Page 1

R -4A52

R-4E52

SHARP SERVICE MANUAL

S0005R4A52PJZ

I’

MICROWAVE OVEN

MODELS

R-4A52

Photo R-4A52

R -4,E52

In interests of user-safety the oven should be restored to its original

condition and only manufacturer original spare parts must be used.

TABLE OF CONTENTS

GENERAL IMPORTANT INFORMATION

Page

......................................................................................................

1

CAUTION, MICROWAVE RADlATION,WARNING ......................................................................................

PRODUCT SPECIFICATIONS

1

.........................................................................................................................

APPEARANCE VIEW 2 ........................................................................................................................................

OPERATION SEQUENCE 3 .................................................................................................................................

FUNCTION OF IMPORTANT COMPONENTS

4

SERVICING

..............................................................................................

5

............

TEST PROCEDURE

............................................................................................................................................

7

........................................................................................................................................

TOUCH CONTROL ASSEMBLY

10

COMPONENT REPLACEMENT AN’~..~~J.USTM’ENT.PR.O.~E.~UR E ..IIII:::::::I::::::::::::::::::::I:::IIIII::::::Il::::

17

MICROWAVE MEASUREMENT

23

TEST DATA AT A GLANCE

...................................................................................................................

30

WIRING DIAGRAM

................................................................................. -.

........................................

31

.......................

PICTORIAL DIAGRAM

.

...............................................................................................................

32

...

....

CONTROL PANEL CIRCUIT

...........................................................................................................................

34

. .

PRINTED WIRING DIAGRAM

.......................................................................................................................

36

PARTS LIST

.....................................................................................................................

38

....................................................................................................................................................

PACKING AND ACCESSORIES

39

...................................................................................................................

45

SHARP CORPORATION

Page 2

R-4A52

R-4E52

SERVICE MANUAL

SHARP

MICROWAVE OVEN

R-4A521 R-4E52

GENERAL IMPORTANT INFORMATION

This Manual has been prepared to provide Sharp Corp. Service

engineers with Operation and Service Information.

It is recommended that service engineers carefully study the

entire text of this manual, so they will be qualified to render

satisfactory customer service.

CAUTION

MICROWAVE RADIATION

Service engineers should not be exposed to the microwave energy which may radiate from the magnetron or

other microwave generating devices if it is improperly

used or connected. All input and output microwave

connections, waveguides, flanges and gaskets must be

secured. Never operate the device without a microwave

energy absorbing load attached.Never look into an open

waveguide or antenna while the device is energized.

WARNING

Never operate the oven until the following points are

ensured.

(A)The door is tightly closed.

(B) The door brackets and hinges are not defective.

(C)The door packing is not damaged.

(D)The door is not deformed or warped.

(E) There is not any other visible damage with the oven.

Servicing and repair work must be carried out only by

trained service engineers.

All the parts marked

“*Il on parts list are used at voltages

more than 25OV.

SHARP CORPORATION

OSAKA, JAPAN

1

= .” PRODUCT SPECIFICATIONS

.r*&, “7:

OPERATING SEQUENCE

TROUBLESHOOTING CHAR

TEST PROCEDURE

TEST DATA TABLE AND

TEST POINTS ON CONTROL

i$~~?;# ,,,,,Rl,,,G ,-JlAGRA,,,,

-i” -A

; b&g

PRINTED WIRING BOARD

,,&;:$:

nit

,d PARTS LIST

“yb

Page 3

R -4A52

R-4E52

PRODUCT SPECIFICATIONS

SPECIFICATION

ITEM

Power Requirements

_-

Power Consumption

Power Output

____

Outside Dimensions

Cooking Cavity Dimensions

Turntable diameter

Control Complement

Set Weight

DESCRIPTION

240 Volts

50 Hertz

Single phase, 3 wire earthed

14oow

’ 750 watts nominal of RF microwave energy (2 liter water load)

Operating frequency of 2450M Hz

-

’ Width 550mm

Height 312mm

‘-Depth 417mm for R-4E52

420mm for R-4A52

Width 381 mm

1 Height 210 mm

Depth 411 mm

360mm

Touch Control System

Clock( 1 :OO - 12:59 )

Timer (0 - 99 minutes 99 seconds )

Microwave Power for Variable Cooking

Repetition Rate;

HIGH *.........*....................*.

Full power throughout the cooking time

MEDIUM

HIGH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

approx.

70% of Full

Power

MEDIUM

..,...,,..................*.........*..........,.* approx. 50% of Full Power

MEDIUM LOW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

approx.

30% of Full Power

LOW

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

approx. 10% of Full Power

For R-4A52

For R-4E52

AUTO COOK

INSTANT ACTION

EASY REHEAT

EASY DEFROST

EASY DEFROST

DOUBLE QUANTITY

INSTANT COOK/START

TRIPLE QUANTITY

MEMORY

AUTO START/CLOCK

AUTO START/CLOCK

POWER LEVEL

VARIABLE COOKING CONTROL

NUMBER

NUMBER

INSTANT COOK/START

STOP/CLEAR

STOP/CLEAR

Approx. 17.0 kg

2

Page 4

:.

APPEARANCE VIEW

R-4A52

R-4E52

1.

Ventilation

openings

8. Touch Control Panel

2. Oven lamp

9. Digital readout

3. Hinges

10. Waveguide cover

4. Safety door latches 11. Access cover for oven lamp replacement

5. See through door

12. Power supply cord

6. Coupling

13. Roller Stay

7. Door open

button

14. Turntable

i

Touch Control Panel for R-4A52

AUTO COOK MENUS

1

NUMBER PADS

clock trme. wecght or quantrty

of food, or to select the Auto

Cook or Easy Reheat menus.

VARIABLE COOKING

CONTROL PADS

Touch to select microwave

power settmg.

ff not touched, HIGH is automatrcally selected.

STOP/CLEAR PAD

Touch to erase during programming.

Touch once to stop operatron

of oven during cookmg; touch

lwce to cancel cookrng pro---gramme.

- EASY REHEAT PAD

Touch to select EasV Reheat

mode.

-EASY REHEAT MENUS

-EASY DEFROST PAD

Touch to defrost meat by

entering weight.

. MEMORY

Touch to enter one frequently

used cookmg programme.

Touch to recall the memonzed

programme.

‘MOREI n I. LESS( v 1 PADS

Touch to increase/decrease

the time in one mcnute mcrements during cookmg or to

increase/decrease the trme

whrlst programmrng the Easy

Reheat, Auto Cook or Easy

Defrost modes.

INSTANT COOK/START PAD

Touch once to cook for 1

mmute at HIGH or Increase by

1 mrnute multrples each trme

this pad IS touched during

cookmg.

Touch to start oven after

settmg programmes.

*Place the roller stay on

the coupling in the oven

and seat the turntable on

the roller stay.

Touch Control Panel for R-4E52

7 INSTANT ACTION -

INSTANT ACTION PADS

Touch once to cook or reheat 10 popular menus

entenng weight.

touchmg the INSTANT ACTION

pad.

wL2zl(I 111

-TRIPLE QUANTITY PAD

To cook triple quantrty, touch this pad prior to

touchrng the INSTANT ACTION pad.

I INUMBER PADS

Touch to enter weight, cookrng and clock trmes

Touch to select cooking power control settmg.

AUTO START/CLOCK PAD

Touch to set clock or Auto Start trme.

‘INSTANT COOK/START PAD

Touch once to cook for 1 minute at HIGH or

increase by 1 minute multiples each trme thus pad IS

touched dunng cookmg. Touch to start oven after

setting programmes.

J

L STOP/CLEAR PAD

Touch to erase during programming.

Touch once to stop operatron of oven dunng

cookrng; touch twrce to cancel cooking programme.

Page 5

R-&u2

R-4E52

OPERATING SEQUENCE

OFF CONDITION

Closing the door activates all door interlock switches

(Upper latch switch,

Lower latch switch and stop

switch)

IMPORTANT

When the oven door is closed, the monitor switch

contacts COM-NC must be open.

When the microwave oven is pluged in a wall outlet

(240V 50Hz), 240 volts A.C. is supplied to the point

Al + A3 in the control unit.

Figure O-l on page 32 or 33

1 . The display flashes “88:88”. --

2. To set any programmes or set the clock, you must

first touch the STOP/CLEAR key.

3. [lappears in the display and the time counts

up every minute.

NOTE: When the oven door is opened, the oven

lamp comes on at this time.

MICROWAVE COOKING CONDITION

HIGH COOKING

Enter a desired cooking time with the touching

NUMBER key and start the oven with touching

START key.

Function sequence Figure O-2 on page 32 or 33

CONNECTED COMPONENTS

RELAY

Oven lame, Fan motor, Turntable motor

RYI

Power transformer

RY2

1. 240 volts AC. is supplied to the primary winding

of the power transformer. The voltage is converted

to about 3.3 volts AC. output on the filament

winding and high voltage of approximately 2000

volts A.C. on the secondary winding.

2. The filament winding voltage (3.3 volts) heats the

magnetron filament and the high voltage (2000

volts) is sent to the voltagedoubling circuit, where

it is doubled to negative voltage of approximately

4000 volts D.C..

3. The 2450 MHz microwave energy produced in the

magnetron generates a wave length of 12.24 cm.

This energy is channeled through the waveguide

(transport channel) into the oven cavity, where the

food is placed to be cooked.

4. When the cooking time is up, a signal tone is heard

and the relays RYI + RY2 go back to their home

position.

The circuits to the oven lamp, power

transformer, fan motor and turntable motor are cut

off.

When the door is opened during a cook cycle, the

switches come to the following condition.

CONDITION

DURING

DOOR OPEN

SWITCH CONTACT

COOKING (NO COOKING)

Upper latch switch COM - NO Closed

Open

Monitor switch

COM- NC

Open ’ Closed

Lower latch switch COM - NO Closed

Open

Stop switch

COM- NO Closed

Open

The circuits to the power transformer, fan motor and

turntable motor are cut off when the upper latch

switch, and stop switch are made open.

The oven lamp remains on even if the oven door is

opened after the cooking cycle has been interrupted, because the relay RYI stays closed. Shown

in the display is the remaining time.

MONITOR SWITCH CIRCUIT

The monitor switch SW3 is mechanically controlled

by oven door, and monitors the operation of the

upper and lower latch switches SW1 + SW2.

6-2

When the oven door is opened during or after the

cycle of a cooking program, the upper latch and

lower latch switches SW1 + SW2 must open their

contacts first.

After that the contacts (COM NC) of the monitor switch SW3 can be closed

and then contacts of the stop switch SW4 can be

opened.

When the oven door is closed, the contacts

(COM-

NC) of the monitor switch SW3 must

be opened first, and the contacts (COM - NO)

of the stop switch SW4 must be closed. After that

the contacts of the upper latch switch SW1 latch

and lower latch switches SW1 + SW2 are closed.

6-3. When the oven door is opened and the contacts

of the upper and lower latch switches SW1 +

SW2 remain closed. The fuse E M8A will blow,

because the monitor switch is closed and a short

circuit is caused.

4

Page 6

R-4A52

R-4E52

MEDIUM HIGH, MEDIUM, MEDIUM LOW,

SETTING

LOW COOKING

When the microwave oven is preset for variable cooking power, 240 volts A.C. power is supplied to the

power transformer intermittently within a 32-second

time base through the’relay contact which is coupled

with the current-limiting relay RY2.

The following

levels of microwave power are given.

HIGH

MEDIUM HIGH

MEDIUM

MEDIUM LOW

LOW

32 sec. ON

24 sec. ON 8 sec. OFF

-1 Approx. 70% = 525 Watts

lEsac.ON 14 sec. OFF

m-1 Approx. 50% = 375 Watts

12secON 20 sec. OFF

m-1 Approx. 30% = 225 Watts

6 sec. ON 26 sac. OFF

m------j Approx. 10% = 75 Watts

NOTE: The ON/OFF time ratio does not exactly corre-

I

spond to the percentage of microwave power,

because approx. 2 seconds are needed for

heating up the magnetron filament.

FUNCTION OF IMPORTANT COMPONENTS

DOOR OPEN MECHANISM

The door can be opened by pushing the door open

button on the control panel. When the door open

button is pushed, the latch lever is moved upward,

operating the latch head. The latch head is moved

upward, and released from the latch hook. Now, the

door can be opened.

.LATCH MONITOR

HOOK \

, SWITCH

DOOR

LATCH

HEAD

KE

SWITCH

I

-. -.

SWITCH

LOWER

kGGON~ L -s-w:T:! _ _ /

--7

Figure D-l. Door Open Mechanism

UPPER LATCH SWITCH SW1

LOWER LATCH SWITCH SW2

STOP SWITCH SW4

1. When the oven door is closed, the contacts

(COM - NO) must be closed.

2. When the oven door is opened, the contacts

(COM - NO) must be opened.

M’ONITOR SWITCH SW3

1. When the oven door is closed, the contacts

(COM- NC) must be opened.

2. When the oven door is opened, the contacts

(COM - NC) must be closed.

3. If the oven door is opened and the contacts

(COM -

NO) of the upper and lower latch switches

SW1 + SW2 fail to open, the fuse E M8A blows simultaneously with closing the contacts (COM- NC)

of the monitor switch SW3

CAUTION: BEFORE REPLACING A BLOWN FUSE F

M8A TEST THE UPPER AND LOWER

LATCH SWITCHES SW1 + SW2 MONITOR SWITCH SW3 AND MONITOR RESISTOR FOR

OPERATlON.(:EFER TO

PROPER

CHAPTER

“TEST PROCEDURE”.)

MONITOR RESISTOR- R 0.8 Q 20W

The monitor resistor prevents the fuse E M8A bursting

when the fuse E M8A blows due to the operation of

the monitor switch.

THERMAL CUT-OUT TC 145°C (OVEN)

The thermal cut-out located on the top of the oven

cavity is designed to prevent damage to the oven if the

foods in the oven catch fire due to over heating

produced by unproper setting of cook time or failure

of control unit.

Under normal operation, the oven thermal cut-out re-

mains closed. However, when abnormally high temperatures are reached within the oven cavity, the oven

thermal cut-out will open at 145”C, causing the oven

to shut down.

The thermal cut-out TC will be close its contacts again

when its temperature goes down lower than -20°C.

5

Page 7

R-4A52

R-4E52

FUSE _E M8A 250A

1. If the wire harness or electrical components are

short-circuited, this fuse blows to prevent an elec-

tric shock or fire hazard.

2. The fuse blows when the asymmetric rectifier, H.V.

rectifier,

H.V. wire harness, H.V. capacitor,

magnetron or secondary winding of power transformer is shorted.

3. The fuse also blows when upper and lower latch

switches SW1 + SW2 remains closed with the oven

door open and when the monitor switch SW3

closes.

TEMPERATURE FUSE E 150”C(MG)

This fuse protects the magnetron against overheating.

If the temperature goes up higher than 150°C because

the fan motor is interrupted, the air inlet duct is blocked

or the ventilation openings are obstructed, the fuse

blows and puts the oven out of operation. The defective fuse must be replaced with new rated one.

TURNTABLE MOTOR

The turntable motor drives the turntable roller assembly

to rotate the turntable.

FAN MOTOR

The fan motor drives a blade which draws external cool

air. This cool air is directed through the air vanes surrounding the magnetron and cools the magnetron.

This air is channeled through the oven cavity to remove

steam and vapors given off from the heating foods. It

is then exhausted through the exhausting air vents at

the oven cavity

ASYMMETRIC RECTIFIER

The asymmetric rectifier is a solid state device that

prevents current flow in both directions. And it prevents the temperature rise of the power transformer by

blowing the fuse E M8A when the high voltage rectifier

is shorted.

*qlG” VOLTAGE RECTIF,ER

The rated peak reverse voltage of Dl of the asymmetric

rectifier is 6 KV The rated peak reverse voltage of D2

of the asymmetric rectifier is 1.7 KV. Dl and D2 of the

asymmetric rectifier or high voltage rectifier are shorted

when the each peak reverse voltage goes beyond the

each rated peak reverse voltage.

(The process of blowing the fuse E M8A.)

1.

2.

3.

4.

5.

6.

7.

The high voltage rectifier is shorted by any causes

when microwave cooking.

The peak reverse voltage of D2 of the rectifier goes

beyond the rated peak reverse voltage 1.7 KV in the

voltage doubler circuit.

D2 of the rectifier is shorted.

The large electric currents flow through the high

voltage winding of the power transformer.

The large electric currents beyond 8A flow through

the primary winding of the power transformer.

The fuse E M8A blows by the large electric currents.

The power supply to the power transformer is cut

off.

NOISE FILTER

(For New Zealand Model)

The noise filter prevents the radio frequency interference that might flow back in the power circuit.

Page 8

R-4A52

R-4E52

SERVICING

WARNING TO SERVICE PERSONNEL

Microwave ovens contain circuitry capable of producing very high voltage and current, contact with any part

of the high voltage circuit will result in electrocution.

REMEMBER TO CHECK 3D

REMEMBER TO CHECK 4R

1) Disconnect the supply.

2) Door opened, and wedged open.

3) Discharge high voltage capacitor.

WARNING AGAlNST THE CHARGE OF THE

HIGH-VOLTAGE CAPACITOR

1) Reconnect all leads removed from components

during testing.

2) Replace the outer case (cabinet).

3) Reconnect the supply.

4) Run the oven. Check all functions.

The high-voltage capacitor remains charged

about 60 seconds after the oven has been

switched off. Wait for 60 seconds and then

short-circuit

the connection of

the

high-voltage capacitor (that is, of the connecting lead of the high-voltage rectifier)

against the chassis with the use of an insulated screwdriver.

Microwave ovens shouid not be run empty. To test

for the presence of microwave energy within a

cavity, place a cup of cold water on the oven

turntable, close the door and set the power level to

HIGH. And set the timer for two (2) minutes. When

the two minutes has elapsed (timer at zero) carefully check that the water is now hot. If the water

remains cold carry out 3D checks and re-examine

Sharp

recommend

that

wherever possible

the connections to the component being tested.

faultifinding is carried out with the supply.disconnetted. It may in,

some cases, be necessary to

connect the supply after the outer case has been

removed, in this event carry out 30 checks and then

disconnect the leads to the pnmary of the power

transformer. Ensure that these leads remain isolated

from other components and the oven chassis. (Use

insulation tape if necessary.) When the testing is

completed carry out 3D checks and reconnect the

leads to the primary ofihe power transformer.

When all service work is completed, and the oven is fully assembled, the microwave power output should

be checked and a microwave leakage test carried out.

TROUBLESHOOTING GUIDE

When troubleshooting the microwave oven, it is helpful

to follow the Sequence of Operation in performing the

checks. Many of the possible causes of trouble will

require that a specific test be performed. These tests

are given a procedure letter which wiil be found in the

“Test Procedure”section.

IMPORTANT: If the oven becomes inoperative be-

cause of a blown fuse E (M8A) in the

upper latch switch - lower latch

switch - monitor switch - monitor

resisitor circuit, check the lower latch

switch, monitor switch and monitor

resistor before replacing the fuse E

(M8A).

7

Page 9

R-4A52

R-4E52

NOTE: “0” means direct cause and part. “A” means indirect cause and part.

~UOO~03Uw

a

al

0

a

LJJ w

w w

LL

s

2 >

g;g

C

IFU

qiz

0

icr<

N

D

-:

E

u 5

2

LL

G

d

:,

t5

i=

2

2

c

2

g

N

ih

Lii

3 2

3

6

E

CT

5

0

cl

u-l

6

:

Ii

E

ff

I=

E

6

r: un

23;

ii

2

z p

2

G

EZ

-I

5

F

cn

2 E

2 6 ;;

ul

3Z$;$E

k

PROBLEM

2

: 8 5

g

2 i? I’a I Z 5 2 L 222

Home fuse blows when power supply

cord is plugged into wall outlet.

Fuse M8A blows when power supply

cord is plugged into wall receptacle.

0 0

88 : 88 does not appear in display but

OFF

CONDITION

power supply cord is plugged into wall

0

outlet.

Display does not operate properly when

STOP/CLEAR pad is touched.

Oven lamp does not light at door

opened. (Display appears.)

Oven does not start when START pad

is touched. (Display appears.)

0

0

Oven lamp does not light. (Display

appears.)

Fan motor does not operate. (Display

appears.)

0

Turntable motor assembly does not

operate. (Display apears.)

0

Oven or any electrical parts does not

stop. But cooking time is 0 or

STOP/CLEAR pad is touched.

IN

:ONDITION

Oven seems to be operating but little or

no heat is produced in oven load. (Micro-

000 00 0

wave power level is set at HIGH.)

Oven does not seem to be operating

properly when MEDIUM HIGH, MEDIUM, MEDIUM LOW or LOW is set. (Oven

operates properly at HIGH and then the

STOP/CLEAR pad is touched the oven

stops.)

Oven goes into cook cycle but shuts

down before end of cooking cycle.

Oven stops as soon as when the START

pad is touched.

ALlAAnn

8

Page 10

R -4A52

R-4E52

I

I

z

s

2

I

E

r

t?

Z

2

0

z

Y

o_

u

0

%

7

5

9

I-

:

2

22

23

F

0

0 0

0 0 0 0

0

0

0

0

0

0

0 0

0 0

0

0

0

0

0 0

-0

0

0

0

0

0

0

Page 11

R -4A52

R-4E52

TEST PROCEDURES

PROCEDURE

LETTER

COMPONENT TEST

MAGNETRON TEST

-----. -

-

j NEVER TOUCH ANY PART IN THE CIRCUIT WITH YOUR HAND OR AN INSULATED

I

1 TOOL WHILE THE OVEN IS IN OPERATION.

CARRY OUT 3D CHECKS

Isolate the magnetron from the high voltage circuit by removing all leads connected to the filament

terminal.

To test for an open circuit filament use an ohmmeter to make a continuity test between the

magnetron filament terminals, the meter should show a reading of less than 1 ohm.

To test for a short circuit filament to anode condition, connect ohmmeter between one of the filament terminals and the case of the magnetron (ground). This test should be indicated an inifinite

resistance. If a low or zero resistance reading is obtained then the magnetron should be replaced.

MICROWAVE OUTPUT POWER

The following test procedure should be carried out with the microwave oven in a fully assembled

condition (with outer case fitted).

Microwave output power from the magnetron can be measured by way of substitution, i.e. it can

be measured by using a water load how much it can be absorbed by the water load. To measure

the microwave output power in the microwave oven, the relation of calorie and watt is used.

When P(W) heating works for t(second), approximately P x t/4.2 calorie is generated. On the

other hand, if the temperature of the water with V(ml) rises AT (“C) during this microwave

heating period, the calorie of the water is V x AT.

1 The formulae is as follows;

I

P x t / 4.2 = V x AT

P (W) = 4.2 x V x AT / t

Our condition for the water load is as follows:

Room temperature . . .

around 2O”C, Power supply Voltage . . . 240 volts.

Water load . . .

2000 ml, Initial temperature . . . 1 O&l OC, Heating time . ..I min. 52 sec.

P = 75 x AT

Measuring method:

A) Use two 1 litre Pyrex beakers with a diameter of approximately of 12cms.

B) Place 1 litre of 10°C water in each beaker.

C) Mark Tl on the one beaker and mark T2 on the other one. And stir the water and measure the

temperature of water the thermometer and note them. The graduation of the thermometer must

be scaled by 0.1 “C at minimum and an accurate mercury thermometer is recommended.

Example: The initial temperature Tl = 1 O’C, T2 = 11 “C

D) Place the two beakers as touching each other in the centre of the cavity.

E) Set the timer to 1 minute 52 seconds at 100% power (the time required to raise the water

temperature 10 degrees C.)

F) The time must be measured with stopwatch or wristwatch.

G) After 1 minute and 52 seconds, stop the oven by opening the door.

H) Remove the two beakers from the oven and measure the temperature of the water by stiring the

water with the thermometer and noting the readings.

10

Page 12

R-4A52

R-4E52

TEST PROCEDURES (CONT’D)

PROCEDURE

LETTER

COMPONENT TEST

Example: Tl = 20°C, T2 = 21 “C

initial temperature

~~

Temperature after 1 min. 52 sec.

Temperature difference Cold-Warm

---

Mean temperature rise LIT

i

T

T

Measured output power

The equation is as follows:

P= 75 x AT

Tl

‘=lO”C T2=11”C

I

Tl = 20°C T2 = 21 “C

,!LTl =lO”C LIT~=IO”C /

-------------,

LIT = (LIT1 + LLT2) / 2

!

= (10°C + IOOC) / 2

j

= 10°C

P= 75 x 10°C

= 750 Watts

-I

NOTE:

The measured output power should be at least +I5 % of the rated

output power.

CAUTION: 1 “C CORRESPONDS TO 75 WATTS.

REPEAT MEASUREMENT IF THE POWER IS INSUFFICIENT.

(Tl OC)

lT2 OC)

(T2 OCI

Heat up for 1 min. 52 sec.

B

POWER TRANSFORMER TEST

WARNING: High voltages and large currents are present at the secondary winding

and filament winding of the power transformer. It is very dangerous to

work near this part when the oven is on.

NEVER make any voltage

measurements of the high-voltage circuits, including the magnetron

filament.

CARRY OUT D CHECKS.

Disconnect the leads to the primary winding of the power’transformer.

Disconnect the filament

and secondary winding connections from the rest of the HV circuitry. Using an ‘ohmmeter, set

on a low range, it is possible to check the continuity of all three windings. The following readings

should be obtained :-

a. Primary winding ------b.

---l .42 ohms approximately.

Secondary winding - - - - - - -78.9 ohms approximately.

c. Filament winding ---------less than 1 ohm.

If the reading obtained are not as stated above, then the power transformer is probably faulty and

should be replaced.

CARRY OUT 4R CHECKS

11

Page 13

R-4A52

R-4E52

TEST PROCEDURES (CONT’D)

PROCEDURE

LETTER

COMPONENT TEST

C

HIGH VOLTAGE RECTIFIER ASSEMBLY TEST

HIGH VOLTAGE RECTIFIER TEST

CARRY OUT 3D CHECKS.

Isolate the high voltage rectifier assembly from the HV circuit. The high voltage rectifier can be

tested using an ohmmeter set to its highest range. Connect the ohmmeter across the terminal

B+C of the high voltage rectifier and note the reading obtained. Reverse the meter leads and note

this second reading. The normal resistance is intinte in one direction and mor than 100 kQ in

the other direction.

CARRY OUT 4R CHECKS

ASYMMETRIC RECTIFIER TEST

CARRY OUT 3D CHECKS.

Isolate the high voltage rectifier assembly from the HV circuit. The asymmetric rectifier can be

tested using an ohmmeter set to its highest range. Connect the ohmmeter across the terminals

A+B of the asymmetric rectifier and note the reading obtained. Reverse the meter leads and note

this second reading. If an open circuit is indicated in both directions then the asymmetric rectifier

is good. If an asymmetric rectifier is shorted in either direction, then the the asymmetric rectifier

is probably faultly and must be replaced with the high voltage rectifier. When the asymmetric

rectifier is defective, check whether magnetron, high voltage rectifier, high voltage wire or filament winding of the power transformer is shorted.

CARRY OUT 4R CHECKS

* +z$“:H “OLTAOE

RECT,F,ER

C

NOTE:

FOR MEASUREMENT OF THE RESISTANCE OF THE RECTIFIER, THE BATTERIES

OF THE MEASURING INSTRUMENT MUST HAVE A VOLYAGE AT LEAST 6 VOLTS,

BECAUSE O*THERWISE AN INFINITE RESISTANCE MIGHT BE SHOWN IN BOTH

DIRECTIONS.

D

HIGH VOLTAGE CAPACITOR TEST

CARRY OUT 3D CHECKS.

A.

Isolate the high voltage capacitor from the circuit.

B.

Continuity check must be carried out with measuring instrument which is set to the highest

resistance range.

C.

A normal capacitor shows continuity for a short time (kick) and then a resistance of about

10 Mf2 after it has been charged.

D.

A short-circuited capacitor shows continuity all the time.

E.

An open capacitor constantly shows a resistance about 10 MO because of its internal 10

MO resistance.

F.

When the internal wire is opened in the high voltage capacitor, the capacitor shows an infinite resistance

G.

The resistance across all the terminals and the chassis must be inifinte when the capacitor

is normal.

If incorrect readings are obtained, the high voltage capacitor must be replaced.

CARRY OUT 4R CHECKS

12

Page 14

R -4A52

R-4E52

TEST PROCEDURES (CONT’D)

PROCEDURE

LETTER

COMPONENT TEST

E SWITCH TEST

CARRY OUT 3D CHECKS.

Isolate the switch to be tested and using an ohmmeter check between the terminals as described

in the following table.

Table: Terminal Connection of Switch

Plunger Operation

Released

Depressed

COM to NO

COM to NC

O.C. S.C.

_--- ---

S.C. O.C.

COM; Common terminal

S.C.; Short circuit

NO; Normally open terminal O.C.; Open circuit

NC; Normally closed terminal

If incorrect readings are obtained, make the necessary switch adjustment or replace the switch.

CARRY OUT 4R CHECKS.

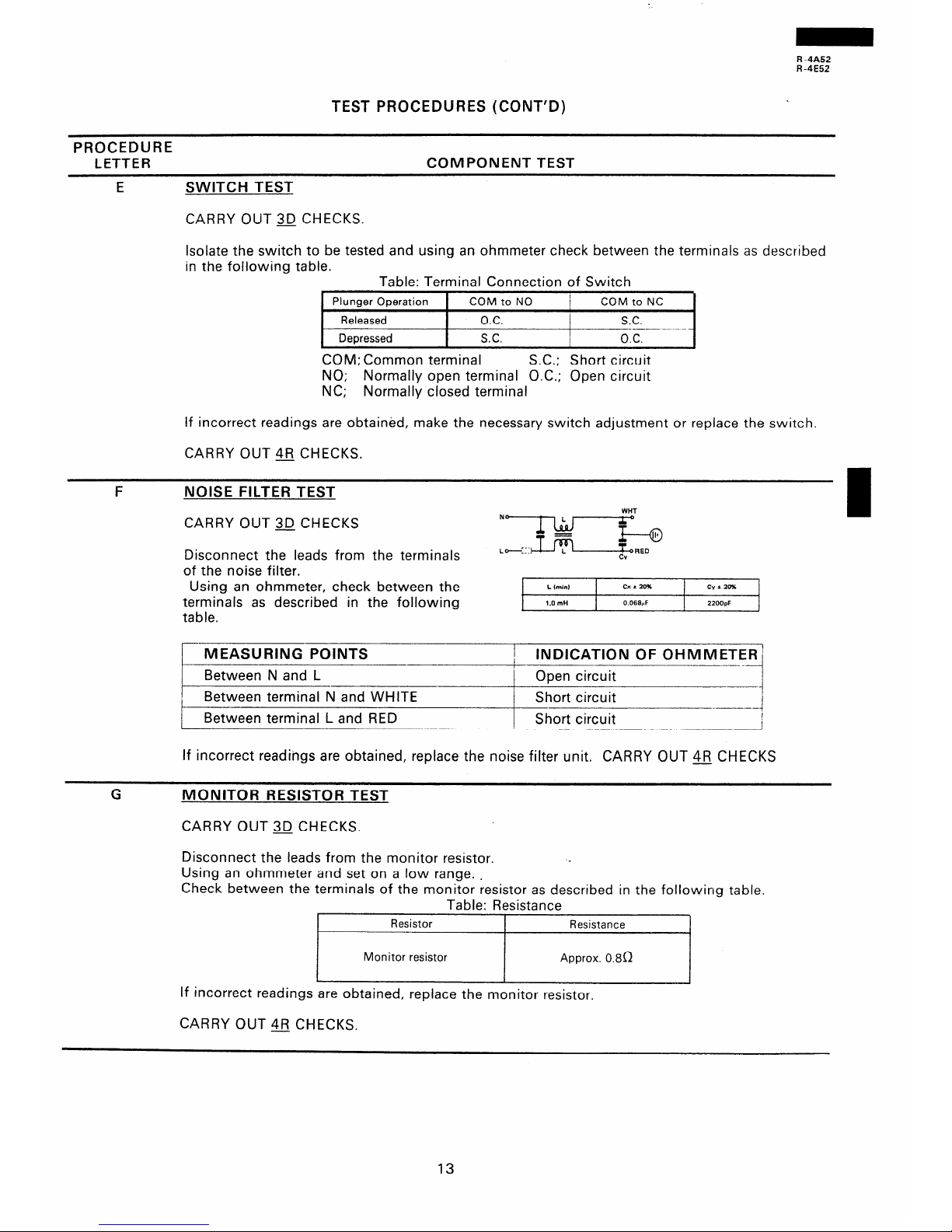

F NOISE FILTER TEST

CARRY OUT 3D CHECKS

Disconnect the leads from the terminal’

of the noise filter.

WHT

N*

0

g--Q

Using an ohmmeter, check between the

terminals as described in the following

table.

L hinl

Cx*ZO% CvtZmb

1.0 mti

0.066,lF 22OOpF

MEASURING POINTS

Between N and L

/ INDICATION OF OHMMETEf2i

1

I Open circuit

I

I

1 Between terminal N and WHITE

Short circuit

I

I

-..-----4

Between terminal L and RED Short circuit

---

----l

If incorrect readings are obtained, replace the noise filter unit. CARRY OUT 4R CHECKS

MONITOR RESISTOR TEST

CARRY OUT 3D CHECKS.

Disconnect the leads from the monitor resistor.

-<

Using an ohmmeter and set on a low range. .

Check between the terminals of the monitor resistor as described in the following table.

Table: Resistance

Resistor

Resistance

Monitor resistor Approx. 0.8R

If incorrect readings are obtained, replace the monitor resistor,

CARRY OUT 4R CHECKS.

13

Page 15

R -4A52

R-4E52

TEST PROCEDURES (CONT’D)

PROCEDURE

LETTER COMPONENT TEST

H

TEMPERATURE FUSE OR THERMAL CUT OUT TEST

CARRY OUT 3D CHECKS

Disconnect the leads from the terminals of the temp. fuse or thermal cut-out. Then using an

ohmmeter, make a continuity test across the each two terminals as described in the table below.

CARRY OUT 4R CHECKS

Table: Temperature Fuse Test

Parts F-ame

Temperature of Temperature of Indication of

“ON” condition . “OFF” condition ohmmeter

(closed circuit).

(open circuit). (When room

(“Cl

(“Cl

temperature is

approx. 20°C.)

Temp. fuse 1 50°C

(Magnetron)

Thermal cut-out

145°C (Oven)

This is not resetable

Above 1 50°C Closed circuit

type.

- 20°C

Above 145’C Closed circuit

If incorrect readings are obtained, replace the temp. fuse or thermal cut-out.

An open circuit temperature fuse (MG) indicates that the magnetron has overheated, this may

be due to resistricted ventilation, cooling fan failure or a fault condition within the magnetron

or HV circuit.

An open circuit thermal cut-out (OVEN) indicates that the foods in the oven catch fire, this may

be due to over heating produced by unproper setting of the cooking timer or failure of the control

panel.

MOTOR WINDING TEST

CARRY OUT 30 CHECKS

Disconnect the leads from the motor. Using an ohmmeter, check the resistance between the two

terminals as described in the table below.

Table: Resistance of Motor

1 Motors

I

Resistance

i F an motor

1 Approximately 246f2

1 Turntable motor

1 Approximately 12.5kn

If incorrect readings are obtained, replace the motor. (Also refer to test procedure J)

CARRY OUT 4R CHECKS

14

Page 16

R -4A52

R-4E52

TEST PROCEDURES (CONT’D)

PROCEDURE

LETTER

COMPONENT TEST

J

LIVE TEST FOR MOTOR WINDINGS

CAUTION: The following procedure requires the oven to be connected to the supply

1.

2.

3.

4.

5.

6.

7.

8.

9.

and should only be used if the relevant “cold” checks for the motor under test are inconclusive.

CARRY OUT 3D CHECKS

Disconnect the leads from the primary of the power transformer. Make sure that the leads

remain isolated from other oven components and chassis. (Use insulation tape if necessary.)

Connect a voltmeter, set to 250V AC, across the motor terminals. (Refer to the relevant motor

test procedure or pictorial diagram for the correct terminal numbers.)

Arrange the meter in a position where it can be read during the test.

(Do not touch the meter, meter leads or oven circuitry while the oven is active.)

Close the oven door.

Set the power level to HIGH and set the relevant timer for about three (3) minutes.

Note the reading on the meter and carefully observe the motor under test to see if it is turning.

CARRY OUT 3D CHECKS

Remove test meter leads.

1 O.Reconnect the leads to the primary of the power transformer.

If a reading of the line voltage was obtained (step 7) but the motor was not turning then it is

faulty and should be replaced. If the meter indicated that no supply was present then the wiring

I

to the motor should be checked for continuity.

K BLOWN FUSE F M8A

CARRY OUT $J CHECKS

1. If the fuse E M8A is blown, there are any shorts or grounds in electrical parts or wire harness. Check them and replace the defective parts or repair the wire harness.

2. If the fuse E M8A is blown, there is a short in the asymmetric rectifier or there is a ground

in wire harness. A short in the asymmetric rectifier may be occured due to short or ground

in H.V. rectifier, magnetron, power transformer or H.V. wire. Check them and replace the

defective parts or repair the wire harness.

3. If the fuse E M8A is blown when the door is opened, check the upper latch switch, monitor

switch, lower latch switch and monitor resistor.

If the fuse E M8A is blown by incorrect door switching replace the defective switch(s) and

the fuse E M8A.

CARRY OUT 4FJ CHECKS

-&

CAUTION\ Only replace fuse E M8A with the correct value replacement

15

Page 17

R-4A52

R-4E52

TEST PROCEDURES (CONT’D)

PROCEDURE

LETTER

COMPONENT TEST

TOUCH CONTROL PANEL ASSEMBLY TEST

M

The touch control panel consists of circuits including semiconductors such as LSI, lCs, etc.

Therefore, unlike conventional microwave ovens, proper maintenance cannot be performed with

only a voltmeter and ohmmeter.

In this service manual, the touch control panel assembly is divided into two units, Control Unit and Key Unit, and troubleshooting by unit replacement is described according to the symptoms indicated.

1. Key Unit.

The following symptoms indicate a defective key unit. Replace the key unit.

a) When touching the pads, a certain pad produces no signal at all.

b) When touching a number pad, two figures or more are displayed.

c) When touching the pads, sometimes a pad produces no signal.

2. Control Unit

The following symptoms indicate a defective control unit. Replace the control unit.

2-l In connection with pads.

a) When touching the pads, a certain group of pads do not produce a signal.

b) When touching the pads, no pads produce a signal.

2-2 In connection with indicators

a) At a certain digit, all or some segments do not light up.

b) At a certain digit, brightness is low.

c) Only one indicator does not light.

d) The corresponding segments of all digits do not light up; or they continue to light up.

e) Wrong figure appears.

f) A certain group of indicators do not light up.

g) The figure of all digits flicker.

2-3 Other possible troubles caused by defective control unit.

a) Buzzer does not sound or continues to sound.

b) Clock does not operate properly.

c) Cooking is not possible.

d) Proper temperature measurement is not obtained.

PROCEDURES TO BE TAKEN WHEN THE FOIL PATTERN ON THE PRINTED WIRING

BOARD (PWB) IS OPEN.

To protect the electronic circuits, this model is provided with a fine foil pattern added to the

primary on the PWB, this foil pattern acts as a fuse. If the foil pattern is open, follow the troubleshooting guide given below for repair.

Problem: POWER ON, indicator does not light up.

STEPS

F---l-

OCCURANCE

CAUSE OR CORRECTION

-I

1

The rated voltage is not applied to POWER terminal Check supply voltage and oven main unit.

I

’ of CPU connector (CN-A)

2 The rated voltage is applied to primary side of power Power transformer or secondary circuit defective.

transformer.

Check and repair.

3

Only pattern at “a” is broken.

*Insert jumper wire 34 and solder.

4 Pattern at “a” and “b” are broken.

*insert the coil RCILF2003YAZZ between “6 and

“d”.

/v=1L/voom wti* .

NOTE:* At the time of these repairs, make a visual in-

spection of the varistor for burning damage

and examine the transformer with tester for the

presence of layer short-circuit (check primary

coil resistance).

If any abnormal condition is detected, replace

the defective parts.

16

Page 18

R-4A52

A-4E52

TOUCH CONTROL PANEL ASSEMBLY

OUTLINE OF TOUCH CONTROL PANEL

The touch control section consists of the following

units as shown in the touch control panel circuit.

(1) Key Unit

(2) Control Unit

The principal functions of these units and the signals

communicated among them are explained below.

Key Unit

The key unit is composed of a matrix, signals generated

in the LSI are sent to the key unit through SO-S6.

When a key pad is touched, a signal is completed

through the key unit and passed back to the LSI

through K4-K7 to perform the function that was requested.

Control Unit

Control unit consists of LSI, power source circuit,

synchronizing signal circuit, ACL circuit, buzzer circuit

and indicator circuit.

1)

a

3)

LSI

This LSI controls the key strobe signal, relay driving

signal for oven function and indicator signal.

Power Source Circuit

This circuit generates voltage necessary in the

control unit.

Symbol Voltage Application

VDD -12v

LSI (ICY), ACL circuit

VREF

VP

~~i:“V LSI (ICI)

Fluorescent display tube : Grid

VF+

and anode voltage.

3V P-P F$rrenent of fluorescent display

VF- (VF+ to VF- voltage)

Synchronizing Signal Circuit

The power source synchronizing signal is available

in order to compose a basic standard time in the

clock circuit.

It accompanies a very small error because it works

on commercial frequency.

4)

5)

6)

7)

8)

ACL Circuit

A circuit to generate a signal which resets the LSI

to the initial state when power is supplied.

Buzzer Circuit

The buzzer is responsive to signals from the

to emit noticing sounds (key touch sound

completion sound).

LSI

and

Door Sensing Switch

A switch to “tell” the LSI if the door IS open or

closed.

Relay Circuit

To drive the magnetron, fan motor, turntable motor

and light the oven lamp.

Indicator Circuit

Indicator element is a Fluorescent Display.

Basically, a Fluorescent Display is a triode having

I

a cathode, a grid and an anode. Usually, the cathode of a Fluorescent Display is directly heated and

the filament serves as cathode.

The Fluorescent Display has 6-digits, 13-segments

are used for displaying figures.

I

17

Page 19

R -4A52

R-4E52

DESCRIPTION OF LSI

LSI( IZA312DR)

The I/O signals of the LSI(IZA312DR) are detailed in the following table,

PIN NO.

/ 1

__ ----

__-.--

1 SIGNAL 1 T

I

l/O

j OUT ’

Signal to sound buzzer.

A: Key touch sound (0.12 sec.).

6: Completion sound (2.4 sec.).

PIN NO. j 2

1 SIGNAL / VDD

------

- _____

Power source voitaqe: -12V

VDD voltage of power source circuit input.

I

l/O

/ IN

PIN NO. i 3

I.-SIGNAL / VREF

I

l/O

IN

A-_-

Reference voltace input terminal.

‘A reference voltage applied to the A/D converter in the LSI. The reference voltage is generally maintained at -6.15V

PIN NO.

i 4

~~-.-.-.-_I_

1 SIGNAL j VP

I

I/O

/ IN

I

Anode (segment) of Fluorescent Displav illumination voltaqe: -27V

Vp voltage of power source circuit input.

PIN NO.

1 5

1 SIGNAL / INT

I

I/O

IN

Signal svnchronized with commercial source frequency(50Hz).

This is the basic timing for time processing of LSI.

PIN NO.

/ 6

1

SIGNAL 1 CNVSS

I

I/O

1 IN

_--

_______- -

Power source voltage input terminal.

Connected to GND.

PIN NO. / 7-10

1 SIGNAL / FO-F3

I

I/O

1 OUT

Segment data signals.

Refer to the touch control panel circuit for the relationship between signals and indicators.

Normally, one pulse is output in every synchronized signal period, and input to the anode of the fluorescent display.

PIN NO. 1 11

1 SIGNAL / SO

I

I/O

1 OUT

Segment data signal.

Signal similar to FO.

Key strobe signal.

Signal applied to touch-key section.

A pulse signal is input to K4-K7 terminal while one of D-8 line keys on key matrix is touched.

Terminal not used.

PIN NO. 12

Segment data signal.

Signal similar to FO.

Key strobe signal.

1 SIGNAL j Sl

I

I/O

/ OUT

Signal applied to touch-key section.

A pulse signal is input to K4-K7 terminal while one of D-7 line keys on key matrix is touched.

18

Page 20

R-4A52

R-4E52

PIN NO. ,

j 13

1 SIGNAL 1 S2

I

I/O

j OUT

Segment data signal.

Signal similar to FO.

Kev strobe signal.

Signal applied to touch-key section;

A pulse signal is input to K4-K7 terminal while one of D-6 line keys on key matrix is touched.

PIN NO.

I 14

SIGNAL S3

I

I/O

/ OUT

Segment data signal.

Signal similar to FO.

KeV strobe signal.

Signal applied to touch-key section.

A pulse signal is input to K4-K7 terminal while one of D-5 line keys on key matrix is touched.

PIN-NO. 1 15

1 SIGNAL / S4

I

I/O

OUT

Segment data signal.

Signal similar to FO.

Kev strobe signal.

Signal applied to touch-key section.

A pulse signal is input to K4-K7 terminal while one of D-4 line keys on key matrix is touched.

-

PIN NO.

1 16

1 SIGNAL 1 S5

I I/O j OUT

Segment data signal.

Signal similar to FO.

Kev strobe signal.

Signal applied to touch-key section.

A pulse signal is input to K4-K7 terminal while one of D-3 line keys on key matrix is touched.

PIN NO. 1 17

-Seclment data siqnal.

1 SIGNAL / S6

I

I/O

1 OUT

Signal similar to FO.

Kev strobe signal.

Signal applied to touch-key section.

A pulse signal is input to K4-K7 terminal while one of D-2 line keys on key matrix is touched.

PIN NO. j 18 1 SIGNAL j 57

I

l/O

/ OUT

-____

Senment data siqnal.

Signal similar to FO.

Key strobe signal.

Signal applied to touch-key section.

A pulse signal is input to K4-K7 terminal while one of D-l line keys on key matrix is touched.

PIN NO. / 19

1 SIGNAL / XOUT

I.. I/O

1 OUT

_----

liiternal clock oscillation freduencv control output.

Output to control oscillation input of XIN.

PIN NO. 1 20

1 SIGNAL / XIN

I

I/O / IN

___---___-

Internal clock oscillation frequency input setting.

The internal clock frequency is set by inserting the ceramic filter oscillation circuit with respect to XOUT terminal.

PIN NO. / 21

1 SIGNAL j VSS

I

I/O

I IN

-

Power source voltage input terminal.

Connected to GND.

19

Page 21

R -4A52

R-4E52

PIN NO.

j 22-24 SIGNAL / Dll-D9

I

I/O

/ OUT

Diqit selection siqnal.

Refer to the touch control panel circuit about the relation between signals and digits.

Normally, one pulse is output in every synchronized signal period, and input to the grid of the fluorescent display.

PIN NO. j 25-27

.I SIGNAL i D8-D6

I I/O

1 OUT

Diqit selection siqnal.

Signal similar to Dl I.

PIN NO. / 28

Seqment data siqial.

Signal similar to FO.

1 SIGNAL / D5

I

I/O

/ OUT

PIN NO. 1 29-31

1 SIGNAL 1 D4-D2

I

I/O

/ OUT

Terminal not used.

PIN NO. 1 32

1 SIGNAL j Dl

Maqnetron Hiqh-voltaqe circuit drivinq siqnal.

To turn on and off the cook relay.

I

I/O

1 OUT

In high operation, the signals holds “H” level during microwave cooking and “L” level while not cooking. In other

cooking modes (MED. HIGH, MED., MED. LOW, LOW) the signal turns to “H” level and “L” level in repetition

according to the power level.

PIN NO. / 33

I

1 SIGNAL 1 DO

I

I/O

1 OUT

&en lamp, turntable motor and coolinq fan motor drivinq siqnal. (Square Waveform: 50Hzl

To turn on and off the control relay.

The pulse signal (50Hz) is delivered to the control relay driving circuit and cook relay control circuit.

I

c--7

v----c

----------H

L-LA--

d-.-d-

L

PIN NO. j 34

Auto clear terminal.

1 SIGNAL ) RESET

I

I/O

/ IN

I

Signal is input to reset the LSI to the initial state when power is supplied.

Temporarily set to “H” level the moment power is supplied, at this time the LSI is set.

Thereafter set at “L” level.

PIN NO. 35

I

1 SIGNAL 1 K7

I

l/O

1 IN

Sinnal coming from touch key.

When either one of D-9 line keys on key matrix is touched, a correspondin signal out of SO-S6 will be input into

K7.

When no key is touched, the signal is held at “L” level,

20

Page 22

R -4A52

R-4E52

PIN NO.

_-_- --_--

i-36

1 SIGNAL 1 K6

~-

L I/O 1 IN

_-__--_______

Signal cominq from touch key.

When either one of D-10 line keys on key matrix is touched, a corresponding signal will be input into K6.

PIN NO. i 37

1 SIGNAL j K5 1 I/O j IN

Sianal coming from touch key.

When either one of D-l 1 line keys on key matrix is touched, a corresponding signal will be input into K5.

PIN NO. / 38

1 SIGNAL j K4 IN

--___~

Signal coming from touch key.

When either one of D-l 2 line keys on key matrix is touched, a corresponding signal will be input into K4.

PIN NO. 39

1 SIGNAL j K3

I

I/O

( IN

--_

Terminal not used.

PIN NO. / 40

SIGNAL j K2

I

I/O

/ IN

Input signal which communicates the do&r open/close information to LSI.

Door closed; “H” level signal.

Door opened; “L” level signal.

PIN NO. 1 41

1 SIGNAL 1 Kl

I

I/O

1 IN

Terminal not used.

PIN NO. 1 42

1 SIGNAL / KO

Terminal not used. Connected to GND.

I/O

I

I IN

-I_---_---

21

Page 23

R-4A52

R-4E52

SERVICING

I. Precautions for Handing Electronic

Components

This unit uses PMOS LSI in the integral part of the

circuits. When handing these parts, the following

precautions should be strictly followed.

PMOS LSI have extremely high impedance at its

input and output terminals. For this reason, it is

easily influenced by the surrounding high voltage

power source, static electricity charged in clothes,

etc,and sometimes it is not fully protected by the

built-in protection circuit.

In order to protect PMOS LSI.

1)

2)

When storing and transporting, thoroughly

wrap them in aluminum foil.

Also wrap PW

aluminium foil.

When soldering, ground the technician as

shown

in the figure and

soldering iron and work table.

use grounded

boards contaf-ning them in

2. Shapes of Electronic Components

Transistor

DTA 143ES

Transistor

2SB910M

L

DTC 114ES

DTD 143ES

3. Servicing of Touch Control Panel

We describe the procedures to permit servicing the

touch control panel of the microwave oven and the

cautions you must consider when doing so.

To carry the servicing, power supply to the touch

control panel is available either from the power line

of the oven proper itself of from an external power

source.

(1) Servicing the touch control panel with

power supply from the oven proper:

CAUTION:

THE HIGH VOLTAGE TRANSFORMER OF

THE MICROWAVE OVEN IS STILL ALIVE

TO GIVE YOU DANGER DURING SERVICING.

Therefore, when checking the performance of

the touch control panel,put the outer cabinet

on the oven proper to keep from touching the

high voltage transformer, or unplug the primary

terminal (connector) of the high voltage transformer to turn it off; and the end of such connector shall be insulated with an insulating

tape.

After servicing, be sure

leads

to their original locations.

to replace the

A. On some models, the power supply cord be-

tween the touch control panel and the oven

proper is so short that they can’t be separated

‘from each other.

4. Servicing Tools

Tools required when servicing the touch control

panel assembly.

1) Soldering iron: 30W (To prevent leaking cur-

rent, it is recommended to use a soldering iron with

a grounding terminal.)

2) Oscilloscope:

Single beam, frequency range:

DC - IOMHz type or more ad-

vanced model.

3) Others: Hand tools

5. Other Precautions

For those models, therefore, check and repair

all the controls (with the sensor-related ones

included) of the touch control panel while

keeping it in contact with the oven proper,

B. On some models, on the other hand, the power

supply cord between the touch control panel

and the oven proper is so long that they may

be separated from each other. For those models, therefore, it is allowed to check and repair

the controls of the touch control panel while

keeping it apart from the oven proper;in this

case you must short both ends of the stop

switch (on PWB) of the touch control panel

. with a jumper, which brings about an opera-

tional state that is equivalent to that with the

oven door being closed.

As to the sensor-related controls of the touch

control panel, their checking is allowed if the

dummy resistor(s) whose resistance is equal to

that of those controls is used.

(2) Servicing the touch control panel with

power supply from an external power

source:

Disconnect the touch control panel completely

from the oven proper,and short both ends of

the stop switch (on PWB) of the touch control

panel,which brings about an operational state

that is equivalent with the oven door being

closed. And connect an external power source

to the power input terminal of the touch control

panel, and then it is allowed to check and repair

the controls of the touch control panel;as in the

case of (1) - B above, it is here also possible to

check the sensor-related controls of the touch

control panel by using the dummy resistor(s).

1) Before turning on the power source of the

control unit, remove the aluminum foil applied

for preventing static electricity.

2) Connect the connectors of the indicator and

key units to the control unit taking care that the

lead wires are not twisted.

3) After aluminum foil is removed, take extra care

that abnormal voltage due to static electricity

etc. is not applied to the input or output terminals.

4) Attach connectors, electrolytic capacitors, etc.

to PWB, taking care that all connections are

tight.

5) Be sure to use specified components where

high precision is required.

22

Page 24

R -4A52

R-4E52

COMPONENT REPLACEMENT AND ADJUSTMENT PROCEDURE

WARNING: Avoid possible exposure to microwave energy. Please follow the instructions below

before oDerating the oven.

1. CARRY OUT 3D CHECKS.

2. Make sure that a definite “click” can be heard when

the microwave oven door is unlatched. (Hold the

door in a closed position with one hand, then push

the door open button with the other, this causes the

latch heads to rise, it is then possible to hear a

“click” as the door switches operate.)

3. Visually check the door and cavity face plate for

damage (dents, cracks, signs of arcing etc.).

I. Door does not close firmly.

2. Door hinge, support or latch hook is damaged.

3. The door gasket or seal is damaged.

4. The door is bent or warped.

5. There are defective parts in the door interlock system.

6. There are defective parts in the microwave generat-

ing and transmission assembly.

7. There is visible damage to the oven.

Carry out any remedial work that is necessary before

operating the oven.

Do not operate the oven:

I. Without the RF gasket (Magnetron).

2. If the wave guide or oven cavity are not intact.

Do not operate the oven if any of the following con-

3. If the door is not closed.

ditions exist;

4. If the outer case (cabinet) is not fitted.

Please refer to ‘OVEN PARTS, CABINET PARTS, DOOR PARTS’, when carrying out any of the following removal

procedures:

OUTER CASE REMOVAL

3. Remove the screws from rear and .along the side

To remove the outer case, proceed as follows.

edge of case.

1. Disconnect oven from power supply.

4. Slide the entire case back about 1 inch (3cm) to

2. Open the oven door and wedge it open.

free it from retaining clips on the cavity face plate.

5. Lift the entire case from the oven.

moved.

6. Discharge the HV capacitor before carring out any

N.B.; Step I,2 and 6 form the basis of the 3D checks.

further work.

CAUTION: DISCHARGE

7. Do not operate the oven with the outer case re-

HIGH VOLTAGE

CAPACITOR BEFORE TOUCHING ANY

OVEN COMPONENTS OR WIRING.

HIGH VOLTAGE COMPONENTS REMOVAL

(HIGH VOLTAGE CAPACITOR AND HIGH VOLTAGE RECTIFIER ASSEMBLY)

To remove the components, proceed as follows.

1. CARRY OUT 3iJ CHECKS

2. Disconnect the high voltage wire A from the

7. Disconnect high voltage wire A and terminals of

high voltage rectifier assembly from high voltage

capacitor.

magnetron.

3. Disconnect the filament lead(shorter one) of the

8. Now high voltage rectifier assembly and capacitor

power transformer.

should be free.

I

4. Disconnect the high voltage wire of the H.V.

rectifier assembly fromt he high’voltage capacitor.

5. Remove one (1) screw holding capacitor holder to

the oven cavity.

6. Remove one (1) screw holding earth side terminal

of high voltage rectifier assembly, and remove

capacitor holder from the high voltage capacitor,

CAUTION: W-HEN REPLACING HIGH VOLTAGE

RECTIFIER ASSEMBLY, ENSURE THAT

THE CATHODE (EARTH) CONNECTION

IS SECURELY FIXED TO THE

CAPACITOR HOLDER WITH A EARTHING SCREW.

POWER TRANSFORMER REMOVAL

1. CARRY OUT3JCHECKS

4. Disconnect the high voltage wire of H.V. rectifier

2. Remove the fan motor assembly from the oven re- assembly from the power assembly.

ferring to “FAN MOTOR ASSEMBLY”.

5. Remove the two (2) screws holding the transformer

3. Disconnect the the filament lead of the power

to bottom plate right.

transformer from high voltage capacitor.

6. Remove the transformer from the bottom plate right.

7. Now, the power transformer is free.

23

Page 25

R-4A52

R-4E52

MAGNETRON REMOVAL

1. CARRY OUT 3D CHECKS

2. Disconnect the H.V. wire A and filament lead(longer

one) of the transformer from the magnetron.

3. Release the main harness from the tabs of the air

duct.

4. Remove the air duct from the oven cavity.

5. Carefully remove four (4) screws holding

magnetron to waveguide, when removing the

screws holding the magnetron to prevent it from

falling.

6. Remove the magnetron from the waveguide with

care so the magnetron antenna should not hit by

any metal object around the antenna

7. Remove the magnetron cushion from the magnetro.

CAUTION: WHEN REPLACING THE MAGNETRON,

BE SURE THE R.F. GASKET IS IN

PLACE AND

THE

MAGNETRON

MOUNTING SCREWS ARE TIGHTENED

SECURELY.

CONTROL PANEL REMOVAL

1. CARRY OUT 3D CHECKS

-_

2. Disconnect the main harness and low voltage harness from the control panel.

3. Remove the single (1) screw holding the control

panel to the oven cavity.

4. Lift up the control panel assembly and pull it forward. Now, the control panel assembly is free,

TURNTABLE MOTOR REMOVAL

I. Disconnect the oven from power supply.

2. Remove the turntable motor cover by removing the

two (2) screws.

3. Disconnect the wire lead from turntable motor and

remove the two(2) screws holding the turntable

motor.

4. Remove the O-ring and washer from the turntable

motor.

5. Turntable motor is now free.

XFTSD40PlOOOO

Figure C-l.

NOTE: The two (2) screws holding the turntable motor

to the oven cavity must be used the specified

screws(XFPSD40P08000) as listed on Parts

list.

TURNTABLE COUPLING. REMOVAL

1. Remove the turntable motor, refer to “Turntable

Motor Removal”.

2. At the time turntable coupling will be free.

TURN TABLE

COUPLING

BOTTOM

OVEN CAVITY

T.T. MOTOR

ANGLE

Figure C-2. Turntable Coupling

FAN MOTOR ASSEMBLY REMOVAL

1. CARRY OUT 3D CHECKS.

2. Disconnect the wire leads from the fan motor.

3. Disconnect the H.V. wire A and the filament

lead(longer one) of the power transformer from the

magnetron.

5. Release the tabs of the fan duct from the holes in

the bottom plate right and the back plate of the

oven cavity.

6. Release the main wire harness from the hole in the

4. Release the H.V. wire A and filament lead from the

fan duct.

holes in the fan duct.

7. Now, the fan motor assembly is free.

24

Page 26

R-4A52

R-4E52

OVEN LAMP SOCKET REMOVAL

1.

2.

3.

4.

5.

1.

2.

3.

4.

5.

6.

7.

CARRY OUT 3D CHECKS

Lift up the tab holding the oven lamp socket.

Remove the oven lamp socket.

Pull the wire leads from the oven lamp socket by

pushing the terminal hole of the oven lamp socket

with the flat type small screw driver.

Now, the oven lamp socket is free.

Oven lamp socket

Flat type

screw dri

Figure C-3. Oven lamp socket

UPPER LATCH SWITCH, LOWER LATCH SWITCH,

STOP SWITCH AND MONITOR SWITCH REMOVAL

CARRY OUT 3D CHECKS.

Remove the air duct from the oven cavity.

Disconnect the main wire harness and switch harness from the control panel.

Disconnect the leads from all switches.

Remove the two (2) screws holding the latch hook

to the oven cavity.

Remove the latch hook.

Push the retaining tab slightly and remove the

switch.

Monitor

I /

Upper latch switch

switch

Lower latch switch

Figure C-4. Switches

25

Page 27

R -4A52

R-4E52

UPPER LATCH SWITCH, LOWER LATCH SWITCH,

STOP SWITCH AND MONITOR SWITCH ADJUSTMENT

If the lower latch latch switch, stop switch, upper latch

5. Reinstall outer case and check for microwave

switch and monitor switch do not operate properly due

leakage around the door with an approved micro-

to a mis-adjustment, the following adjustment should

wave survey meter.

(Refer to Microwave Measure

be made.

ment Procedure.)

1. CARRYOUT3DCHECKS

2. Loosen the two (2) screws holding the latch hook

to the oven cavity front flange.

3. With door closed, adjust the latch hook by moving

it back and forward, or up and down. In and out

play of the door allowed by the latch hook should

be less than 0.5 mm. The horizontal position of the

latch hook should be placed where the stop switch

and monitor switch have activated--with the door

closed.

LATCH

The vertical position of the latch hook should be

placed where the lower latch switch and upper

latch switch have activated with the door closed.

4. Secure the screws with washers firmly.

5. Make sure of the upper latch switch, stop switch,

lower latch switch and monitor switch operation. If

those switches have not activated with the door

closed, two (2) screws holding latch hook to oven

cavity front flange and adjust the latch hook position.

After adjustment, make sure of following:

1. In and out play of door remains less than 0.5 mm

when latched position. First check latch hook position, pushing and pulling the door toward the oven

i

face. The results (plays of the door) should be less

I

than 0.5mm.

2. The upper latch switch and lower latch switch interrupt the circuit before the door can be opened.

3. The monitor switch contacts close when the door

is opened.

4. The stop switch contacts open when the door is

opened.

Figure C-5 Latch Switches Adjustment

26

Page 28

R -4A52

R-4E52

DOOR REPLACEMENT AND ADJUSTMENT

DOOR REPLACEMENT

1. CARRY OUT 3D CHECKS

2. Remove two (2) screws holding the lower oven

hinge to the oven cavity. The lower oven hinge is

now free.

3. ,“z;re the door assembly from the upper oven

4. Remove door assembly.

5. Door assembly is now free.

6. Re-install upper oven hinge to the new door assembly.

7. On re-installing new door assembly, secure the

lower oven hinges with the two (2) mounting

screws to the oven cavity. Make sure the door is

parallel with bottom line of the oven face plate and

the latch heads pass through the latch holes cor-

rectly.

8. CARRY OUT JIFJ CHECKS

Note: After any service to the door, an approved

microwave survey meter should be used to

assure compliance with proper .microwave ra-

diation standards. ( Refer to Microwave

Measurement Procedure.)

DOOR ADJUSTMENT

When removing and/or loosening hinges such as in

door replacement, the following adjustment criteria are

taken.

Door is adjusted to meet the following three

conditions by keeping screws of hinge loose.

1. Adjust door latch heads at a position where they

smoothly catch the latch hook through the latch

1

holes. Refer to latch switch adjustments.

2. Deviation of the door alignment from horizontal line

of cavity face plate is to be less than 1 .Omm.

3. The door is positioned with its face depressed toward the cavity face plate.

4. Reinstall outer case and check for microwave

leakage around the door with an approved microwave survey meter.

(Refer to Microwave Measure

ment Procedure.)

CABINET

Figure C-6. Door Assembly Replacement

and Adjustment

CHOKE COVER REMOVAL

1. Insert an iron plate(thrckness of about 0.5mm) or

flat type screw driver to the gap between the choke

cover and door panel as shown in the figure to free

the engaging part.

2. Lift up the choke cover, now cover is free.

FLAT TYPE

SCREW-DRIVER

PROTECT BY TAPE

FLAT TYPE

SCREW-DRIVE

Figure C-7. Choke Cover Removal

DOOR PARTS REMOVAL

Remove the door assembly, referring to from item 1

through item 5 of “DOOR REPLACEMENT”.

1. Place the door assembly on a soft c,loth with latch

heads facing up.

2. Remove the.* choke cover, referring to “CHOKE

COVER REMOVAL”.

LATCH HEAD REMOVAL

3. Lift up the latch head towards the direction that the

arrow shows in the figure C-8, and release the latch

head from the holes in the door panel.

4. Release the latch spring with the latch head from

the tabs of the door panel.

5. Release the latch spring from the latch head.

6. Now, the latch head is free.

27

Page 29

R-4A52

R-4E52

\

Tab of the door panel

Figure C-8. Latch head removal

Figure C-9. Latch head re-install

LATCH HEAD RE-INSTALL

1. Pick up the latch spring and catch the one ring of

the latch spring on the tab of the door panel as

shown in Figure C-9.

2. Catch the other ring of the latch spring on the tab

of the latch head.

3. Install the latch head to the holes in the door panel.

POWER SUPPLY CORD REPLACEMENT

(FOR AUSTRALIA MODEL)

Removal

1. CARRY OUT 30 CHECKS.

2. Disconnect the brown wire of the power supply

cord from the fuse holder.

3. Remove the connector CE-230 by cutting the connected wire leads to it.

4. Remove the single (1) screw holding the

green/yellow wire of the power supply cord to the

oven cavity.

5. Remove the single (1) screw holding the cord

anchorage to the oven cavity.

6. Remove the power supply cord from the oven.

Re-install

1. Insert the power supply cord into the cord

anchorages.

2. Connect the brown wire of the power supply cord

to the fuse holder.

3. Install the green/yellow wire of the power supply

cord to the oven cavity with the single (1) screw

tightly.

4. Make sure that the blue wire and the white wires

are stripped for 15 mm length as shown in Figure

C-II.

5. Wind the conductors of Blue and White wires each

other.

6. Insert the stripped wire leads into the connector

CE-230.

7. Clamp the connector CE-230 with the correct tool

tightly.

Cord anchorage

I

Brown wire \

Fuse holder

Green/Yellow wire

Figure C-10 Power Supply Cord Replacement

for Australia Model

Blue wire of power supply cord

White wire of main harness

33::

Conductors

Connector CE-230

Figure C-II Wiring

28

Page 30

FL4A52

R-4E52

POWER SUPPLY CORD REPLACEMENT

(FOR NEW ZEALAND MODEL)

Removal

1.

2.

3.

4.

5.

CARRY OUT 3D CHECKS

Loosen the two (2) screws holding the brown and

blue wires of the power supply cord to the cord

connector on the noise filter.

Loosen the single (1) screw holding the earth angle

and earth wire of power supply cord.

Remove the single (1) screw holding the cord

anchorages to the oven cavity.

Remove the power supply cord.

Re-install

1.

2.

3.

4.

5.

Insert the power supply cord into the cord

anchorages.

Insert the brown and blue wires of power supply

cord into the terminals of cord connector, referring

to pictorial disgram. And tighten the screws.

Insert the earth wire of power supply cord into the

earth angle, and tighten the screw holding the earth

angle.

Tighten the single (1) screw holding the cord

anchorages.

CARRY OUT Q CHECKS

Note:Step 5 above is important, and it must be done

after replacing power supply cord.

Procedure

1. Pushing the lever of positive lock@ connecotr,

2. Pull down the connector from the terminal.

3. Now, the connector is free.

Note: If the positive lock@’ has a insulation sleeve, first

remove it. If you do not so, you can not push

the lever of positive lock@’ .

CAUTION: The positive lock@ terminal can not be

disconnected by only pulling. Because

once you (Service personnal) have connected the positive lock@ connector to the

terminal, the positive lock connector has

been locked.

Cord connector

Blue wire

rem I Yellow wire

Figure C-12. Power Supply Cord Replacement

For New Zealand Model

Positive lock@

cunnector

\

Terminal

Figure C-13. How to release the

positive lock

connector

29

Page 31

R -4A52

R-4E52

MICROWAVE MEASUREMENT

After adjustment of door latch switches, monitor

switch and door are completed individually or collectively, the following leakage test must be performed

with a survey instrument and it must be confirmed that

the result meets the requirements of the performance

standard for microwave oven.

REQUIREMENT

The safety switch must prevent microwave radiation

emission in excess of 5mW/cm2 at any point 5cm or

more from external surface of the oven.

PREPARATION FOR TESTING:

--

Before beginning the actual test for leakage, proceed

as follows;

1. Make sure that the test instrument is operating

normally as specified in its instruction booklet.

Important:

Survey instruments that comply with the requirement for instrumentations as prescribed by the per-

formance standard for microwave ovens must be

used for testing.

Recommended instruments are:

NARDA 8100

NARDA 8200

HOLADAY HI 1500

SIMPSON 380M

2. Place the oven tray into the oven cavity.

3. Place the load of 275 +I 5ml of water initially at

20f5”C in the centre of the oven tray. The water

container should be a low form of 600 ml beaker

with inside diameter of approx. 8.5cm and made of

an electrically non-conductive material such as

glass or plastic.

The placing of this standard load in the oven is im-

portant not only to protect the oven, but also to‘in-

sure that any leakage is measured accurately.

4. Close the door and turn the oven ON with the timer

set for several minutes. If the water begins to boil

before the survey is completed, replace it with

275ml of cool water.

5. Move the probe slowly (not faster that 2.5cm/sec.)

along the gap.

6. The microwave radiation emission should be meas-

ured at any point of 5cm or more from the external

surface of the oven.

Microwave leakage measurement at 5 cm distance

30

Page 32

R-4A52

R-4E52

TEST DATA AT A GLANCE

IP

arts

1 Symbol 1 Value / Data

I---

F

Fuse

-

Monitor resistor

RI

Temp. fuse (MG)

TF

Thermal cut-out (OVEN)

TC

Oven lamp

OL

High voltage capacitor

Magnetron

Power transformer

C

MG

T

M8A 250V

0.8zT 20W

150°C

145°C