-502 BG GX N E

578 352 0054 2-503 AN EG N E

578 352 0054 4-504 AN EG N E

578 684 1103 1- 16 AV FG E

578 684 1114 3- 16 AW FG N E

578 290 0232 2-502 AW FG N E

578 290 0232 4-503 AW FG N E

578 542 0313 2- 10 AR EQ C

578 542 0339 4- 11 AP EQ C

578 542 0340 4- 12 AK DX C

578 542 0328 1- 15 AM EG C

578 542 0328 3- 15 AM EG C

578 542 0345 2- 64 AH DX N C

578 542 0345 4- 64 AH DX N C

578 108 0134 5- 18 BD GN N D

578 110 0240 1- 8 AT EZ N D

578 110 0240 3- 8 AT EZ N D

578 110 0241 1- 1 AQ EQ N D

578 110 0241 3- 1 AQ EQ N D

578 110 0242 1- 24 AP EQ N D

578 110 0243 3- 24 AT EZ N D

572 118 0004 1- 2 AE DJ C

572 118 0004 3- 2 AE DJ C

572 118 0005 1- 3 AE DS C

572 118 0005 3- 3 AE DS C

572 123 0072 1- 19 AC DJ C

572 123 0072 3- 19 AC DJ C

572 202 0270 2- 5 AC DJ C

572 202 0270 4- 5 AC DJ C

572 202 0378 2- 23 AG DX C

572 202 0378 4- 23 AG DX C

572 202 0373 2- 19 AF DX C

572 202 0373 4- 19 AF DX C

578 203 0051 2- 61 AD DJ C

578 203 0051 4- 61 AD DJ C

578 213 0453 2- 38 AU EZ C

578 213 0453 4- 38 AU EZ C

578 214 0265 2- 58 AD DJ C

578 214 0265 4- 58 AD DJ C

572 214 1450 5- 3 AB DJ C

574 214 0010 1- 41 AC DD C

574 214 0010 3- 37 AC DD C

572 218 0087 4- 25 AB DD C

572 218 0093 2- 22 AA DD C

572 218 0093 4- 22 AA DD C

572 221 7143 5- 1 AS EQ C

572 221 7022 3- 6 AE DJ C

572 221 7022 6- 7 AE DJ C

572 221 7023 1- 25 AH DX C

572 221 7023 3- 25 AH DX C

572 221 7089 3- 32 AE DJ C

572 221 7025 1- 5 AQ EQ C

572 221 7025 3- 5 AQ EQ C

572 221 7149 2- 55 AF DS C

572 221 7149 4- 55 AF DS C

572 221 7155 1- 30 AF DS C

572 221 7155 3- 30 AF DS C

572 221 7157 2- 41 AD DJ C

572 221 7157 4- 41 AD DJ C

572 221 7158 1- 31 AD DJ C

572 221 7158 3- 31 AD DJ C

578 221 0760 5- 4 AD DJ C

572 230 0062 5- 17 AB DD C

572 233 0113 1- 4 AB DJ C

572 233 0113 3- 4 AB DJ C

572 990 0230 2- 42 AA DD C

572 990 0230 4- 42 AA DD C

572 240 0337 3- 21 AD DJ C

572 240 0341 1- 21 AD DJ C

572 240 0274 2- 2 AE DS C

572 240 0274 4- 2 AE DS C

578 248 0257 2- 35 AE DS C

NO.

PRICE R.

Ex. Ja.

NEW P/R

PARTS CODE

MLEVP0039QSZ1

MLEVP0046QSZZ

"

MLOKZ0001QSZZ

"

MSPRC0141QSZZ

"

MSPRC0152QSZZ

MSPRC0157QSZZ

"

MSPRC0161QSZZ

"

MSPRC0334QSZZ

MSPRC1145FCZZ

MSPRC1315FCZ1

"

MSPRD0134QSZ2

"

MSPRD0135QSZZ

"

MSPRD0156QSZZ

"

MSPRT0128QSZZ

"

MSPRT0129QSZ1

"

MSPRT0130QSZ1

"

MSPRT0136QSZZ

[N]

NBLTT0012QSZZ

NBRGC0188FCZZ

"

NBRGC0529FCZZ

"

NBRGM0501FCZZ

"

NGERH0041QSZZ

"

NGERH0193FCZZ

NGERH0990FCZZ

"

NGERH1132FCZZ

"

NGERH1169FCZZ

"

NGERH1207FCZZ

"

NPLYZ0012QSZZ

"

NROLP0044QSZ2

NROLP0045QSZ1

NROLP1060FCZZ

"

NSFTZ0067QSZZ

"

[P]

PCLR-0011QSZZ

"

PGIDM0048QSE2

"

PGIDM0049QSE2

"

PGUMM0013QSZZ

"

PGUMS0003QSZZ

PPIPP0007QSZZ

"

PPIPP0011QSZZ

"

PPIPP0109FCZZ

"

PRNGP0019FCZZ

"

PSHEZ0145QSZZ

PSHEZ0171QSZZ

PSHEZ0172QSZZ

PSHEZ0173QSZZ

PSHEZ0441QSZZ

PSPAZ0022QSZZ

PSPO-0005QSZZ

JAPAN ONLY

ORDER CODE

578 248 0257 4- 35 AE DS C

572 248 1162 2- 36 AD DJ C

572 248 1162 4- 36 AD DJ C

572 252 0020 1- 12 AC DJ C

572 252 0020 3- 12 AC DJ C

572 258 3248 1- 11 AB DJ C

572 258 3248 3- 11 AB DJ C

572 258 3303 5- 15 AB DJ C

572 258 3324 2- 43 AC DJ C

572 258 3324 4- 43 AC DJ C

578 258 0554 2- 6 AF DS C

578 258 0554 4- 6 AF DS C

578 258 0793 5- 11 AD DJ N C

572 258 1272 5- 16 AA DD C

572 258 2131 2- 21 AD DJ C

572 258 2131 4- 21 AD DJ C

572 258 3334 2- 27 AC DJ C

572 258 3334 4- 27 AC DJ C

572 258 3261 1- 18 AD DJ C

572 258 3261 3- 18 AD DJ C

572 258 3318 2- 52 AB DJ C

572 258 3318 4- 52 AB DJ C

572 258 3280 2- 3 AB DJ C

572 258 3280 4- 3 AB DJ C

572 258 3300 1- 23 AC DJ C

572 258 3300 3- 23 AC DJ C

572 258 3322 2- 31 AB DJ C

572 258 3322 4- 31 AB DJ C

572 258 3283 3- 36 AB DJ C

572 271 0606 3- 34 AG DX B

572 272 0243 2- 17 AB DD C

572 272 0243 4- 17 AB DD C

572 272 0498 2- 44 AD DJ C

572 272 0498 4- 44 AD DJ C

572 272 0461 2- 9 AB DJ C

572 272 0461 4- 9 AB DJ C

572 281 1801 2- 28 AF DS C

572 281 1801 4- 28 AF DS C

572 281 0318 5- 14 AB DD C

572 281 1125 2- 29 AB DJ C

572 281 1125 4- 29 AB DJ C

572 281 1349 2- 8 AH DX C

572 281 1349 4- 8 AH DX C

572 281 1385 1- 13 AF DS C

572 281 1385 3- 13 AF DS C

572 281 1388 2- 1 AF DS C

572 281 1388 4- 1 AF DS C

572 284 0717 3- 33 AD DJ C

572 284 0717 4- 24 AD DJ C

578 287 0386 2- 13 AQ EQ C

572 287 1928 4- 13 AR EQ C

572 287 1396 1- 22 AF DS C

572 287 1396 3- 22 AF DS C

578 290 0229 2- 57 AK DX C

578 290 0229 4- 57 AK DX C

578 318 0040 2- 60 AC DJ C

578 318 0040 4- 60 AC DJ C

578 345 0451 1- 10 BB FX N C

578 345 0451 3- 10 BB FX N C

578 345 0452 1- 9 BA FX N C

578 345 0452 3- 9 BA FX N C

578 352 0053 2- 62 AG DX C

578 352 0053 4- 62 AG DX C

578 352 0039 6- 26 AC DJ C

572 395 0209 2- 7 AD DJ C

572 395 0209 4- 7 AD DJ C

572 395 0218 2- 45 AC DJ C

572 395 0218 4- 45 AC DJ C

572 395 0039 2- 20 AB DD C

572 395 0039 4- 20 AB DD C

572 399 0026 1- 14 AA DD C

572 399 0026 3- 14 AA DD C

572 403 4559 3- 38 AC DJ C

572 403 4618 1- 40 AD DJ C

572 403 4619 1- 33 AB DJ C

572 403 4620 1- 34 AB DJ C

578 403 0876 5- 2 AD DJ N C

578 413 0120 5- 20 AC DJ C

572 415 0005 2- 53 AA DJ C

NO.

PRICE R.

Ex. Ja.

NEW P/R

– 11 –

Page 31

PARTS CODE

PSPO-0007QSZZ

PSPO-0008QSZZ

PSPO-0009QSZZ

PSPO-0010QSZZ

PSPO-0011QSZZ

PSPO-0014QSZZ

PTME-0016QSZZ

"

PTME-0017QSZZ

"

[Q]

QSW-B0017QSZZ

"

[R]

RCORF0006QSZZ

"

RHET-0011QSZZ

"

RPLU-0012QSZ1

"

RPLU-0013QSZ1

"

[S]

SPAKA0151QSZZ

SPAKA0153QSZZ

SPAKA0154QSZZ

SSAKA0302CCZZ

SSAKH3012KCZZ

[T]

TCADZ0248QSZZ

TCADZ0249QSZZ

TLABH0064QSZ1

TLABH0065QSZ2

TLABH0069QSZ2

TLABH0116QSZ1

TLABH0117QSZ1

TTAG-0004QSZZ

TTAG-0005QSZZ

[V]

VHPGP1A71A1-1

"

[X]

XBBSD30P06000

"

XBBSE30P06000

"

XEBSD30P08000

XEBSE30P08000

"

XEBSE30P12000

"

XEBSE40P12000

"

"

XEPSD30P08X00

"

XHBSE30P08000

"

XHBSE30P14000

"

XHBSE40P10000

XRESP40-06000

"

"

XRESP50-06000

"

XWHSD30-08100

XWHSD60-10000

"

XWUSD40-04085

JAPAN ONLY

ORDER CODE

572 415 0006 2- 54 AB DJ C

572 415 0007 1- 35 AC DJ C

572 415 0008 1- 36 AD DJ C

572 415 0009 1- 37 AD DJ C

578 415 0004 1- 38 AD DJ C

572 415 0010 1- 39 AG DS C

572 420 0308 2- 32 AD DJ C

572 420 0308 4- 32 AD DJ C

572 420 0309 2- 30 AD DJ C

572 420 0309 4- 30 AD DJ C

572 530 0719 2- 26 AF DS B

572 530 0719 4- 26 AF DS B

572 615 0074 2- 47 AL EB C

572 615 0074 4- 47 AL EB C

578 623 0006 2- 50 AQ EQ E

578 623 0006 4- 50 AQ EQ E

578 647 0029 2- 16 AM EG N B

578 647 0029 4- 16 AM EG N B

578 647 0030 2- 33 AM EG N B

578 647 0030 4- 33 AM EG N B

572 902 1476 6- 10 AR EQ D

572 902 1477 6- 14 AK EB D

572 902 1478 6- 13 AF DS D

541 906 5004 6- 6 AA DD D

588 906 0009 6- 11 AD DJ D

578 913 0291 6- 9 AQ EQ N D

578 913 0294 6- 9 AG DS N D

572 917 3369 5- 8 AC DJ D

578 917 0624 6- 28 AG DX N D

578 917 0630 6- 28 AG DX N D

578 917 0621 6- 28 AN EG D

578 917 0627 6- 28 AP EQ N D

572 921 0003 5- 19 AC DJ D

578 921 0010 6- 27 AC DJ D

572 574 0114 2- 15 AG DX B

572 574 0114 4- 15 AG DX B

541 970 5028 2- 34 AA DD C

541 970 5028 4- 34 AA DD C

595 970 0127 2- 46 AA DD C

595 970 0127 4- 46 AA DD C

578 970 0105 5- 12 AA DD C

595 970 0121 2- 51 AA DD C

595 970 0121 4- 51 AA DD C

595 970 0345 2- 59 AA DD C

595 970 0345 4- 59 AA DD C

572 970 1447 1- 7 AA DD C

572 970 1447 3- 7 AA DD C

572 970 1447 6- 8 AA DD C

595 970 0136 1- 27 AA DD C

595 970 0136 3- 27 AA DD C

595 970 0163 2- 56 AA DD C

595 970 0163 4- 56 AA DD C

572 970 1430 1- 28 AA DD C

572 970 1430 3- 28 AA DD C

595 970 0167 6- 16 AA DD C

509 399 5001 2- 18 AA DD C

509 399 5001 4- 18 AA DD C

509 399 5001 5- 7 AA DD C

572 399 0063 2- 4 AA DD C

572 399 0063 4- 4 AA DD C

505 990 5001 5- 13 AA DD C

572 990 0490 2- 48 AA DD C

572 990 0490 4- 48 AA DD C

571 990 0036 3- 35 AA DD C

NO.

PRICE R.

Ex. Ja.

NEW P/R

PARTS CODE

JAPAN ONLY

ORDER CODE

NO.

PRICE R.

Ex. Ja.

NEW P/R

– 12 –

Page 32

Page 33

CAUTION FOR BATTERY REPLACEMENT

(Danish) ADVARSEL !

Lithiumbatteri - Eksplosionsfare ved fejlagtig håndtering.

(English) Caution !

Dispose of used batteries according to manufacturer's instructions.

(Finnish) VAROITUS

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan

(French) ATTENTION

ll y a danger d'explosion s'il y a remplacement incor re ct

de la batterie. Remplacer uniquement avec une batterie du

Mettre au rébut les batteries usagées conformément aux

Udskiftning må kun ske med batteri

Levér det brugte batteri tilbage til leverandoren.

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

Paristo voi räjähtää,jos se on virheellisesti asennettu.

tyyppiin. Hävitä käytetty paristo valmistajan ohjeiden

même type on d'un type équivalent recommandé par

af samme fabrikat og type.

recommended by the manufacturer.

mukaisesti.

le constructeur.

instructions du fabricant.

(Swedish) VARNING

(German) Achtung

Als Ersatzbatterien dürfen nur Batterien vom gleichen Typ oder

(For USA,CANADA)

Contains lithium-ion battery. Mu st be disposed of properly.

Remove the battery from the product and contact

agencies for information on recycling and disposal options.

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent

typ som rekornmenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens

Explosionsgefahr bei Verwendung inkorrekter Batterien.

vom Hersteller empfohlene Batterien verwendet werden.

Entsorgung der gebrauchten Batterien nur nach den vom

Hersteller angegebenen Anwerisugen.

CAUTION FOR BATTERY DISPOSAL

Instruktion.

federal or state environmental

Page 34

q

COPYRIGHT

No part of this publication may be reproduced,

electronic, mechanical, photocopying, recording, or otherwise,

without prior written permission of the publisher.

2003 BY SHARP CORPORATION

All rights reserved.

Printed in Japan.

stored in a retrieval system, or transmitted.

In any form or by any means,

SHARP CORPORATION

Digital Document Systems Group

Products Quality Assurance Department

Yamatokoriyama, Nara 639-1186, Japan

2003 June Printed in Japan t

Loading...

Loading...