Page 1

q

SERVICE MANUAL

Digital copier

MODEL

CONTENTS

CODE : 00Z

ARD22//A1E

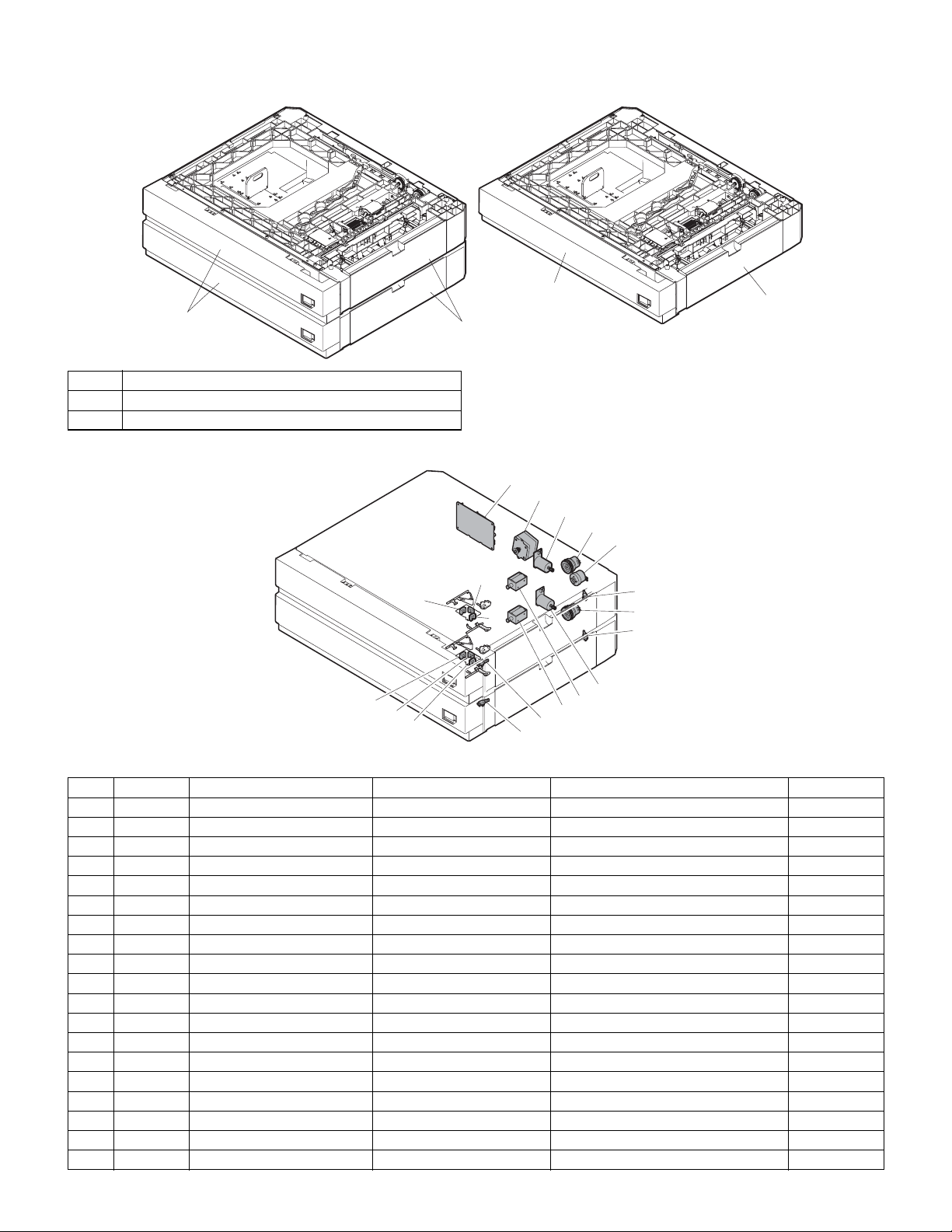

: Paper feed unit

1-Stage paper

AR-D21

AR-D22

feed unit

2-Stage paper

feed unit

[1] GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

[2] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

[3] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . 1

[4] EXTERNAL VIEW AND INTERNAL STRUCTURE . . . . . . . . . . . 6

[5] OPERATION DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

[6] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . 7

[7] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

[8] ELECTRICAL SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Parts mark ed w ith "!" are important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

This document has been pub lished to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

Page 3

[1] GENERAL

The AR-D21 (1-stage paper feed unit) and the AR-D22 (2-stage paper

feed unit) are optional paper feed units added to the digital copier, and

their cassettes are common with those of the main machine.

[2] SPECIFICATIONS

1. Paper feed unit (AR-D21/AR-D22)

AR-D21 AR-D22

No. of stage 1-stage 2-stage

Capacity 550 pages x 1 stage

Size detection No (The paper size is set with the user program.)

Paper empty

detection

Paper feed

size

Size when

shipping

Size selection User selection (Set by the user program.)

Cassette

installation

Heater Provided only for Japan.

Power source Supplied from the copier. DC24V.

Power

consumption

Drive supply

External

dimensions

Weight About 6.1kg About 11.8kg

(Japan)

500 pages x 1 stage

(EX)

(Note) Japan: 64g/m

Provided

A3, B4, A4, A4R, B5, B5R, 16k, 16kR, 8k,

11 x 17, 8.5 x 14, 8.5 x 13, 8.5 x 11, 8.5 x 11R

AB series: A4

Inch series: 8.5 x 11

A3, B4, A4, A4R, B5, B5R, 11 x 17, 8.5 x 14, 8.5 x 13,

8.5 x 11, 8.5 x 11R

Installed by the user.

5.6W 8.4W

• When installed as the

2-stage cassette fo r the

2-stage cassette standard

model: Supplied via gears

from the copier.

• When installed as the

optional 2-stage or 3stage cassette:

Sup plied by the

individu al m otor.

596(W) x 498(D) x

97(H) mm

550 pages x 2 stages

(Total 1,100pages)

(Japan)

500 pages x 2 stages

(Total 1,000 pages)

(EX)

2

, EX: 80g/m

Supplied by the

individual motor.

596(W) x 498(D) x

194(H)mm

2

[3] UNPACKING AND INSTALLATION

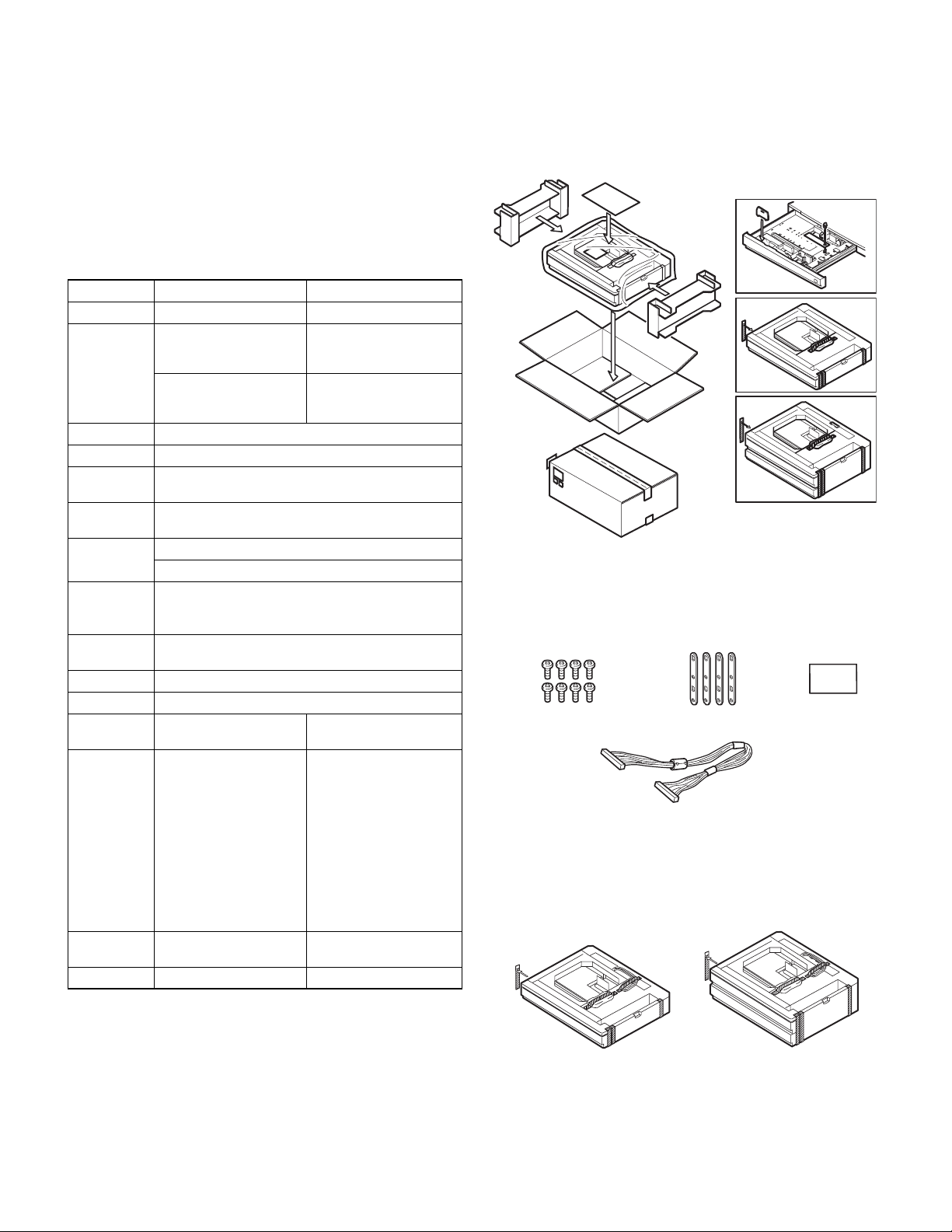

1. Unpacking

AR-D21

AR-D22

2. Installation

PARTS INCLUDED

Fixing plates: 4 pcs. Paper size labelScrews (M4 x 12): 8 pcs.

Cassette relay harness

(contained in the optional paper feed unit)

Remove all pieces of fixing tape and fixing materials from the paper

feed unit.

AR-D21/D22 GENERAL

– 1 –

Page 4

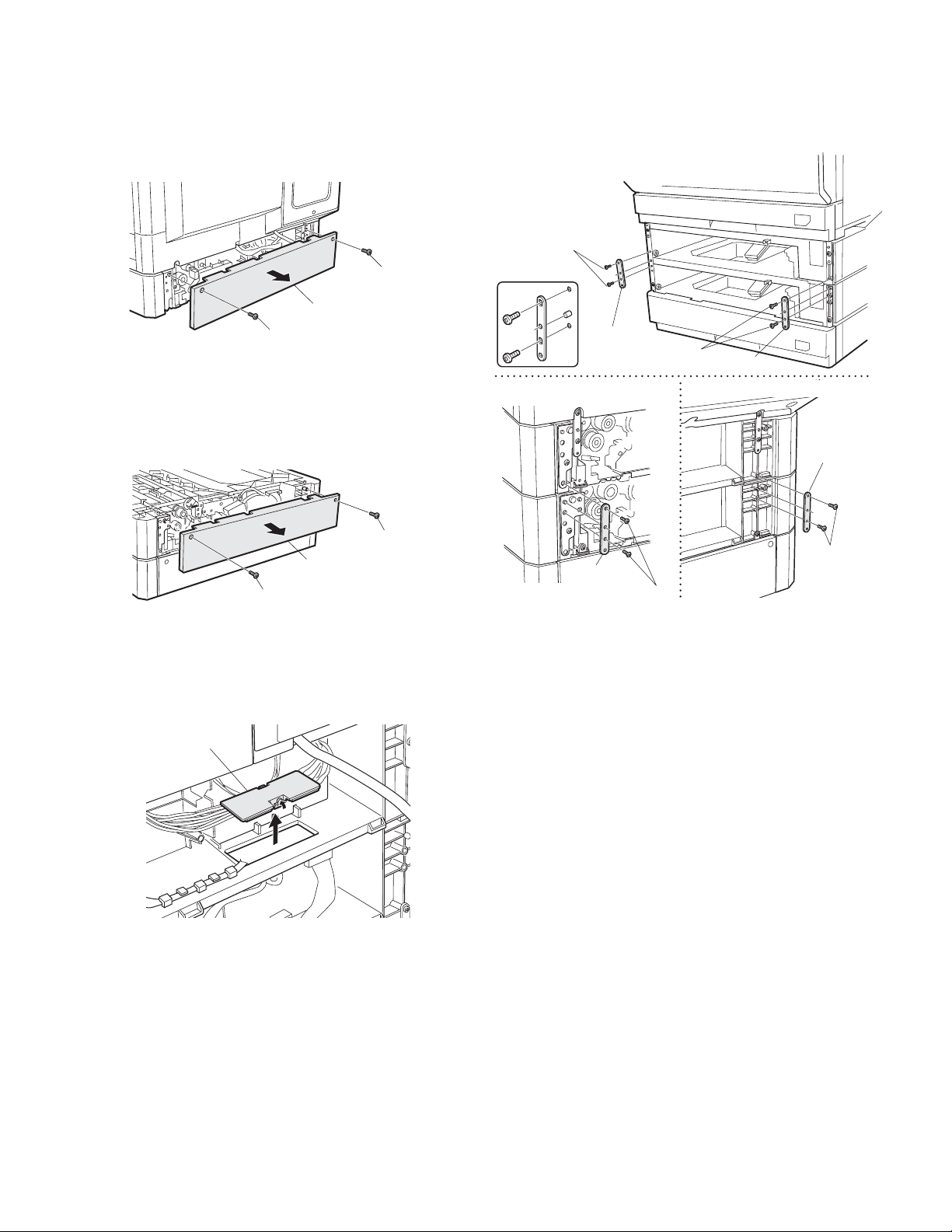

Turn off the main switch of the copier and then remove the power

plug of the copier from the outlet.

1. Remove the rear cover from the copier.

Remove the two screws and then remove the rear cover from the

copier.

Screw

Rear cover

Screw

2. Remove the rear cover from the optional paper feed unit.

Remove the two screws and then remove the rear cover from the

optional paper feed unit.

4. Attach the copier

Place the copier on the optional paper feed unit and remove the second

and third paper trays.

Connect the copier to the paper feed unit using four fixing plates and

two screws (M4 x 12) for each plate.

Front side

Screws (M4 x 12)

Detailed view

Fixing plate

Screws (M4 x 12)

Left of rear side

Fixing plate

Right of rear side

Fixing plate

Screw

3. Remove the connector cover.

Remove the cover from the connector.

Connector cover

Rear cover

Screw

Fixing plate

Screws

(M4 x 12)

Screws

(M4 x 12)

AR-D21/D22 UNPACKING AND INSTALLATION

– 2 –

Page 5

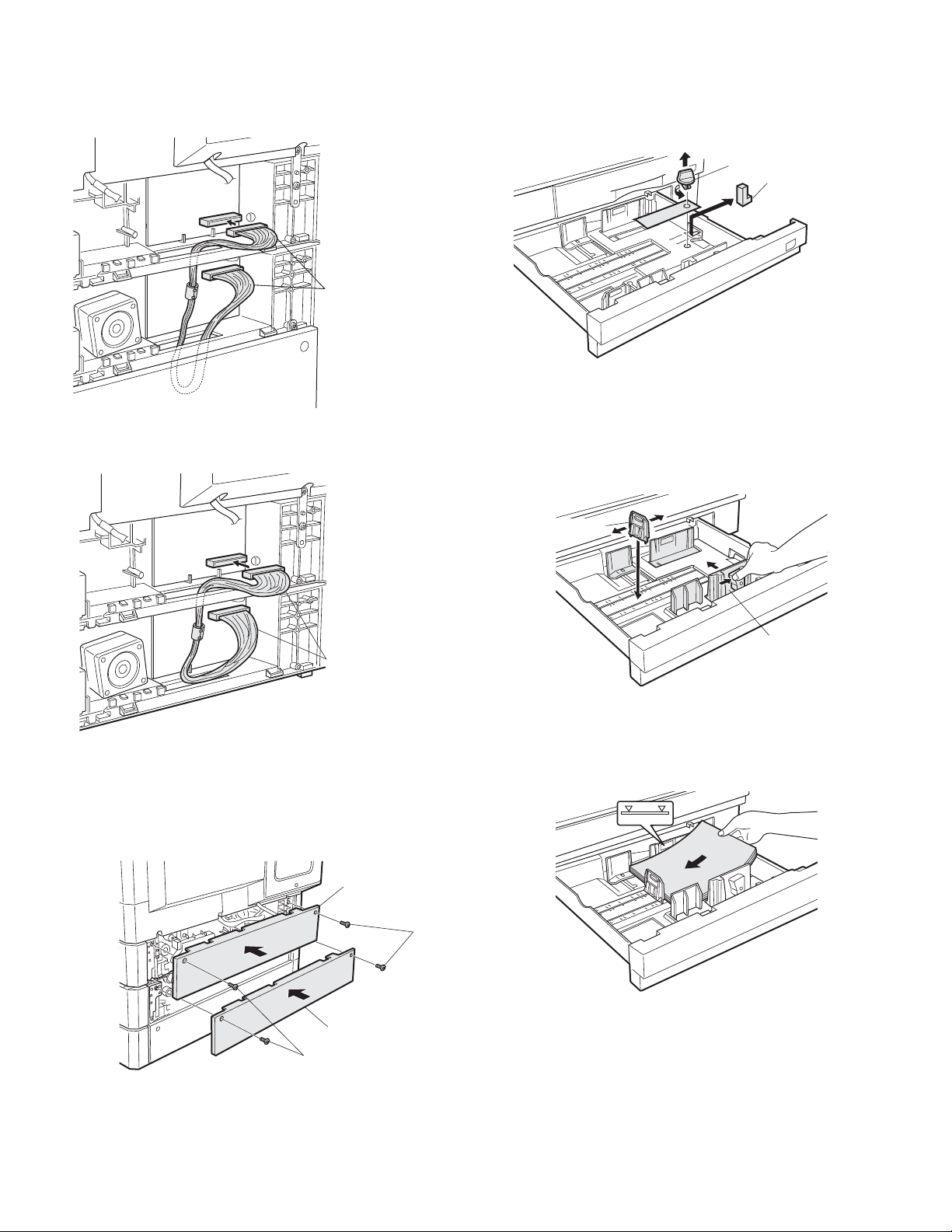

5. Connect the harness.

Connect the cassette interface harness contained in the opt ional paper

feed unit to the paper feed unit interface PWB.

• For two tray type

Cassette relay harness

• For one tray type

7. Remove the securing fixture for packing the paper feed

unit and remove the packing material.

Remove the securing fixture for packing that fixes the paper pressure

plate of the tray by rotating it in the direction of the arr ow and remove

the packing material.

Securing fixture for packing

Packing material

Caution: Be sure to remove the securing fixture bofore turning on the

power.

8. Change the paper size in the tray.

Hold the grip and slide the cassette side plate to adjust it to the paper to

be used.

Then, fit the rear end plate to the specified size position.

Cassette relay harness

6. Attach the rear covers of the copier and the optional

paper feed unit.

Attach the rear covers of the copier and the optional paper feed unit

using two screws respectively.

Rear cover

Screws

Rear plate

Side plate

Insert the power plug of the copier to the outlet and turn on the

main switch of the copier. Then, ca r r y out the followi ng procedure.

9. Load paper into the paper tray.

Do not exceed the maximum height line.

Real cover

Screws

10.Check for center displacement.

• Set an original on the document glass and copy it using the paper

tray in the copier.

Then, copy an original using the attached optional paper feed unit.

• If the center of the copy image from the tray in t he copier is different

from that of the copy image from the optional paper feed unit, carry

out adjustment referring to the service manual.

Installation of Pa per feed unit is now complet e.

AR-D21/D22 UNPACKING AND INSTALLATION

– 3 –

Page 6

Page 7

[4] EXTERNAL VIEW AND INTERNAL STRUCTURE

1. External view

1

No. Name

1 Paper feed tray

2 Paper feed right cover

AR-D22

1

2

AR-D21

2

2. Internal strec t ure

1

2

3

4

5

13

12

14

10

18

9

15

16

17

11

Moter and sensor solenoid etc.

No. Code Name Type Function/Operation Remark

1PWBInterface PWB

2 DM Drive motor Hybrid Drive s gears.

3 LUM3 Lift-up motor (No. 1 tray)

4 CPFS3 Paper feed clutch Electromagnetic clutch Rotates the paper feed roller.

5 TRC3 Transport clutch Electromagnetic clutch Rotates the transport roller.

6 CD3 Cassette detection SW Contact Detects cassette empty.

7 CD4 Cassette detection SW Contact Detects cassette empty. AR-D22 only

8 LUM4 Lift-up motor (No. 2 tray)

9 CPFC3 Paper feed solenoid DC solenoid Feeds paper.

10 DSWR3 Door open/close detection SW Contact Detects door open/close.

11 DSWR4 Door open/close detection SW Contact Detects door open/close. AR-D22 only

12 PED3 Paper empty sensor Photo transmission Detects paper empty in the cassette.

13 LUD3 Upper limit sensor Photo transmission Detects the upper limit for paper pickup.

14 PFD3 Paper entry sensor Photo transmission Detects paper transport.

15 PED4 Paper empty sensor Photo transmission Detects paper empty in the cassette. AR-D22 only

16 LUD4 Upper limit sensor Photo transmission Detects the upper limit for paper pickup. AR-D22 only

17 PFD4 Paper entry sensor Photo transmission Detects paper transport. AR-D22 only

18 CPFC4 Paper feed solenoid DC solenoid Feeds paper. AR-D22 only

19 CPFS4 Paper feed clutch Electromagnetic clutch Rotates the paper feed roller AR-D22 only

6

19

7

8

AR-D21/D22 EXTERNAL VIEW AND INTERNAL STRUCTURE

– 4 –

Page 8

Page 9

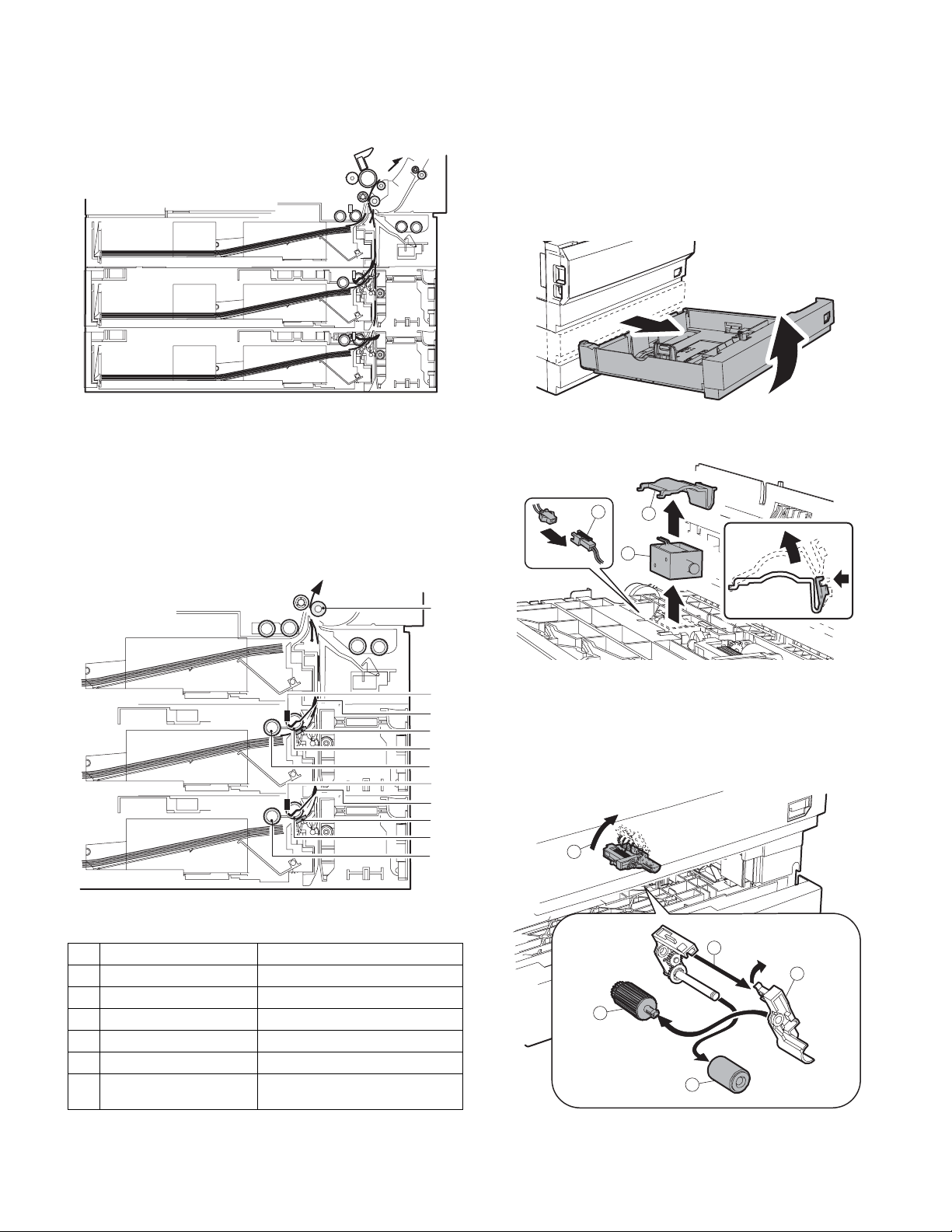

[5] OPERATION DESCRIPTION

1. Paper transport path

2. Operation descriptio ns

The operations of this unit is controlled by the copier, and the pickup

roller, the paper feed roller, etc. are driven by the drive motor. Paper

picked up by the pickup roller is transported by the paper feed roller,

detected by the paper entry sensor, and fed to the resist roller.

[6] DISASSEMBLY AND ASSEMBLY

For disassembly, follow instructions of illustrations 1, 2, 3, ... in this

sequence. For assembly, reverse the disassembly procedures.

For replacement of parts described in this manual, refer to the Pa rts

Guide.

1. Paper feed solenoid

1 - 1

1 - 2

2

1

3

No. Part name Operation

1 Pickup roller Picks up paper.

2 Paper feed roller Transports paper.

3 Separation sheet Press paper t o t h e p a p e r f e e d r oller.

4 Paper entry detection ACT Detects transport of paper.

5 Paper entry sensor Detects transport of paper.

6 Resist roller Synchronizes the p aper lea d edge

and the image lead edge.

6

5

4

2. Paper feed roller

3

2

1

Refer to 1 - 1.

2 - 1

5

4

3

2

1

1

3

2

4

4

AR-D21/D22 OPERATION DESCRIPTION

– 5 –

Page 10

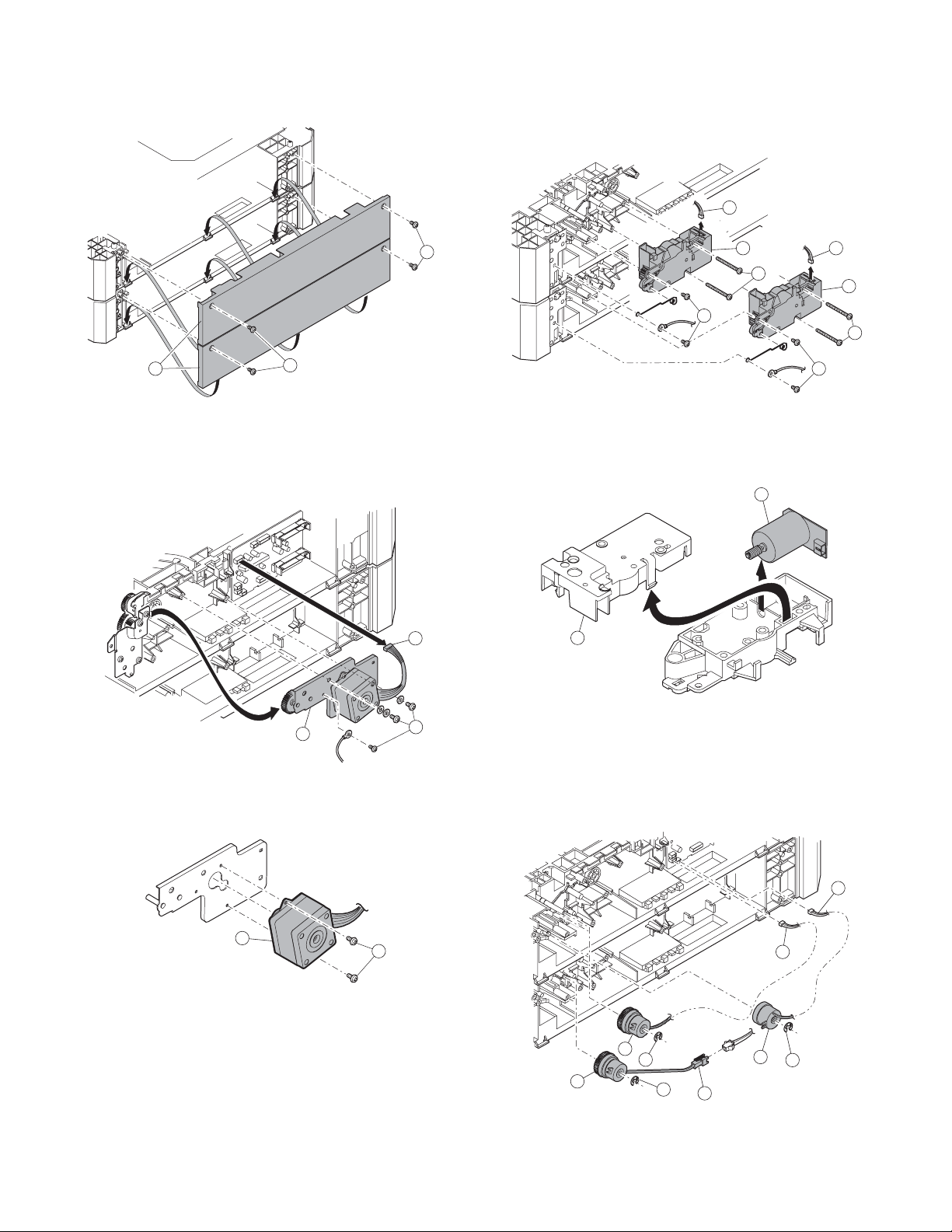

3. Motor, Clutch, Belt, Sensor PWB, Dehumidifier heater

3 - 1

2

A. Drive motor

3 - A - 1

B. Lift-up motor

3 - B - 1

1

1

1

3 - 5

3

2

2

2

1

3

2

2

3 - A - 2

1

3

2

1

C. Paper feed clutch, Transport clutch

3 - C - 1

1

2

1

3

2

3

2

1

1

3

2

AR-D21/D22 DI SASSEMBLY AND ASSEMBLY

– 6 –

Page 11

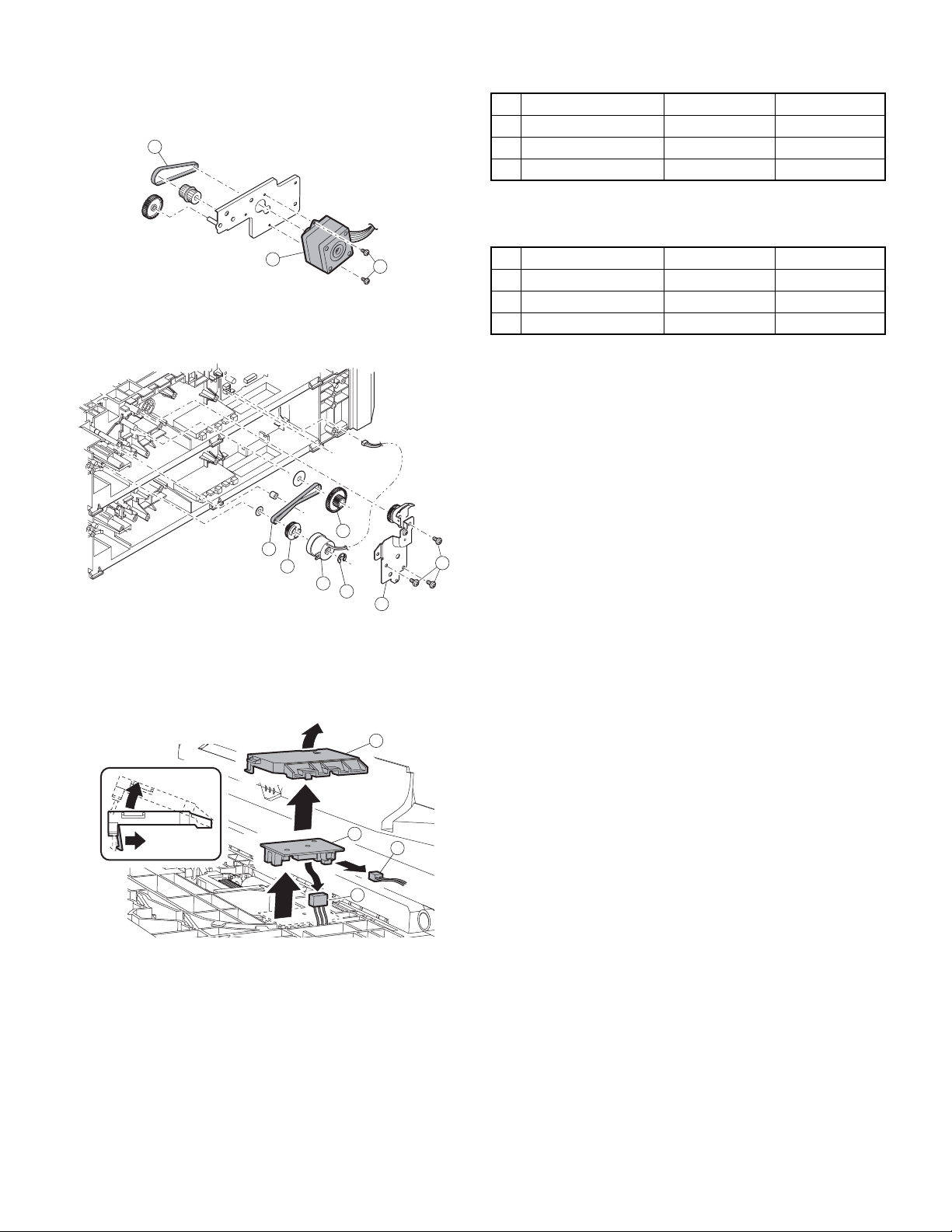

D. Belt

Refer to 3 - A - 1.

3 - D - 1

[7] MAINTENANCE

No. Name Work item When service call

1 Pickup roller Cleaning 50K

3

2 Paper feed roller Cleaning 50K

3 Separation sheet Cleaning 50K

For the replacement method of the pickup roller and paper feed roller,

refer to “[6] DISASSEMBLY AND AS SEMBLY”.

3 - D - 2

E. Sensor PWB

3 - E - 1

2

6

5

4

1

3

1

3

2

No. Name Work item When service call

1 Pickup rollor Replacement 100K

2 Paper feed roller Replacement 100K

3 Separation sheet Replacement 100K

1

2

3

3

AR-D21/D22 MAINTENANCE

– 7 –

Page 12

Page 13

D

D

D

D

[8] ELECTRICAL SECTION

12345678

12345678

12345678

12345678

1. BLOCK DIAGRAM

B

B

B

C

C

C

C

B

A

Copier

(MCU PWB)

CSSEL(A,B,C)

Y2

2

(PCL,PCS,LUM)

AI,BI,/AI,/BI

OPCASSEL

Y1B

1B

(PCL,PCS,

TRCL,LUM)

Y1A

1A(PCL,PCS,

TRCL,LUM)

DATA

SELECTOR

5V

DATA

SELECTOR

TRANSISTOR

ARRAY

24V

MOTOR

DRIVER

CASSETTE INTERFACE PWB

DATA

SELECTOR

PPD1B

PAP1B

LUD1B

DRS1B

CSS1B

24V

/PCL1B

/PCS1B

/TRCLB

LUM1BD

MOTOR

(A,/A,B,/B)

24V

PPD1B

PAP1B

LUD1B

5V

5V

5V

PPD2

PAP2

LUD2

DRS2

CSS2

/PCL2

/PCS2

LUM2D

24V

21

21

21

21

3

3

3

3

:MULTI CASSETTE LOWER

D

D

D

D

5V

DATA

SELECTOR

TRANSISTOR

ARRAY

24V

MOTOR

DRIVER

CASSETTE INTERFACE PWB

:OPTION 2nd CASSETTE or MULTI CASSETTE

B

B

B

C

C

C

C

AR-D21/D22 EL EC T R I C AL SECTION

– 8 –

B

DRS1B

CSS1B

24V

/PCL1B

/PCS1B

/TRCLB

LUM1BD

MOTOR

(A,/A,B,/B)

24V

5V

PPD2

PAP2

LUD2

DRS2

CSS2

/PCL2

/PCS2

LUM2D

24V

A A

A A

A A

A

87654

87654

87654

87654

Page 14

B

B

B

B

1

2

179228-2(AMP)

PHR-3

LB

GL

123

DRS

HPIN

SGND

B3B-PH-K-S

Sensor PWB

PAP1H:

LUD1H:Lift-up upper

limit sensor

PPD1H:Paper entry sensor

DRS:Door sensor

PPD

LUD

HPIN

PAP

+5V

SGND

1

26543

B6B-PH-K-S

GLORPKLBBR

BR

PHR-6

PHDR-14VS

GLORPKLBBRBRRDPLRD

PL

GL

3+5V

2PPD2

6

5DRS2

7

4PAP2

1SGND

PGND

LUD2

CSS2

CN4(B14B-PHDSS-B)

SMP-02V-NC(RD)(JST)

Paper feed

BR

BR

1

1

RD

BR

solenoid

2

2

Lift-up motor

321

GL

LB

PHR-3

SMR-02V-N(RD)(JST)

Cassette

detection

1

2

Paper feed

clutch

179228-2(AMP)

PL

GL

PL

PL

1

2

SMR-02V-B(JST)

1

2

RD

PL

SMP-02V-BC(JST)

GL

BR

LB

9108

14

13PGND

12

11

LUM2D

+24V

/PCL2

/PCS2

+24V

SMP-02V-NC(RD)(JST)

Paper feed

BR

BR

1

1

BR

RD

solenoid

2

2

SMR-02V-N(RD)(JST)

CN3(B3B-PH-K-S)

C

C

C

C

Paper feed

clutch

PHR-3

PLPLLB

1

N.C. 2

/PCL1A

3

+24V

HPR-3(BK)

1

TRCLA

CN2(B3B-PH-K-K(BK))

Lift-up motor

Cassette

detection

123

1

2

GL

GL

N.C. 2

3

PGND

179228-2(AMP)

PL

GL

PHR-3(BL)

PL

GL

3

1

N.C. 2

CSS1

SGND

CN7(B3B-PH-K-B(BL))

LB

PHR-3

PHR-3(RD)

LB

LB

1

3

N.C. 2

+24V

LUM1AD

CN1(B3B-PH-K-R(RD))

D

D

D

D

12345678

12345678

12345678

12345678

1

2

179228-2(AMP)

PHR-3

PL

GL

123

SRA-21T-4

PHR-5

1AI

CN6(B5B-PH-K-S)

2/AI

PULSE

3BI

MOTOR

FG

SRA-01T-3.2

524V1

4/BI

MULTI CASSETTE (UPPER)

Sensor PWB

PPD1H:Paper entry sensor

PPD

+5V

SGND

1

26543

B6B-PH-K-S

GLORPKLBBR

BR

PHR-6

PHR-8

GLBRORPKLB

1

CN8(B8B-PH-K-S)

DRS

HPIN

SGND

B3B-PH-K-S

LUD1H:Lift-up upper

limit sensor

HDRS:Door sensor

PAP1H:

LUD

PAP

DRS1

BR

BR

7

4

LUD1

/PCS1B

PAP13PPD1 26SGND5+5V

DRS1

RD

8+24V

A

21

21

21

21

MULTI CASSETTE (LOWER)

3

3

3

3

CASSETTE INTERFACE PWB

2nd CASSETTE

FG

SRA-01T-3.2

OPTION 2nd CASSETTE ONLY

SRA-21T-4

PLUSE

MOTOR

PHR-5

3BI

2/AI

524V1

4/BI

1AI

CN6(B5B-PH-K-S)

+24V

+24V

PGND

PGND

CASSETTE INTERFACE PWB

1A

2A

20B

19B

CN9(53314-1015)

GL

GL

GL

RD

RD

+24V

+24V

1A

20B

CN9(53314-1015)

RD

RD

SENSOR PWB

B6B-PH-K-S

CN8(B8B-PH-K-S)

SGND

SGND

SGND

18B

GL

GL

SGND

PGND

PGND

SGND

2A

18B

19B

GL

GL

GL

GL

PHR-3

B3B-PH-K-S

PPD1H:Paper entry sensor

PAP1H:

PPD

PAP

+5V

SGND

1

26543

GLORPKLBBR

BR

PHR-8 PHR-6

GLBRORPKLBBRBR

4

1

PAP13PPD1 26SGND5+5V

SGND

+5V3A+5V4A+3.3V

5A

6A

16B

17B

BL

GL

OR

OR

SGND

+5V3A+5V4A+3.3V

SGND

5A

16B

17B

GL

GL

OR

OR

1

2

179228-2(AMP)

PL

GL

123

DRS

HPIN

SGND

LUD1H:Lift-up upper

limit sensor

DRS:Door sensor

LUD

DRS1

RD

7

8+24V

LUD1

/PCS1A

DRS1

+3.3V

LUM2#

PGND

Y1A

8A

7A

15B

14B

BL

PK

GL

BR

BL

PL

6A

PCS2#

13B

+3.3V

15B

BL

SMP-02V-NC(RD)(JST)

Y1B

LB

LUM2#

PGND

7A

14B

PK

GL

Paper feed

solenoid

BR

BR

1

2

1

2

BR

RD

PCL2#

Y2

12B9A10A

PK

BR

Y1A

8A

BR

SMR-02V-N(RD)(JST)

LUM1B#

11B

PL

PCS2#

13B

LB

PL

PHR-3

PL

CN3(B3B-PH-K-S)

CSSELA#

11A

LB

PK

PCL2#

Y1B

12B9A10A

PK

Paper feed

clutch

1

N.C. 2

/PCL1A

TRCLB#

CSSELC#

10B

12A

BR

LUM1B#

Y2

CSSELA#

11A

11B

PL

LB

BR

HPR-3(BK)

PL

LB

1

3

TRCLA

+24V

CN2(B3B-PH-K-K(BK))

PCS1B#

PCL1B#

CSSELB#

9B

8B

13A

LB

PL

PK

PK

BR

TRCLB#

10B

BR

LB

N.C. 2

BI#

14A

PL

CSSELC#

PCS1B#

9B

12A

PL

3

+24V

CN1(B3B-PH-K-R(RD))

/BI#

AI#

7B

15A

LB

PCL1B#

CSSELB#

8B

13A

LB

PK

Lift-up motor

123

LB

PHR-3

PHR-3(RD)

LB

1

N.C. 2

LUM1AD

OPCASSEL#

/AI#

6B

16A

PK

BR

BI#

AI#

7B

14A

PL

BR

GL

GL

3

PGND

LUM1A#5B

+24V17A

PL

RD

/BI#

/AI#

LUM1A#5B

OPCASSEL#

6B

15A

16A

PL

LB

PK

BR

Cassette

detection

1

2

179228-2(AMP)

PL

GL

PHR-3(BL)

PL

GL

3

1

N.C. 2

CSS1

SGND

CN7(B3B-PH-K-B(BL))

TRCLA#4B

+24V18A

PCS1A#3B

PGND19A

LB

PK

GL

RD

+24V17A

RD

PCL1A#2B

BR

TRCLA#4B

LB

RD

CN5(53314-1015)

PGND20A

GL

GL

+24V18A

PCS1A#3B

PGND19A

GL

PK

51089-4005

1A

20B

+24V

+24V

SGND1B

BR

GLRDRD

PCL1A#2B

2A

PGND

GL

GL

PGND20A

19B

PGND

GL

GL

SGND1B

SGND

GL

18B

SGND

GL

SGND

GL

17B

SGND

ORORBL

5A

CN5(53314-1015)

6A

16B

+5V3A+5V4A+3.3V

MULTI CASSETTTE

PL

11B

N.C.

LB

11A

CSSELA#

PKBRBR

PL

9B

10B

12A

13A

N.C.

N.C.

CSSELC#

CSSELB#

1SGND

3+5V

2 PPD2

CN4(B14B-PHDSS-B)

PK

PLLBBR

PK

8B

N.C.

4 PAP2

14A

BI#

5 DRS2

7B

AI#

LUD2

6

LB

15A

/BI#

PGND

7

PKBRRDGLGL

PLRDBRGLLB

6B

16A

LUM1B# 5B

+24V 17A

TRCLB# 4B

+24V 18A

PCS1B# 3B

PGND 19A

PCL1B# 2B

PGND 20A

OPCASSEL#

/AI#

+24V

/PCL2

CSS2

+24V

9108

11

SGND 1B

LUM2D

/PCS2

14

13 PGND

12

2nd CASSETTTE

PK

PK

BL

GL

BR

LB

PL

8A

7A

15B

14B

13B

12B9A10A

PCS2#

+3.3V

LUM2#

PGND

Y1B

PCL2#

Y2

N.C.

2. Actual wiring diagram

MCU PWB

D

D

D

D

51089-4005

+24V

+24V

1A

20B

GLRDRD

PGND

2A

GL

PGND

19B

GL

SGND

GL

SGND

18B

GL

SGND

GL

SGND

17B

ORORBL

5A

+5V3A+5V4A+3.3V

6A

16B

PL

LUM1B#

11B

PKBRBR

LB

CSSELA#

11A

TRCLB#

10B

PL

CSSELC#

PCS1B#

9B

12A

PK

PCL1B#

CSSELB#

8B

13A

C

C

C

C

PLLBBR

LB

/BI#

/AI#

BI#

AI#

LUM1A#5B

+24V17A

OPCASSEL#

7B

6B

14A

15A

16A

SGND1B

TRCLA#4B

+24V18A

PCS1A#3B

PGND19A

PCL1A#2B

PGND20A

87654

87654

87654

87654

B

B

B

B

A A

A A

A A

A

PK

PK

BL

GL

BR

LB

PL

+3.3V

LUM2#

PGND

Y1B

Y1A

PCS2#

PCL2#

Y2

8A

7A

14B

13B

15B

12B9A10A

PK

PKBRRDGLGL

PLRDBRGLLB

AR-D21/D22 EL EC T R I C AL SECTION

– 9 –

Page 15

B

B

B

D

D

D

D

12345678

12345678

12345678

12345678

C

C

C

C

CSS1

PPD1

DRS1

PAP1

LUD1

10Kx7

R37

3.3V

R41 R40R42R43

R39 R38

JP2 JP1

B

PPD2

PAP2

CSS2

DRS2

LUD2

2200pF/50Vx5

C35

C38 C37C39C40

JP1 MOTOR L MOTOR

JP2 1, 2 Cassette L 1 Step

10Kx5

3.3V

R15R13 R1 2

R14 R16

C9C12

C13

C11

C10

A

Multi Cassette Only

(QS53)

21

21

21

2200pF/50Vx6

21

Option Cassette Only

(QS52,QS53)

R23

R31

C31

24V

7.5K

C22

2200pF/

7.5K

2200pF/50V

(2-1A)

AIBI24V1

/BI

/AI

F2

ICP-N38

47uF/35V

C1

+

0.047uF/50V

C18

0.047uF/50V

C19

8

20

10

18

1

NC17NC16NC15NC14NC12NC

Vmm

OUT A

OUT B

OUT /A

OUT /B

CrA2CrB26VsA4RsA9VrefA3VrefB25RsB19VsB24In /A5In A6In /B23In B

IC2

R20

1K

50V

C20

3300pF/50V

C33

0.1uF/25V

R3 1.5(1W)

R4 1.5(1W)

R33 2.4k

R36 2.4k

R32

1.5kF

27

11

PG7PG13PG21LG

MTD1361

22

R22

1K

C21

3300pF/50V

C34

0.1uF/25V

R34

430F

AI#

BI#

/AI#

/BI#

C36

0.1uF/25V

PCL1A#

R30 1.5K

IC1

COM

9

24V

D04D13D22D31D415D514D613D7

IC5

VCC

W6Y

5

16

Y1A

PCL2#

LUM1A#

TRCLA#

PCS1A#

PCS2#

R25 1.5K

R27 1.5K

R29 1.5K

R28 1.5K

R26 1.5K

I11I22I33I44I55I66I7

O116O215O314O413O512O611O7

12

7

G

74HC151AF

GND

A11B10C

8

9

1Kx3

R17

R18

R19

CSSELB#

CSSELA#

LUM2#

R24 1.5K

7

8

GND

TD62001

10

C7

0.047uF/50V

C8

CSSELC#

0.047uF/

UDZS3.9B

ZD2

UDZS3.9B

ZD3

UDZS3.9B

ZD1

50V

C26

0.1uF/25V

IC4

16

D04D13D22D31D415D514D613D7

VCC

W6Y

5

Y2

12

A11B10C

7

G

74HC151AF

GND

8

9

C24

C25 C23

3

3

3

3

1000pF/50Vx3

C32

0.1uF/25V

R11

R35

1

VOUT

IC3

KIA78S05P

VIN

3

R5

3. Interface PWB circuit diagram (1/2)

24V

D

D

D

D

C5

10uF/16V

GND

2

C6

10uF/35V

R6

3.6K 1/4W

3.6K 1/4W

2.4KF

Q5

DTC143ZKA

47k

4.7k

OPCASSEL#

C

C

C

C

24V

/PCL2

/PCS2

/PCL1A

/TRCLA

/PCS1A

10k

R2

1.5k(1/2W)

F3

ICP-N38

5

6

3

Q4

IMZ4

LUM1AD

Q3

2

DTC114EKA

1 3

R10

1.5k

2

R21

47

4 1

24V

Multi Cassette Only

B

B

B

B

(QS53)

R7

10k

R1

1.5k(1/2W)

F1

ICP-N38

5

6

Q2

IMZ4

LUM2D

2

Q1

DTC114EKA

1 3

R8

1.5k

2

R9

47

4 1

3

87654

87654

87654

87654

A A

A A

A A

A

AR-D21/D22 EL EC T R I C AL SECTION

– 10 –

Page 16

B

B

B

PCS2#

PCL2#

B

AI#

LUM1B#

/AI#

3133353739

PCS1B#

TRCLB#

PCL1B#

40

B40B-PADKS-1

7

3

•¢

•¢

C17

0.1uF/25V

C16

0.1uF/25V

Option Cassette Only

(QS51,QS52)

D

D

D

D

12345678

12345678

12345678

12345678

123

CN7

CN1

B3B-PH-K-E(BL)

123

LUM1AD/TRCLA

B3B-PH-K-R(RD)

C

C

C

C

LUM2#

3.3V

5V

246

8

101214161820222426283032363438

CN5

1357911131517192123252729

4

•¢

A

NOTE

QS51:STANDARD 2ND CASSETTE

QS52:OPTION 2ND CASSETTE

QS53:OPTION MULTI CASSETTE

21

21

21

21

3

3

3

3

CN3

24V

5V 3.3V

CN9

123

/PCL1A CSS1

246

8

101214161820222426283032363438

1357911131517192123252729

B3B-PH-K-S

LUM2#

PCS2#

PCL2#

CN2

LUM1B#

TRCLB#

123

PCL1B#

PCS1B#

AI#

B3B-PH-K-K(BK)

/AI#

TRCLA#

PCS1A#

PCL1A#

3133353739

40

7

C29

B40B-PADSS-1

•¢3•¢

C30

0.1uF/25V

+

C3

0.1uF/25V

+

C4

10uF/16V

10uF/16V

C15

0.047uF/50V

24V

Y2

BI#

LUD2

CSSELA#

CSS2

/PCL2

8

101214

CSSELB#

CSSELC#

/PCS2

LUM2D

/BI#

OPCASSEL#

B14B-PHDSS-B

Y1B

PPD2

PAP2

Multi Cassette Only

(QS53)

246

135791113

CN4

5V

C14

0.047uF/50V

12345

CN6

Option Cassette Only

(QS52,QS53)

AI

BI

/AI

/BI

1234567

CN8

5V

24V1

8

B5B-PH-K-S

B8B-PH-K-S

24V

C2

47uF/35V

+

F4

ICP-N50

24V

BI#

CSSELB#

CSSELA#

CSSELC#

/BI#

OPCASSEL# LUM1A#

3. Interface PWB circuit diagram (2/2)

D

D

D

D

Y1AY2Y1B

C27

C

C

C

C

C28

0.047uF/50V

0.047uF/50V

DRS2

B

B

B

B

PPD1

PAP1

24V

LUD1

DRS1

/PCS1A

A A

A A

A A

A

87654

87654

87654

87654

AR-D21/D22 EL EC T R I C AL SECTION

– 11 –

Page 17

B

B

B

D

D

D

D

12345678

12345678

12345678

12345678

C

C

C

C

12345

PPD

PAP

DRS

LUD

6

S6B-PH-K-S

C3

102pF

CN1

5V

B

123

CN2

S3B-PH-K-S

DRS

A

21

21

21

21

3

3

3

3

PT3

GP1S58V

R3

220J/ 1/4W

Upper limit

C2

102pF

PT2

GP1S58V

R2

220J/ 1/4W

C1

102pF

PT1

GP1S58V

R1

5V

220J/ 1/4W

4. Sensor PWB circuit diagram

D

D

D

D

C

C

C

C

AR-D21/D22 EL EC T R I C AL SECTION

– 12 –

87654

87654

87654

87654

B

B

B

B

A A

A A

A A

A

Page 18

5. Parts layout

1) Cassette interface PWB

a. Parts surface

CN3 (B3B-PH-K-S)

3 +24V

2 N.C.

1 /PCL1A

CN4 (B14B-PHDSS-B)

13 PGND

11 +24V

9 +24V

7 PGND

5 DRS2

3 +5V

1 SGND

14 LUM2D

12 /PCS2

10 /PCL2

8 CSS2

6 LUD2

4 PAP2

2 PPD2

CN2 (B3B-PH-K BL)

3 +24V

2 N.C.

1 TRCLA

CN1 (B3B-PH-K-R RD)

3 PGND

2 N.C.

1 LUM1AD

CN6 (B5B-PH-K-S)

5 24V1

4 /B1

3 B1

2 /A1

1 A1

CN7 (B3B-PH-K BL)

3 SGND

2 N.C.

1 CSS1

CN8 (B8B-PH-K-S)

8 +24V

7 /PCS1B

6 LUD1

5 DRS1

4 PAP1

3 +5V

2 PPD1

1 SGND

CN5 (53314-1015) CN9 (53314-1015)

2 +24V

4 PGND

6 SGND

8 SGND

10 +5V

12 +3.3V

14 LUM2#

16 PCS2#

18 PCL#

20 N.C.

22 N.C.

24 N.C.

26 N.C.

28 A1#

30 /A1#

32 LUM1B#

34 TRCLB#

36 PCS1B#

38 PCL1B#

40 SGND

AR-D21/D22 EL EC T R I C AL SECTION

1 +24V

3 PGND

5 SGND

7 SGND

9 +5V

11 +3.3V

13 PGND

15 Y1B

17 N.C.

19 Y2

21 CSSELA#

23 CSSELC#

25 CSSELB#

27 B1#

29 /B1#

31 OPCASSEL#

33 +24V

35 +24V

37 PGND

39 PGND

2 +24V

4 PGND

6 SGND

8 SGND

10 +5V

12 +3.3V

14 LUM2#

16 PCS2#

18 PCL2#

20 LUM1B#

22 TRCLB#

24 PCS1B#

26 PCL1B#

28 A1#

30 /A1#

32 LUM1A#

34 TRCAL#

36 PCS1A#

38 PCL1A#

40 SGND

– 13 –

1 +24V

3 PGND

5 SGND

7 SGND

9 +5V

11 +3.3V

13 PGND

15 Y1A

17 Y1B

19 Y2

21 CSSELA#

23 CSSELC#

25 CSSELB#

27 B1#

29 /B1#

31 OPCASSEL#

33 +24V

35 +24V

37 PGND

39 PGND

Page 19

b. Solder surface

2) Cassette sensor PWB

a. Parts surface b. Solder surface

CN1 (S6B-PH-K-S)

6 LUD

5 DRS

4 PAP

3 5V

2 PPD

1 SGND

3 DRS

2 N.C.

1 SGND

AR-D21/D22 EL EC T R I C AL SECTION

– 14 –

Page 20

Page 21

q

PARTS GUIDE

CODE:00ZARD22//P1/

デジタル複合機

デジタル複合機

デジタル複合機デジタル複合機

給紙ユニット

給紙ユニット

給紙ユニット給紙ユニット

[AR-D21]

[AR-D22]

1

外装部 (Exteriors)

2

搬送部 (Paper transfer section)

3

給紙部 (Paper feed section)

DIGITAL COPIER

Paper feed unit

AR-D21

MODEL

このパーツガイドに掲載されている表示価格ランクは消費税抜きです。

CONTENTS

AR-D22

4

駆動部 (Drive section)

5

リフトアップユニット (Lift up unit)

6

550 枚カセット (550 sheets cassette unit)

7

梱包&付属品 (Packing material & Accessories)

8

カセット中継基板 (Cassette interface PWB)

■

本書はサービス活動用に作成した資料です。

一部内容が製品の改良・改善等により予告

なしに変わることがあります。

索引 (Index)

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 22

Page 23

補修部品のランク付

市場における補修部品の在庫管理が、適正に運営出来る手助けとなることを、目的とします。

Aランク : メンテナンスパーツ、メンテナンスパーツには入っていないがメンテナンスパーツに近い消耗パーツ。

Bランク : 性能・機能パーツ(センサー、クラッチ等の電気パーツ)、消耗パーツ。

Eランク : 基板含むユニットパーツ。

Dランク : 整備パーツ(外装、パッキング、同梱パーツ)。

Cランク : 上記ランク以外のパーツ(基板の子部品を除いたもの)。

DEFINITION

Rank A : Maintenance parts, and consumable parts which are not included in but closely related to maintenance parts

Rank B : Performance/function parts (sensors, clutches, and other electrical parts), consumable parts

Rank E : Unit parts including PWB

Rank D : Preparation parts (External fitting, packing, parts packed together)

Rank C : Parts other than the above (excluding sub components of PWB)

安全性・信頼性確保のため部品は、必ず正規のものをご使用下さい。

! 印の商品は、安全上重要な部品です。交換をする時は、安全及び性能維持のため必ず指定の部品をご使用下さい。

Because parts marked with "!" is indispensable for the machine safety maintenance and operation, it must be replaced with

the parts specific to the product specification.

F

当モデルのサービス資料には、この資料以外にサービスマニュアル ( 回路図含む ) があります。合わせてご利用下さい。

F Other than this Parts Guide, please refer to documents Service Manual (including Circuit Diagram)of this model.

F Please use the 13 digit code described in the right hand corner of front cover of the document, when you place an order.

F For U.S. only-Use order codes provided in advertising literature. Do not order from parts department.

– 1 –

Page 24

1

外装部 (Exteriors)

NO. PARTS CODE

1 GCAB-0030QSZA AN EG N D

2 XEBSE40P12000 AA DD C

3 LPLTM0240QSZZ AC DJ C

5 GCOVA0025QSZB AS EQ N D

7 LFRM-0039QSZB BK HG N C

8 LPLTM0236QSZZ AG DX C

10 PCOVP0063QSZB AD DJ N C

12 NSFTZ0048QSZZ AG DX C

13 NKOM-0005QSZZ AC DJ C

14 XBPSD30P08KS0 AA DD C

15 GLEGG0064FCZZ AC DJ C

16 LPLTM0237QSZZ AH DX C

17 RHET-0006QSZZ AQ EQ B

18 LPLTP0192QSZZ AK DX C

19 XEBSD30P08000 AA DD C

20 DHAI-0393QSZZ AK EB N C

22 PSHEZ0325QSZZ AB DJ C

23 LX-BZ0037QSZZ AB DD C

24 PSHEZ0278QSZZ AE DJ C

25 MSPRD0277QSZZ AN EG C

26 TLABS4306FCZZ AC DJ D

1

外装部 (Exteriors)

PRICE RANK

Ex. Ja.

MARK

NEW

PART

RANK

Left cabinet 左キャビネット

Screw(4×12) ビス

Joint plate 連結板

Rear cover 後カバー

Frame フレーム

Reinforce plate R 補強板 R

Front cover 前カバー

Cassette collar shaft カセットコロ軸

Cassette guide collar カセットガイドコロ

Screw(3×8KS) ビス

Rubber foot ゴム足

Reinforce plate F 補強板 F

Cassette dry heater [Japan only] カセット除湿ヒータ

Dry heater fixing plate [Japan only] カセット除湿ヒータ取付板

Screw(3×8) [Japan only] ビス

Dry heater harness [Japan only] 除湿ヒータ分岐ハーネス

Frame lower mylar フレーム下マイラー

Screw(4×12) ビス

Heat insulation sheet 多段断熱シート

2nd joint earth spring [Taiwan] 2nd 連結アーススプリング

Noise label A [U.S.A,Canada] ノイズラベル A

DESCRIPTION

2

2

25

2

26

1

2

3

2

2

5

2

23

14

3

19

13

19

12

15

16

23

20

24

22

3

2

7

15

17

18

19

2

10

8

3

2

FCP06676

2

– 2 –

Page 25

2

搬送部 (Paper transfer section)

NO. PARTS CODE

1 MSPRC0141QSZZ AB DJ C

2 MLOKZ0001QSZZ AC DJ C

3 XEPSD30P08X00 AA DD C

4 PGIDM0068QSZZ AP EQ C

5 MARMP0015QSZZ AD DJ C

6 NSFTZ0054QSZZ AE DJ C

7 NROLP1060FCZZ AF DS C

MSPRP0345QSZZ AD DJ N C

8

MSPRP0273QSZZ AD DJ C

9 XEBSD30P08000 AA DD C

10 GCOVA0026QSZB AP EQ N D

11 XEBSD30P10000 AA DD C

12 PCOVP0089QSZZ AD DJ C

13 LPLTP0297QSZZ AC DJ C

14 PSHEZ0378QSZZ AG DX C

15 NROLR0052QSZZ AN EQ C

16 MSPRC0270QSZZ AB DJ C

17 NBRGZ0503FCZZ AC DJ C

18 LSTPP0011QSZZ AC DJ C

19 LRALP0009QSZZ AQ EQ C

20 XBPSD30P08KS0 AA DD C

21 NKOM-0005QSZZ AC DJ C

22 NSFTZ0048QSZZ AG DX C

23 PGIDM0074QSZZ AK DX C

24 XEBSE40P12000 AA DD C

25 MSPRD0259QSZZ AC DJ C

26 MSPRD0287QSZZ AC DJ C

27 NSFTZ0064QSZZ AD DJ C

28 NROLP0087QSZZ AD DJ C

29 PSHEZ0301QSZZ AC DJ C

30 PSHEZ0302QSZZ AC DJ C

501 CCOVP0089RS51 AQ EQ E

502 CGIDM0068RS51 AS EQ E

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

Lock spring ロックスプリング

Paper guide lock ペーパーガイドロック

Screw(3×8X) ビス

Transport paper guide 搬送ペーパーガイド

Door arm ドアアーム

Transport paper guide shaft 搬送ペーパーガイドシャフト

U-turn roller U ターンローラー

Transport paper guide spring [AR-D21] 搬送ペーパーガイドスプリング

Transport paper guide spring [AR-D22] 搬送ペーパーガイドスプリング

Screw(3×8) ビス

Right cover 右カバー

Screw(3×10) ビス

Plate cover プレートカバー

Separation plate 捌きプレート

Separation sheet 捌きシート

Transport roller 搬送ローラー

Separation plate spring 捌きプレートスプリング

Bearing(B-F5-13) 軸受

E-ring E- リング

Cassette rail R カセットレール R

Screw(3×8KS) ビス

Cassette guide collar カセットガイドコロ

Cassette collar shaft カセットコロ軸

U-turn guide U ターンガイド

Screw(4×12) ビス

U turn guide spring [AR-D22] 多段 U ターンガイドスプリング

Paper feed assistance roller SP 給紙補助ローラースプリング

Paper feed assistance roller shaft 給紙補助ローラー軸

Paper feed assistance roller 給紙補助ローラー

Rail R side mylar F レール R サイドマイラー F

Rail R side mylar R レール R サイドマイラー R

Plate cover unit プレートカバーユニット

Transport paper guide unit [AR-D21] 搬送ペーパーガイドユニット

DESCRIPTION

2

搬送部 (Paper transfer section)

23

e

30

29

22

14

13

26

21

24

15

17

18

20

24

23

f

30

29

19

14

13

26

22

21

20

24

24

19

28

501

28

501

27

26

16

12

27

26

16

12

25

1

11

3

3

1

2

2

1

502

4

a

8

9

6

b

10

c

d

10

FCP06677

11

a

b

7

e

3

11

2

f

1

2

c

5

d

4

5

– 3 –

Page 26

3

給紙部 (Paper feed section)

NO. PARTS CODE

1 CPWBF0082QSE3 BE GN E

2 PCOVP0070QSZZ AD DJ C

3 XEBSD30P10000 AA DD C

5 MLEVP0063QSZZ AD DJ C

6 MLEVP0064QSZZ AD DJ C

7 MLEVP0062QSZZ AC DJ C

8 PCOVP0064QSZZ AD DJ C

9 RPLU-0026QSZ1 AR EQ B

10 MARMP0026QSZZ AD DJ C

11 MSPRC0209QSZ1 AC DJ C

13 NSFTZ0050QSZ1 AH DX C

14 QSW-B0017QSZZ AF DS B

17 DHAI-0397QSZZ AD DJ N C

18 NBRGC0100FCZ1 AC DJ C

19 MSPRD0206QSZZ AC DJ C

20 MARMP0021QSZZ AD DJ C

21 NGERH0107QSZZ AD DJ C

22 LPIN-0026MCZZ AA DD C

23 NROLR0055QSZ1 AR EQ C

24 MARMP0019QSZZ AD DJ C

25 LSTPP0011QSZZ AC DJ C

26 NGERH0990FCZZ AB DJ C

27 NROLR0054QSZZ AP EQ C

29 DHAI-0394QSZZ AD DJ N C

30 MSPRD0204QSZZ AC DJ C

31 DHAI-0395QSZZ AG DX N C

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

Cassette interface PWB [AR-D22] 多段カセット中継基板

Sensor cover センサーカバー

Screw(3×10) ビス

Upper limit detect actuator 上限検知アクチュエーター

Paper detect actuator 紙検知アクチュエーター

P-IN detect actuator 入紙検知アクチュエーター

Solenoid cover ソレノイドカバー

Paper feed solenoid 給紙ソレノイド

Solenoid arm ソレノイドアーム

Solenoid spring ソレノイドスプリング

Paper feed roller shaft 給紙ローラ軸

Cassette detect switch カセット検知スイッチ

Cassette detect interface harness カセット検知中継ハーネス

Bearing 6 ベアリング 6

Pick up roller pressure spring ピックアップローラー加圧スプリング

Pick up arm R ピックアップアーム R

Paper feed gear 給紙ギヤ

Spring pin(φ2-10) スプリングピン

Paper feed roller 給紙ローラー

Pick up arm F ピックアップアーム F

E-ring E- リング

Gear(16T) ギヤ

Pick up roller ピックアップローラー

Door open/close detect harness ドア開閉検知ハーネス

P-IN detect actuator spring 入紙検知アクチュエータースプリング

Cassette sensor PWB harness カセットセンサー基板ハーネス

DESCRIPTION

3

給紙部 (Paper feed section)

1

a

2

8

14

17

3

10

4

9

11

5

13

a

7

31

30

6

19

14

24

27

26

21

18

20

22

29

25

23

FCP06678

– 4 –

Page 27

4

駆動部 (Drive section)

NO. PARTS CODE

1 PCOVP0084QSZZ AE DJ C

2 CPWBF0082QSE3 BE GN E

3 XEBSD30P08000 AA DD C

4 DHAI-0392QSZZ AU EZ N C

5 NBRGC0100FCZ1 AC DJ C

6 MARMP0018QSZZ AD DJ C

7 PCLC-0014QSZZ AS EQ B

8 XRESP40-06000 AA DD C

9 XRESP50-06000 AA DD C

10 MSPRT0203QSZZ AC DJ C

11 NGERH0119QSZZ AD DJ C

12 NGERH1207FCZZ AF DS C

13 CDAIU0024RS52 BA FX E

14 XEBSD40P30000 AA DD C

15 XEBSE40P12000 AA DD C

16 NGERH1207FCZZ AF DS C

17 DHAI-0396QSZZ AD DJ N C

20 LPLTM0203QSZ1 AF DS C

24 NGERH0121QSZZ AE DJ C

25 NBLTT0029QSZZ AG DX B

26 PCLC-0011QSZZ AS EQ B

28 NPLYZ0027QSZZ AD DJ C

29 PSHEZ0250QSZZ AB DJ C

30 NROLP0008QSZZ AD DJ C

31 PSHEZ0249QSZZ AB DJ C

32 NBRGC0529FCZZ AD DJ C

33 LPLTM0176QSZZ AH DX C

34 CFRM-0053QS02 AK DX C

35 NBLTT0025QSZZ AG DX C

36 NGERH0154QSZZ AD DJ C

37 NGERH1207FCZZ AF DS C

38 RMOTS0030QSZZ BA FX B

39 XHBSE30P08000 AA DD C

40 DHAI-0401QSZZ AC DJ N C

41 DHAI-0402QSZZ AL EB N C

42 XHBSE30P08000 AA DD C

43 CARMM0040QS02 AL EB C

44 PCLC-0015QSZZ AS EQ B

45 NGERH0022QSZZ AC DJ C

46 RCORF1036ACZZ AP EQ C

47 LX-BZ0322FCZZ AB DD C

48 XWHSD50-08120 AA DD C

49 LHLDZ0091QSZZ AD DJ C

50 LX-WZ5022BCZZ AA DD C

51 PSHEZ0276QSZZ AB DJ C

52 PSHEZ0277QSZZ AA DJ C

53 LX-BZ0342FCZZ AB DD C

501 CFRM-0053RS51 BC GJ E

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

Bottom cover 底カバー

Cassette interface PWB [AR-D22] 多段カセット中継基板

Screw(3×8) ビス

Cassette harness 2ND/ タダンハーネス

Bearing 6 ベアリング 6

Body joint arm [AR-D22] 本体連結アーム

Paper feed clutch(42T) 給紙クラッチ

E type ring E- リング

E type ring E- リング

Joint spring [AR-D22] 連結スプリング

Gear(36T) [AR-D22] ギヤ

Joint gear(40T) 連結ギヤ

Lift up unit リフトアップユニット

Screw(4×30) ビス

Screw(4×12) ビス

Joint gear(40T) [AR-D22] 連結ギヤ

Lift up harness リフトアップハーネス

Drive plate 多段駆動プレート

Gear(20T/45T/26P) ギヤ

Vertical delivery belt 縦搬送ベルト

Transport clutch 搬 送クラッチ

Vertical transport pulley 縦搬送プーリー

Flange mylar フランジマイラー

Pulley プーリー

Flange mylar フランジマイラー

Bearing 軸受

Clutch earth plate クラッチアース板

Motor frame モータ - フレーム

Drive belt 多段駆動ベルト

Gear(21T/28P) ギヤ

Gear(40T) ギヤ

Drive motor 駆動モータ -

Screw(3×8) ビス

Cassette earth harness カセットアースハーネス

Cassette harness [AR-D22] 4 段目カセットハーネス

Screw(3×8) ビス

Joint arm 多段連結アーム

Transport clutch [AR-D22] 搬送クラッチ

Gear(33T) ギヤ

Core コア

Screw ビス

Washer ワッシャ

Joint holder 多段連結ホルダー

Washer ワッシャ

Oscillating prevention sheet A 多段防振シート A

Oscillating prevention sheet B 多段防振シート B

Power supply SW stage screw 電源 SW 段ビス

Motor frame unit モーターフレームユニット

DESCRIPTION

5

リフトアップユニット (Lift up unit)

NO. PARTS CODE

1 CMOTV0778FCE2 AW FG E

2 NGERH0158QSZ1 AE DJ C

3 LDAIU0024QSZ1 AH DX C

4 NGERH0102QSZZ AD DJ C

5 NSFTZ0045QSZZ AC DJ C

6 NGERH0103QSZZ AE DJ C

7 NSFTZ0044QSZZ AC DJ C

8 NSFTZ0060QSZZ AC DJ C

9 NGERH0104QSZZ AE DJ C

10 NGERH0105QSZZ AD DJ C

11 PCOVP0061QSZ1 AH DX N C

12 MSPRD0251QSZZ AD DJ C

13 MSPRC0263QSZZ AC DJ C

(Unit)

901 CDAIU0024RS52 BA FX E

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

Lift up motor unit リフトアップモーターユニット

Gear(29T/11T) ギヤ

Lift up base リフトアップベース

Gear(53T/14T) ギヤ

Shaft シャフト

Gear(54T/13T) ギヤ

Shaft シャフト

Shaft シャフト

Gear(13T/42T) ギヤ

Gear(19T) ギヤ

Lift up cover リフトアップカバー

Cassette earth spring カセットアーススプリング

Lift up spring リフトアップスプリング

Lift up unit リフトアップユニット

DESCRIPTION

– 5 –

Page 28

4

駆動部 (Drive section)

45

11

3

4

2

3

46

e

d

41

a

b

33

5

リフトアップユニット (Lift up unit)

43

51

36

15

50

52

51

501

35

37

29

c

30

32

9

5

10

5

9

31

25

8

28

7

6

44

24

8

e

26

8

8

8

49

16

52

3

12

d

20

15

51

48

51

47

48

34

38

42

53

b

15

15

47

17

13

39

4

a

14

14

17

40

15

15

1

c

FCP06679

13

14

14

11

3

1

13

12

2

5

7

8

4

6

9

10

FCP06680

– 6 –

Page 29

6

550 枚カセット (550 sheets cassette unit)

NO. PARTS CODE

1 LPLTP0159QSZZ AD DJ C

2 LHLDW1226FCZZ AB DJ C

3 LPLTM0179QSZ1 AR EQ C

4 PSHEZ0274QSZZ AC DJ C

5 GCASP0005QSZ2 BA FX N D

6 PGIDM0070QSZ1 AM EG C

7 PTPE-0021QSZZ AD DJ C

8 LPLTM0181QSZ1 AB DJ C

9 PGIDM0071QSZZ AL EB C

10 LX-BZ0884FCZZ AB DD C

11 NGERH0193FCZZ AB DD C

12 MSPRC2631FCZZ AC DJ C

13 MLEVP0755FCZ1 AE DJ C

14 LX-BZ0833FCZZ AC DD C

15 CSHEZ0244QS02 AE DJ C

16 XRESP70-08000 AA DD C

17 NGERH0108QSZZ AD DJ C

18 MSPRC0210QSZZ AC DJ C

19 NSFTZ0047QSZZ AP EQ C

20 LPLTM0180QSZ1 AE DS C

21 NBRGP0041GCZZ AD DJ C

22 XEBSE40P10000 AA DD C

23 JHNDP0005QSZZ AY FQ N D

24 XBPSD40P08KS0 AA DD C

26 PCOVP0096QSZZ AN EQ N D

27 LPLTM0277QSZZ AC DJ C

(Unit)

901 CCASP0005RS55 BM HR N E

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

Cassette rear side plate カセット後端板

Turn fastener ターンファスナー

Rotation plate 回転板

Rotation plate sheet 回転板シート

550 sheets cassette 550 枚カセット

Guide F ガイド F

GID tape GID 両面テープ

Side plate guide 側板ガイド

Guide R ガイド R

Screw ビス

UC manual feed gear UC 手差しギヤ

Fusing pressure spring 定着加圧スプリング

Side plate F lever 側板 F レバー

Screw ビス

Cassette mylar カセットマイラー

E type ring E- リング

Lift gear(22T) リフトギヤ

Lift gear spring リフトギヤスプリング

Lift shaft リフトシャフト

Lift plate リフトプレート

Bearing 軸受

Screw(4×10) ビス

Cassette panel カセットパネル

Screw(4×8KS) ビス

Cassette panel line カセットパネルライン

Side plate guide R 側板ガイド R

550 sheets cassette unit 550 枚カセットユニット

DESCRIPTION

6

550 枚カセット (550 sheets cassette unit)

1

2

3

22

22

22

8

6

7

501

9

10

4

11

11

13

14

12

5

15

16

17

7

27

18

22

FCP06681

22

23

26

22

– 7 –

21

20

19

24

Page 30

7

梱包&付属品 (Packing material & Accessories)

NO. PARTS CODE

SSAKH3012KCZZ AD DJ D

3

SSAKH2002WCZZ AE DJ D

6 SPAKA0392QSZZ AD DJ D

7 LHLDW1226FCZZ AB DJ C

8 TCADZ1275FCZZ AB DJ D

9 TCADZ0288QSZZ AD DJ N D

10 SSAKA0231QCZZ AA DD D

TLABH0486QSZZ AE DS N D

11

TLABH0484QSZZ AE DS N D

7

梱包&付属品 (Packing material & Accessories)

4

PRICE RANK

Ex. Ja.

1

NEW

MARK

PART

RANK

9

3

11

10

DESCRIPTION

Vinyl bag [AR-D21] ポリ袋

Vinyl bag [AR-D22] ポリ袋

Packing add 保護材 C

Turn fastener ターンファスナー

Caution card 注意カード

Inst manual [Other Countries] 設置手順書

Vinyl bag ポリ袋

Size display label [Japan only] サイズ表示ラベル

Size display label [Inch series] サイズ表示ラベル

6

7

8

AR-D21

1

5

5

4

AR-D22

2

FCP06682

– 8 –

Page 31

8

カセット中継基板 (Cassette interface PWB)

NO. PARTS CODE

1 QCNCM0068QSZZ AL EB C

2 QCNCM0071QSZZ AL EB C

3 QCNCM0923FC14 AE DJ C

4 QCNCM2401SC0C AB DJ C

5 QCNCM7014SC0C AA DD C

6 QCNCM7014SC0E AB DJ C

7 QCNCM7014SC0H AB DD C

8 QCNCP0340QCZZ AC DJ C

9 QCNCP0341QCZZ AC DJ C

10 VCEAGA1VW106M AA DD C

11 VCEAGU1CW106M AA DD C

12 VCEAZA1VW476M AC DD C

VCKYCY1EF104Z AA DD C

13

VCKYCY1EF104Z AA DD C

14 VCKYCY1HB102K AA DD C

VCKYCY1HB222K AA DD C

15

VCKYCY1HB222K AA DD C

16 VCKYCY1HB332K AA DD C

VCKYCY1HF473Z AA DD C

17

VCKYCY1HF473Z AA DD C

18 VHEUDZ3.9B/-1 AC DJ B

VHI74HC151M-1 AD DJ B

19

VHI74HC151M-1 AD DJ B

20 VHIKA78S05P-1 AE DJ B

21 VHIMTD13611-1 AR EQ B

22 VHIT62001AP-1 AH DX B

VHVICPN38//-1 AF DS B

23

VHVICPN38//-1 AF DS B

24 VHVICPN50//-1 AE DJ B

25 VRD-HT2EY362J AA DD C

VRD-HT2HY152J AA DD C

26

VRD-HT2HY152J AA DD C

27 VRS-CY1JD102J AA DD C

VRS-CY1JD103J AA DD C

28

VRS-CY1JD103J AA DD C

29 VRS-CY1JD152F AA DD C

VRS-CY1JD152J AA DD C

30

VRS-CY1JD152J AA DD C

31 VRS-CY1JD242J AA DD C

VRS-CY1JD470J AA DD C

32

VRS-CY1JD470J AA DD C

33 VRS-CY1JD471F AB DD C

34 VRS-CY1JD622F AA DD C

35 VRS-CY1JD752J AA DD C

36 VRS-RE3AA1R5J AB DD C

VSDTC114EKA-1 AC DJ B

37

VSDTC114EKA-1 AC DJ B

38 VSDTC143ZKA-1 AC DJ B

VSIMZ4+++++-1 AD DJ B

39

VSIMZ4+++++-1 AD DJ B

(Unit)

901 CPWBF0082QSE3 BE GN E

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

Connector(40pin) [AR-D21][CN5] コネクター

Connector(40pin) [CN9] コネクター

Connector(14pin) [AR-D22][CN4] コネクター

Connector(3pin) [CN1] コネクター

Connector(3pin) [CN3] コネクター

Connector(5pin) [CN6] コネクター

Connector(8pin) [CN8] コネクター

Connector(3pin) [CN2] コネクター

Connector(3pin) [CN7] コネクター

Capacitor(35WV 10µF) [C6] コンデンサー

Capacitor(16WV 10µF) [C3,4,5] コンデンサー

Capacitor(35WV 47µF) [C1,2] コンデンサー

Capacitor(16WV 0.1µF) [C16,17,29,30,32,33,34,36] コンデンサー

Capacitor(16WV 0.1µF) [AR-D22][C26] コンデンサー

Capacitor(50WV 1000pF) [C23,24,25] コンデンサー

Capacitor(50WV 2200pF) [AR-D22][C9∼13] コンデンサー

Capacitor(50WV 2200pF) [C22,31,35,37∼40] コンデンサー

Capacitor(50WV 3300pF) [C20,21] コンデンサー

Capacitor(50WV 0.047µF) [C7,8,18,19,27,28] コンデンサー

Capacitor(50WV 0.047µF) [AR-D21][C14,15] コンデンサー

Zener diode(3.89-4.16)(UDZ3.9B) [DZ1,2,3] ツェナーダイオード

IC(74HC151M) [IC5] IC

IC(74HC151M) [AR-D22][IC4] IC

IC(KA78S05P) [IC3] IC

IC(MTD13611) [IC2] IC

IC(T62001AP) [IC1] IC

IC protector(ICPN38) [F2,3] IC プロテクター

IC protector(ICPN38) [AR-D22][F1] IC プロテクター

IC protector(ICP-N50) [F4] IC プロテクター

Resistor(1/4W 3.6KΩ ±5%) [R5,6] 抵抗

Resistor(1/2W 1.5KΩ ±5%) [R2] 抵抗

Resistor(1/2W 1.5KΩ ±5%) [AR-D22][R1] 抵抗

Resistor(1/16W 1.0KΩ ±5%) [R17,18,19,20,22] 抵抗

Resistor(1/16W 10KΩ ±5%) [R11,37∼43] 抵抗

Resistor(1/16W 10KΩ ±5%) [AR-D22][R7,12∼16] 抵抗

Resistor(1/16W 1.5KΩ ±1%) [R32] 抵抗

Resistor(1/16W 1.5KΩ ±5%) [R10,24∼30] 抵抗

Resistor(1/16W 1.5KΩ ±5%) [AR-D22][R8] 抵抗

Resistor(1/16W 2.4KΩ ±5%) [R33,36] 抵抗

Resistor(1/16W 47Ω ±5%) [R21] 抵抗

Resistor(1/16W 47Ω ±5%) [AR-D22][R9] 抵抗

Resistor(1/16W 470Ω ±1%) [R34] 抵抗

Resistor(1/16W 6.2KΩ ±1%) [R35] 抵抗

Resistor(1/16W 7.5KΩ ±5%) [R23,31] 抵抗

Resistor(1W 1.5Ω ±5%) [R3,4] 抵抗

Transistor(DTC114EKA) [Q3] トランジスター

Transistor(DTC114EKA) [AR-D22][Q1] トランジスター

Transistor(DTC143ZKA) [Q5] トランジスター

Transistor(IMZ4) [Q4] トランジスター

Transistor(IMZ4) [AR-D22][Q2] トランジスター

Cassette interface PWB [AR-D22] 多段カセット中継基板

DESCRIPTION

– 9 –

Page 32

Page 33

■

索引 (Index)

PARTS CODE

[C]

CARMM0040QS02

CCASP0005RS55

CCOVP0089RS51

CDAIU0024RS52

CFRM-0053QS02

CFRM-0053RS51

CGIDM0068RS51

CMOTV0778FCE2

CPWBF0082QSE3

CSHEZ0244QS02

DHAI-0392QSZZ

DHAI-0393QSZZ

DHAI-0394QSZZ

DHAI-0395QSZZ

DHAI-0396QSZZ

DHAI-0397QSZZ

DHAI-0401QSZZ

DHAI-0402QSZZ

GCAB-0030QSZA

GCASP0005QSZ2

GCOVA0025QSZB

GCOVA0026QSZB

GLEGG0064FCZZ

JHNDP0005QSZZ

LDAIU0024QSZ1

LFRM-0039QSZB

LHLDW1226FCZZ

LHLDZ0091QSZZ

LPIN-0026MCZZ

LPLTM0176QSZZ

LPLTM0179QSZ1

LPLTM0180QSZ1

LPLTM0181QSZ1

LPLTM0203QSZ1

LPLTM0236QSZZ

LPLTM0237QSZZ

LPLTM0240QSZZ

LPLTM0277QSZZ

LPLTP0159QSZZ

LPLTP0192QSZZ

LPLTP0297QSZZ

LRALP0009QSZZ

LSTPP0011QSZZ

LX-BZ0037QSZZ

LX-BZ0322FCZZ

LX-BZ0342FCZZ

LX-BZ0833FCZZ

LX-BZ0884FCZZ

LX-WZ5022BCZZ

MARMP0015QSZZ

MARMP0018QSZZ

MARMP0019QSZZ

MARMP0021QSZZ

MARMP0026QSZZ

MLEVP0062QSZZ

MLEVP0063QSZZ

MLEVP0064QSZZ

MLEVP0755FCZ1

MLOKZ0001QSZZ

MSPRC0141QSZZ

MSPRC0209QSZ1

MSPRC0210QSZZ

MSPRC0263QSZZ

MSPRC0270QSZZ

MSPRC2631FCZZ

MSPRD0204QSZZ

MSPRD0206QSZZ

MSPRD0251QSZZ

"

"

"

[D]

[G]

[J]

[L]

"

"

[M]

JAPAN ONLY

ORDER CODE

578 240 0102 4- 43 AL EB C

578 108 0139 6- 901 BM HR N E

578 110 0214 2- 501 AQ EQ E

578 210 0095 4- 13 BA FX E

578 210 0095 5- 901 BA FX E

578 213 0362 4- 34 AK DX C

578 213 0399 4- 501 BC GJ E

578 345 0409 2- 502 AS EQ E

578 630 0126 5- 1 AW FG E

578 684 0941 3- 1 BE GN E

578 684 0941 4- 2 BE GN E

578 684 0941 8- 901 BE GN E

578 403 0707 6- 15 AE DJ C

578 542 0378 4- 4 AU EZ N C

578 542 0379 1- 20 AK EB N C

578 542 0380 3- 29 AD DJ N C

578 542 0381 3- 31 AG DX N C

578 542 0382 4- 17 AD DJ N C

578 542 0383 3- 17 AD DJ N C

572 542 2451 4- 40 AC DJ N C

572 542 2452 4- 41 AL EB N C

578 107 0582 1- 1 AN EG N D

578 108 0137 6- 5 BA FX N D

578 110 0269 1- 5 AS EQ N D

578 110 0270 2- 10 AP EQ N D

572 123 0072 1- 15 AC DJ C

578 172 0020 6- 23 AY FQ N D

578 210 0090 5- 3 AH DX C

572 213 2278 1- 7 BK HG N C

572 214 1450 6- 2 AB DJ C

572 214 1450 7- 7 AB DJ C

578 214 0256 4- 49 AD DJ C

589 218 0012 3- 22 AA DD C

578 221 0607 4- 33 AH DX C

578 221 0719 6- 3 AR EQ C

578 221 0711 6- 20 AE DS C

578 221 0717 6- 8 AB DJ C

578 221 0730 4- 20 AF DS C

578 221 0624 1- 8 AG DX C

578 221 0625 1- 16 AH DX C

578 221 0626 1- 3 AC DJ C

578 221 0718 6- 27 AC DJ C

578 221 0654 6- 1 AD DJ C

578 221 0638 1- 18 AK DX C

578 221 0738 2- 13 AC DJ C

578 223 0018 2- 19 AQ EQ C

578 230 0043 2- 18 AC DJ C

578 230 0043 3- 25 AC DJ C

578 970 0236 1- 23 AB DD C

572 970 0195 4- 47 AB DD C

572 970 0256 4- 53 AB DD C

572 970 1816 6- 14 AC DD C

572 970 1964 6- 10 AB DD C

578 990 0014 4- 50 AA DD C

572 240 0341 2- 5 AD DJ C

578 240 0076 4- 6 AD DJ C

578 240 0077 3- 24 AD DJ C

578 240 0078 3- 20 AD DJ C

578 240 0087 3- 10 AD DJ C

578 248 0221 3- 7 AC DJ C

578 248 0222 3- 5 AD DJ C

578 248 0223 3- 6 AD DJ C

572 248 1206 6- 13 AE DJ C

572 252 0020 2- 2 AC DJ C

572 258 3248 2- 1 AB DJ C

578 258 0730 3- 11 AC DJ C

578 258 0621 6- 18 AC DJ C

578 258 0713 5- 13 AC DJ C

578 258 0720 2- 16 AB DJ C

572 258 2943 6- 12 AC DJ C

578 258 0646 3- 30 AC DJ C

578 258 0648 3- 19 AC DJ C

578 258 0660 5- 12 AD DJ C

NO.

PRICE R.

Ex. Ja.

NEW P/R

PARTS CODE

MSPRD0259QSZZ

MSPRD0277QSZZ

MSPRD0287QSZZ

MSPRP0273QSZZ

MSPRP0345QSZZ

MSPRT0203QSZZ

[N]

NBLTT0025QSZZ

NBLTT0029QSZZ

NBRGC0100FCZ1

"

NBRGC0529FCZZ

NBRGP0041GCZZ

NBRGZ0503FCZZ

NGERH0022QSZZ

NGERH0102QSZZ

NGERH0103QSZZ

NGERH0104QSZZ

NGERH0105QSZZ

NGERH0107QSZZ

NGERH0108QSZZ

NGERH0119QSZZ

NGERH0121QSZZ

NGERH0154QSZZ

NGERH0158QSZ1

NGERH0193FCZZ

NGERH0990FCZZ

NGERH1207FCZZ

"

"

NKOM-0005QSZZ

"

NPLYZ0027QSZZ

NROLP0008QSZZ

NROLP0087QSZZ

NROLP1060FCZZ

NROLR0052QSZZ

NROLR0054QSZZ

NROLR0055QSZ1

NSFTZ0044QSZZ

NSFTZ0045QSZZ

NSFTZ0047QSZZ

NSFTZ0048QSZZ

"

NSFTZ0050QSZ1

NSFTZ0054QSZZ

NSFTZ0060QSZZ

NSFTZ0064QSZZ

[P]

PCLC-0011QSZZ

PCLC-0014QSZZ

PCLC-0015QSZZ

PCOVP0061QSZ1

PCOVP0063QSZB

PCOVP0064QSZZ

PCOVP0070QSZZ

PCOVP0084QSZZ

PCOVP0089QSZZ

PCOVP0096QSZZ

PGIDM0068QSZZ

PGIDM0070QSZ1

PGIDM0071QSZZ

PGIDM0074QSZZ

PSHEZ0249QSZZ

PSHEZ0250QSZZ

PSHEZ0274QSZZ

PSHEZ0276QSZZ

PSHEZ0277QSZZ

PSHEZ0278QSZZ

PSHEZ0301QSZZ

PSHEZ0302QSZZ

PSHEZ0325QSZZ

PSHEZ0378QSZZ

PTPE-0021QSZZ

[Q]

QCNCM0068QSZZ

QCNCM0071QSZZ

QCNCM0923FC14

QCNCM2401SC0C

QCNCM7014SC0C

QCNCM7014SC0E

JAPAN ONLY

ORDER CODE

578 258 0697 2- 25 AC DJ C

578 258 0735 1- 25 AN EG C

578 258 0759 2- 26 AC DJ C

578 258 0739 2- 8 AD DJ C

578 258 0827 2- 8 AD DJ N C

578 258 0681 4- 10 AC DJ C

578 271 0061 4- 35 AG DX C

578 271 0065 4- 25 AG DX B

572 272 0465 3- 18 AC DJ C

572 272 0465 4- 5 AC DJ C

572 272 0498 4- 32 AD DJ C

578 272 0061 6- 21 AD DJ C

572 272 0463 2- 17 AC DJ C

572 281 1763 4- 45 AC DJ C

578 281 0324 5- 4 AD DJ C

578 281 0325 5- 6 AE DJ C

578 281 0326 5- 9 AE DJ C

578 281 0327 5- 10 AD DJ C

578 281 0329 3- 21 AD DJ C

578 281 0330 6- 17 AD DJ C

578 281 0338 4- 11 AD DJ C

578 281 0339 4- 24 AE DJ C

578 281 0356 4- 36 AD DJ C

578 281 0385 5- 2 AE DJ C

572 281 0318 6- 11 AB DD C

572 281 1125 3- 26 AB DJ C

572 281 1388 4- 12 AF DS C

572 281 1388 4- 16 AF DS C

572 281 1388 4- 37 AF DS C

578 273 0004 1- 13 AC DJ C

578 273 0004 2- 21 AC DJ C

578 284 0067 4- 28 AD DJ C

572 287 1832 4- 30 AD DJ C

578 287 0368 2- 28 AD DJ C

572 287 1396 2- 7 AF DS C

578 287 0319 2- 15 AN EQ C

578 287 0321 3- 27 AP EQ C

578 287 0341 3- 23 AR EQ C

578 290 0199 5- 7 AC DJ C

578 290 0200 5- 5 AC DJ C

578 290 0202 6- 19 AP EQ C

578 290 0203 1- 12 AG DX C

578 290 0203 2- 22 AG DX C

578 290 0208 3- 13 AH DX C

578 290 0205 2- 6 AE DJ C

578 290 0214 5- 8 AC DJ C

578 290 0221 2- 27 AD DJ C

578 316 0038 4- 26 AS EQ B

578 316 0037 4- 7 AS EQ B

578 316 0041 4- 44 AS EQ B

578 323 0254 5- 11 AH DX N C

578 323 0291 1- 10 AD DJ N C

578 323 0226 3- 8 AD DJ C

578 323 0215 3- 2 AD DJ C

578 323 0229 4- 1 AE DJ C

578 323 0263 2- 12 AD DJ C

578 323 0289 6- 26 AN EQ N D

578 345 0345 2- 4 AP EQ C

578 345 0394 6- 6 AM EG C

578 345 0358 6- 9 AL EB C

578 345 0348 2- 23 AK DX C

578 403 0633 4- 31 AB DJ C

578 403 0634 4- 29 AB DJ C

578 403 0656 6- 4 AC DJ C

578 403 0714 4- 51 AB DJ C

578 403 0715 4- 52 AA DJ C

578 403 0716 1- 24 AE DJ C

578 403 0680 2- 29 AC DJ C

578 403 0681 2- 30 AC DJ C

578 403 0719 1- 22 AB DJ C

578 403 0803 2- 14 AG DX C

578 423 0061 6- 7 AD DJ C

578 510 0272 8- 1 AL EB C

578 510 0273 8- 2 AL EB C

572 510 0937 8- 3 AE DJ C

595 510 0762 8- 4 AB DJ C

595 510 0338 8- 5 AA DD C

595 510 0744 8- 6 AB DJ C

NO.

PRICE R.

Ex. Ja.

NEW P/R

– 10 –

Page 34

PARTS CODE

QCNCM7014SC0H

QCNCP0340QCZZ

QCNCP0341QCZZ

QSW-B0017QSZZ

[R]

RCORF1036ACZZ

RHET-0006QSZZ

RMOTS0030QSZZ

RPLU-0026QSZ1

[S]

SPAKA0392QSZZ

SSAKA0231QCZZ

SSAKH2002WCZZ

SSAKH3012KCZZ

[T]

TCADZ0288QSZZ

TCADZ1275FCZZ

TLABH0484QSZZ

TLABH0486QSZZ

TLABS4306FCZZ

[V]

VCEAGA1VW106M

VCEAGU1CW106M

VCEAZA1VW476M

VCKYCY1EF104Z

VCKYCY1HB102K

VCKYCY1HB222K

VCKYCY1HB332K

VCKYCY1HF473Z

VHEUDZ3.9B/-1

VHI74HC151M-1

VHIKA78S05P-1

VHIMTD13611-1

VHIT62001AP-1

VHVICPN38//-1

VHVICPN50//-1

VRD-HT2EY362J

VRD-HT2HY152J

VRS-CY1JD102J

VRS-CY1JD103J

VRS-CY1JD152F

VRS-CY1JD152J

VRS-CY1JD242J

VRS-CY1JD470J

VRS-CY1JD471F

VRS-CY1JD622F

VRS-CY1JD752J

VRS-RE3AA1R5J

VSDTC114EKA-1

VSDTC143ZKA-1

VSIMZ4+++++-1

[X]

XBPSD30P08KS0

"

XBPSD40P08KS0

XEBSD30P08000

"

"

XEBSD30P10000

"

XEBSD40P30000

XEBSE40P10000

XEBSE40P12000

"

"

XEPSD30P08X00

XHBSE30P08000

"

XRESP40-06000

XRESP50-06000

XRESP70-08000

XWHSD50-08120

JAPAN ONLY

ORDER CODE

595 510 0348 8- 7 AB DD C

572 510 0921 8- 8 AC DJ C

572 510 0922 8- 9 AC DJ C

572 530 0719 3- 14 AF DS B

596 615 0107 4- 46 AP EQ C

578 623 0004 1- 17 AQ EQ B

578 630 0115 4- 38 BA FX B

578 647 0024 3- 9 AR EQ B

578 902 0302 7- 6 AD DJ D

541 906 1003 7- 10 AA DD D

541 906 1017 7- 3 AE DJ D

588 906 0009 7- 3 AD DJ D

572 913 1007 7- 9 AD DJ N D

572 913 0734 7- 8 AB DJ D

572 917 3762 7- 11 AE DS N D

572 917 3763 7- 11 AE DS N D

572 917 3307 1- 26 AC DJ D

572 594 0093 8- 10 AA DD C

571 594 0095 8- 11 AA DD C

578 594 0149 8- 12 AC DD C

507 591 5036 8- 13 AA DD C

594 593 0044 8- 14 AA DD C

595 593 0027 8- 15 AA DD C

595 593 1209 8- 16 AA DD C

594 593 0207 8- 17 AA DD C

596 571 0169 8- 18 AC DJ B

578 573 1185 8- 19 AD DJ B

578 573 1138 8- 20 AE DJ B

578 573 1140 8- 21 AR EQ B

578 573 1214 8- 22 AH DX B

585 577 0022 8- 23 AF DS B

594 577 0003 8- 24 AE DJ B

572 581 0031 8- 25 AA DD C

571 581 0411 8- 26 AA DD C

571 581 0007 8- 27 AA DD C

500 581 5097 8- 28 AA DD C

567 581 0441 8- 29 AA DD C

571 581 0003 8- 30 AA DD C

596 581 2169 8- 31 AA DD C

571 581 0877 8- 32 AA DD C

596 581 2161 8- 33 AB DD C

500 581 5120 8- 34 AA DD C

596 581 0258 8- 35 AA DD C

578 581 0316 8- 36 AB DD C

595 576 0491 8- 37 AC DJ B

594 576 0231 8- 38 AC DJ B

596 576 0655 8- 39 AD DJ B

541 970 1097 1- 14 AA DD C

541 970 1097 2- 20 AA DD C

541 970 0013 6- 24 AA DD C

578 970 0105 1- 19 AA DD C

578 970 0105 2- 9 AA DD C

578 970 0105 4- 3 AA DD C

578 970 0106 2- 11 AA DD C

578 970 0106 3- 3 AA DD C

572 970 1429 4- 14 AA DD C

572 970 0575 6- 22 AA DD C

572 970 1447 1- 2 AA DD C

572 970 1447 2- 24 AA DD C

572 970 1447 4- 15 AA DD C

595 970 0136 2- 3 AA DD C

595 970 0163 4- 39 AA DD C

595 970 0163 4- 42 AA DD C

509 399 5001 4- 8 AA DD C

572 399 0063 4- 9 AA DD C

571 399 0027 6- 16 AA DD C

571 990 0056 4- 48 AA DD C

NO.

PRICE R.

Ex. Ja.

NEW P/R

PARTS CODE

JAPAN ONLY

ORDER CODE

NO.

PRICE R.

Ex. Ja.

NEW P/R

– 11 –

Page 35

注意

・電池を正しく交換しないと爆発を起こす危険がある。

・機器製造者が指定したものと同一型名のもの、又は、

その同等の電池とのみ交換すること。

・使用済みの電池は、製造者の指示に従って処分すること。

CAUTION FOR BATTERY REPLACEMENT

(Danish) ADVARSEL !

Lithiumbatteri – Eksplosionsfare ved fejlagtig håndtering.

(English) Caution !

Danger of explosion if battery is incorrectly replaced.

Dispose of used batteries according to manufacturer’s instructions.

(Finnish) VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan

(French) ATTENTION

Il y a danger d’explosion s’ il y a remplacement incorrect

de la batterie. Remplacer uniquement avec une batterie du

même type ou d’un type équivalent recommandé par

Mettre au rebut les batteries usagées conformément aux

(Swedish) VARNING

(German) Achtung

Explosionsgefahr bei Verwendung inkorrekter Batterien.

Als Ersatzbatterien dürfen nur Batterien vom gleichen Typ oder

vom Hersteller empfohlene Batterien verwendet werden.

Entsorgung der gebrauchten Batterien nur nach den vom

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandoren.

Replace only with the same or equivalent type

recommended by the manufacturer.

tyyppiin. Hävitä käytetty paristo valmistajan ohjeiden

mukaisesti.

le constructeur.

instructions du fabricant.

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent

typ som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens

instruktion.

Hersteller angegebenen Anweisungen.

CAUTION FOR BATTERY DISPOSAL

(For USA, CANADA)

"BATTERY DISPOSAL"

THIS PRODUCT CONTAINS A LITHIUM PRIMARY

(MANGANESS DIOXIDE) MEMORY BACK-UP BATTERY

THAT MUST BE DISPOSED OF PROPERLY. REMOVE THE

BATTERY FROM THE PRODUCT AND CONTACT YOUR

LOCAL ENVIRONMENTAL AGENCIES FOR INFORMATION

ON RECYCLING AND DISPOSAL OPTIONS.

"TRAITEMENT DES PILES USAGÉES"

CE PRODUIT CONTIENT UNE PILE DE SAUVEGARDE DE

MÉMOIRE LITHIUM PRIMAIRE (DIOXYDE DE MANGANÈSE)

QUI DOIT ÊTRE TRAITÉE CORRECTEMENT. ENLEVEZ LA

PILE DU PRODUIT ET PRENEZ CONTACT AVEC VOTRE

AGENCE ENVIRONNEMENTALE LOCALE POUR DES

INFORMATIONS SUR LES MÉTHODES DE RECYCLAGE ET

DE TRAITEMENT.

Page 36

q

COPYRIGHT

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted.

electronic, mechanical, photocopying, recording, or otherwise,

without prior written permission of the publisher.

2003 BY SHARP CORPORATION

All rights reserved.

Printed in Japan.

In any form or by any means,

SHARP CORPORATION

Digital Document Systems Group

Products Quality Assurance Department

Yamatokoriyama, Nara 639-1186, Japan

2003 August Printed in Japan

t

Loading...

Loading...