Page 1

R-490C(S)

SHARP CORPORATION

SUPPLEMENTAL SER VICE MANU AL

S9907R490CPJS

MICROWAVE OVEN

MODEL

R-490C(S)

In interests of user-safety the oven should be restored to its

original condition and only parts identical to those specified

should be used.

TABLE OF CONTENTS

Page

CAUTION, MICROWAVE RADIATION............................................................................................................. 1

WARNING..........................................................................................................................................................1

PRODUCT SPECIFICATIONS ......................................................................................................................... 2

GENERAL INFORMATION................................................................................................................................2

APPEARANCE VIEW ....................................................................................................................................... 3

COMPONENT REPLACEMENT AND ADJUSTMENT PROCEDURE ..............................................................4

MICROWAVE MEASUREMENT .......................................................................................................................6

WIRING DIAGRAM ............................................................................................................................................7

PICTORIAL DIAGRAM ......................................................................................................................................8

PARTS LIST ......................................................................................................................................................9

This is a supplemental Service Manual for Model R-490C(S). This model is quite similar to base model R-480C.

Use this supplemental manual together with the Base Model Service Manual (Refer No. is S6903R480CPJ/) for

complete operation, service information, etc..

Sensor

SENSOR DEFROST COOK

HELP

Info Display

Sensor Instant Reheat

Sensor Cook

DINNER

PLATE

CASSEROLE

SOUP

PIZZA RICE PIE

VEGETABLES RICE/PASTA

DESSERTS

MEAT

LESS

POWER

LEVEL

STOP

CLEAR

CLOCK TIMER

HELP

MORE

SLOW

COOK

EASY

DEFROST

12345

67890

INSTANT COOK

START

Page 2

R-490C(S)

Page 3

R-490C(S)

1

SERVICE MANUAL

MICROWAVE OVEN

R-490C(S)

GENERAL IMPORTANT INFORMATION

This Manual has been prepared to provide Sharp Corp. Service engineers with Operation and Service Information.

It is recommended that service engineers carefully study the entire text of this manual and base model's manual (Refer

No. is S6903R480CPJ/), so they will be qualified to render satisfactory customer service.

CAUTION

MICROWAVE RADIATION

DO NOT BECOME EXPOSED TO RADIATION FROM THE MICROWAVE GENERATOR OR OTHER PARTS

CONDUCTING MICROWAVE ENERGY.

Service engineers should not be exposed to the microwave energy which may radiate from the magnetron or other

microwave generating devices if it is improperly used or connected. All input and output microwave connections,

waveguides, flanges and gaskets must be secured. Never operate the device without a microwave energy absorbing

load attached. Never look into an open waveguide or antenna while the device is energized.

WARNING

Never operate the oven until the following points are ensured.

(A) The door is tightly closed.

(B) The door brackets and hinges are not defective.

(C) The door packing is not damaged.

(D) The door is not deformed or warped.

(E) There is not any other visible damage with the oven.

Servicing and repair work must be carried out only by trained service engineers.

All the parts marked "*" on parts list are used at voltages more than 250V.

Removal of the outer wrap gives access to potentials above 250V.

All the parts marked "∆" on parts list may cause undue microwave exposure, by themselves, or when they are damaged,

loosened or removed.

SHARP CORPORATION

OSAKA, JAPAN

Page 4

2

R-490C(S)

PRODUCT SPECIFICATIONS

ITEM DESCRIPTION

Power Requirements 230 - 240 Volts

50 Hertz

Single phase, 3 wire earthed

Power Consumption 1.6 kW

Power Output 1100 watts nominal of RF microwave energy (IEC 705)

Operating frequency 2450 MHz

Case Dimensions Width 550 mm

Height 315 mm

Depth 441 mm

Cooking Cavity Dimensions Width 378 mm

Height 223 mm

Depth 425 mm

Turntable diameter 360mm

Control Complement Touch Control System

Clock ( 1:00 - 12:59)

Timer (0 - 99 minutes 99 seconds)

Microwave Power for Variable Cooking

Repetition Rate;

HIGH ............................................... Full power throughout the cooking time

MEDIUM HIGH ..................................................approx. 70% of Full Power

MEDIUM .............................................................approx. 50% of Full Power

MEDIUM LOW ....................................................approx. 30% of Full Power

LOW ....................................................................approx. 10% of Full Power

HELP pad

SENSOR INSTANT REHEAT pads

SENSOR COOK pads

SLOW COOK pad

EASY DEFROST pad

MORE, LESS pads

NUMBER pads

POWER LEVEL pad

CLOCK pad

TIMER pad

STOP/CLEAR pad

INSTANT COOK/START pad

Weight Approx. 20 kg

GENERAL INFORMATION

WARNING

THIS APPLIANCE MUST BE EARTHED

IMPORTANT

THE WIRES IN THIS MAINS LEAD ARE COLOURED IN ACCORDANCE WITH THE FOLLOWING CODE:

GREEN-AND-YELLOW : EARTH

BLUE : NEUTRAL

BROWN : LIVE

Page 5

R-490C(S)

3

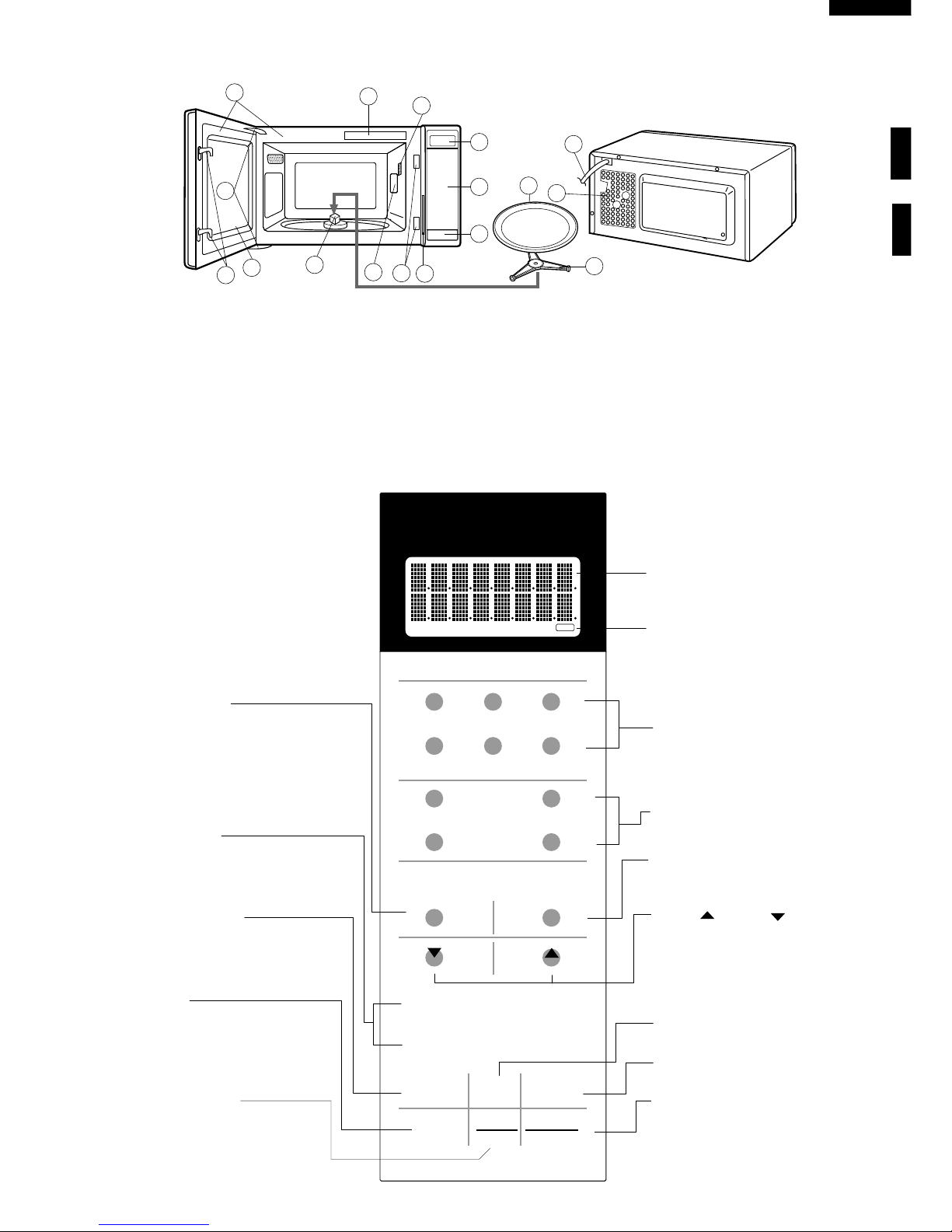

APPEARANCE VIEW

1. Ventilation openings

2. Oven lamp

3. Door hinges

4. Door safety latches

5. See through door

10

3

4

2

7

13

5

6

14

4

11

8

16

9

12

15

1

SENSOR DEFROST COOK

HELP

Info Display

Sensor Instant Reheat

Sensor Cook

DINNER

PLATE

CASSEROLE

SOUP

PIZZA RICE PIE

VEGETABLES RICE/PASTA

DESSERTS

MEAT

LESS

POWER

LEVEL

STOP

CLEAR

CLOCK TIMER

HELP

MORE

SLOW

COOK

EASY

DEFROST

1234 5

6789 0

INSTANT COOK

START

STOP/CLEAR PAD

Press to clear during programming.

Press once to stop operation of

oven during cooking; press twice to

cancel cooking programme.

POWER LEVEL PAD

Press to select microwave power

setting. If not pressed, HIGH is automatically selected.

INSTANT COOK/START PAD

Press once to cook for 1 minute on

HIGH or increase in 1 minute increments each time this pad is pressed

during cooking. Press to start the oven

after setting programmes.

HELP PAD

Press to select auto start, information

guide on/off, child lock, demonstration modes or info on pads.

Press to get cooking information.

SENSOR COOK PADS

Press to select Sensor Cook menus.

SENSOR INSTANT REHEAT PADS

Press once to reheat 1 of 6 popular

menus.

EASY DEFROST PAD

Press to defrost frozen food by entering quantity.

MORE( ), LESS ( ) PADS

Press to increase/ decrease the time

in one minute increments during

cooking or alter the cooking result for

Sensor Instant Reheat, Sensor Cook

or Easy Defrost modes.

NUMBER PADS

Press to enter cooking times, clock time,

weight or quantity of food.

TIMER PAD

Press to set Timer

CLOCK PAD

Press to set Clock.

SLOW COOK PAD

Press to cook slowly and for a long

time.

Indicator

Display

6. Door seals and sealing surfaces

7. Coupling

8. Door open button

9. Touch control panel

10.Digital readout

11.Waveguide cover

12.Power supply cord

13.Rating label

14.Menu label

15.Turntable

16.Roller stay

TOUCH CONTROL PANEL

Page 6

4

R-490C(S)

CONTROL PANEL ASSEMBLY REMOVAL

1. CARRY OUT 3D CHECKS.

2. Disconnect wire leads from panel components.

3. Release one (1) nail holding the control panel assembly

to the oven flange.

4. Remove control panel assembly and slide upward.

5. Now, the control panel assembly is free.

NOTE: The key unit can not be exchanged by itself.

Because the control panel decoration is fixed by

the both sides adhesive tape. The Control panel

frame with key unit should be available as spare

part.

CPU UNIT AND POWER UNIT

NOTE: Handle the CPU unit carefully so that the ribbon

cable does not come off. Because the ribbon cable

is sticked on the LCD and the printed wiring board

only by heated paste.

Figure C-3. CPU unit

Printed wiring board

of CPU unit

Liquid Crystal

Display (LCD)

Ribbon cable

COMPONENT REPLACEMENT AND ADJUSTMENT PROCEDURE

WARNING:

Avoid possible exposure to microwave energy. Please follow the instructions below before

operating the oven.

1. Disconnect the oven from the power supply.

2. Make sure that a definite “click” can be heard when the

microwave oven door is unlatched. (Hold the door in a

closed position with one hand, then push the door open

button with the other, this causes the latch leads to rise,

it is then possible to hear a “click” as the door switches

operate.)

3. Visually check the door and cavity face plate for damage

(dents, cracks, signs of arcing etc.).

Carry out any remedial work that is necessary before

operating the oven.

Do not operate the oven if any of the following conditions

exist;

1. Door does not close firmly.

2. Door hinge, support or latch hook is damaged.

3. The door gasket or seal or damaged.

4. The door is bent or warped.

5. There are defective parts in the door interlock system.

6. There are defective parts in the microwave generating

and transmission assembly.

7. There is visible damage to the oven.

Do not operate the oven:

1. Without the RF gasket (Magnetron).

2. If the wave guide or oven cavity are not intact.

3. If the door is not closed.

4. If the outer case (cabinet) is not fitted.

Please refer to ‘OVEN PARTS, CABINET PARTS, CONTROL PANEL PARTS, DOOR PARTS’, when carrying out any

of the following removal procedures:

WARNING FOR WIRING

To prevent an electric shock, take the following

manners.

1. Before wiring,

1) Disconnect the power supply.

2) Open the door and wedge the door open.

3) Discharge the high voltage capacitor and wait for

60 seconds.

2. Don't let the wire leads touch to the following parts;

1) High voltage parts:

Magnetron, High voltage transformer, High

voltage capacitor, High voltage rectifier assembly

and High voltage fuse.

2) Hot parts:

Oven lamp, Magnetron, High voltage transformer

and Oven cavity.

3) Sharp edge:

Bottom plate, Oven cavity, Waveguide flange,

Chassis support and other metallic plate.

4) Movable parts (to prevent a fault)

Fan blade, Fan motor, Switch, Switch lever,

Open button.

3. Do not catch the wire leads in the outer case cabinet.

4. Insert the positive lock connector certainly until its

pin is locked. And make sure that the wire leads

should not come off even if the wire leads is pulled.

5. To prevent an error function, connect the wire leads

correctly, referring to the Pictorial Diagram.

Page 7

R-490C(S)

5

DOOR REPLACEMENT

REMOVAL

1. Disconnect the power supply cord.

2. Push the open button and open the door slightly.

3. Insert a putty knife (thickness of about 0.5mm) into the

gap between the choke cover and door frame as shown

in Figure C-6 to free engaging parts.

4. Pry the choke cover by inserting a putty knife as shown

Figure C-6.

5. Release choke cover from door panel.

6. Now choke cover is free.

7. Release two (2) pins of door panel from two (2) holes

of upper and lower oven hinges by lifting up.

8. Now, door panel with door frame is free from oven

cavity.

Figure C-6. Door Disassembly

9. Remove the two (2) screws holding the door panel to

the door frame.

10.Release door panel from nine (9) tabs of door frame.

11.Now, door panel with sealer film is free.

12.Tear sealer film from door panel.

13.Now, door panel is free.

14.Slide latch head upward and remove it from door frame

with releasing latch spring from door frame and latch

head.

15.Now, latch head and latch spring are free.

16.Now, the door frame assembly is free.

NOTE: The door glass can not be exchanged by itself.

Because the door decoration is fixed by the both

sides adhesive tape. The Door frame assembly

should be available as spare part.

RE-INSTALL

1. Re-install the latch spring to the latch head. Re-install

the latch spring to the door frame. Re-install latch head

to door frame.

2. Re-install door panel to door frame by fitting nine (9)

tabs of door frame to nine (9) holes of door panel.

3. Hold the door panel to the door frame with the two (2)

screws.

4. Put sealer film on door panel. Refer to “Sealer Film”

about how to handle new one.

5. Catch two (2) pins of door panel on two (2) hole of upper

and lower oven hinges.

6. Re-install choke cover to door panel by pushing.

Note: After any service to the door;

(A) Make sure that 1st. latch switch, 2nd. latch switch,

stop switch and monitor switch are operating

properly. (Refer to chapter “Test Procedures”.).

(B) An approved microwave survey meter should be

used to assure compliance with proper microwave

radiation emission limitation standards.

After any service, make sure of the following :

1. Door latch heads smoothly catch latch hook through

latch holes and that latch head goes through center of

latch hole.

2. Deviation of door alignment from horizontal line of

cavity face plate is to be less than 1.0mm.

3. Door is positioned with its face pressed toward cavity

face plate.

4. Check for microwave leakage around door with an

approved microwave survey meter. (Refer to Microwave

Measurement Procedure.)

Note: The door on a microwave oven is designed to act

as an electronic seal preventing the leakage of

microwave energy from oven cavity during cook

cycle. This function does not require that door be

air-tight, moisture (condensation)-tight or lighttight. Therefore, occasional appearance of

moisture, light or sensing of gentle warm air

movement around oven door is not abnormal and

do not of themselves indicate a leakage of

microwave energy from oven cavity.

Figure C-7. Door Replacement

SEALER FILM

Installation

1. Put the adhesive tape on the backing film of the sealer

film as shown in Fig. C-8.

2. Tear the backing film by pulling the adhesive tape.

3. Put the pasted side of the sealer film on the door panel

Figure C-8. Sealer film

Sealer film

Backing film

Adhesive tape

Choke Cover

Door Frame

Putty Knife

Pin

Pin

Upper

Oven Hinge

Upper Oven

Hinge

Lower Oven

Hinge

Lower

Oven Hinge

Choke Cover

Door Panel

Page 8

6

R-490C(S)

mW cm

2

mW cm

2

Microwave leakage measurement at 5 cm distance

SHARP

MICROWAVE MEASUREMENT

After adjustment of door latch switches, monitor switch

and door are completed individually or collectively, the

following leakage test must be performed with a survey

instrument and it must be confirmed that the result meets

the requirements of the performance standard for microwave oven.

REQUIREMENT

The safety switch must prevent microwave radiation emission in excess of 5mW/cm2 at any point 5cm or more from

external surface of the oven.

PREPARATION FOR TESTING:

Before beginning the actual test for leakage, proceed as

follows;

1. Make sure that the test instrument is operating normally

as specified in its instruction booklet.

Important:

Survey instruments that comply with the requirement

for instrumentations as prescribed by the performance

standard for microwave ovens must be used for testing.

Recommended instruments are:

NARDA 8100

NARDA 8200

HOLADAY HI 1500

SIMPSON 380M

2. Place the oven tray into the oven cavity.

3. Place the load of 275 ± 15ml of water initially at 20

± 5˚C in the centre of the oven tray. The water

container should be a low form of 600 ml beaker with

inside diameter of approx. 8.5cm and made of an

electrically non-conductive material such as glass

or plastic.

The placing of this standard load in the oven is important

not only to protect the oven, but also to insure that any

leakage is measured accurately.

4. Close the door and turn the oven ON with the timer set

for several minutes. If the water begins to boil before

the survey is completed, replace it with 275ml of cool

water.

5. Move the probe slowly (not faster that 2.5cm/sec.)

along the gap.

6. The microwave radiation emission should be measured

at any point of 5cm or more from the external surface

of the oven.

Page 9

R-490C(S)

7

SCHEMATIC

NOTE: CONDITION OF OVEN

1.DOOR CLOSED.

2.CLOCK APPEARS ON DISPLAY.

NOTE: " " indicates components with potentials above 250V.

Figure O-1. Oven Schematic-OFF Condition

SCHEMATIC

NOTE: CONDITION OF OVEN

1. DOOR CLOSED.

2. COOKING TIME PROGRAMMED.

3. START KEY TOUCHED.

Figure O-2. Oven Schematic-Cooking Condition

POWER TRANSFORMER

MAGNETRON

H.V. RECTIFIER

H. V. FUSE

0.75A

CAPACITOR

1.13µ

AC2300V

TURNTABLE MOTOR

FAN MOTOR

OVEN LAMP

STOP

SWITCH

MONITOR SWITCH

CONTROL

UNIT

MAGNETRON

TEMPERATURE

FUSE

1ST. LATCH

SWITCH

B1

B2

A2

OL

FM

TTM

N.O.

N.O.

RY-1

COM.

COM.

A1

THERMAL

CUT-OUT

145˚C (OVEN)

RY-2

2ND. LATCH

SWITCH

MONITOR

RESISTOR

0.8/20W

EARTH

BLU

BRN

230-240V/50Hz

G-Y

FUSE

M10A

N

L

LINE CROSS CAPACITOR

0.068µ/AC250V

NOISE SUPPRESSION COIL

LINE BYPASS

CAPACITOR

0.0022µ/AC250V

LINE BYPASS

CAPACITOR

0.0022µ/AC250V

F1

F2

F3

AH

SENSOR

POWER TRANSFORMER

MAGNETRON

H.V. RECTIFIER

H. V. FUSE

0.75A

CAPACITOR

1.13µ

AC2300V

TURNTABLE MOTOR

FAN MOTOR

OVEN LAMP

STOP

SWITCH

MONITOR SWITCH

CONTROL

UNIT

MAGNETRON

TEMPERATURE

FUSE

1ST. LATCH

SWITCH

B1

B2

A2

OL

FM

TTM

N.O.

N.O.

RY-1

COM.

COM.

A1

THERMAL

CUT-OUT

145˚C (OVEN)

RY-2

2ND. LATCH

SWITCH

MONITOR

RESISTOR

0.8/20W

EARTH

BLU

BRN

230-240V/50Hz

G-Y

FUSE

M10A

N

L

LINE CROSS CAPACITOR

0.068µ/AC250V

NOISE SUPPRESSION COIL

LINE BYPASS

CAPACITOR

0.0022µ/AC250V

LINE BYPASS

CAPACITOR

0.0022µ/AC250V

F1

F2

F3

AH

SENSOR

Page 10

8

R-490C(S)

6

45

1

2

3

6

45

1

2

3

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

Figure S-1. Pictorial Diagram

COM.

MONITOR

SWITCH

COM.

N.O.

N.C.

1ST.

LATCH

SWITCH

2ND.

LATCH

SWITCH

STOP

SWITCH

(CABINET SIDE)

(OVEN SIDE)

TURNTABLE

MOTOR

COM.

N.O.

BLK

GRY

GRY

WHT

GRN

WHT

WHT

BLU

BLK

WHT

WHT

WHT

RED

WHT

WHT

THERMAL

CUT-OUT (OVEN)

NOISE FILTER

GRN

GRY

COM.

N.O.

BLK

RED

GRN

ORG

BLK

ORG

RED

RED

GRY

2

1

CN-A

GRN

GRY

2

1

CN-B

BLU

BRN

POWER

SUPPLY

CORD

EARTH

NEUTRAL

LIVE

G

/

Y

N

L

WHT

RED

M10A

CONTROL PANEL

RY1

N.O.

N.O.

COM.

COM.

RY2

CN-A

CN-B

T1

112

2

(CPU UNIT)

(POWER UNIT)

CN-F

CN-C

CN-G

RED

ORG

ORG

W

H

T

OVEN LAMP

AND SOCKET

BLACK

MARK

NOTE:

Neutral (WHT) wire

must be connected

to the terminal with

black mark on the

oven light socket.

ORGWHT

ORG

RED

MAGNETRON

TEMPERATURE

FUSE

(OVEN SIDE)

BLK

ORG

MONITOR

RESISTOR

H.V.RECTIFIER

H.V. FUSE

HIGH VOLTAGE

CAPACITOR

HIGH VOLTAGE COMPONENTS

MAGNETRON

POWER

TRANSFORMER

ORG

BLK

BLU

GRY

BLK

AH SENSOR

RED

WHT

123

CN-F

Page 11

R-490C(S)

9

PARTS LIST

Note: The parts marked "∆" may cause undue microwave exposure.

The parts marked "*" are used in voltage more than 250V.

REF. NO. PART NO. DESCRIPTION Q'TY CODE

*

*

*

*

∆*

*

ELECTRICAL PARTS

1- 1 QFS-TA014WRE0 Temp. fuse 150˚C (MG) 1 AG

1- 2 FPWBFA331WRK0 Noise filter 1 AU

1- 3 QSW-MA131WRE0 1st. latch switch, 2nd. latch switch, Stop switch 3 AG

1- 4 QSW-MA132WRE0 Monitor switch 1 AH

1- 5 RTHM-A075WRE0 Thermal cut-out 145˚C (OVEN) 1 AN

1- 6 QACCAA047WRE0 Power supply cord 1 AP

1- 7 FH-DZA069WRK0 H.V. rectifier assembly 1 AP

1- 7 FH-DZA067WRK0 H.V. rectifier assembly (Interchangeable) 1 AQ

1- 8 RC-QZA258WRE0 High Voltage capacitor 1 AW

1- 9 RMOTEA328WRE0 Fan motor 1 AX

1- 9 RMOTEA342WRE0 Fan motor (Interchangeable) 1 AX

1-10 QFS-CQ001YBE0 Fuse M10A 1 AE

1-11 QSOCLA022WRE0 Oven lamp socket 1 AG

1-12 RLMPTA069WRE0 Oven lamp 1 AK

1-12 RLMPTA029WRE0 Oven lamp (Interchangeable) 1 AL

1-13 RMOTDA173WRE0 Turntable motor 1 AX

1-13 RMOTDA226WRE0 Turntable motor (Interchangeable) 1 AT

1-14 RTRN-A585WRE0 Power transformer 1 BQ

1-15 RV-MZA295WRE0 Magnetron 1 BF

1-16 RR-WZA022WRE0 Monitor resistor 0.8 ohm 20W 1 AK

1-17 FDTCTA179WRK0 AH sensor assembly 1 BA

1-18 QFS-IA002WRE0 H.V. fuse 1 AQ

CABINET PARTS

2- 1 GCABUA732WRP0 Outer case cabinet 1 BF

2- 2 GDAI-A266WRW0 Bottom plate 1 AL

2- 3 GLEGPA074WRE0 Foot 4 AC

CONTROL PANEL PARTS

3- 1 CPWBFA835WRK0 Power unit (New Zealand only) 1 BB

3- 1A QCNCMA446DRE0 2-pin connector(CN-A) 1 AC

3- 1B QCNCMA275DRE0 2-pin connector(CN-B) 1 AB

3- 1C FW-VZA232DRE0 12-pin harness (CN-C) 1 AE

C1 RC-KZA087DRE0 Capacitor 0.1µF 50V 1 AA

C2 VCEAB31VW108M Capacitor 1000µF 35V 1 AF

C3 RC-KZA087DRE0 Capacitor 0.1µF 50V 1 AA

C4-5 VCEAB31VW106M Capacitor 10µF 35V 2 AA

D1-4 VHD11ES1///-1 Diode (11ES1) 4 AB

D5-8 VHD1SS270A/-1 Diode (1SS270ATA) 4 AA

Q1-2 VS2SB1238//-3 Transistor (2SB1238) 2 AA

Q3 VSKRC243M//-3 Transistor (KRC243M) 1 AB

R1 VRD-B12EF242J Resistor 2.4k ohm 1/4W 1 AA

R2 VRS-B12HF681J Resistor 680 ohm 1/2W 1 AA

R3 VRD-B12HF511J Resistor 510 ohm 1/2W 1 AB

R4 VRD-B12EF270J Resistor 27 ohm 1/4W 1 AB

R5 VRD-B12EF472J Resistor 4.7k ohm 1/4W 1 AA

R6 VRD-B12EF332J Resistor 3.3k ohm 1/4W 1 AA

RY1 RRLY-A076DRE0 Relay (OMIF-S-124LM) 1 AK

RY2 RRLY-A081DRE0 Relay (VRB24) 1 AL

SP1 RALM-A014DRE0 Buzzer (PKM22EPT-THAI) 1 AG

T1 RTRNPA112DRE0 Transformer 1 AS

VRS1 RH-VZA032DRE0 Varistor (10G471K) 1 AE

ZD1 VHEHZ161///-1 Zenor diode (HZ16-1) 1 AA

3- 2 DPWBFB965WRK0 CPU unit 1 BH

3- 3 FPNLCB467WRK0 Control panel frame with key unit 1 BP

3- 3-1 HDECAA205WR10 C/P decoration 1 BF

3- 3-2 JBTN-B091MRF0 Open button 1 AN

3- 3-3 MSPRCA050WRE0 Open button spring 1 AB

3- 4 LHLD-B010MRF0 LCD holder 1 AQ

3- 5 PSHEPA672WRE0 LED sheet 1 AK

3- 6 XEPSD30P08XS0 Screw ; 3mm x 8mm 4 AA

OVEN PARTS

4- 1 PHOK-A095WRF0 Latch hook 1 AN

4- 2 LBNDKA132WRP0 Capacitor holder 1 AD

4- 3 PCOVPA312WRE0 High voltage cover 1 AF

4- 4 NFANJA020WRE0 Fan blade 1 AG

4- 5 FOVN-A387WRT0 Oven cavity 1 BL

∆

∆

Page 12

10

R-490C(S)

HOW TO ORDER REPLACEMENT PARTS

To have your order filled prompty and correctly, please furnish the following information.

1. MODEL NUMBER

2. REF. NO.

3. PART NO.

4. DESCRIPTION

Note: The parts marked "∆" may cause undue microwave exposure.

The parts marked "*" are used in voltage more than 250V.

REF. NO. PART NO. DESCRIPTION Q'TY CODE

∆

∆

∆

4- 6 LANGTA316WRP0 Chassis support 1 AH

4- 7 MLEVPA194WRF0 Switch lever 1 AG

4- 8 NCPL-A052WRF0 Turntable coupling 1 AF

4- 9 PCOVPA311WRE0 Waveguide cover 1 AG

4-10 PCUSUA191WRP0 Cushion 1 AC

4-11 PDUC-A610WRF0 Fan duct 1 AR

4-12 PDUC-A611WRW0 Magnetron air duct 1 AC

4-13 PPACGA119WRE0 Waterproof packing 1 AC

4-14 PCUSUA410WRP0 Cushion 1 AB

4-15 PCUSUA455WRP0 Cushion 1 AD

4-16 PPACGA073WRE0 Cushion 1 AP

4-17 PCUSUA452WRP0 Cushion 1 AB

4-18 PCUSGA531WRP0 Cushion 1 AF

4-19 PCUSUA237WRP0 Cushion 1 AF

4-20 PSKR-A319WRF0 MG air guide 1 AE

4-21 PSKR-A321WRP0 Air guide 1 AY

4-22 PCUSGA532WRP0 Cushion 1 AF

4-23 PDUC-A661WRP0 AH sensor duct 1 BC

4-24 PCUSGA534WRP0 Cushion 1 AF

DOOR PARTS

5- 1 FDORFA290WRT0 Door panel 1 BA

5- 2 FWAKPA234WRK0 Door frame assembly 1 BQ

5-2-1 HDECAB081MRP0 Door decoration 1 AX

5- 3 LSTPPA139WRF0 Latch head 1 AF

5- 4 MSPRTA084WRE0 Latch spring 1 AD

5- 5 XEPSD30P08XS0 Screw; M3 x 8 2 AA

5- 6 GCOVHA414WR10 Choke cover 1 AM

5- 7 PSHEPA336WRP0 Sealer film 1 AF

MISCELLANEOUS

6- 1 TSPCNC816WRR0 Rating label 1 AC

6- 2 FW-VZB122WRE0 Switch harness 1 AP

6- 3 FW-VZB745WRE0 Main wire harness 1 AU

6- 4 FROLPA092WRK0 Turntable support 1 AE

6- 5 TLABMA539WRR0 Menu label 1 AF

6- 6 PZET-A012WRE0 Terminal insulator 1 AB

6- 7 TCAUHA214WRR0 K caution label 1 AC

6- 8 TINSEA817WRR0 Operation manual 1 AR

6- 9 NTNT-A095WRE0 Turntable tray 1 AX

SCREWS, NUTS AND WASHERS

7- 1 XHTSD40P08RV0 Screw; M4 x 8 11 AA

7- 2 LX-CZ0052WRE0 Special screw 2 AA

7- 3 LX-EZA042WRE0 Special screw 2 AB

7- 4 XHPSD30P06000 Screw; M3 x 6 3 AA

7- 5 XHPSD40P08K00 Screw; M4 x 8 9 AA

7- 6 XHPSD30P08XS0 Screw; M3 x 8 1 AA

7- 7 LX-EZA050WRE0 Special screw; 1 AB

7- 8 XOTSD40P12RV0 Screw; M4 x 12 12 AB

7- 9 XOTSD40P12000 Screw; M4 x 12 2 AA

Page 13

R-490C(S)

11

6

45

1

2

3

6

45

1

2

3

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

OVEN AND CABINET PARTS

7-8

7-8

7-8

7-8

2-1

6-9

1-5

4-5

4-23

7-1

4-11

7-1

7-4

7-1

4-6

7-5

1-15

7-1

4-21

7-2

4-9

1-13

7-5

4-1

4-7

1-9

4-4

1-3

1-4

1-3

1-14

1-1

1-11

1-12

7-9

2-3

7-8

2-2

4-15

7-8

2-3

2-3

6-4

6-5

4-8

4-19

7-1

1-7

1-8

7-1

4-16

4-2

4-17

A

A

4-3

1-18

7-5

4-24

4-12

4-18

4-20

4-10

6-7

1-3

1-6

7-7

7-5

1-10

1-2

7-5

7-8

7-1

7-8

7-8

7-1

1-16

4-14

4-13

7-1

7-6

7-3

7-1

7-4

1-17

4-22

Page 14

12

R-490C(S)

6

45

1

2

3

6

45

1

2

3

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

CONTROL PANEL PARTS

MISCELLANEOUS

6-2

6-6

Actual wire harness may be different from illustration.

6-3

5-6

5-5

5-5

5-7

5-3

5-1

5-4

5-2-1

5-2

3-1

3-6

3-6

3-6

3-6

3-2

3-3

6-1

3-4

3-5

3-3-3

3-3-2

3-3-1

DOOR PARTS

Page 15

R-490C(S)

13

6

45

1

2

3

6

45

1

2

3

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

PACKING AND ACCESSORIES

DOOR PROTECTION SHEET

SPADPA204WRE0

TOP PAD ASSEMBLY

FPADBA317WRK0

PLASTIC BAG

SSAKHA032WRE0

Not replaceable items.

PACKING CASE

SPAKCD305WRE0

BOTTOM PAD ASSEMBLY

FPADBA318WRK0

6-9 TURNTABLE TRAY

6- 8 OPERATION MANUAL

6-4 TURNTABLE SUPPORT

TRAY PACK

SPADFA389WRE0

INTO THE

OVEN CAVITY

Page 16

14

R-490C(S)

'99SHARP CORP. (09S0.720E) Printed in Australia

Loading...

Loading...