Page 1

TopPage

DESTINATION E

Refer to "REFRIGERATING-CYCLE REPAIR MANUAL" for handling this refrigerant.

Refrigerant; R600a

SJF800SPSL

SERVICE MANUAL

No.S2904SE78PTUET

Refrigerator-freezer

MODELS

SJ-F750SP-SL/BK

SJ-F800SP-SL/BK

CONTENTS

CHAPTER 1. ENERGY LABEL/INSTALATION

[1] ENERGY LABEL ...........................................1-1

[2] INSTALATION ............................................... 1-1

CHAPTER 2. SPECIFICATION

CHAPTER 3. FICHE

CHAPTER 4. DESIGNATION OFVARIOUS PARTS

[1] EXTERNAL DESCRIPTION .......................... 4-1

[2] CONSTRUCTIONS ....................................... 4-2

CHAPTER 5. DIMENTIONS

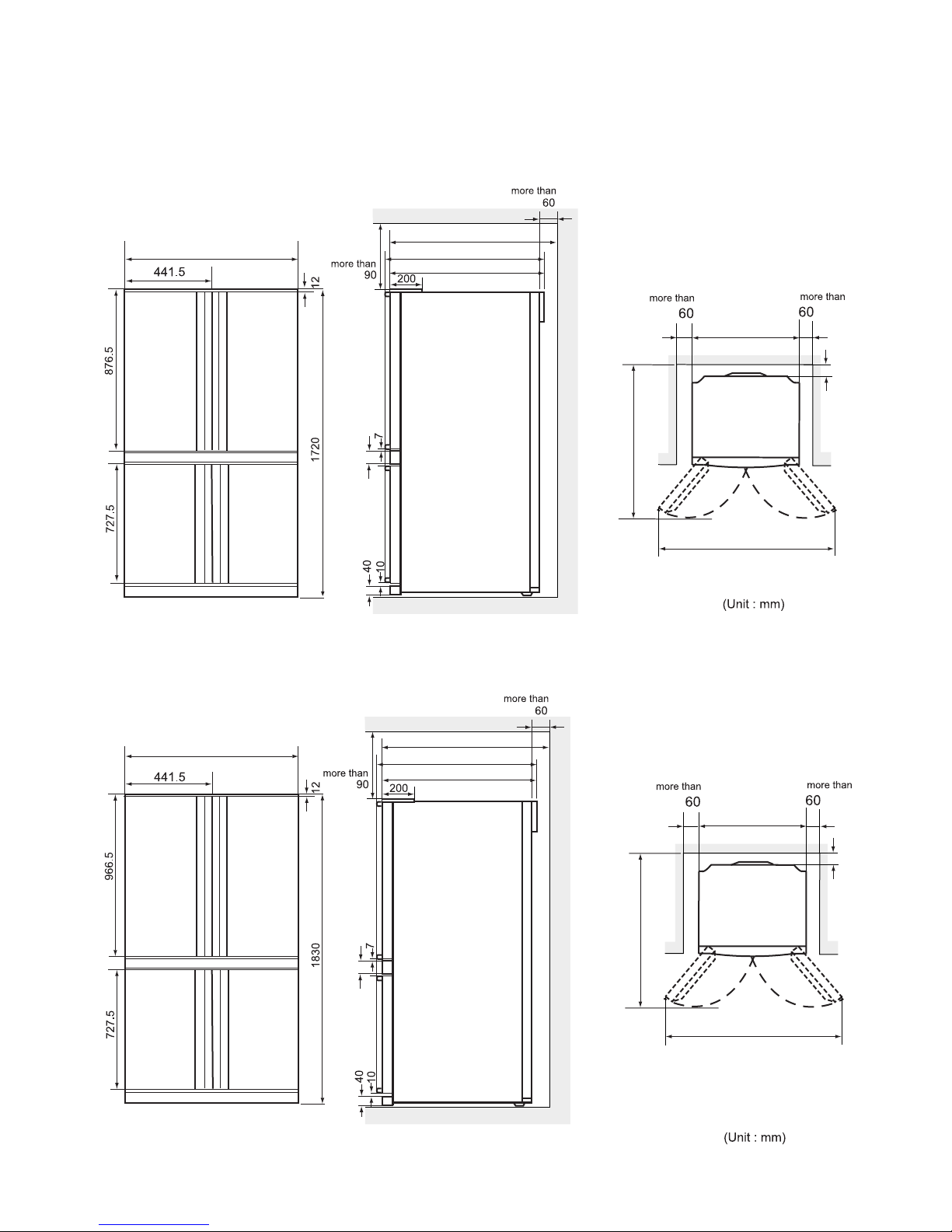

[1] OUTER DIMENTIONS AND CLEARANCE........ 5-1

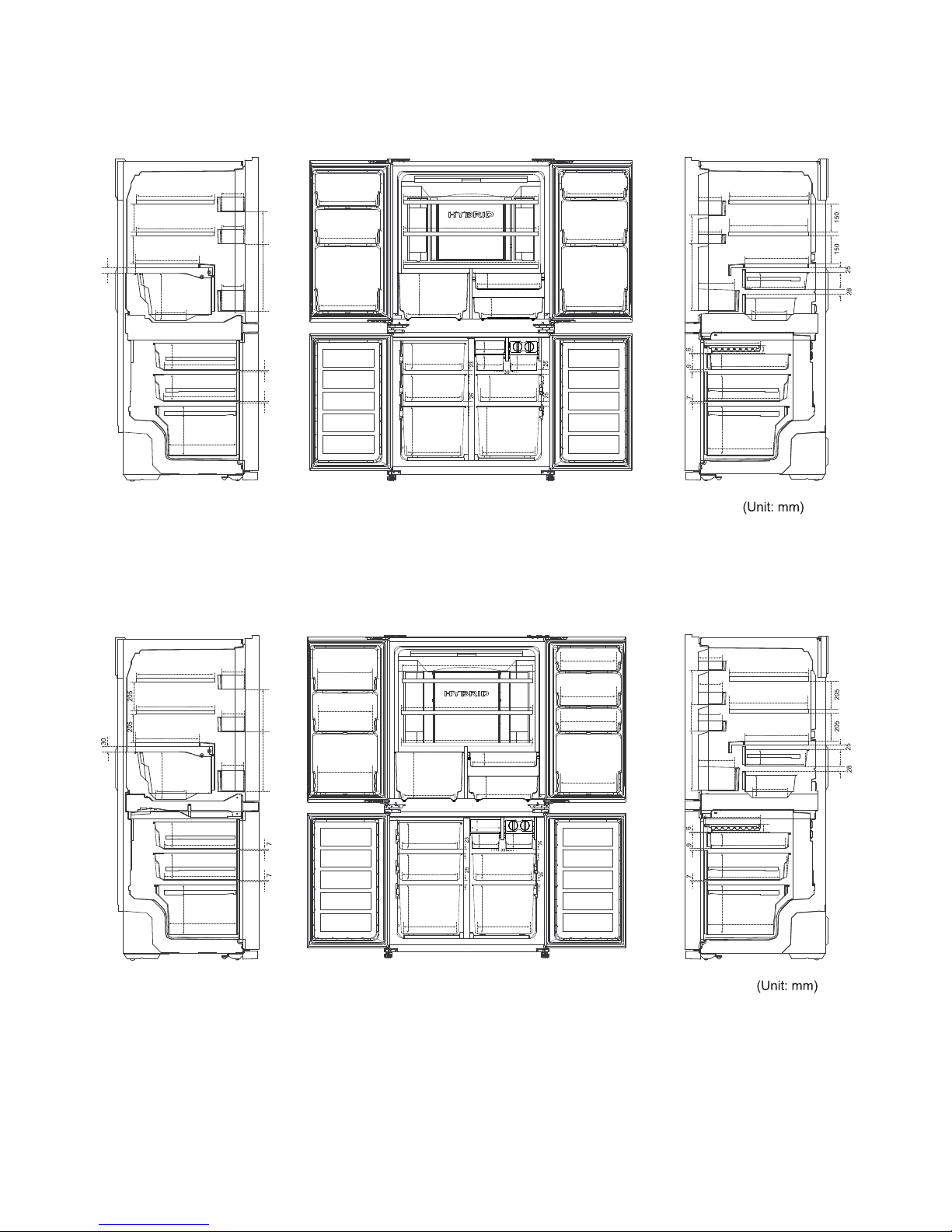

[2] INNER DIMENTIONS.................................... 5-2

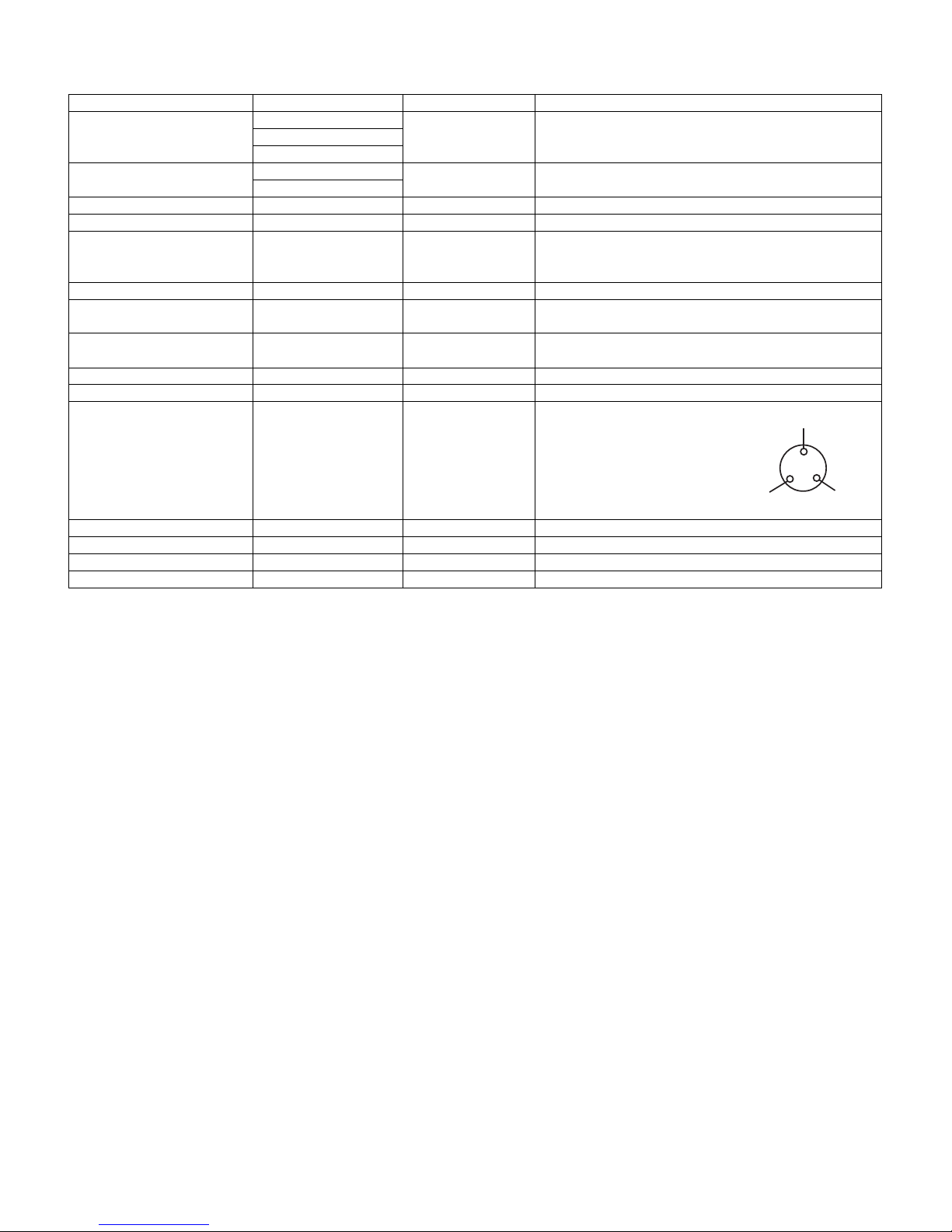

CHAPTER 6. LIST OF ELECTORICAL PARTS

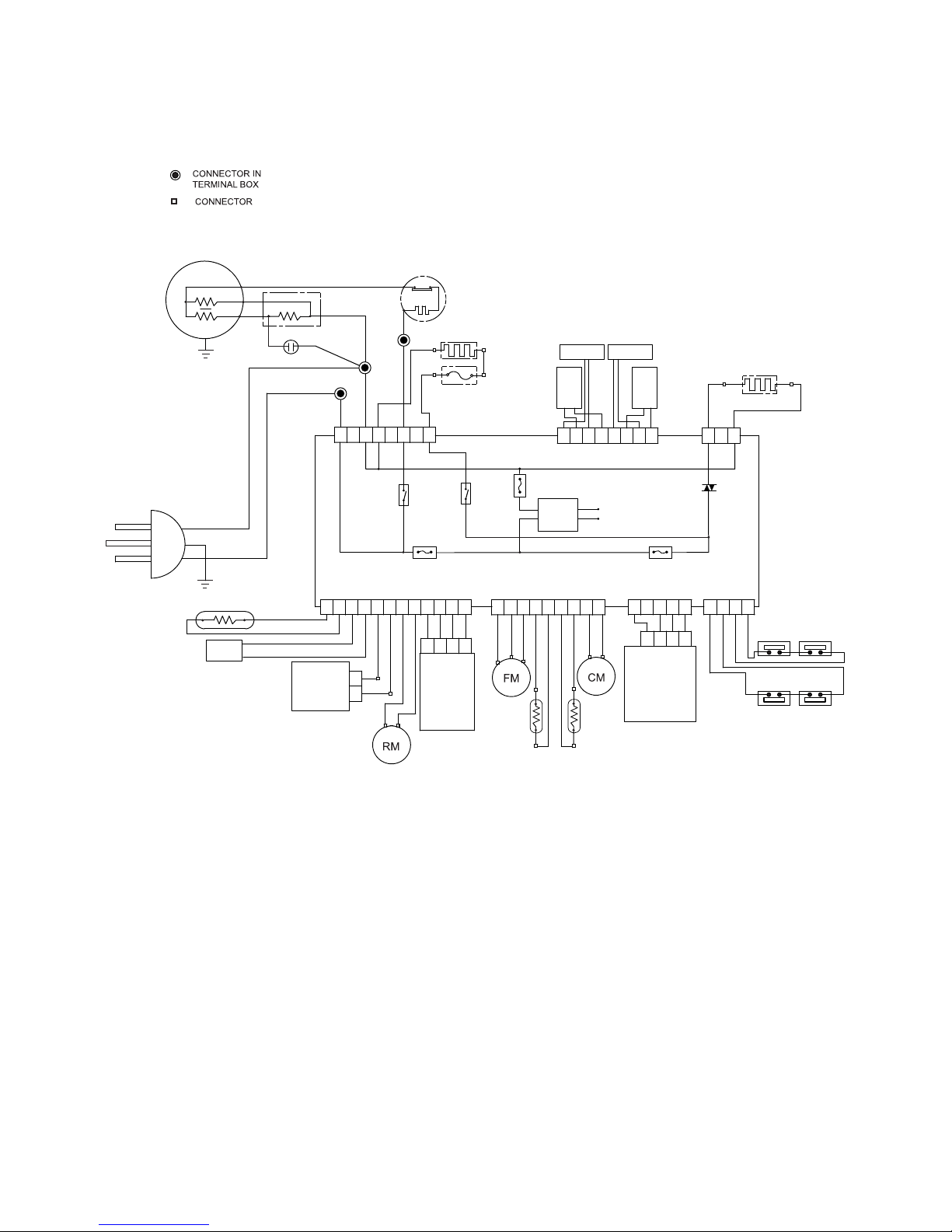

CHAPTER 7. WIRING DIAGRAM

[1] WIRING DIAGRAM ....................................... 7-1

[2] ELECTRIC ACCESSORIES LAYOUT........... 7-2

CHAPTER 8. FAILURE DIAGNOSIS

[1] OUTLINE OF CONTROL .............................. 8-1

[2] WHEN THE DEFROSTING FAILURE IS

DOUBTFUL ...................................................8-1

[3] RE-SETTING OF MICROCOMPUTER AT

POWER FAILURE......................................... 8-1

[4] DIAGNOSIS METHOD OF FAILURE

AROUND PWB .............................................. 8-2

[5] CONVERSION TABLE BETWEEN TEM-

PERATURE AND RESISTANCE VALUE........ 8-3

[6] CIRCUIT DIAGRAM OF MAIN PWB ............. 8-4

[7] CIRCUIT DIAGRAM OF LCD PWB ............... 8-5

CHAPTER 9. SELF-DIAGNOSIS MODE

CHAPTER 10. MODE FOR DISPLAY

CHAPTER 11. DISASSEMBLING/ASSEMBLING

PROCEDURES

[1] REFRIGERATOR COMPARTMENT.............11-1

[2] FREEZER COMPARTMENT ........................11-7

[3] HOW TO REMOVE THE CONTROL BASE.....11-12

[4] DEFROST HEATER ...................................11-13

[5] WHEN LEFT AND RIGHT DOORS ARE

NOT ON THE SAME LEVEL ......................11-15

CHAPTER 12. COOLING UNIT

[1] COOLING UNIT........................................... 12-1

[2] LOCATION................................................... 12-2

Parts Guide

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

SJF800SPSL

1 – 1

SJF800SPSL

ServiceManual

CHAPTER 1. ENERGY LABEL/INSTALATION

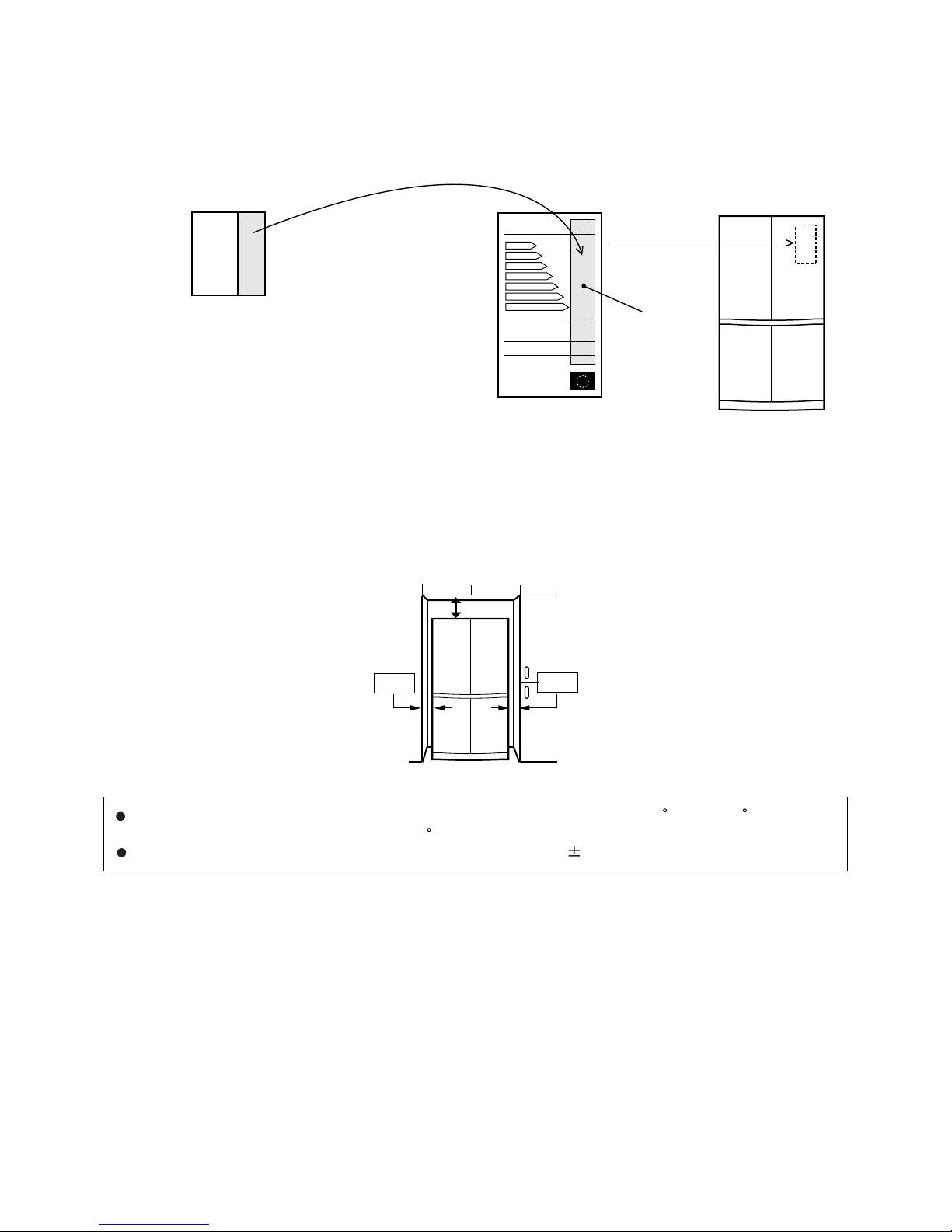

[1] ENERGY LABEL

Usage of "the ENERGY LABEL"

• When displaying this refrigerator in the shop-window, attach the "ENERGY LABEL" to it in the following procedure.

[2] INSTALATION

Free standing type

• To ensure adequate ventilation for this refrigerator, install with 6 cm space at the rear and both sides, with aminimum space of 9 cm above the

refrigerator.

"ENERGY LABEL (DATA)"

(This label is in Operation manual)

"ENERGY LABEL (BASE)"

of each language

Refrigerator

Data part

E

B

A

C

D

E

G

F

G

Fix the data part of

"ENERGY LABEL (DATA)"

on the data part of

"ENERGY LABEL (BASE)"

6cm

6cm

9cm

This refrigerator shall be used under the ordinary place condition between +5 C and +38 C of ambient

temperature, and also not be left under -10 C for long days.

To be used this refrigerator within the range of the rated voltage˴6%

Page 3

SJF800SPSL

2 – 1

SJF800SPSL

ServiceManual

CHAPTER 2. SPECIFICATION

Items SJ-F750SP SJ-F800SP

Type 4 Door

Outer dimensions Height 1720mm(67.7") 1830mm(72.0")

Width 890mm(35.0") 890mm(35.0")

Depth 770mm(30.3") 770mm(30.3")

Rated storage volume Total 556liter(19.6cu.ft) 605liter(21.4cu.ft)

Freezer 211liter(7.5cu.ft) 211liter(7.5cu.ft)

Refrigerator 345liter(12.1cu.ft) 394liter(13.9cu.ft)

Rated gross volume 602liter(21.3cu.ft) 653liter(23.1cu.ft)

Defrosting System Heater system

Start Automatic

Finish Automatic

Temperature control Automatic (Adjustable)

No-frost freezer Yes

Interior lamp (LED) 36

Plasmacluster light (LED, Blue) 1

Caster 4

Evaporating pan 1 (unremovable)

Refrigerator Compartment R-shelf ass'y 2

V-shelf ass'y 1

Bttl rack ass'y 1

Fruit case ass'y 1

Fresh case ass'y 1

V-case ass'y 1

Door pocket ass'y 3

Btl-pok L ass'y 1

Btl-pok R ass'y 1

U-pok door 1

Utility pok ass'y 1

Egg pok ass'y — 1

Egg tray 1

Freezer Compartment Ice cube maker 1

Quick ice maker 1

Ice storage ass'y 2

F-case S ass'y 3

F-case L ass'y 2

Control panel Plasmacluster Yes

Express Ice making Yes

Express Freezing Yes

Vacation mode Yes

Door alarm Yes

Timer Yes

Temp. control Yes

Child lock Yes

Aluminum panel Yes

Deodorizing unit (Honeycomb type) Yes

RATING

Items SJ-F750SP SJ-F800SP

Rated voltage (V~) 220-240

Rated frequency (Hz) 50

Climate class ST

Rated current (A) 0.8-0.9

Rated input of heating systems (W) 173-206

Defrosting input (W) 173-206

Refrigerant (Charging quantity) [Flammable] R-600a(52g) R-600a(52g)

Insulation blowing gas [Flammable] Cyclo pentane (HC)

Net Weight (kg) 111 114

Page 4

SJF800SPSL

2 – 2

PLUG TYPE

Plug cord 2 pin + Earth

Plug type CS

Destination mark E

COLOR

Items -SL -BK

Outside color Silver Black

Inside color White White

Receptacle

Page 5

SJF800SPSL

3 – 1

SJF800SPSL

ServiceManual

CHAPTER 3. FICHE

1

NO.

2

3

4

5

6

8

9

11

12

13

14

Trade mark

Items

Description

Remarks

Model name

Type

Energy efficiency class

Eco-award mark

Energy consumption

(220V 50Hz at 25 C)

Star rating of frozen food

compartment

Temperature rise time

Freezing capacity

Climate class

Noise

10 No frost

7

Net storage volume of frozen

food storage compartment

SJ-F750SP SJ-F800SP

Category; 7

A+

ST ST

38 dB(A)

re1pw

38 dB(A)

re1pw

450

kWh/year

1017

kWh/year

1066

kWh/year

345 L

No frost

11 h

9.5 kg /24h

Net storage volume of fresh

food storage compartment

Category; 7

A+

465

kWh/year

394 L

11 h

9.5 kg /24h

880/92

EN153

86/594/EEC

No frost

THE FICHE (according to ANNEX : 94/2/EC)

15

Maximum allowable electricity

consumption (Emax)

(96/57/EC)

211 L

4-STAR

211 L

4-STAR

E max

(2.92)(2.79) (kWh/day)

fridge / freezer

A++/A+/A~G

at 25

at 25

Page 6

SJF800SPSL

4 – 1

SJF800SPSL

ServiceManual

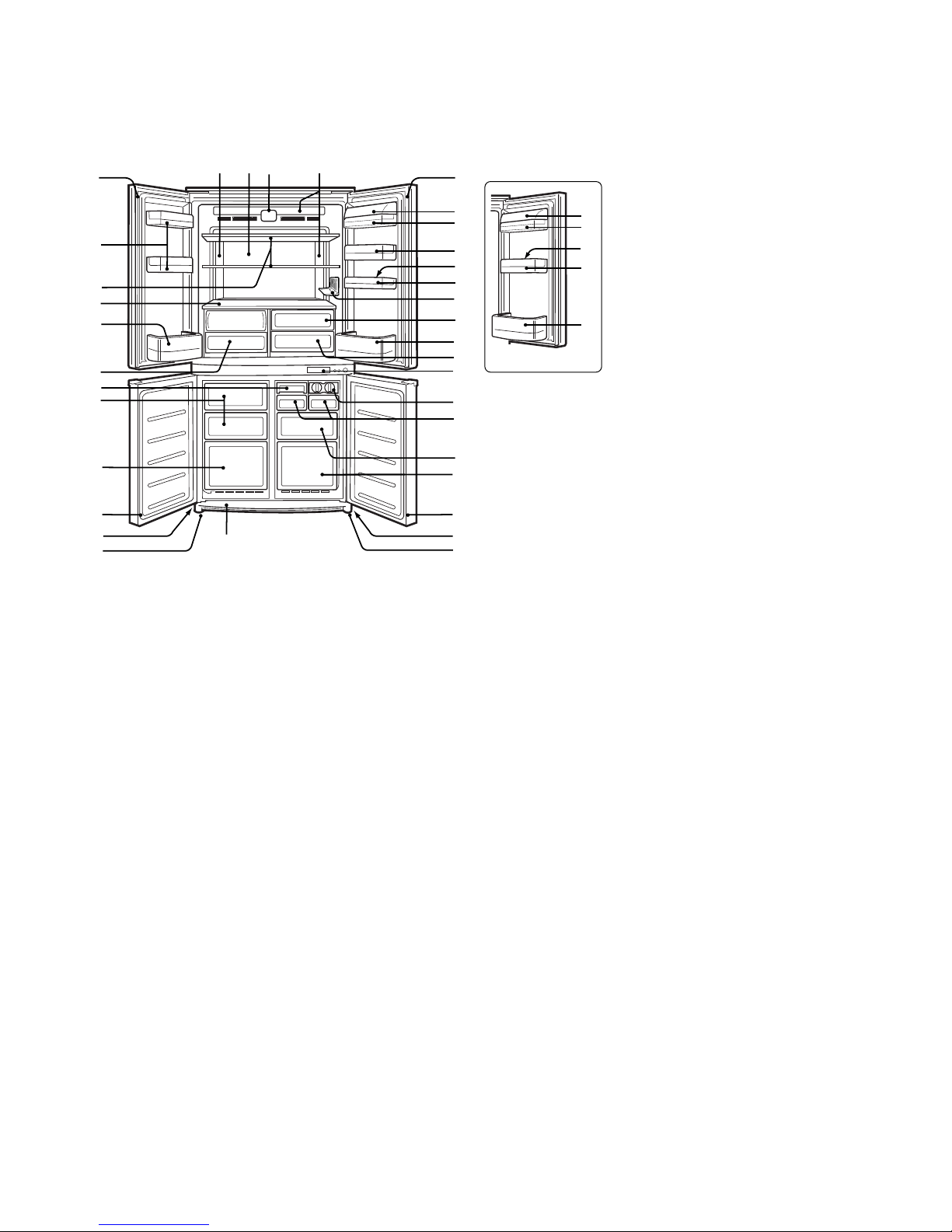

CHAPTER 4. DESIGNATION OFVARIOUS PARTS

[1] EXTERNAL DESCRIPTION

The names in parenthesis “[ ]” are the denominations used in the REPLACEMENT PARTS LIST.

25

13

12 14

13

25

15

1

17

18

19

20

22

21

26

23

24

7

8

25

9

10

1

2

3

4

5

6

7

8

25

9

10

11

16

15

16

1

22

17

SJ-F800SP

SJ-F750SP

1. Door pocket [Door pocket ass'y]

2. Refrigerator shelf [R-shelf ass'y]

3. Shelf [V-shelf ass'y]

4. Bottle pocket(left) [Btl-pok L ass'y]

5. Vegetable crisper [V-case ass'y]

6. Quick ice maker [Quick ice maker]

7. Freezer case(small) [F-case S ass'y]

8. Freezer case(large) [F-case L ass'y]

9. Caster

10. Adjustable feet [Adjustable leg ass'y]

11. Foot cover [Base cover]

12. Aluminum panel [AL panel]

13. Refrigerator LED Light

[LED pwb ass'y]

14. Plasmacluster Light [PCI pwb ass’y]

15. Utility pocket cover [U-pok door]

16. Utility pocket [Utility pok ass'y]

17. Egg holder [Egg tray]

18. Egg pocket [Egg pok ass’y]

(Only for SJ-F800SP)

19. Bottle rack [Bttl rack ass'y]

20. Fruit case [Fruit case ass'y]

21. Fresh case [Fresh case ass'y]

22. Bottle pocket(right) [Btl-pok R ass'y]

23. Ice cube maker [Ice cube maker]

24. Ice cube box [Ice storage ass'y]

25. Magnetic door seal [Door packing]

26. Control panel

Page 7

SJF800SPSL

4 – 2

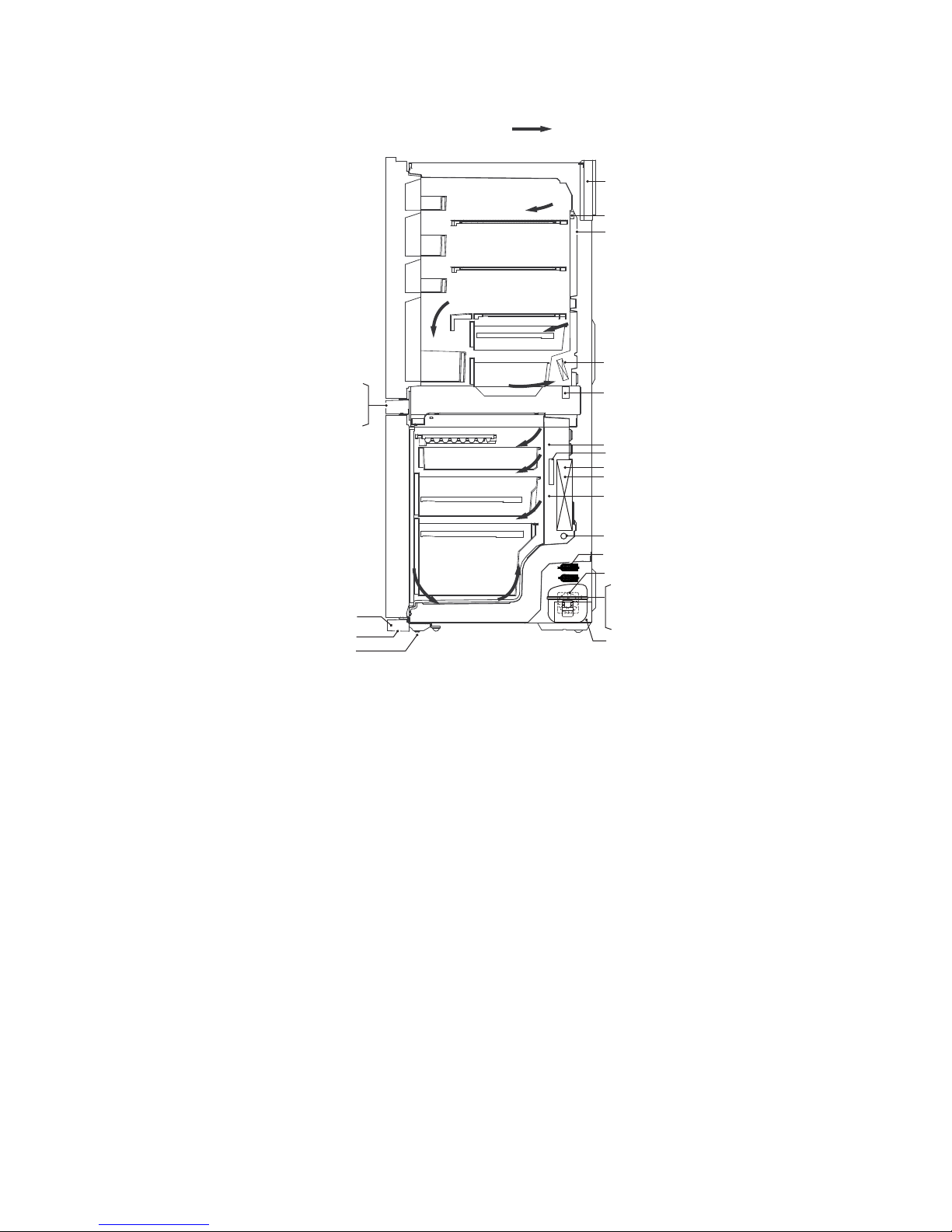

[2] CONSTRUCTIONS

PWB-s ass'y

Ionizer-K

R-thermistor

R fan motor

Damper ass'y

Compressor

Protector

Starting relay

Sub condenser

Evaporator

Fuse ass'y

F-thermistor

Def-thermistor

F-fan motor

Defrost heater

Reed sw

LCD PWB s ass'y

Control panel

C fan motor

Running capacitor

Evaporating pan

Foot cover

Adjustable feet

Caster

mark : cold air flow

Page 8

SJF800SPSL

5 – 1

SJF800SPSL

ServiceManual

CHAPTER 5. DIMENTIONS

[1] OUTER DIMENTIONS AND CLEARANCE

1. SJ-F750SP

2. SJ-F800SP

890

50

1180

1500

787

890

60

817

770

890

1180

1500

890

60

50

787

770

817

Page 9

SJF800SPSL

5 – 2

[2] INNER DIMENTIONS

The dimensions between shelves can be changed by setting the shelves on the other rails.

1. SJ-F750SP

2. SJ-F800SP

186340

77

30

328

328

250

136.5

136.5

136.5

346

260.5

365

365

142.5

142.5

316

316

316

316

316

316

708

708

708

282

217

166

217

320

282

96.5

125.5

308

308

298 298

142.5142.5260.5

260.5

125.5 125.5

80

80

308

142.5

136.5

136.5

191

328

328

250

240

96.5

188

125.5

66

311

406

80

365

346

142.5

260.5

168

66

150150

340 230

708

708

328

328

250

136.5

136.5

136.5

217

166

365

365

142.5

142.5

346

260.5

316

316

316

282

217

320

282

96.5

125.5

316

316

316

316

308

308

142.5142.5260.5

298

168

125.5

66

80

80

125.5

308

142.5

260.5

298

136.5

136.5

136.5

191

328

328

250

240

96.5

188

125.5

311

66

406

80

365

346

142.5

260.5

225345

708

190135345

Page 10

SJF800SPSL

6 – 1

SJF800SPSL

ServiceManual

CHAPTER 6. LIST OF ELECTORICAL PARTS

“ • “ denotes parts that cannot be replaced or parts that cannot be replaced as an individual unit.

ITEMS TYPE NAME RATING SPECIFICATIONS

R Thermistor — DC 5V R0 = 6.4 kΩ, B(0) = 3811

F Thermistor — DC 5V R0 = 6.4 kΩ, B(0) = 3811

Defrost Themistor — DC 5V R0 = 15 kΩ, B(0) = 3811

• RD Heater (F750SP) — 220-240V 8021Ω 6.6W at 230V

• RD Heater (F800SP) — 220-240V 8365Ω 6.32W at 230V

Thermo. fuse SF70E 250V 10A Working temp. : 70 °C

Defrost heater MM6-4350 220-240V 286Ω 185W at 230V

R-Fan motor D08A-12PM.05(K) DC12V 0.07A —

F-Fan motor FBA12J15VXD DC14.5V 0.28A —

C-Fan motor D09T-12CS307(EX) DC12V 0.09A —

Damper NSBC101FA1 DC12V —

Reed SW MS-332/651 DC5V Magnetic Switch

SW Magnet FM10.9X7X25.4(SR-3) — Magnet Switch

Lamp (Side) FPWB-A617CBKZ DC14.5V 150mA white LED Lamp

Lamp (Top) FPWB-A619CBKZ DC14.5V 75mA white LED Lamp

LCD operation FPWB-A615CBKZ DC14.5V Blue LCD

Ionizer indicator FPWB-A621CBKZ DC14.5V Blue LED

Compressor EGM90CLC 220-240V/50Hz Cooling capacity : 218W (50Hz)

Main coil : 18.40Ω

Aux. coil : 25.50Ω

(at 25 °C)

Starting Relay PTH8M220MD2 — 22Ω (at 25 °C)

Overload Relay (Protector) 4TM189NFBYY-53 — Open/Close : 120/ 61 °C

Running capacitor RC-EZA254CBZZ — 400V 5μF

Ionizer-K (Plasmacluster unit) CKITTA131AKKZ DC15V 4.55kV p-p (Second wave)

Common

Aux. coil

Main coil

Page 11

SJF800SPSL

7 – 1

SJF800SPSL

ServiceManual

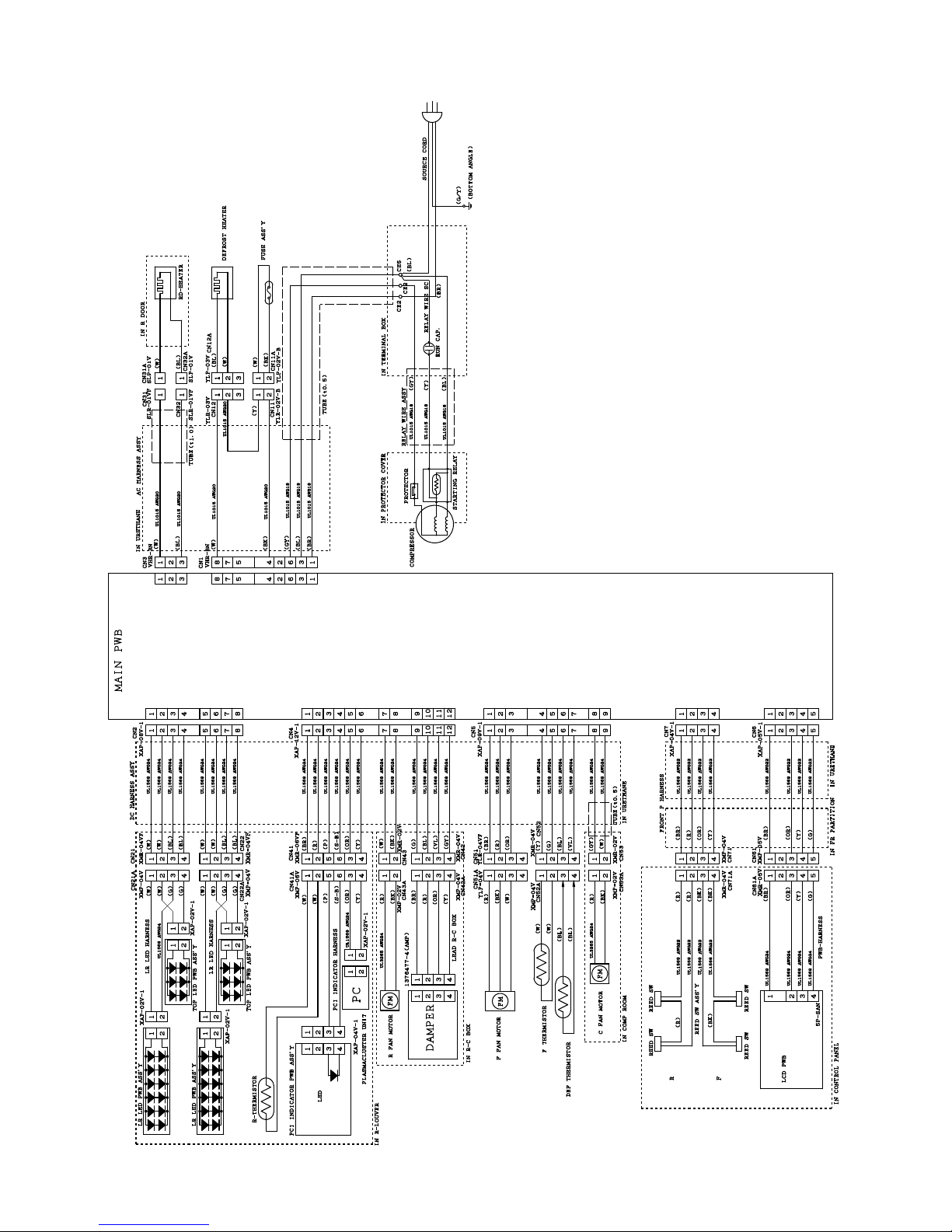

CHAPTER 7. WIRING DIAGRAM

[1] WIRING DIAGRAM

Be sure to replace the electrical parts with specified ones for maintaining the safety and performance of the set.

Fuse1 Fuse3

Fuse2

Relay2

AC/DC

DC

MAIN

PWB

G

B

Br

Relay1

111222333

1234

1234

445

12345

566778

12345678

9

112234

1234

5678

9

101112

8

Compressor

Starting relay

Protector

Fuse

Defrost Heater

Running capacitor

R-door heater

F-reed SW

R-reed SW

Defrost-thermistor

LCD Control

PWB

F-thermistor

Damper

Plasmacluster

R-thermistor

Plasmacluster light

Light

Plug / Cord

LED

LED

LED

LEDLED

Page 12

SJF800SPSL

7 – 2

[2] ELECTRIC ACCESSORIES LAYOUT

Page 13

SJF800SPSL

8 – 1

SJF800SPSL

ServiceManual

CHAPTER 8. FAILURE DIAGNOSIS

[1] OUTLINE OF CONTROL

1. ON/OFF Control of Compressor

• ON/OFF of the compressor will be controlled depend on the temperature detected by

the R-thermistor and F-thermistor. (Normal cooling control)

• In case the surrounding temperature is high at the power supply input, the compressor will be ON at once and the normal cooling control will start

after several hours.

• When the rapid ice making or rapid freezing is requested by user during the operation, the compressor will be ON and cooling operation will be

started regardless of the detected temperature by the thermistors. However, if requested during the defrosting operation, the request will be executed after the completion of defrosting and ON of the compressor might be delayed.

• During 5 minutes after the compressor stops, it will not start regardless of the detected temperature by R-thermistor and F-thermistor.

2. Defrosting

Microcomputer calculates the appropriate timing of defrosting and defrosting is made automatically. Therefore no manual operation by user is

required. The cycle of defrosting varies depend on the usage condition of the refrigerator. (Maximum time about 50 hours, minimum time 8 hours)

3. Thermistor

Thermistors are installed in 4 places; in the refrigerator and freezer compartment, and close to the Control panel and Evaporator. (R-thermistor, Fthermistor, Outside temp-thermistor, Def-thermistor)

R-thermistor and F-thermistor detects the temperature in the refrigerator and freezer compartment respectively and controls ON/OFF of compressor.

Def-thermistor detects the temperature around the evaporator and shows the progress of defrosting.

Outside temp-thermistor detects the surrounding temperature of refrigerator. It decides the defrost timing and changes the operation mode when the

outside temperature is high.

[2] WHEN THE DEFROSTING FAILURE IS DOUBTFUL

Execute the Self-Diagnosis Mode. (Refer to the Chapter “SELF-DIAGNOSIS MODE”)

• In case the diagnosis result is “EE03” (Def-thermistor system defect), follow up the flowchart of EE03. (In case of any abnormity in the Def-thermistor, defrosting will not be made for safety reasons.)

• In case the diagnosis result is “EE07” (Defrost defect), follow up the flowchart of EE07.

(This diagnosis result will be displayed when defrosting is made for 120 minutes, the maximum time length. In this case, the defect of PWB itself

and also the breakage of heater and heater circuit (melt down of current fuse and temperature fuse) are considerable.)

[3] RE-SETTING OF MICROCOMPUTER AT POWER FAILURE

• At the power failure for over 0.4 second, the control of the microcomputer will might be reset.

• Microcomputer might continue to operate for approximately 10 seconds maximum at power failure depending on the load at the operation. Approximately 30 seconds is necessary for the definite power OFF condition.

• When the power is re-supplied, the normal cooling will be resumed.(If cold enough in the cabinet, the microcomputer will begin defrosting in 40

minutes according to the condition.)

• The temperature and operation mode set by user will be maintained even if a power failure occurred.

(However defrosting, rapid freezing, rapid ice making, and timer will not be maintained.)

• When the self diagnosis is made, each mode and setting are resumed to the initial condition.

Page 14

SJF800SPSL

8 – 2

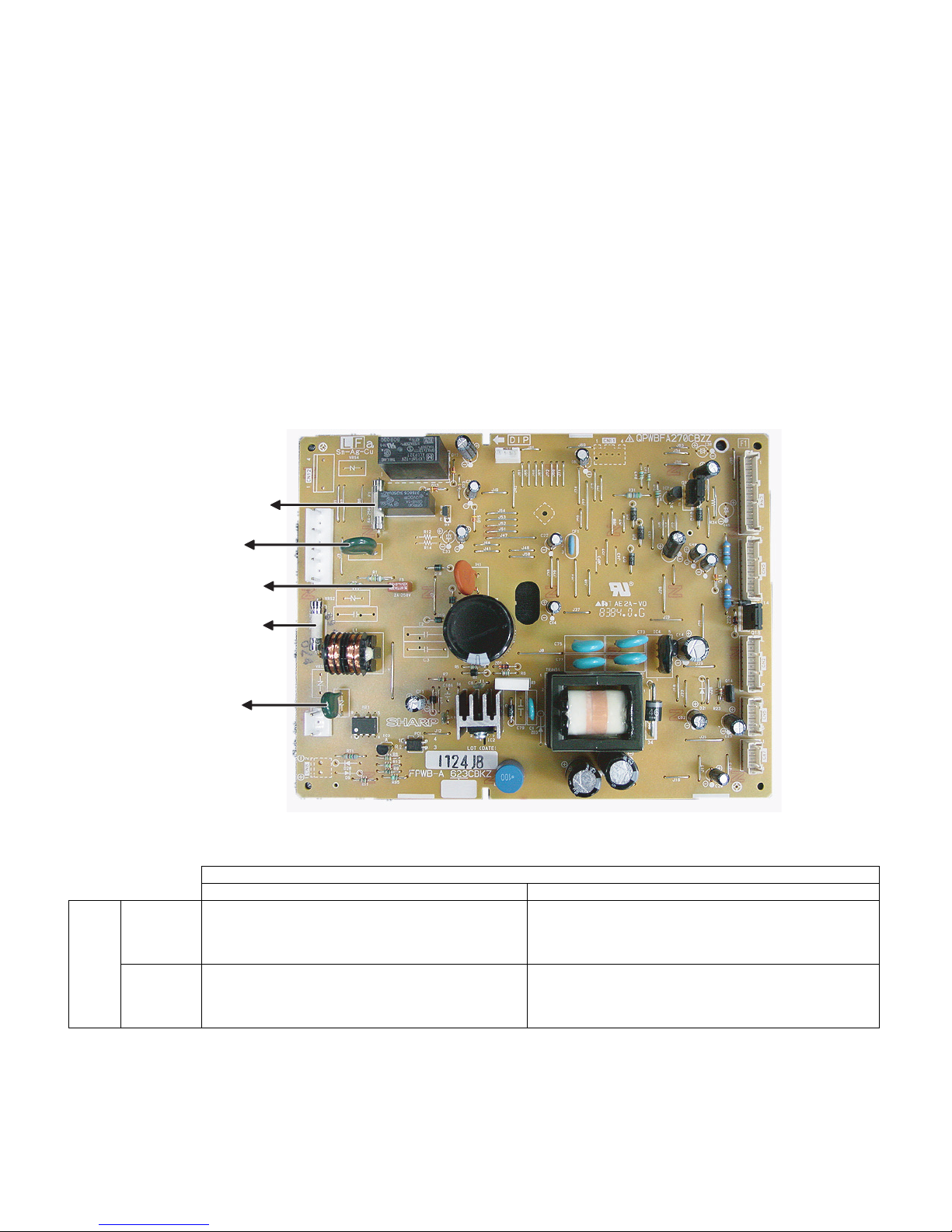

[4] DIAGNOSIS METHOD OF FAILURE AROUND PWB

First of all, check by using the self-diagnosis.

In case that the power supply doesn't enter, check by the following procedure.

1. Disconnect power supply and check the following point.

• Is there any failure portion in inserting connectors?

2. Detach the PWB and check the appearance.

• Is there any burning or abnormal damage?

3. Check the conditions of the fuse and the varistor. (Fuse and varistor are located at the position in the figure.)

• Under the condition of power supply plug connected;

In case of no cooling and no indoor lamp lighting, there might be a possibility of fuse (F1 or F2) melt down.

When the fuse F1 or F2 is melt down, PWB does not operate at all.

When the fuse F3 is melt down, defrosting heater and refrigerator door heater are not electrified. (Defrosting error will be diagnosed as

“Defrosting failure” by the self diagnosis.) In this case, the cooling performance may deteriorate or dew generation may occur on the door,

because the defrosting is not done.

• Melting in the fuse cannot be checked visually (as the safer one than transparent glass tube is used). Be sure to detach the connector “CN1”

before measuring the resistance between the both ends of the fuse by the tester.

• Next, measure the resistance value between the both leads of the varistor.

4. Check whether the temperature (resistance value) shown by R-thermistor is correct or not. (Refer to the table below.)

• Detach the connector “CN4” on the PWB and measure the resistance between 1 and 2 pins of harness side.

5. Check whether the temperature (resistance value) shown by Def-thermistor is correct or not. (Refer to the table below.)

• Detach the connector “CN5” on the PWB and measure the resistance value between 6 and 7 pins of harness side.

6. Check whether the temperature (resistance value) shown by F-thermistor is correct or not. (Refer to the table below.)

• Detach the connector “CN5” on the PWB and measure the resistance value between 4 and 5 pins of harness side.

Var is tor

Normal (over approx.1.5MΩ) Damage

Fuse

Melting

Flow of excessive current is considerable for some reasons.

Check for any portion to cause short circuits especially on

the primary circuit.

There is a possibility of excessive voltage applied from outside with the factor such as thunder etc. When repeated with a

factor other than thunder, there might be the apparatus near

by generating noises.

Conduction

Fuse and varistor are normal.

Possibility to be caused by excessive current or voltage

near the power supply is low. Proceed to the other check

item.

-

Var istor 1

Fuse 2

Fuse 1

Var istor 3

Fuse 3

Page 15

SJF800SPSL

8 – 3

[5] CONVERSION TABLE BETWEEN TEMPERATURE AND RESISTANCE VALUE

1. R-thermistor

2. Def-thermistor, F-thermistor

Temperature

(°C)

Resistance Value

(KΩ)

Temperature

(°C)

Resistance Value

(KΩ)

Temperature

(°C)

Resistance Value

(KΩ)

-25 26.1 -9 10.3 7 4.52

-24 24.54 -8 9.75 8 4.3

-23 23.08 -7 9.24 9 4.1

-22 21.72 -6 8.76 10 3.91

-21 20.46 -5 8.3 11 3.73

-20 19.27 -4 7.87 12 3.56

-19 18.16 -3 7.47 13 3.4

-18 17.13 -2 7.09 14 3.24

-17 16.16 -1 6.74 15 3.1

-16 15.25 0 6.4 20 2.47

-15 14.4 1 6.08 25 1.99

-14 13.6 2 5.78 30 1.61

-13 12.85 3 5.5 35 1.31

-12 12.15 4 5.23 40 1.08

-11 11.49 5 4.98

-10 10.88 6 4.74

Temperature

(°C)

Resistance Value

(KΩ)

Temperature

(°C)

Resistance Value

(KΩ)

Temperature

(°C)

Resistance Value

(KΩ)

-25 61.17 -9 24.13 7 10.58

-24 57.51 -8 22.85 8 10.09

-23 54.1 -7 21.65 9 9.61

-22 50.92 -6 20.52 10 9.16

-21 47.94 -5 19.46 11 8.74

-20 45.17 -4 18.46 12 8.34

-19 42.57 -3 17.51 13 7.96

-18 40.14 -2 16.63 14 7.6

-17 37.86 -1 15.79 15 7.26

-16 35.74 0 15 20 5.79

-15 33.74 1 14.26 25 4.66

-14 31.87 2 13.55 30 3.77

-13 30.12 3 12.89 35 3.08

-12 28.48 4 12.26 40 2.52

-11 26.94 5 11.67

-10 25.49 6 11.11

Page 16

SJF800SPSL

8 – 4

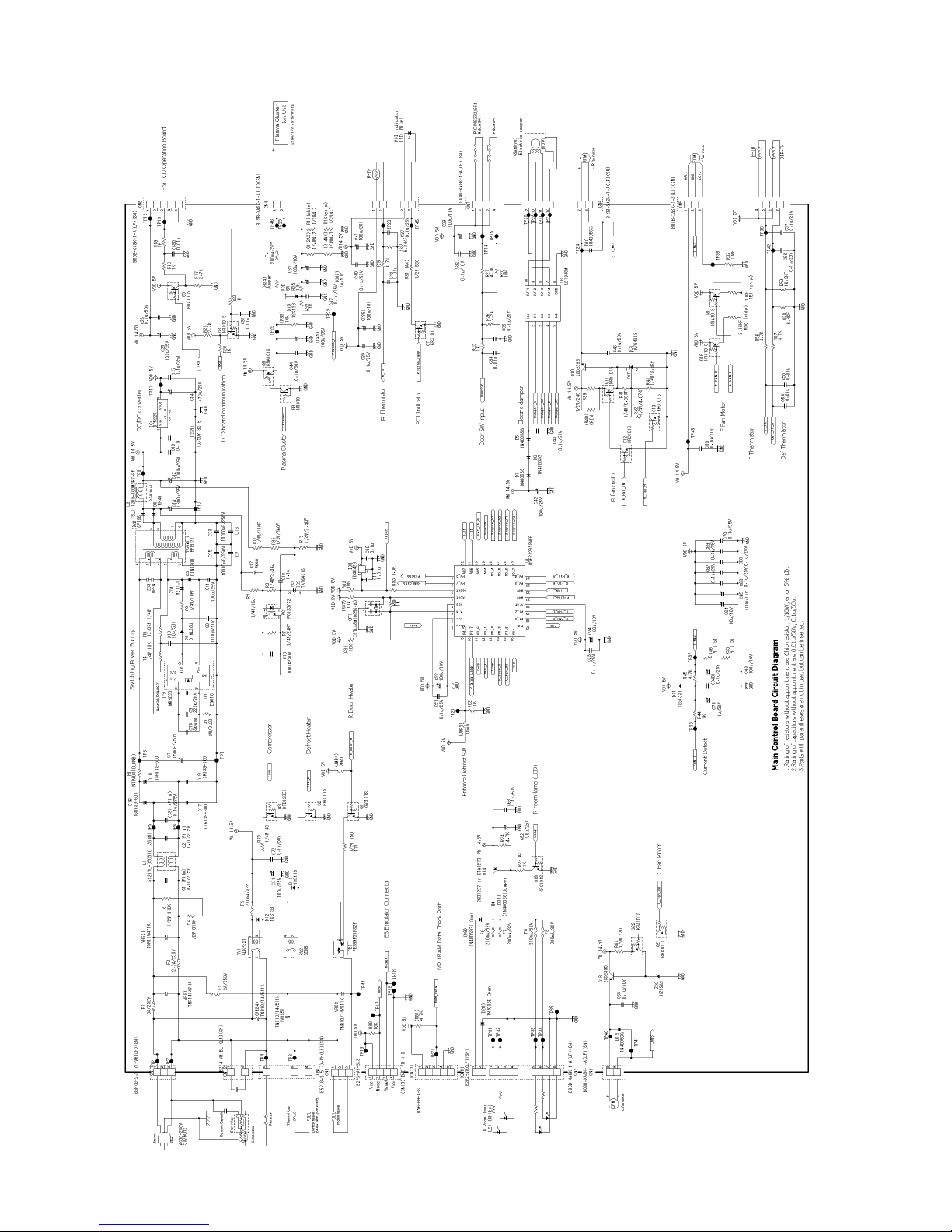

[6] CIRCUIT DIAGRAM OF MAIN PWB

Page 17

SJF800SPSL

8 – 5

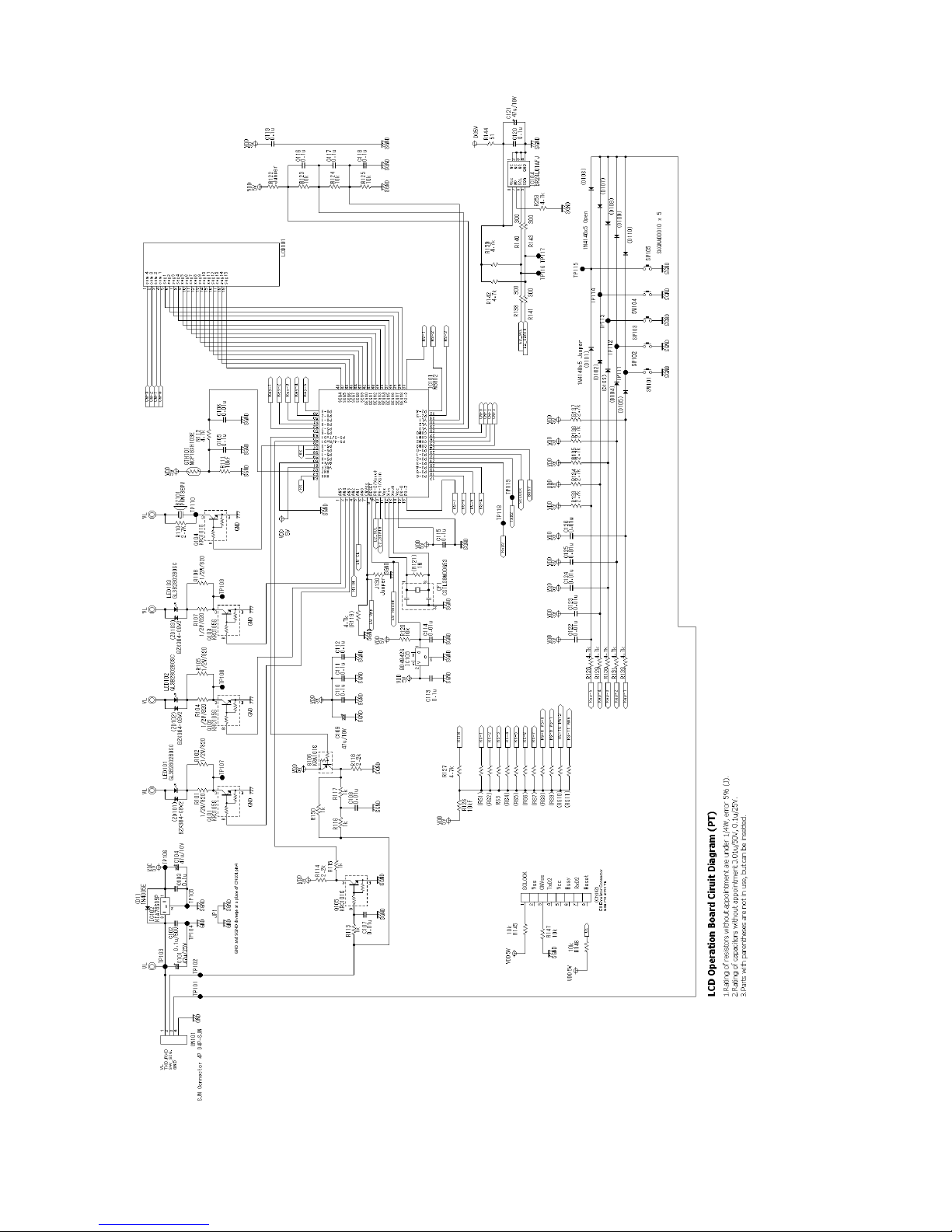

[7] CIRCUIT DIAGRAM OF LCD PWB

Page 18

SJF800SPSL

9 – 1

SJF800SPSL

ServiceManual

CHAPTER 9. SELF-DIAGNOSIS MODE

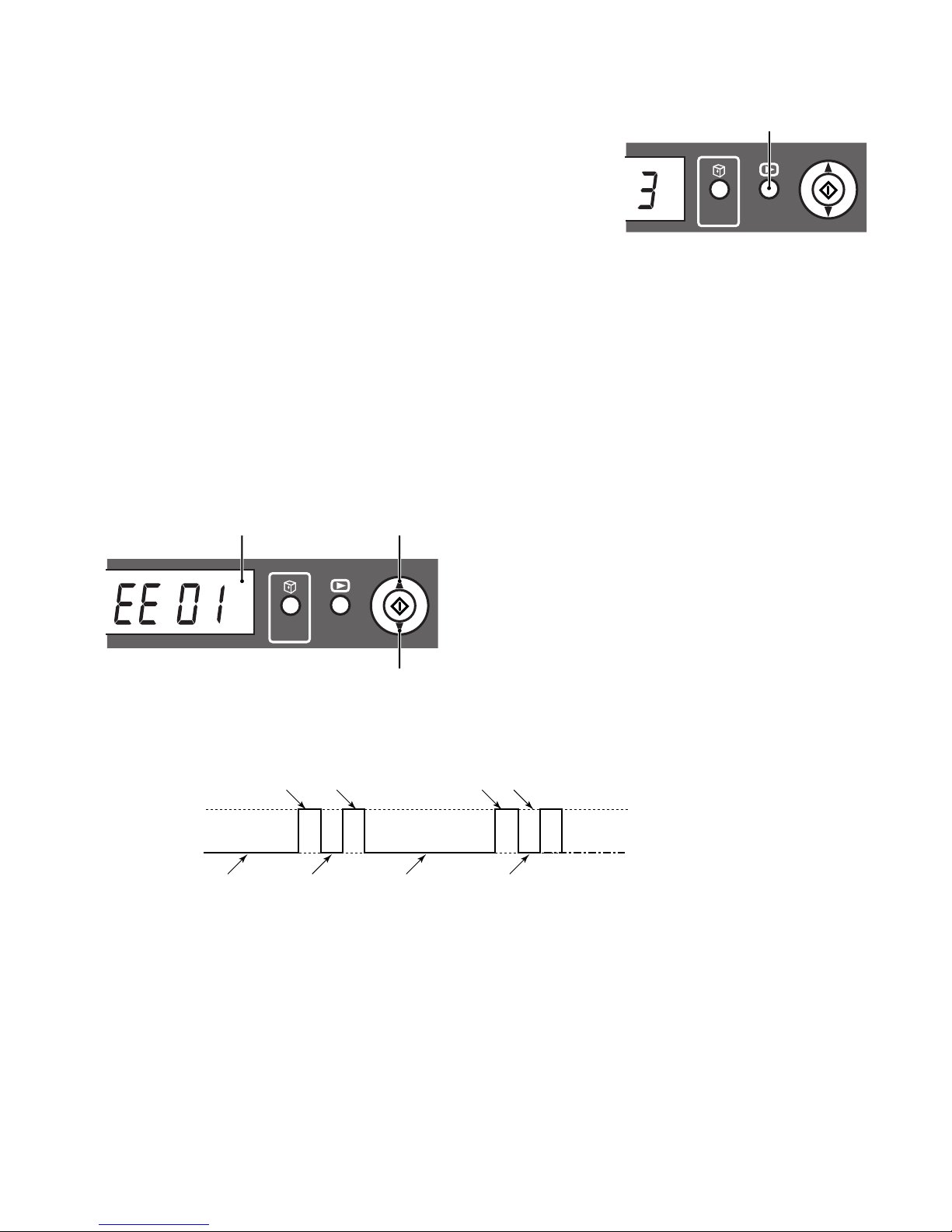

1. Entering method of the mode

1) Press the [Select] button on the LCD panel over 5 seconds at the opening condition of the

freezer and refrigerating room doors.

2) With a beep sound of buzzer, the self-diagnosis mode is entered. When the self-diagnosis

mode is not entered by the above operation, defect of Reed SW system can be considered.

2. When the self-diagnosis mode is entered, the following movements will be made. Forced release operation is not prepared for the self-diagnosis

mode. It returns to the normal movement after a lapse of 2 minutes.

• During the express ice making, express freezing or timer, the mode is released.

• Plasmacluster will not release the mode, and ON is forced for 2 minutes whether it is ON or OFF.

• When the self-diagnosis mode is entered, beep sound for reminding of closing the door must not be sounded for 20 minutes.

• Defect and various conditions are shown by the beeping buzzer pattern.

• Defect and various conditions are displayed on the LCD panel. In case of plural defects and various conditions, these are displayed one after

another by button operation and all contents are notified.

3. Display of self-diagnosis

• Display example of LCD panel (at the defect of F-thermistor system)

• Buzzer notice example; (at defrost defect, 2 times of 0.5 second ON)

ḥ

EXPRESS

ICE

SELECT BUTTON

SELECT

EXPRESS

ICE

Results of diagnosis

Move to the next display.

Move to the previous display.

SELECT

ON

OFF

3 seconds stop

Repeating

0.5 second stop

3 seconds stop

0.5 second stop

0.5 second 0.5 second 0.5 second 0.5 second

Buzzer

Page 19

SJF800SPSL

9 – 2

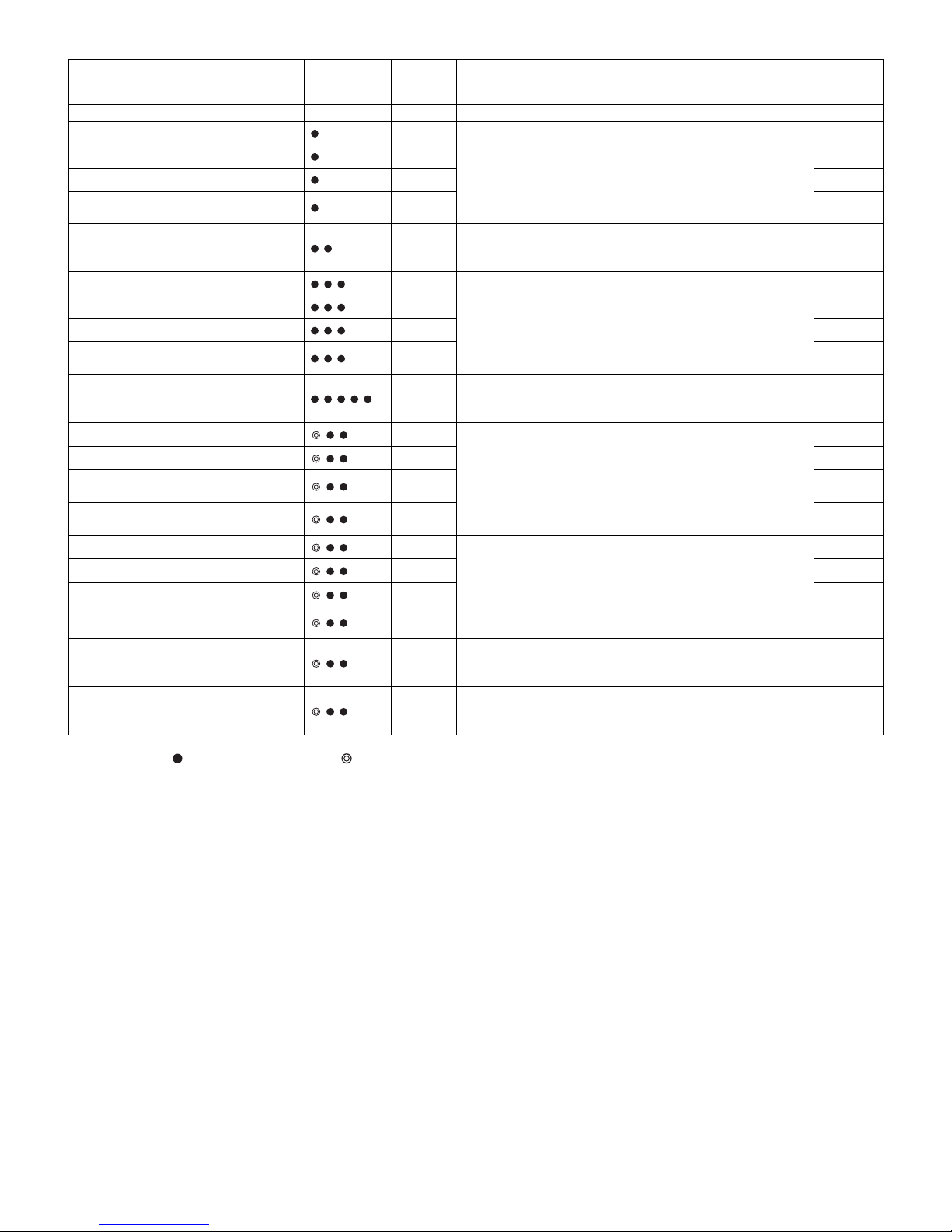

• Buzzer: =0.5 sec ON/0.5 sec OFF, =2 sec ON/0.5 sec OFF

No

.

Status Buzzer LCD

Display

Content

Correspon-

dence

method

- No defects None - - - -

1 F-thermistor system defect EE 01

Defect of each thermistor, short circuit/wire breakage of thermistor wiring and defect of main PWB

→[1]

2 R-thermistor system defect EE 02 →[2]

3 DEF-thermistor system defect EE 03 →[3]

4

Outside temperature-thermistor

system defect

EE 04 →[4]

5 Defrost defect EE 07

Wire breakage of fuse•defrost heater, defect of main PWB

(120-minute defrosting has been occurred continuously 2 times

within the past 48 hours.)

→[5]

6 F fan motor system defect EE 08

Defect of each fan motor, fan-lock and defect of wiring/main

PWB

(When fan motor is ON, over current or no current is detected.)

→[6]

7 C fan motor system defect EE 09 →[7]

8 R fan motor system defect EE 10 →[8]

9

Ionizer (Plasmacluster) system

defect

EE 11 →[9]

10 LCD Display communication defect EE 12

Short circuit/wire breakage of wiring and defect of LCD or main

PWB (Communication with LCD PWB has been abnormal over

3 times within the past 48 hours.)

→[10]

11 F-thermistor system defect history EH 61

Defect of thermistor system has been occurred over 1 minute

continuously within the past 48 hours.

→[1]

12 R-thermistor system defect history EH 62 →[2]

13

DEF-thermistor system defect history

EH 63 →[3]

14

Outside temperature-thermistor

system defect history

EH 64 →[4]

15 F fan motor system defect history EH 66

Defect of fan motor has been occurred over 3 times continuously within the past 48 hours.

→[6]

16 C fan motor system defect history EH 67 →[7]

17 R fan motor system defect history EH 68 →[8]

18

Ionizer (Plasmacluster) electrifying

defect history

EH 72

Defect of Ionizer (Plasmacluster) electrifying has been

occurred over 3 times continuously within the past 48 hours.

→[9]

19 F-room high temperature history EH 76

Temperature of F-thermistor has been reached over -10°C continuously for 6 hours or more within the past 48 hours. (except

right after the installation)

→[1]

20 R-room high temperature history EH 77

Temperature of R-thermistor has been reached over +10°

C

continuously for 6 hours or more within the past 48 hours.

(except right after the installation)

→[2]

Page 20

SJF800SPSL

9 – 3

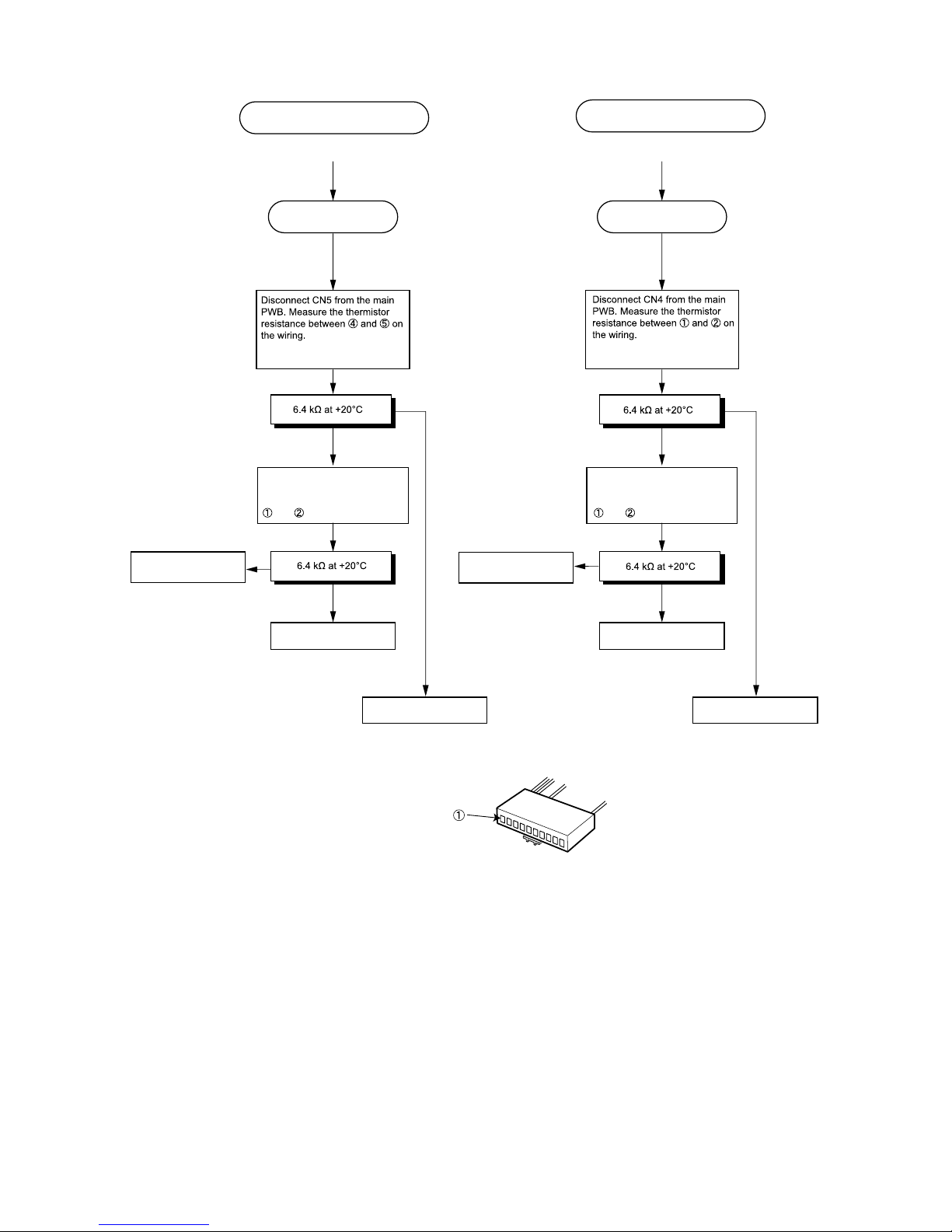

Correspondence method

Power OFF Power OFF

Replace F-thermistor.

Replace main PWB.

(F-thermistor system diagnosis) (R-thermistor system diagnosis)

OK

NG

and .

Replace R-thermistor.

Replace main PWB.

Remove 6P connector from R

louver Assy and measure the

thermistor resistance between

and .

EE 01 / EH 61 / EH 76

EE 02 / EH 62 / EH 77

[1]

[2]

Remove 4P connector (flat) from

E.V. cover Assy and measure the

thermistor resistance between

NG

OK

NG

NG

OK

OK

Check the F-thermistor

system wiring

Check the R-thermistor

system wiring

Page 21

SJF800SPSL

9 – 4

(DEF-thermistor system diagnosis)

Turn power OFF. Reopen door and re-energize.

(Buzzer beeps continuously)

Power OFF

Replace DEF-thermistor.

Replace main PWB.

OK

NG

NG

and .

EE 03 / EH 63

EE 04 / EH 64

(Ambient air temperature - thermistor system diagnosis)

Replace LCD-PWB.

Ambient air

temperature thermistor

is installed on

LCD-PWB.

(Defrosting diagnosis)

EE 07

OK?

Replace main PWB.

Replace fuse Assy.

Replace

defrost heater.

NO

YES

NO

YES

YES

NO

YES

NO

Forced defrosting (Measurement is impossible when

DEF-thermistor is set at 10°C or higher because

defrosting ends immediately)

After approx. 15 sec., the voltage

measured across

and of CN1

on the main PWB is equal to supplied

voltage? (e.g. 240 V)

Disconnect CN1 from the main PWB. Measure the

resistance between

and of CN1 on the wiring.

Resistance of 3P connector on E.V.

cover K is normal?

Check defrost heater wiring for loose

connection or disconnection.

Check cause of defrosting failure

· Check door packing

· Check mounting seal of E.V. cover Assy

2P connector on E.V. cover

Assy is carrying current?

[3]

[4]

[5]

Remove 4P connector (flat) from

E.V. cover Assy and measure the

thermistor resistance between

OK

Check the Def-thermistor

system wiring

See CHAPTER 4. (Heater resistance)

Page 22

SJF800SPSL

9 – 5

Turn OFF and ON power.

Fan locked?

Check position of fan.

Replace F fan motor.

Replace main PWB.

YES

YES

NO

NO

NO

YES

Measure voltage between and

of CN5 on the main PWB.

CN5

- : Approx. 14 V

- : Approx. 2~4 V

EE 08 / EH 66

(F fan motor system diagnosis)

EE 09 / EH 67

(C fan motor system diagnosis)

EE 10 / EH 68

(R fan motor system diagnosis)

F fan motor

rotates?

Check cause of defrosting

failure

· Dislocation of fan

· Check door packing

· Installation of E.V. cover Assy

· Defective seal

(If OK)

Replace C fan motor.

Adjust and power ON again.

Fan locked?

NO

YES

NO

YES

Measure voltage between and

of CN5 on the main PWB:

Approx. 9 to 13 VDC?

Loose connection or disconnection of

C fan motor system (motor connector

voltage)

Replace main PWB or C fan motor.

(If OK)

Replace R fan motor.

Adjust and power ON again.

Fan locked?

NO

YES

NO

YES

Measure voltage between and

of CN4 on the main PWB:

Approx. 9 to 13 VDC?

Loose connection or disconnection of

R fan motor system (motor connector

voltage)

Replace main PWB or R fan motor.

[6][

7

]

[8]

7

8

Page 23

SJF800SPSL

9 – 6

Replace Plasmacluster. Replace LCD-PWB Assy.

(Ionizer system diagnosis)

EE 11 EE 12

(LCD system diagnosis)

Insert connector.

NO

NO

YES

and of CN4 on the main PWB

are positively engaged?

YES

and of 6P connector on R

louver Assy are positively engaged?

Insert connector.

NO

NO

YES

CN6 on the main PWB is positively

engaged?

YES

5P connector on control panel is

positively engaged?

[9]

[10]

5

6

Page 24

SJF800SPSL

10 – 1

SJF800SPSL

ServiceManual

CHAPTER 10. MODE FOR DISPLAY

1. Entering method of the mode

Within 2 minutes after main power input, press the [ ] button over 3 seconds at the opening condition of the refrigerating room door.

NOTE: This cannot be made at the ON condition of CHILD LOCK.

2. Release of the mode

Press the [ ] button over 3 seconds at the opening condition of the refrigerating room door.

(Even without the above operation, release can be made by main power OFF.)

3. Movement in the mode

1) Compressor, each fan motor, heater and Plasmacluster are stopped.

2) Damper is always made [OPEN] condition.

3) Indoor lamp is lit when refrigerating room door is open.

4) LCD display

• Icon will be lit at random.

• In case of starting the timer, express ice making or express freezing, forced termination is made in 20 seconds.

ḥ

EXPRESS

ICE

BUTTON

SELECT

Page 25

SJF800SPSL

11 – 1

SJF800SPSL

ServiceManual

CHAPTER 11. DISASSEMBLING/ASSEMBLING PROCEDURES

CAUTION: DISCONNECT THE UNIT FROM THE POWER SUPPLY BEFORE ANY REPAIRING.

[1] REFRIGERATOR COMPARTMENT

1. Disassembling procedures

1. Remove the accessories(shelves, fresh case, etc.).

2. Remove the v shelf ass'y.

3. Remove the r-case stay

4. Remove the r con cover s, and disconnect the connector.

5. Remove the r lamp cover and the r-louver ass'y.

6. Remove the r control box ass'y.

Parents parts name Included electrical parts

R-louver ass'y

Plasmacluster unit, Lr led pwb ass'y, Top led pwb ass'y, Pci pwb ass'y,

Lr led harness, Pci indicator harness, R-thermistor

R control box ass'y Damper ass'y, Lead r-c box, R fan motor

Latch

V shelf ass'y

Latch

R-case stay

Latch

R-louver ass'y

R con cover s

Latch

Screw

Screw

Screw

R lamp cover r

R lamp cover l

Screw

Latch

Latch

R contorol box ass'y

Page 26

SJF800SPSL

11 – 2

2. Assembling procedures of R CONTROL BOX ASS’Y.

1. Insert Lead r-c box to Damper ass’y and next stick A-sealer rc-d to Damper ass’y (lead wire shall be fix by A-sealer rc-d)

2. Stick A-sealer rc-a to R fan motor.

3. Stick A-sealer ag4 to deodorizer.

A-sealer rc-c

A-sealer ag4

Deodorizer

R-C box cover

A-sealer rc-d

A-sealer rc-a

R fan motor

R air guider a

R air guider b

Damper ass'y

Lead r-c box

A-sealer rc-g

A-sealer rc-f

Damper ass’y

Lead r-c box

Damper ass’y

A-sealer rc-d

10~20 over rap

R fan motor

A-sealer rc-a

A-sealer ag4

A-sealer ag4

Deodorizer

Page 27

SJF800SPSL

11 – 3

4. Insert R fan motor and damper ass’y to R air guider b, and Stick A-sealer rc-f to R air guider b.

5. Assemble R air guider b to R air guider a. Wire-harness are fixed with kraft tapes. Stick A-sealer rc-c to R air guider a/b (lead wire shall surely

insert slot of R air guider).

6. Stick A-sealer rc-g to R air guider a.

7. Insert Deodorizer to R-C box cover. Assemble these sets and R-C box cover.

Damper ass’y

R air guider b

R fan motor

View from A

>PS<

A-sealer rc-f

R air guider b

View from A

R fan motor

R air guider b

Lead rc box

Kraft tape

20*30

R air guider a

A-sealer rc-c

A-sealer rc-c

Kraft tape

20*30

Kraft tape

20*30

Kraft tape

20*30

Slot

View from b

Kraft tape

Section A-A

Wire

Kraft tape

20*30

View from b

R fan motor

R air guider b

(Unit : mm)

HOLE

All around

0~2

A-sealer rc-g

>PS<

[Front side]

R-C box cover

Deodorizer

Page 28

SJF800SPSL

11 – 4

3. Assembling procedures of R-louver ass’y.

1. Connect Pci indicator harness to

Pci pwb ass'y.

2. Insert Pci pwb ass'y into Led holder.

3. Fix Light guide on Led holder.

4. Stick Al sheet l-guide to Light guide

and Led holder.

5. Stick A-sealer r-lv a to R-louver

insu.

A- sealer r-lv a

Plasmacluster

unit

R-louver insu

Pci indicator harness

Lr led harness

Lr led harness

R lamp cover t

Top led pwb ass’y

Lr led pwb ass’y

Al panel

R-louver

LIght guide

Led holder

Pci pwb ass’y

Lr led pwb ass’y

Al sheet l-guide

R thermistor

A-sealer r-lv b

Light guide

Pci pwb ass’y

Pci indicator harness

Pass the harness

through the hole.

Led holder

Al sheet l-guide

Light guide

Al sheet l-guide

40x90mm

Led holder

0~2

Standard for affixing of

Al sheet l-guide

Put the tape which

protruded in the side

A-sealer r-lv a

A-sealer r-lv a

R-louver insu

>PS<

B886

extention

Stick A-sealer r-lv a to

the bottom side.

(Both right and left side)

Page 29

SJF800SPSL

11 – 5

6. Fix Al panel to R-louver.

7. Fix 4) ass'y on the R-louver with tapping screw.

8. Connect Lr led harness to Lr led pwb ass'y and Top led pwb ass'y.

9. Fix 8) ass'y on R-louver.

10.Connect Pci indicator harness to plasmacluster unit.

11.Insert Plasmacluster unit into 5) ass'y.

12.Fix 5) ass'y to R-louver.

13.Fix R lamp cover t by taping screw to R-louver.

14.Fix Plasmacluter unit and Pci indicator harness by buffalo tape to R-louver insu.

15.Stick A-sealer r-lv b to R-louver insu.

?P

?Q

?R?S

R-louver

Al panel

Al panel

Al panel

Al panel

Bend hook

of Al panel

Bend hook

of Al panel

Bend hook

of Al panel

Lr led harness

Pci indicator harness

Lr led harness

Lr led pwb ass’y

T

op led pwb ass’y

Hook

T

apping screw

R lamp cover t

Lr led pwb ass’y

Plasmacluter

unit

5) ass'y

4) ass'y

A-sealer r-lv b

Pci indicator harness

R-louver insu

Buffalo tape

30x40

Buffalo tape

30x40

over lap

All around

3

A-sealer r-lv b

Page 30

SJF800SPSL

11 – 6

16.Fix each harness by buffalo tape to R-louver.

Lr led harness

R-thermistor

Pass the harness

through the hole.

Pass the harness

through the hole.

Tapping

screw

R-louver

Hook Hook

Hook

Lr led pwb ass’y

Hook

Hook

Pci indicator harness

Lr led harness

Fix R-thermistor with hooks.

Hook

Buffalo tape

30 x 40

Tapping

screw

Buffalo tape

30x40

Buffalo tape

30x50

Buffalo tape

30 x 50

Buffalo tape

30 x 50

Page 31

SJF800SPSL

11 – 7

[2] FREEZER COMPARTMENT

1. Disassembling procedures

1. Remove the accessories(shelves, case, etc.).

2. Remove the i-case stay.

3. Remove the c-part ffb ass'y.

4. Remove the f return cover.

5. Remove the fan louver.

6. Remove the connect cover, and disconnect the connector.

7. Remove the ev cover ass'y.

Parents parts name Included electrical parts

Ev cover ass'y F/df-thermistor, F fan motor

Evaporator ass'y Fuse ass'y

Def-heater ass'y Defrost heater

Latch

I-case stay

Screw

C-part ffb ass'y

Latch

Latch

Latch

Latch

F return cover

Screw

Fan louver

Screw

Latch

Screw

Screw

Ev cover ass'y

Connect cover

Page 32

SJF800SPSL

11 – 8

2. Assembling procedures of C PARTITION FFB ASS’Y.

1. Stick Sealer c to V-Partition lfb.

2. Fix V-partition lfb and V-Partition rfb with the tapping screw.

Sealer d

Sealer c

Sealer e

V-partition rfb

V-partition lfb

V-PARTITION LFB

SEALER C

V-PARTITION LFB

V-PARTITION RFB

TAPPING SCREW

Page 33

SJF800SPSL

11 – 9

3. Stick Sealer d to the back side.

Stick Sealer e to the bottom side.

3. Assembling procedures of E.V. COVER ASS’Y.

SEALER D

SEALER E

F/df-thermistor

Sealer fm

EV-cover insu

EV-cover sealer

EV cover

EV-c sealer l

EV-cov. sealer b

EV-cov. sealer c

F fan motor

Fan louver

E.V. PE-AL sheet

Connect cover

Page 34

SJF800SPSL

11 – 1 0

1. Assembly F fan motor

i) Sticking of sealer to F fan motor.

ii) Insert F fan motor to E.V cover .Then fix with tapping screw.

2. Sticking of sealers and PE-AL sheet to E.V cover.

3. Insert F/df-thermistor ( wire color : Blue) to E.V cover.

4. Insert E.V cover insulation to E.V cover.

5. Insert F/df-themistor ( wire color : White) to connect cover.

6. Fix 5) ass’y to E.v cover with tapping screw.

Tappig screw

(Unit : mm)

F/df- thermistor

Page 35

SJF800SPSL

11 – 11

4. Banding the connectors

1. It is necessary to bind the connector joint of the Defrost heater and fuse ass’y in the band.

Only the lower side

3P-connector

(Defrost heater)

2P-connector

(Fuse ass'y)

lock

lock

Attach to each inside face. (reverce of lock)

Page 36

SJF800SPSL

11 – 1 2

[3] HOW TO REMOVE THE CONTROL BASE

1. Insert the sharp tool into gap between control panel and control base, and then push it for take out the claw from control base.

2. Remove the control panel carefully by hand.

(Take out the claw of control panel from control base)

3. Insert the screw driver for take out 5 screws in the position as see the picture.

4. Take off the connector (2 connectors) and then remove the control base.

INSERT SHARP IN THIS POSITION

CLAW

Control panel

REMOVE IT BY THIS WAY

CLAW

screw

screw

Control base

screw screw

screw

Reed sw (for refrigerator compartment)

(harness color : Red)

( 4mm)

( 4mm)

( 4mm)( 5mm)

( 5mm)

Reed sw

(for freezer compartment)

(harness color : Black)

Control base

Connector

Page 37

SJF800SPSL

11 – 1 3

[4] DEFROST HEATER

1. Taking-out Evaporator

1. Take-out C Partition ffb ass’y.

2. Take-out Fan louver.

3. Take-out E.V cover ass’y.

4. As shown in the above figure, pull the upper part of Evaporator

toward you, pull it diagonally so that the pipe of Evaporator does

not contact the convex part of food liner.

5. Pull the Evaporator for remove as shown in the above figure.

NOTE: When pulling Evaporator and bending the pipes,pay attention

so as not to break and deform the pipes. Still, take care not to

hurt yourself by fin of Evaporator.

2. Replacement of Def. heater.

1. Remove the center screw of Heater support to take it off from the

food liner.

2. Raise the protrusion part of Heater support. Then remove Heater

cover.

3. Open Def.heater fixed part of Heater support to the right and left,

then remove Def.heater.

E vaporator

F ood liner co nve x pa rt

Food liner convex part

Evaporator

Pipe

Evaporator

Heater support

Heater cover

Protrusion parts

Protrusion part of Drain support al(2 pcs.)

Heater cover

Def. heater ass'y

Heater support

Fixed parts

Def.heater

Heater support

Page 38

SJF800SPSL

11 – 1 4

4. Replace Def. heater with new one.

5. Bend end of heater support.

6. Assemble Defrost heater to Heater Support.

7. Assemble Heater cover to Heater Support. Bend top edge to outside.

8. Roll the leading wire Sealer to Lead wire Defrost Heater.

3. Installing of Evaporator

1. Install Evaporator as shown in 1-3 in the reverse order of 1-4.

2. Correct the deformed fin.

NOTE: 1.When installing Evaporator, take care not to deform signifi-

cantly and break the pipes.

2.Take care not to damage the lead wires and hurt yourself by

the fin of Evaporator.

Heater support

(Unit : mm)

Page 39

SJF800SPSL

11 – 1 5

[5] WHEN LEFT AND RIGHT DOORS ARE NOT ON THE SAME LEVEL

1. Cause

The floor is not flat and refrigerator is slanting.

2. Adjustment

1. Unscrew 4 screws on the bottom of the cabinet,and remove the foot cover.

2. Adjust the adjustable feet as follows:

[When left door is raised]

1) Raise and then lower the both feet until they touch the floor.

2) Measure the height difference between right and left doors.

3) Extend the right adjustable foot until the left adjustable foot floats by the distance equal to the door level difference.

4) Several days are required until the both feet touch the floor and refrigerator seats stably.

5) If the height difference is not completely compensated, place a plate of the right thickness under the adjustable foot.

NOTE: When the right door is higher than the left door, extend the left adjustable foot.

Foot cover

Adjustable foot

3) Lower the foot

at right side.

1) Touch floor surface.

2) Check height difference.

3) Raise by the height difference

between doors.

Left door

is raised

Page 40

SJF800SPSL

12 – 1

SJF800SPSL

ServiceManual

CHAPTER 12. COOLING UNIT

[1] COOLING UNIT

Page 41

SJF800SPSL

12 – 2

[2] LOCATION

1. Location 1

2. Location 2

Capillary tube

Eva. pan

pipe ass’y

-HC-L

-HC-S

DC

P-Connector

From Bottom condenser

to Hot pipe

From Compressor

to CHRG-PIPR-HC-

From CHRG-PIPE-HC-S

to Dryer

From Suction pipe ass

to S Connector

From S connector

to Compressor

From Compressor

to DC P-Connector

From DC P-Connector

to Sub condernser

From Sub condenser

to E pan pipe s ass

From E pan pipe s ass

to BTM condenser

From Hot pipe

to Dryer

Form Dryer

to Capillary tube

Page 42

SJF800SPSL

12 – 3

Page 43

PartsGuide

SJF800SPSL

PARTS GUIDE

Refrigerator-freezer

MODELS

SJ-F750SP-SL/BK

SJ-F800SP-SL/BK

[1] SJ-F750SP DOOR

[2] SJ-F750SP CABINET1

[3] SJ-F750SP CABINET2

[4] SJ-F750SP CYCLE

[5] SJ-F750SP OTHERS

[]

CONTENTS

[6] SJ-F800SP DOOR

[7] SJ-F800SP CABINET1

[8] SJ-F800SP CABINET2

[9] SJ-F800SP CYCLE

[10] SJ-F800SP OTHERS

INDEX

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 44

SJF800SPSL

3-40

3-21

3-11

5-21

5-22

5-23

5-27

5-28

5-27

5-27

5-28

5-22-1

5-24

3-2

5-1

3-22

5-6

5-5

5-4

5-3

5-2

5-2

3-32

3-1-3

3-1-2

3-1

3-21-3

3-21-2

3-21-5

3-21-1

3-31-1

3-31-4

3-31-2

3-31-5

3-31-3

3-21-4

3-1-3

3-1-1

3-11-2

3-1-1

3-31

5-3-1

3-28

3-28

3-2

3-8

3-19

3-9

3-19

3-8

3-9

3-55

3-51

3-57

3-53

3-26

3-54

3-58

3-52

3-56

3-55

3-51

3-57

3-53

3-6

3-54

3-58

3-52

3-56

3-55

3-51

3-57

3-53

3-26

3-54

3-58

3-52

3-56

3-55

3-51

3-57

3-53

3-6

3-54

3-58

3-52

3-56

3-46

3-47

3-47

3-46

3-47

[1] SJ-F750SP DOOR

2

Page 45

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PART

RANK

DESCRIPTION

[1] SJ-F750SP DOOR

3-1 FDORFC066CBKZ BR F-door l ass'y [SL]

3-1 FDORFC073CBKZ BT F-door l ass'y [BK]

3-1-1 LSTPMA008CBM0 AD F-door stopper r

3-1-2 LSTPPA146CBFA AF Fd-stp spring l

3-1-3 NBRGPA022CBFA AC Nylon bearing 3s

3-2 FPACGA431CBYA AT F door packing

3-6 JHNDPA296CBPZ AY Fd-handle

3-8 PPACGA226CBZA AM F-sub packing a

3-9 PPACGA227CBZA AK F-sub packing b

3-11 FDORFC067CBKZ BR F-door r ass'y [SL]

3-11 FDORFC074CBKZ BT F-door r ass'y [BK]

3-11-2 LSTPPA147CBFA AF Fd-stp spring r

3-19 PPACGA241CBZA AK F-sub packing c

3-21 FDORRC074CBKZ BT R-door l ass'y [SL]

3-21 FDORRC094CBKZ BT R-door l ass'y [BK]

3-21-1 LSTPPA150CBFA AF Stp-spring tl

3-21-2 LSTPPA151CBFA AF Stp-spring bl

3-21-3 LSTPPA152CBFA AF R lock spring l

3-21-4 MSLI-A070CBFA AE Door cam tl

3-21-5 MSLI-A071CBFA AE Door cam bl

3-22 FPACGA504CBYA AX R door packin l

3-26 JHNDPA298CBPZ AZ Rd-handle

3-28 PPACGA294CBZA AP R-sub packing

3-31 FDORRC075CBKZ BT R-door r ass'y [SL]

3-31 FDORRC095CBKZ BT R-door r ass'y [BK]

3-31-1 LSTPPA148CBFA AF Stp-spring tr

3-31-2 LSTPPA149CBFA AF Stp-spring br

3-31-3 LSTPPA153CBFA AF R lock spring r

3-31-4 MSLI-A068CBFA AE Door cam tr

3-31-5 MSLI-A069CBFA AE Door cam br

3-32 FPACGA505CBYA AX R door packin r

3-40 HBDGDB020CBZA AZ Badge

3-46 PSEL-E036CBZZ AE R-sub packing sealer

3-47 PSEL-E040CBZZ AE

3-51 HDECQA597CBFA AF Hd base t

3-52 HDECQA598CBFA AF Hd base b

3-53 HDECQA599CBTA AG Hd-cover t [SL]

3-53 HDECQA599CBTB AG Hd-cover t [BK]

3-54 HDECQA600CBTA AG Hd-cover b [SL]

3-54 HDECQA600CBTB AG Hd-cover b [BK]

3-55 HDECQA601CBTA AG Hd cap t [SL]

3-55 HDECQA601CBTB AG Hd cap t [BK]

3-56 HDECQA602CBTA AG Hd cap b [SL]

3-56 HDECQA602CBTB AG Hd cap b [BK]

3-57 LPLTPA559CBPZ AE Hd-support t

3-58 LPLTPA560CBPZ AE Hd-support b

5-1 FPOK-A270CBKZ AW Btl-pok l ass'y

5-2 FPOK-A271CBKZ AP Door pocket ass'y

5-3 FPOK-A272CBKZ AZ Btl-pok r ass'y

5-3-1 LSTYPA044CBFA AL B-pok partition

5-4 FPOK-A273CBKZ AN Utility pok ass'y

5-5 GDORPA078CBFA AN U-pok door

5-6 UTNA-A397CBFA AH Egg tray

5-21 FSRA-A244CBYZ AP Ice cube maker

5-22 FSRA-A245CBKZ BM Quick ice maker

5-22-1 PSKR-A329CBFA AK Q-ice parition

5-23 FYOK-A232CBKZ AV Ice storage assy

5-24 LSTYPA043CBFA AW I-case stay

5-27 FYOK-A306CBKZ AZ F-case s ass'y

5-28 FYOK-A305CBKZ BB F-case l ass'y

Rd packing sealer

SJF800SPSL

3

Page 46

SJF800SPSL

2-5

2-7-2

2-121

2-122

2-7-1

2-7

2-8-2

2-7-1

5-12-3

5-12-1

5-12-2

5-11

5-12

5-13

5-13-1

5-13-2

5-13-3

2-8

5-11-3

5-11-1

5-11-2

2-115

5-16

5-18

5-17

5-15

2-116

2-117

2-118

2-108

2-107

2-113

2-114

2-106

2-105

2-111

2-112

2-3

2-4

5-14

5-42

4-21

2-145

2-146

2-144

2-142

2-143

2-93

2-93

2-36

2-49

5-25

5-11-4

3-45

5-11-5

5-12-4

90-33

2-119

[2] SJ-F750SP CABINET1

4

Page 47

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PART

RANK

DESCRIPTION

[2] SJ-F750SP CABINET1

2-3 PCOVPA398CBFA AR Hinge cover [SL]

2-3 PCOVPA398CBFF AT Hinge cover [BK]

2-4 LPLTPA416CBTA AX Hinge support-t [SL]

2-4 LPLTPA416CBTB AW Hinge support-t [BK]

2-5 JHNDMA025CBPZ AE Carrying bar

2-7 FLEGPA127CBKZ AN Leg holder-ls k

2-7-1 FAJS-A028CBKZ AZ Adjustable leg ass'y

2-7-2 FLEGPA123CBYZ AH Leg holder-lk

2-8 FLEGPA128CBKZ AN Leg holder-rs k

2-8-2 FLEGPA124CBYZ AH Leg holder-rk

2-36 PCAP-A006CBFW AB Screw cover

2-49 LSTPPA108CBFA AC Chilled stopper

2-93 PCAP-A068CBFA AC C sliding cap a

2-105 DHNG-A537CBMZ BA F-hinge lt assy

2-106 DHNG-A538CBMZ BA F-hinge rt assy

2-107 DHNG-A539CBMZ BA F-hinge lb assy

2-108 DHNG-A540CBMZ BA F-hinge rb assy

2-111 FHNG-A231CBMZ AH R-hinge lbk

2-112 MSLI-A072CBFA AE Hinge cam bl

2-113 FHNG-A232CBMZ AH R-hinge rbk

2-114 MSLI-A073CBFA AE Hinge cam br

2-115 FHNG-A233CBYZ AH R-hinge ltk

2-116 MSLI-A074CBFA AE Hinge cam tl

2-117 FHNG-A234CBYZ AH R-hinge rtk

2-118 MSLI-A075CBFA AE Hinge cam tr

2-119 FPLTPA152CBKZ AN Temp.meter ass'y

2-121 GCOV-A280CBFA AV F-ret cover bl

2-122 GCOV-A281CBFA AV F-ret cover br

2-142 PSEL-C558CBZZ AD Sealer c

2-143 PSEL-C559CBZZ AD Sealer d

2-144 PSEL-C560CBZZ AD Sealer e

2-145 PSKR-A327CBFA AU V-partition lfb

2-146 PSKR-A328CBFA AU V-partition rfb

3-45 PPACGA244CBZA AF

4-21 LX-TZA091CBTA AE Special screw [SL]

4-21 LX-TZA091CBTF AD Special screw [BK]

5-11 FTNA-A537CBKZ BE R-shelf ass'y

5-11-1 UTNA-A396CBRA AY R-glass shelf

5-11-2 UWAKPA046CBFA AQ G guard rb

5-11-3 UWAKPA044CBFA AV G guard r

5-11-4 LPLTMA753CBPZ AP R shelf support

5-11-5 HDEC-A085CBZZ AR G guard r trim

5-12 FTNA-A536CBKZ BE V-shelf ass'y

5-12-1 UTNA-A395CBRA AY V-glass shelf

5-12-2 UWAKPA045CBFA AQ G guard vb

5-12-3 UWAKPA043CBFA AV G guard v

5-12-4 HDEC-A084CBZZ AR G guard v trim

5-13 FTNA-A419CBKZ AR Bttl rack ass'y

5-13-1 LHLD-A712CBFA AK B-r holder

5-13-2 NSFT-A041CBFA AE B-r shaft

5-13-3 UTNA-A398CBFA AK Bottle rack

5-14 FYOK-A303CBKZ AZ Fruit case assy

5-15 FYOK-A304CBKZ AY Fresh case assy

5-16 FYOK-A229CBKZ AZ V-case ass'y

5-17 GFTA-A117CBRA AR V-case door

5-18 LSTYPA042CBFA AT R-case stay

5-25 LRAL-A092CBFA AM Ice room rail

5-42 HGRL-A243CBFA AS Base cover [SL]

5-42 HGRL-A243CBFF AS Base cover [BK]

90-33 TLAB-B220CBRZ AE Temp.caution label

F-sub packing d

SJF800SPSL

5

Page 48

SJF800SPSL

2-66

6-12

2-95

2-20

2-67

1-21

2-2

1-55

2-132

2-147

2-133

2-131

1-10

2-1

1-6

2-138

2-139

2-34

1-27

2-74

2-38

2-72

2-39

2-27

1-4

1-26

2-97

2-16

2-21

2-28

2-22

2-140

2-100

1-17

2-120

2-141

6-31

2-149

2-148

1-1

2-125

2-25

2-26

2-55

2-161

2-29

1-64

1-65

1-62

1-64

1-61

1-61

2-163

1-63

2-162

2-56

1-45

2-58

2-165

2-164

2-160

1-3

2-37

2-37

2-166

2-167

[3] SJ-F750SP CABINET2

6

Page 49

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PART

RANK

DESCRIPTION

[3] SJ-F750SP CABINET2

1-1 RH-HXA108CBZZ AW F/df-thermistor

1-3 RH-HXA123CBZZ AM R-thermistor

1-4 DTHM-A031CBKZ AX Damper ass'y

1-6 RMOTRA096CBZZ BE F fan motor

1-10 FSW-LA001CBKZ AW Reed sw ass'y

1-17 FFS-TA087CBKZ AM Fuse ass'y

1-21 FHETBA193CBZZ BA Defrost heater

1-26 QCNW-B146CBZZ AK Lead r-c box

1-27 RMOTRA095CBZZ BA R fan motor

1-45 CKITTA131AKKZ BE Plasmacluster unit

1-55 FPWB-A615CBKZ BL Lcd pwb s ass'y

1-61 FPWB-A617CBKZ BF Lr led pwb ass'y

1-62 FPWB-A619CBKZ BE Top led pwb ass'y

1-63 FPWB-A621CBKZ BB Pci pwb ass'y

1-64 QCNW-B363CBZZ AH Lr led harness

1-65 QCNW-B364CBZZ AM Pci indicator harness

2-1 HPNL-A466CBFA AX Control panel [SL]

2-1 HPNL-A468CBRA AV Control panel [BK]

2-2 GDAI-A078CBTA AU Control base

2-16 GCOV-A282CBFB AX Ev-cover

2-20 PSEL-C573CBZZ AE E.v.pe-al sheet

2-21 PFPFPB565CBFZ AE Ev-cover insu

2-22 PSEL-C569CBZZ AC Ev-cover sealer

2-25 PCOV-A435CBFA AK R lamp cover l

2-26 PCOV-A436CBFA AK R lamp cover r

2-27 GCOVPA274CBFA AX R-c box cover

2-28 HGRL-A244CBFA AX Fan louver

2-29 PCOV-A434CBFA AK R lamp cover t

2-34 PFIL-A047CBEZ AC Deodorizer

2-37 LHLD-A860CBFA AE Screw cover

2-38 PGID-A169CBFZ AG R air guider a

2-39 PGID-A170CBFZ AE R air guider b

2-55 MLOV-A079CBFA AY R-louver

2-56 PFPFPB887CBFZ AK

2-58 PSEL-E015CBZZ AG A-sealer r-lv a

2-66 PSHEMA296CBPZ AC Heater cover

2-67 LPLTPA428CBPZ AQ Heater support

2-72 PSEL-C562CBZZ AC A-sealer rc-a

2-74 PSEL-C564CBZZ AG A-sealer rc-c

2-95 LANG-A064CBPZ AF Eva holder 75

2-97 PCOV-A340CBFA AF R con cover s

2-100 GCOVPA199CBFZ AF Connect cover

2-120 GCOV-A279CBFA AM F return cover

2-125 LPLTMA933CBPZ BP Al panel

2-131 JBTN-A030CBMA AH Button

2-132 JBTN-A031CBMA AK Button l

2-133 JBTN-A032CBMA AH Button j

2-138 PSEL-C600CBZZ AD Ev-cov.sealer b

2-139 PSEL-C601CBZZ AE Ev-cov.sealer c

2-140 PSEL-C640CBZZ AD Ev-c sealer l

2-141 PSEL-C661CBZZ AD Sealer fm

2-147 LHLD-A713CBFA AE Lcd-pwb holder

2-148 PSEL-C669CBZZ AD A-sealer rc-d

2-149 PSEL-C081CBEZ AA A-sealer ag4

2-160 GCOV-A344CBFA AH R-cbox return cover

2-161 HDECAA097CBRA AP Plasma badge

2-162 LHLD-A861CBFA AH Led holder

2-163 LPLTPA561CBFA AH Light guide

2-164 PSEL-E068CBZZ AE A-sealer rc-f

2-165 PSEL-E069CBZZ AD A-sealer rc-g

2-166 PSEL-E076CBZZ AE Al sheet l-guide

2-167 PSEL-E084CBZZ AE A-sealer r-lv b

6-12 PEVA-A201CBZZ BE Evaporator

6-31 PKYU-A035CBE0 AG Sp-butyl h

R-louver insu

SJF800SPSL

7

Page 50

SJF800SPSL

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PART

RANK

DESCRIPTION

2-123

1-50

2-51

1-31

1-23

1-11

6-10

2-24

2-152

2-153

6-11

6-1

4-1

2-87

2-87

6-9

6-2

4-17

1-2

6-4

1-9

6-18

6-5

6-17

6-3

6-7

6-8

2-126

4-10

4-4

2-78

2-99

1-22

4-15

2-77

5-41

1-41

2-80

6-32

2-151

2-136

6-27

6-28

6-27

6-28

2-88

4-14

6-42

6-41

6-36

6-21

6-40

[4] SJ-F750SP CYCLE

[4] SJ-F750SP CYCLE

1-2 RSTT-A179CBZZ AR Ptc relay

1-9 QACC-A156CBZZ AQ Source cord

1-11 RHOG-A189CBEZ AZ Protector

1-22 FCNW-A860CBZZ AH Relay wire assy

1-23 QCNW-A916CBZZ AE Reray wire sc

1-31 RC-EZA254CBZZ AS Running capacitor

1-41 RMOTRA097CBZZ BA C fan motor

1-50 FPWB-A661CBKZ BP Pwb-s ass'y

2-24 GCOVPA200CBFB AR Terminal cover [SL]

2-24 GCOVPA200CBFC AR Terminal cover [BK]

2-51 LHLD-A711CBFA AQ Pwb holder

8

Page 51

SJF800SPSL

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PART

RANK

[4] SJ-F750SP CYCLE

2-77 LHLD-A359CBFA AE T-box holder

2-78 LPLTMA399CBP0 AD Dryer support

2-80 PBOX-A148CBFA AE Terminal box

2-87 LBND-A018CBE0 AP Fastening band a

2-88 LBND-A019CBE0 AB Nylon band

2-99 PPIPPA126CBFZ AF Drain pipe s

2-123 GCOV-A283CBPZ AH Comp.cover

2-126 LHLD-A710CBFZ AH Cfm frame

2-136 LPLTMA553CBP0 AM Ev.pan support

2-151 PSEL-C555CBZZ AD U-sealer rd

2-152 PSEL-C571CBZZ AC Sealer

2-153 PSEL-C662CBZZ AD Sealer fm-b

4-1 LBND-A023CBE0 AC L-band c

4-4 QTAN-A012CBE0 AH Solderless term. B

4-10 QTAN-A013CBE0 AH Solderless term. A

4-14 LBND-A040CBZZ AD Band l150

4-15 LX-BZA090CBZZ AC Special screw

4-17 LX-WZA035CBZZ AB Washer

5-41 USRA-A297CBFA AP Drain pan

6-1 PCMPLA262CBZZ CA Compressor

6-2 PKYU-A173CBKZ AS Rubber mount ass'y

6-3 FCONSA101CBZZ BB Sub condenser

6-4 FFRM-A145CBKZ AM Base frame assy

6-5 FDRY-A006CBK0 AX Dryer ass'y

6-7 LPLTPA418CBFA AF S-con support l

6-8 LPLTPA419CBFA AF S-con support r

6-9 PSPAFA055CBEZ AP Sleeve

6-10 PPIPCA533CBZZ AW Dcp connector

6-11 PPIPCA534CBZZ AW Sp-connector

6-17 PPIPCA517CBZZ AE Chrg pipe hc s

6-18 PPIPCA518CBZZ AE Chrg pipe hc l

6-21 PCOVPA271CBEZ AH Terminal cover

6-27 PGUM-A004CBF0 AH Absorbent rubber a

6-28 PKYU-A175CBZZ AF

6-32 PGUM-A027CBFZ AF Comp. Spacer-e

6-36 FPIPCA255CBKZ AR Eva pan pipe s ass'y

6-40 LHLD-A465CBE0 AG Cord clip

6-41 PKYU-A177CBZZ AF Sub-con holder iir

6-42 PKYU-A178CBZZ AG Comp.cover iir

Sub-con p iir a

[5] SJ-F750SP OTHERS

90-1 TINS-A946CBRZ AM Op-manual

90-3 SPAKCA475CBZZ BC Packing case 73

90-6 CPADBA076CBKZ AU Bottom pad ass'y

90-7 CPADBA077CBKZ AU Top pad ass'y

90-8 TINSEA046CBRZ AG Set label

90-12 TLAB-B822CBRZ AK Energy label

90-13 TLAB-A637CBR0 AG Energy label(gb)

90-13 TLAB-A638CBR0 AG Energy label(d)

90-13 TLAB-A639CBR0 AG Energy label(f)

90-13 TLAB-A640CBR0 AG Energy label(e)

90-13 TLAB-A641CBR0 AG Energy label(i)

90-13 TLAB-A642CBR0 AG Energy label(gr)

90-13 TLAB-A643CBR0 AG Energy label(p)

90-13 TLAB-A644CBR0 AG Energy label(nl)

90-19 TINS-A743CBRZ AE Caution sheet

90-21 TLAB-B396CBRZ AG Caution label rof-hc

90-25 TLAB-B419CBRZ AE Freezer label

90-34 SPADBA260CBZZ AY Top sheet

90-35 SPADBA261CBFZ AK Corner post bl

90-36 SPADBA262CBFZ AK Cornet post br

90-37 SPADBA263CBFZ AM Corner post fl

90-38 SPADBA264CBFZ AM Corner post fr

90-39 SPADBA265CBZZ AT Cab-prot sheet

90-40 SPADBA266CBZZ AM Door prot sheet

90-41 SPADSA032CBZZ AE Door support

90-42 SPADSA033CBZZ AE Door support s

90-43 SSAKHA011CBZZ AP Poly cover

DESCRIPTION

9

Page 52

SJF800SPSL

3-40

3-21

3-11

5-21

5-22

5-23

5-27

5-28

5-27

5-27

5-28

5-22-1

5-24

5-7

3-2

5-1

3-22

5-6

5-5

5-4

5-3

5-2

5-2

3-32

3-1-3

3-1-2

3-1

3-21-3

3-21-2

3-21-5

3-21-1

3-31-1

3-31-4

3-31-2

3-31-5

3-31-3

3-21-4

3-1-3

3-1-1

3-11-2

3-1-1

3-31

5-3-1

3-28

3-28

3-2

3-8

3-19

3-9

3-19

3-8

3-9

3-55

3-51

3-57

3-53

3-26

3-54

3-58

3-52

3-56

3-55

3-51

3-57

3-53

3-6

3-54

3-58

3-52

3-56

3-55

3-51

3-57

3-53

3-26

3-54

3-58

3-52

3-56

3-55

3-51

3-57

3-53

3-6

3-54

3-58

3-52

3-56

3-46

3-47

3-47

3-46

3-47

[6] SJ-F800SP DOOR

10

Page 53

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PART

RANK

DESCRIPTION

[6] SJ-F800SP DOOR

3-1 FDORFC066CBKZ BR F-door l ass'y [SL]

3-1 FDORFC073CBKZ BT F-door l ass'y [BK]

3-1-1 LSTPMA008CBM0 AD F-door stopper r

3-1-2 LSTPPA146CBFA AF Fd-stp spring l

3-1-3 NBRGPA022CBFA AC Nylon bearing 3s

3-2 FPACGA431CBYA AT F door packing

3-6 JHNDPA296CBPZ AY Fd-handle

3-8 PPACGA226CBZA AM F-sub packing a

3-9 PPACGA227CBZA AK F-sub packing b

3-11 FDORFC067CBKZ BR F-door r ass'y [SL]

3-11 FDORFC074CBKZ BT F-door r ass'y [BK]

3-11-2 LSTPPA147CBFA AF Fd-stp spring r

3-19 PPACGA241CBZA AK F-sub packing c

3-21 FDORRC072CBKZ BT R-door l ass'y [SL]

3-21 FDORRC091CBKZ BT R-door l ass'y [BK]

3-21-1 LSTPPA150CBFA AF Stp-spring tl

3-21-2 LSTPPA151CBFA AF Stp-spring bl

3-21-3 LSTPPA152CBFA AF R lock spring l

3-21-4 MSLI-A070CBFA AE Door cam tl

3-21-5 MSLI-A071CBFA AE Door cam bl

3-22 FPACGA502CBYA AX R door packin l

3-26 JHNDPA297CBPZ AZ Rd-handle

3-28 PPACGA293CBZA AP R-sub packing

3-31 FDORRC073CBKZ BT R-door r ass'y [SL]

3-31 FDORRC092CBKZ BT R-door r ass'y [BK]

3-31-1 LSTPPA148CBFA AF Stp-spring tr

3-31-2 LSTPPA149CBFA AF Stp-spring br

3-31-3 LSTPPA153CBFA AF R lock spring r

3-31-4 MSLI-A068CBFA AE Door cam tr

3-31-5 MSLI-A069CBFA AE Door cam br

3-32 FPACGA503CBYA AX R door packin r

3-40 HBDGDB020CBZA AZ Badge

3-46 PSEL-E035CBZZ AE R-sub packing sealer

3-47 PSEL-E040CBZZ AE

3-51 HDECQA597CBFA AF Hd base t

3-52 HDECQA598CBFA AF Hd base b

3-53 HDECQA599CBTA AG Hd-cover t [SL]

3-53 HDECQA599CBTB AG Hd-cover t [BK]

3-54 HDECQA600CBTA AG Hd-cover b [SL]

3-54 HDECQA600CBTB AG Hd-cover b [BK]

3-55 HDECQA601CBTA AG Hd cap t [SL]

3-55 HDECQA601CBTB AG Hd cap t [BK]

3-56 HDECQA602CBTA AG Hd cap b [SL]

3-56 HDECQA602CBTB AG Hd cap b [BK]

3-57 LPLTPA559CBPZ AE Hd-support t

3-58 LPLTPA560CBPZ AE Hd-support b

5-1 FPOK-A270CBKZ AW Btl-pok l ass'y

5-2 FPOK-A271CBKZ AP Door pocket ass'y

5-3 FPOK-A272CBKZ AZ Btl-pok r ass'y

5-3-1 LSTYPA044CBFA AL B-pok partition

5-4 FPOK-A273CBKZ AN Utility pok ass'y

5-5 GDORPA078CBFA AN U-pok door

5-6 UTNA-A397CBFA AH Egg tray

5-7 FPOK-A274CBKZ AN Egg pok ass'y

5-21 FSRA-A244CBYZ AP Ice cube maker

5-22 FSRA-A245CBKZ BM Quick ice maker

5-22-1 PSKR-A329CBFA AK Q-ice parition

5-23 FYOK-A232CBKZ AV Ice storage assy

5-24 LSTYPA043CBFA AW I-case stay

5-27 FYOK-A306CBKZ AZ F-case s ass'y

5-28 FYOK-A305CBKZ BB F-case l ass'y

Rd packing sealer

SJF800SPSL

11

Page 54

SJF800SPSL

2-5

2-7-2

2-121

2-122

2-7-1

2-7

2-8-2

2-7-1

5-12-3

5-12-1

5-12-2

5-11

5-12

5-13

5-13-1

5-13-2

5-13-3

2-8

5-11-3

5-11-1

5-11-2

2-115

5-16

5-18

5-17

5-15

2-116

2-117

2-118

2-108

2-107

2-113

2-114

2-106

2-105

2-111

2-112

2-3

2-4

5-14

5-42

4-21

2-145

2-146

2-144

2-142

2-143

2-93

2-93

2-36

2-49

5-25

5-11-4

3-45

5-11-5

5-12-4

90-33

2-119

[7] SJ-F800SP CABINET1

12

Page 55

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PART

RANK

DESCRIPTION

[7] SJ-F800SP CABINET1

2-3 PCOVPA398CBFA AR Hinge cover [SL]

2-3 PCOVPA398CBFF AT Hinge cover [BK]

2-4 LPLTPA416CBTA AX Hinge support-t [SL]

2-4 LPLTPA416CBTB AW Hinge support-t [BK]

2-5 JHNDMA025CBPZ AE Carrying bar

2-7 FLEGPA127CBKZ AN Leg holder-ls k

2-7-1 FAJS-A028CBKZ AZ Adjustable leg ass'y

2-7-2 FLEGPA123CBYZ AH Leg holder-lk

2-8 FLEGPA128CBKZ AN Leg holder-rs k

2-8-2 FLEGPA124CBYZ AH Leg holder-rk

2-36 PCAP-A006CBFW AB Screw cover

2-49 LSTPPA108CBFA AC Chilled stopper

2-93 PCAP-A068CBFA AC C sliding cap a

2-105 DHNG-A537CBMZ BA F-hinge lt assy

2-106 DHNG-A538CBMZ BA F-hinge rt assy

2-107 DHNG-A539CBMZ BA F-hinge lb assy

2-108 DHNG-A540CBMZ BA F-hinge rb assy

2-111 FHNG-A231CBMZ AH R-hinge lbk

2-112 MSLI-A072CBFA AE Hinge cam bl

2-113 FHNG-A232CBMZ AH R-hinge rbk

2-114 MSLI-A073CBFA AE Hinge cam br

2-115 FHNG-A233CBYZ AH R-hinge ltk

2-116 MSLI-A074CBFA AE Hinge cam tl

2-117 FHNG-A234CBYZ AH R-hinge rtk

2-118 MSLI-A075CBFA AE Hinge cam tr

2-119 FPLTPA152CBKZ AN Temp.meter ass'y

2-121 GCOV-A280CBFA AV F-ret cover bl

2-122 GCOV-A281CBFA AV F-ret cover br

2-142 PSEL-C558CBZZ AD Sealer c

2-143 PSEL-C559CBZZ AD Sealer d

2-144 PSEL-C560CBZZ AD Sealer e

2-145 PSKR-A327CBFA AU V-partition lfb

2-146 PSKR-A328CBFA AU V-partition rfb

3-45 PPACGA244CBZA AF

4-21 LX-TZA091CBTA AE Special screw [SL]

4-21 LX-TZA091CBTF AD Special screw [BK]

5-11 FTNA-A537CBKZ BE R-shelf ass'y

5-11-1 UTNA-A396CBRA AY R-glass shelf

5-11-2 UWAKPA046CBFA AQ G guard rb

5-11-3 UWAKPA044CBFA AV G guard r

5-11-4 LPLTMA753CBPZ AP R shelf support

5-11-5 HDEC-A085CBZZ AR G guard r trim

5-12 FTNA-A536CBKZ BE V-shelf ass'y

5-12-1 UTNA-A395CBRA AY V-glass shelf

5-12-2 UWAKPA045CBFA AQ G guard vb

5-12-3 UWAKPA043CBFA AV G guard v

5-12-4 HDEC-A084CBZZ AR G guard v trim

5-13 FTNA-A419CBKZ AR Bttl rack ass'y

5-13-1 LHLD-A712CBFA AK B-r holder

5-13-2 NSFT-A041CBFA AE B-r shaft

5-13-3 UTNA-A398CBFA AK Bottle rack

5-14 FYOK-A303CBKZ AZ Fruit case assy

5-15 FYOK-A304CBKZ AY Fresh case assy

5-16 FYOK-A229CBKZ AZ V-case ass'y

5-17 GFTA-A117CBRA AR V-case door

5-18 LSTYPA042CBFA AT R-case stay

5-25 LRAL-A092CBFA AM Ice room rail

5-42 HGRL-A243CBFA AS Base cover [SL]

5-42 HGRL-A243CBFF AS Base cover [BK]

90-33 TLAB-B220CBRZ AE Temp.caution label

F-sub packing d

SJF800SPSL

13

Page 56

SJF800SPSL

2-66

6-12

2-95

2-20

2-67

1-21

2-2

1-55

2-132

2-147

2-133

2-131

1-10

2-1

1-6

2-138

2-139

2-34

1-27

2-74

2-38

2-72

2-39

2-27

1-4

1-26

2-97

2-16

2-21

2-28

2-22

2-140

2-100

1-17

2-120

2-141

6-31

2-149

2-148

1-1

2-125

2-25

2-26

2-55

2-161

2-29

1-64

1-65

1-62

1-64

1-61

1-61

2-163

1-63

2-162

2-56

1-45

2-58

2-165

2-164

2-160

1-3

2-37

2-37

2-166

2-167

[8] SJ-F800SP CABINET2

14

Page 57

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PART

RANK

DESCRIPTION

[8] SJ-F800SP CABINET2

1-1 RH-HXA108CBZZ AW F/df-thermistor

1-3 RH-HXA123CBZZ AM R-thermistor

1-4 DTHM-A031CBKZ AX Damper ass'y

1-6 RMOTRA096CBZZ BE F fan motor

1-10 FSW-LA001CBKZ AW Reed sw ass'y

1-17 FFS-TA087CBKZ AM Fuse ass'y

1-21 FHETBA193CBZZ BA Defrost heater

1-26 QCNW-B146CBZZ AK Lead r-c box

1-27 RMOTRA095CBZZ BA R fan motor

1-45 CKITTA131AKKZ BE Plasmacluster unit

1-55 FPWB-A615CBKZ BL Lcd pwb s ass'y

1-61 FPWB-A617CBKZ BF Lr led pwb ass'y

1-62 FPWB-A619CBKZ BE Top led pwb ass'y

1-63 FPWB-A621CBKZ BB Pci pwb ass'y

1-64 QCNW-B363CBZZ AH Lr led harness

1-65 QCNW-B364CBZZ AM Pci indicator harness

2-1 HPNL-A466CBFA AX Control panel [SL]

2-1 HPNL-A468CBRA AV Control panel [BK]

2-2 GDAI-A078CBTA AU Control base

2-16 GCOV-A282CBFB AX Ev-cover

2-20 PSEL-C573CBZZ AE E.v.pe-al sheet

2-21 PFPFPB565CBFZ AE Ev-cover insu

2-22 PSEL-C569CBZZ AC Ev-cover sealer

2-25 PCOV-A432CBFA AK R lamp cover l

2-26 PCOV-A433CBFA AK R lamp cover r

2-27 GCOVPA274CBFA AX R-c box cover

2-28 HGRL-A244CBFA AX Fan louver

2-29 PCOV-A434CBFA AK R lamp cover t

2-34 PFIL-A047CBEZ AC Deodorizer

2-37 LHLD-A860CBFA AE Screw cover

2-38 PGID-A169CBFZ AG R air guider a

2-39 PGID-A170CBFZ AE R air guider b

2-55 MLOV-A078CBFA AY R-louver

2-56 PFPFPB886CBFZ AK

2-58 PSEL-E009CBZZ AG A-sealer r-lv a

2-66 PSHEMA296CBPZ AC Heater cover

2-67 LPLTPA428CBPZ AQ Heater support

2-72 PSEL-C562CBZZ AC A-sealer rc-a

2-74 PSEL-C564CBZZ AG A-sealer rc-c

2-95 LANG-A064CBPZ AF Eva holder 75

2-97 PCOV-A340CBFA AF R con cover s

2-100 GCOVPA199CBFZ AF Connect cover

2-120 GCOV-A279CBFA AM F return cover

2-125 LPLTMA931CBPZ BM Al panel

2-131 JBTN-A030CBMA AH Button

2-132 JBTN-A031CBMA AK Button l

2-133 JBTN-A032CBMA AH Button j

2-138 PSEL-C600CBZZ AD Ev-cov.sealer b

2-139 PSEL-C601CBZZ AE Ev-cov.sealer c

2-140 PSEL-C640CBZZ AD Ev-c sealer l

2-141 PSEL-C661CBZZ AD Sealer fm

2-147 LHLD-A713CBFA AE Lcd-pwb holder

2-148 PSEL-C669CBZZ AD A-sealer rc-d

2-149 PSEL-C081CBEZ AA A-sealer ag4

2-160 GCOV-A344CBFA AH R-cbox return cover

2-161 HDECAA097CBRA AP Plasma badge

2-162 LHLD-A861CBFA AH Led holder

2-163 LPLTPA561CBFA AH Light guide

2-164 PSEL-E068CBZZ AE A-sealer rc-f

2-165 PSEL-E069CBZZ AD A-sealer rc-g

2-166 PSEL-E076CBZZ AE Al sheet l-guide

2-167 PSEL-E084CBZZ AE A-sealer r-lv b

6-12 PEVA-A201CBZZ BE Evaporator

6-31 PKYU-A035CBE0 AG Sp-butyl h

R-louver insu

SJF800SPSL

15

Page 58

SJF800SPSL

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PART

RANK

DESCRIPTION

2-123

1-50

2-51

1-31

1-23

1-11

6-10

2-24

2-152

2-153

6-11

6-1

4-1

2-87

2-87

6-9

6-2

4-17

1-2

6-4

1-9

6-18

6-5

6-17

6-3

6-7

6-8

2-126

4-10

4-4

2-78

2-99

1-22

4-15

2-77

5-41

1-41

2-80

6-32

2-151

2-136

6-27

6-28

6-27

6-28

2-88

4-14

6-42

6-41

6-36

6-21

6-40

[9] SJ-F800SP CYCLE

[9] SJ-F800SP CYCLE

1-2 RSTT-A179CBZZ AR Ptc relay

1-9 QACC-A156CBZZ AQ Source cord

1-11 RHOG-A189CBEZ AZ Protector

1-22 FCNW-A860CBZZ AH Relay wire assy

1-23 QCNW-A916CBZZ AE Reray wire sc

1-31 RC-EZA254CBZZ AS Running capacitor

1-41 RMOTRA097CBZZ BA C fan motor

1-50 FPWB-A661CBKZ BP Pwb-s ass'y

2-24 GCOVPA200CBFB AR Terminal cover [SL]

2-24 GCOVPA200CBFC AR Terminal cover [BK]

2-51 LHLD-A711CBFA AQ Pwb holder

16

Page 59

SJF800SPSL

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PART

RANK

[9] SJ-F800SP CYCLE

2-77 LHLD-A359CBFA AE T-box holder

2-78 LPLTMA399CBP0 AD Dryer support

2-80 PBOX-A148CBFA AE Terminal box

2-87 LBND-A018CBE0 AP Fastening band a

2-88 LBND-A019CBE0 AB Nylon band

2-99 PPIPPA126CBFZ AF Drain pipe s

2-123 GCOV-A283CBPZ AH Comp.cover

2-126 LHLD-A710CBFZ AH Cfm frame

2-136 LPLTMA553CBP0 AM Ev.pan support

2-151 PSEL-C555CBZZ AD U-sealer rd

2-152 PSEL-C571CBZZ AC Sealer

2-153 PSEL-C662CBZZ AD Sealer fm-b

4-1 LBND-A023CBE0 AC L-band c

4-4 QTAN-A012CBE0 AH Solderless term. B

4-10 QTAN-A013CBE0 AH Solderless term. A

4-14 LBND-A040CBZZ AD Band l150

4-15 LX-BZA090CBZZ AC Special screw

4-17 LX-WZA035CBZZ AB Washer

5-41 USRA-A297CBFA AP Drain pan

6-1 PCMPLA262CBZZ CA Compressor

6-2 PKYU-A173CBKZ AS Rubber mount ass'y

6-3 FCONSA101CBZZ BB Sub condenser

6-4 FFRM-A145CBKZ AM Base frame assy

6-5 FDRY-A006CBK0 AX Dryer ass'y

6-7 LPLTPA418CBFA AF S-con support l

6-8 LPLTPA419CBFA AF S-con support r

6-9 PSPAFA055CBEZ AP Sleeve

6-10 PPIPCA533CBZZ AW Dcp connector

6-11 PPIPCA534CBZZ AW Sp-connector

6-17 PPIPCA517CBZZ AE Chrg pipe hc s

6-18 PPIPCA518CBZZ AE Chrg pipe hc l

6-21 PCOVPA271CBEZ AH Terminal cover

6-27 PGUM-A004CBF0 AH Absorbent rubber a

6-28 PKYU-A175CBZZ AF

6-32 PGUM-A027CBFZ AF Comp. Spacer-e

6-36 FPIPCA255CBKZ AR Eva pan pipe s ass'y

6-40 LHLD-A465CBE0 AG Cord clip

6-41 PKYU-A177CBZZ AF Sub-con holder iir

6-42 PKYU-A178CBZZ AG Comp.cover iir

Sub-con p iir a

[10] SJ-F800SP OTHERS

90-1 TINS-A946CBRZ AM Op-manual

90-3 SPAKCA474CBZZ BD Packing case 78

90-6 CPADBA076CBKZ AU Bottom pad ass'y

90-7 CPADBA077CBKZ AU Top pad ass'y

90-8 TINSEA046CBRZ AG Set label

90-12 TLAB-B820CBRZ AK Energy label

90-13 TLAB-A637CBR0 AG Energy label(gb)

90-13 TLAB-A638CBR0 AG Energy label(d)

90-13 TLAB-A639CBR0 AG Energy label(f)

90-13 TLAB-A640CBR0 AG Energy label(e)

90-13 TLAB-A641CBR0 AG Energy label(i)

90-13 TLAB-A642CBR0 AG Energy label(gr)

90-13 TLAB-A643CBR0 AG Energy label(p)

90-13 TLAB-A644CBR0 AG Energy label(nl)

90-19 TINS-A743CBRZ AE Caution sheet

90-21 TLAB-B396CBRZ AG Caution label rof-hc

90-25 TLAB-B419CBRZ AE Freezer label

90-34 SPADBA260CBZZ AY Top sheet

90-35 SPADBA261CBFZ AK Corner post bl

90-36 SPADBA262CBFZ AK Cornet post br

90-37 SPADBA263CBFZ AM Corner post fl

90-38 SPADBA264CBFZ AM Corner post fr

90-39 SPADBA265CBZZ AT Cab-prot sheet

90-40 SPADBA266CBZZ AM Door prot sheet

90-41 SPADSA032CBZZ AE Door support

90-42 SPADSA033CBZZ AE Door support s

90-43 SSAKHA010CBZZ AN Poly cover

DESCRIPTION

17

Page 60

SJF800SPSL

INDEX

PARTS CODE No .

[ C ]

CKITTA131AKKZ 3-1-45 BE

"8-1-45BE

CPADBA076CBKZ 5-90-6 AU

" 10-90-6 AU

CPADBA077CBKZ 5-90-7 AU

" 10-90-7 AU

[ D ]

DHNG-A537CBMZ 2-2-105 BA

" 7-2-105 BA

DHNG-A538CBMZ 2-2-106 BA

" 7-2-106 BA

DHNG-A539CBMZ 2-2-107 BA

" 7-2-107 BA

DHNG-A540CBMZ 2-2-108 BA

" 7-2-108 BA

DTHM-A031CBKZ 3-1-4 AX

" 8-1-4 AX

[ F ]

FAJS-A028CBKZ 2-2-7-1 AZ

" 7-2-7-1 AZ

FCNW-A860CBZZ 4-1-22 AH

"9-1-22AH

FCONSA101CBZZ 4-6-3 BB