Page 1

SERVICE MANUAL

THERMAL PRINTER

MODEL PR-45M

PR-45M : MANUAL CUTTER

CONTENTS

CHAPTER 1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

CHAPTER 2. OUTLINE OF DRIVING CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . 3

CHAPTER 3. HANDLING THE PRINTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

CHAPTER 4. MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

CHAPTER 5. TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

CHAPTER 6. DISASSEMBLY AND ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . 12

CHAPTER 7. PWB LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

PARTS GUIDE (Ki-OB2359BHZZ)

APPLICATION MODEL (As of Dec.)

ER-A455X Series, ER-A450/A450S ("V" Version), ER-A450T ("U" and "A" Version)

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

CHAPTER 1. SPECIFICATIONS

2. Specifications

1) Printer

Item Description

No. of station 2: Receipt and Journal

Validation No

Printing system Line thermal

No. of dot Receipt: 288 dots

Journal 288 dots

Dot pitch Horizontal: 0.125 mm

Vertical: 0.125 mm

Font 10 dots (W) × 24 dots (H)

Printing capacity Receipt: Max. 24 characters

Journal: Max. 24 characters

Character size 1.25 mm (W) × 3.0 mm (H): At 10 × 24 dots

Print pitch Column distance: 1.5 mm

Row distance: 3.75 mm

Paper feed speed Approximate 50 mm/s

Reliability Mechanism: MCBF 5 million lines

Thermal head: 5 million pulses

Paper end sensor Yes (Receipt and Journal)

Cutter Manual

Paper near end sensor No

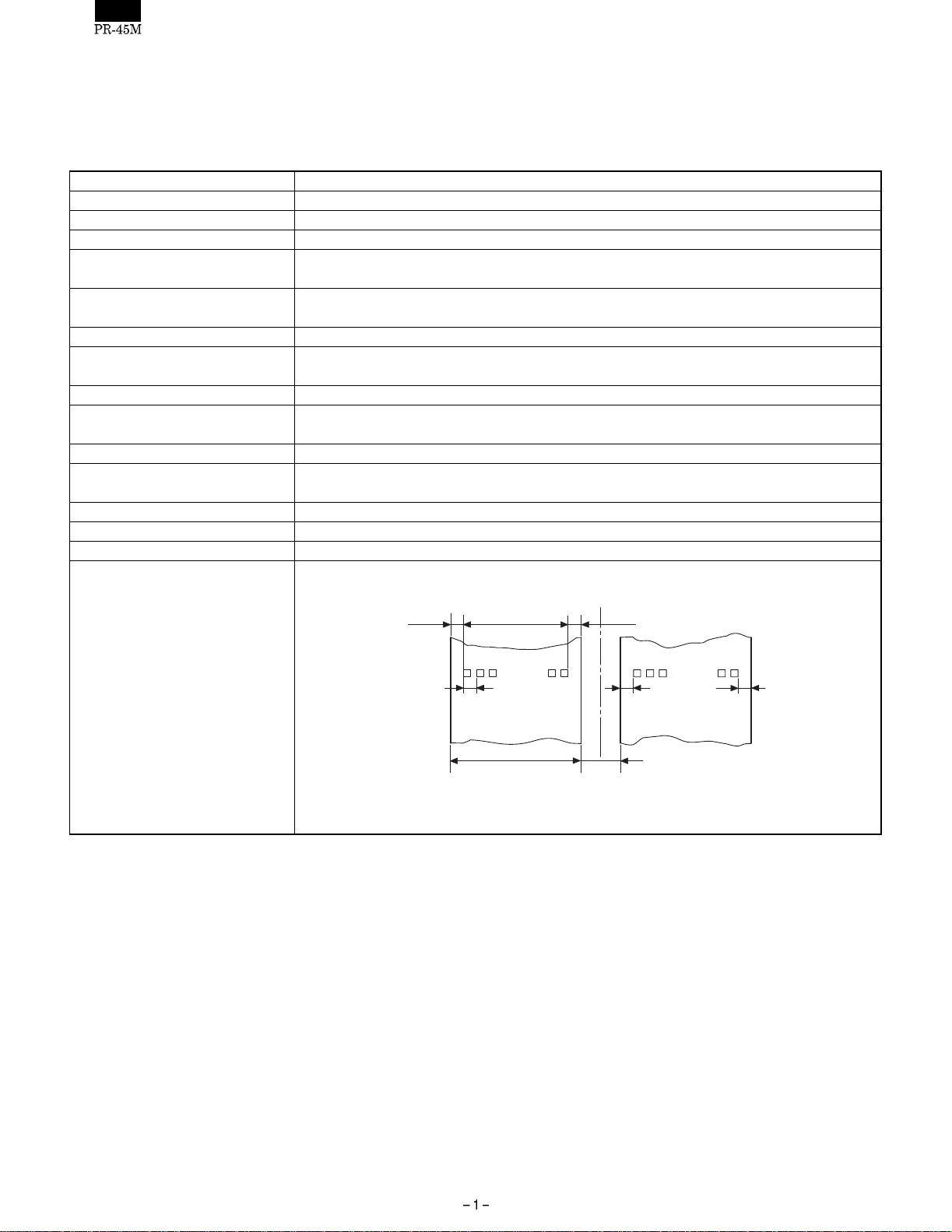

Printing area

(4.5) (4)

0.125

288dots

(36)

44.5 ±0.5

3.0

(4)

(4.5)

UNIT: mm

Page 3

Item Description

Printing format 12 × 24 font

1.5 (12dots) 1.5 (12dots)

0.125

0.125

3.0 (24dots)

3.75 (30dots)

2) Tools required for maintenance and repair

For NAME Remarks

Mainrenance Cleaning brush

Cotton swab

Clean cloth

Alcoholic solvent Ethanol, Methanol, IPA

Cleaning brush

Repair (+) Screwdriver

(-) Screwdriver

Tweezers

Pliers

Nippers

Soldering iron

ET holder

Grease : G-36 00BB703600001

Cleaning brush

Cotton swab

Clean cloth

Alcoholic solvent Ethanol, Methanol, IPA

Cleaning brush

3.75 (30dots)

UNIT: mm

Page 4

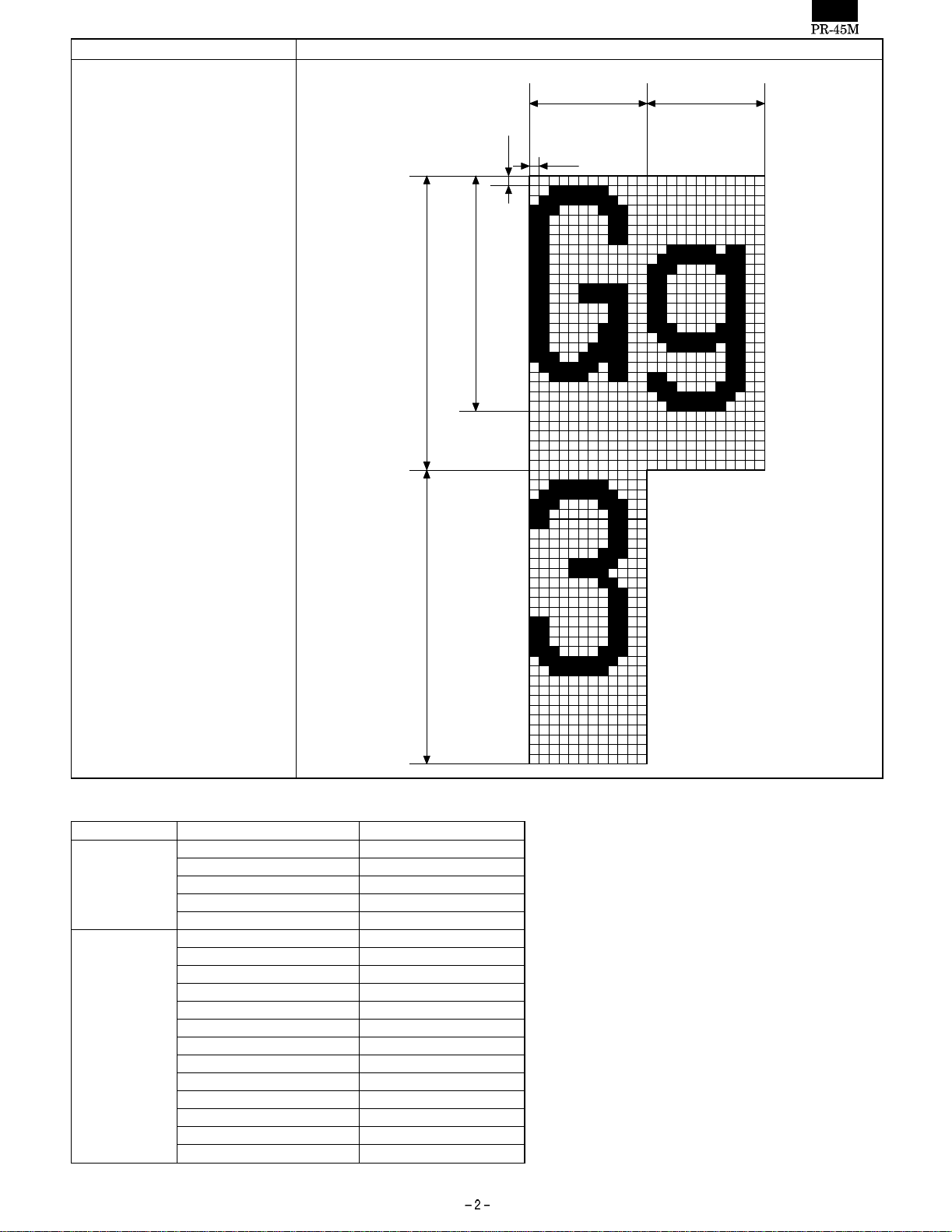

CHAPTER 2. OUTLINE OF DRIVING

CIRCUIT

1. Block diagram & Connection diagram

1) Block diagram

CON2(9P)

FOR ECR PWB

Signal

GND

Pin

No.

2

5

8

Pin

No.

PWB UNIT

CON1(40P)

Pin

No.

15

Signal

VH

/LAT

GND

Signal

CON3(9P)

TM

Signal

CON7(6P)

CON5(2P)

Non-paper

detection

sensor(R)

Pin

No.

3

6

9

Pin

No.

Pin

No.

16

Dout

/STB3

GND

6

HEAD UP

SENSOR

Signal

VDD

(+5V)

Signal

Signal

MOTOR

CON6(6P)

J

6

MOTOR

CON4(4P)

Non-paper

detection

sensor(J)

FOR THERMAL HEAD FOR THERMAL HEAD

2) Connector table

Connect to the ECR PWB

CON1: <For ECR PWB>

PinNo. Signal

1VHIN 2NC 3NC 4NC

5 VJCOM 6 VJPFD 7 /JPFA 8 /JPFB

9 /JPFC 10 /JPFD 11 /JPES 12 GND

GND

13

17 /STB4 18 /STB3 19 Din 20 VH

21 VH 22 VH 23 VH 24 Dout

25 CLK 26 /LAT 27 /STB2 28 /STB1

29 GND 30 GND 31 GND 32 /RPES

33 VRCOM 34 VRCOM 35 /RPFA 36 /RPFB

37 /RPFC 38 /RPFD 39 PHUPS 40 VHOUT

CON2: <For Thermal head connector A>

Pin

No.

1VH

4 CLK

7 /STB1

CON3: <For Thermal head connector B>

Pin

No.

1GND 2GND 3NC

4 TM 5 VDD (+5V) 6 /STB4

7/STB3 8Din 9VH

10 VH

CON4: Not used

Pin

No.

14

Signal

Signal

CON5: <For Head up detector>

Pin

No.

Signal

Pin

No.

Signal

1 PHUPS 2 GND-L

CON6: <For Journal paper feed motor>

Pin

No.

Signal

Pin

No.

Signal

Pin

No.

Signal

1VJCOM 2VJCOM 3/JPFA

4/JPFB 5/JPFC 6/JPFD

CON7: <For Receipt paper feed motor>

R

Pin

No.

Signal

Pin

No.

Signal

Pin

No.

Signal

1 VRCOM 2 VRCOM 3 /RPFA

4/RPFB 5/RPFC 6/RPFD

3) Thermal head block diagram

DOT #864

8, 9

VH

DI

TM

Connector B

1, 2

5

6

7

4

3

4 3

THERMISTOR

LATCH REGISTER

SHIFT REGISTER

The STB terminal is pulled

in the IC.

GND

STB4

STB3

VDD

Thermal head connector A

Pin No. Signal Description

1

VH Head application voltage

2

3 D out Data output signal

4 CLK Clock signal

5 /LAT Latch Signal

6 /STB2 Strobe Signal 2

7 /STB1 Strobe Signal 1

8

GND GND

9

Thermal head connector B

Pin No. Signal Description

1

GND GND

2

3 TM Thermistor detecting signal

4VDD +5V

5 /STB4 Strobe Signal 4

6 /STB3 Strobe Signal 3

7 D in Data input signal

8

VH Head application voltage

9

Print data which has been entered through Din signal synchronization

with the CLOCK signal is stored in /LAT according to the timing (864

dots) of the /LATCH signal. Stored print data is output by the

/STROBE1, /STROBE2, /STROBE3, and /STROBE4 signals to energize the heating element. The print data (864 dots) is divided by four

STROBE signals into the following four parts before being output.

DOT #1

12

1, 2

8, 9

7

6

5

3

4

Connector A

VH

GND

STB1

STB2

LAT

DO

CLK

Page 5

STROBE No. DOT No. Dots/ Strobe Note

/STROBE4 577 ∼ 864 288 Excluding dots No.1 ∼ 88,

/STROBE3 433 ∼ 576 144

/STROBE2 289 ∼ 432 144

/STROBE1 1 ∼ 288 288

377 ∼ 488 and 777 ∼ 864

4) Motor block diagram

stepping motor

/RPFA, /JPFA

/RPFB, /JPFB

/RPFC, /JPFC

/RPFD, /JPFD

VRCOM, VJCOM

VRCOM, VJCOM

<JOURNAL MOTOR>

PIN

SIGNAL

No.

<RECEIPT MOTOR>

PIN

No.

The paper feed motors are stepping motors with 4-phase driving

coils. The motors are driven by switching over the driving coils.

<MOTOR DRIVE SEQUENCE> ON: Energized/OFF: Not energized

JOURNAL MOTOR

STEP No. PHASE A PHASE B PHASE C PHASE D

NAME

1

VJCOM COMMON voltage

2

3/JPFA

4/JPFB

5/JPFC

6/JPFD

SIGNAL

NAME

1

VRCOM COMMON voltage

2

3/RPFA

4/RPFB

5/RPFC

6/RPFD

1ONOFFOFFON

2ONOFFONOFF

3 OFF ON ON OFF

4OFFONOFFON

JOURNAL-side paper feed motor phase A

driving signal

JOURNAL-side paper feed motor phase B

driving signal

JOURNAL-side paper feed motor phase C

driving signal

JOURNAL-side paper feed motor phase D

driving signal

RECEIPT-side paper feed motor phase A

driving signal

RECEIPT-side paper feed motor phase B

driving signal

RECEIPT-side paper feed motor phase C

driving signal

RECEIPT-side paper feed motor phase D

driving signal

DESCRIPTION

DESCRIPTION

C

D

AB

M

5) End sensor block diagram

reflex photo sensor

+5V

0.1µF

/RPES, /JPES

GND-L

SIGNAL NAME DESCRIPTION

+5V +5V

/RPES Receipt paper end sensor detecting signal

/JPES Journal paper end sensor detecting signal

GNDL GND

The photo diode on the PWB detects the presence/absence of the

paper passing under the journal and receipt platens.

3

2

4

1

39KΩ 220Ω

6) Head up sensor

micro switch

PHUPS

GND-L

SIGNAL NAME DESCRIPTION

PHUPS Head-up detecting signal

GNDL GND

The micro switch at the left side of the printer detects the head-up

state.

ON: Head-down

OFF: Head-up

RECEIPT MOTOR

STEP No. PHASE A PHASE B PHASE C PHASE D

1ONOFFONOFF

2ONOFFOFFON

3OFFONOFFON

4 OFF ON ON OFF

Page 6

CHAPTER 3. HANDLING THE

PRINTER

1 Special Handling Considerations

(1) When transporting the printer

•

When transporting the printer, the head up le ver should be raised

in the

B: Head up position so that the head does not contact the

platen rollers.

Failure to do so will may result in pear the printer performance.

• When the printer is carried, it should not be held at the connectors,

the lead wires, paper take-up frame, etc.

• When carrying the printer, never allow large impacts to occur, such

as by dropping, collision, etc.

• When carrying the printer, hold the frame with both hands, as

shown in the figure below.

:Head-up position

The head is not in contact with the platen roller.

When the printer is out of service for a long time or when it

is to be transported.

The illustration shows the state when the PT-cover is removed

for explanation purposes only.

Head

Platen roller

Fig. Carrying the printer unit

• When transporting the printer, pack it using anti-static packaging.

Do not touch the thermal head and the surface of the PWB. When

handling the printer, properly ground yourself.

Head up lever position

: Close position

The head is in contact with the platen roller

The printer operates and feeds the paper.

The illustration shows the state when the PT-cover is removed

for explanation purposes only.

(In contact)

Head

Platen roller

Head Up Lever

Head-up position

Fig.

H-Spring

: Cleaning position

When the head and platen roller are to be cleaned.

Do not leave the head-up lever in this position; Failure to do

so might result in a deformed H-spring, thus leading to poor

print or paper feed quality.

The illustration shows the state when the PT-cover is removed

for explanation purposes only.

Head

Platen roller

Head Up Lever

Fig.

Close position

H-Spring

Head Up Lever

Fig.

H-Spring

Cleaning position

Page 7

(2) When storing the printer

Printer

• When stori ng the printer, make sure to raise the head up lever

in the

position or

: Head up position. Never store it with the : Close

: Cleaning position.

• Avoid st oring the printer in areas with a lot of dust, direct sun-

light, or high humidity.

• I f the printer is stored for an extended period, put it in a anti-

static bag and store it in a dry place.

• The t hermal paper should not be left for an extended period

(more than two weeks at normal temperature) held between

the platen roller and the head (

: Close position).

• Do not leave the printer in the : Checking position for more

than 2 days.

Paper (thermal paper)

• Since t hermal paper gradually darkens from about 70°C, pay

attention to heat, humidity, sun light, etc., regardless whether or

not the paper has been printed on.

• Avoid high temperature and high humidity areas.

• Avoid direct sun light.

(When thermal paper is left near the window in direct sun

light, the base color may change and discoloring may take

place.)

(3) When using the printer

Printer

• Since t he printer contains a thermal head, permanent magnets

(motor) and micro switches, avoid using it in areas with a lot of

iron powder, dust, etc.

• Never operate with no paper loaded.

• Never pul l out the paper (forward or backward) with the head

head against the platen rollers.

• Do not touch the head heating elements and driver Ics, espe-

cially with hard or metal objects.

• Duri ng printing and just after printing completes (for about 15

minutes), the area around the head and the motor surface are

very hot. Never directly touch them with your hand.

• Operate the head up lever only when required.

Never touch the surface of the head heating elements.

(Dirt may stick to the heating elements and affect the printing.)

• Never leave the printer with the platen rollers and the head

directly touching (

Do not leave the head-up lever in the

more than 2 days.

(When the printer is left for a while, make sure to raise the head

up lever in the ➡

: Close position).

: Cleaning position for

: direction in Fig. Loading paper.)

• Since el ectronic parts are used in the print head, never touch

the thermal head with your bare hand.

Before handling the printer, execute proper body grounding

procedures to avoid static electricity.

Paper (thermal paper)

• Use only the specified thermal paper.

(Thermal paper with a rough surface may result in poor printer

quality and shorten the print head life.)

(4) When mounting the printer

•

Make sure the power is turned OFF before installing the printer to

an ECR.

• When att aching the printer to your product, avoid areas with a lot

of iron powder, dust, etc.

2. Loading the Paper (insertion and

removal)

Use only the paper specified in the specification sheet issued by our

company.

(1) Loading paper

Load paper following the procedure below.

Cut the edge of the paper as shown in the figure below.

Good WrongGood Wrong

Fig. Shape of the cut paper edge

Good Bad

Fig. Paper setting state

Recording paper

B

C

Fig. Loading paper

Turn the ECR ON.

Make sure the head-up lever in the (Close) position.

Insert the paper through the paper inlet.

The paper is automatically loaded into the printer by the auto

loading mechanism and the leading edge of the paper roll is delivered a little from the paper outlet.

If there is slackness in the paper or paper is loaded slantly, set the

head up lever in the head up position

position.

If the length of the paper delivered from the outlet is insufficient,

feed the paper properly with the key board of the ECR.

(Notes) If paper is fed without following the above procedure, it

could cause improper paper feeding and jamming.

Head up lever

A

and adjust the paper

Page 8

(2) Unloading the paper

The paper can be unloaded in two ways.

Move the head up lever toward : Head up position and then pull

the paper out by hand in the forward direction (feeding direction)

or in the reverse direction.

Operate the paper feed mechanism to discharge the paper from

the printer. Move the head up lever to the head up position

remove the paper toward the front.

• Operations other than those listed above could cause im-

(Notes)

proper paper feeding and jamming, and could cause

breaking of the head heating elements.

and

• Never pull the paper out without using the head up lever,

regardless of the direction, forward or reverse.

(3) Removing paper after a paper jam

If a paper jam occurs, follow the procedure below.

Put the head-up lever in the Cleaning position to widen the

spacing between the head and platen rollers so that you can

easily check for a paper jam.

Remove a jammed paper by hand.

Return the head-up lever in the Close position.

When a tool such as tweezers, is used to remove paper chips, take

care not to touch the heating elements of the head with the tool.

Since the head is still hot just after the operation printing is stopped,

wait a while for the head to cool down.

CHAPTER 4. MAINTENANCE

2. Inspection

The maintenance and inspection items for the printer are dividend

into 2 types. One is "Daily checks" for the person who uses the

printer, and the other is "Periodic checks" for someone with more

technical knowledge. Maintenance and inspections should be carried

out by properly qualified personnel.

(1) Daily checks

Check that the printer is used properly and kept in the good repair.

Daily check items

The specified paper is being used.

The paper has not become discolored.

Check print quality and if significant deterioration is found, clean

the head heating elements.

<Head cleaning method>

1) Place the head-up lever in the

is securely lock ed .

2) Wipe the heating element of the head and platen rollers clean with

a soft cloth or cotton pledget moistened with alcoholic solvent

(ethanol, methanol or IPA: isopropyl alcohol).

3) After making sure the alcoholic solvent has thoroughly evaporated, undo the head-up lever and platen rollers in t he

position.

If paper dust is attached to the platen roller surface, the paper

feeding power is reduced. Be sure to clean the platen roller surface when cleaning the head.

The illustration shows the state when the PT-cover is removed for

explanation purposes only.

: Cleaning position. Make sure it

Close

Thermal head unit

To maintain proper performance of the printer for a long period of

time and to prevent trouble, carry out the maintenance and management procedures as follows.

1. Cleaning

• Removing stains

Wipe dirt off the head and platen rollers with a clean cloth saturated with an alcoholic solvent (ethanol, met hanol, IPA: Isopropyl

alcohol).

For cleaning the head part, refer to daily checks.

(Notes) Never use thinner, benzine, trichlene or ketone group sol-

vents, since they may damage or deteriorate rubber and

plastic parts.

• Removing dust and fuzz

Cleaning by suction (with a vacuum cleaner) is desirable.

Suck up all the dust and fuzz.

(Notes) Check lubrication at various points after cleaning, and lubri-

cate with oil at the specified locations.

Cotton swab

Fig. Head and Platen roller cleaning

Platen roller

Page 9

(2) Periodic checks

Check the items listed in the table below every 6 months, and correct

any problems.

Table of periodic checks

No. Check items Standard Procedure

1 Dust, fuzz and dirt

sticking to various

parts.

2 Lubrication • See "Chapter 6". • Refer to "Chapter 6" For lubrication.

3 Operational check • Printing is operated without abnormality. • See "Chapter 5".

• The mechanism should not have a lot of dirt, fuzz or dust on its

surface. Foreign substances should not be allowed to collect.

• The paper guide should not be clogged with paper chips, etc. • Remove paper chips with a tweezers.

• Feeding operated without abnormality.

• Observe respective functions. Abnormal operation caused by parts

wear, deformation, bending, etc., do not exist.

• Clean the unit with a vacuum cleaner.

• See "Chapter 5" and "Chapter 6".

CHAPTER 5. TROUBLESHOOTING

Troubleshooting and repair of the printer is classified into two levels

(A and B), depending on the difficulty of the repair.

Persons undertaking a repair should consider their level of technical

skill and the level of the repair before attempting to ensure that the

trouble is handled correctly.

1. Repair Levels

Level A: This requires general knowledge about the operating princi-

ples and structure of the printer, along wi th technical skill

and minimum experience.

Level B: This requires full knowledge of the operating principles and

structure of the printer, adequate technical skill, and repair

experience.

3. Repair Guidelines

2. Repair Procedures

If trouble occurs, observe the symptoms, determine the cause by

referring to Section 3 "Repair Guidelines," and repair it. The "Repair

Guidelines" are divided into the following five columns so that any

trouble can be analyzed and a solution found.

• Problem

Check for symptoms.

• Condition

Compare the problem with the examples given i n this column and

determine if they match.

• Cause

Causes that can be assumed for the problem are listed.

Determine the cause. Also, refer to the repair level indicated for

each cause.

• Checkpoints and Checking Method

How to check for the cause of a problem is listed. Check the

defective part as instructed in this column.

• Repair Method

Repair the defective part as instructed in this column. If the same

problem occurs after the repair, check the other causes in the

"Cause" column again, and repair accordingly.

Phenomenon Condition Cause Level

1. Printing is

not executed.

Nothing is

printed.

(1) The Head cable is

disconnected.

(2) The common or signal line of

the Head cable is broken.

(3) The printhead does not

contact the platens.

(4) The input pulse is defective B • Verify with the oscilloscope

Checkpoints and

Checking Method

A • Verify that the Head cable

is properly connected.

B • Check the common and

signal lines of the Head

cable for continuity.

A • Verify that the head up

lever is set to the proper

position.

that the input pulse is

within the specified range.

Repair Method

• If the FFC-head is not

properly connected,

connect it firmly.

• If continuity cannot be

confirmed, replace the

Head cable.

• Set the head up lever to

the printing position.

• If the input pulse is not

generated or is not within

the specified range, adjust

the drive control circuit.

Page 10

Phenomenon Condition Cause Level

2. Dots are

missing

continuously.

A specific dot is

not printed.

(1) A foreign substance is

attached to the heating

elements of the printhead.

(2) The heating elements of the

printhead are damaged.

(3) The signal line of the Head

cable is broken.

(4) The input pulse is defective. A • See Cause (4) of Phenomenon 1.

3. Dots are

missing

occasionally.

Dots are

missing

occasionally or

the color of

some dots

becomes light.

(1) A foreign substance is

attached to the surface of

each platen roller.

(2) The surface of each platen

roller is deformed.

(3) A foreign substance is

attached to the heating

elements of the printhead.

(4) The heating elements of the

printhead are damaged.

4. The printing

color is light.

The overall

printing color is

(1) The head up lever position is

not correct.

light.

(2) Displaced or deformed

H-springs.

(3) The H/C frame is warped. B • Verify that the H/C frame is

(4) The surface of the platen is

deformed.

(5) The heating elements of the

printhead have deteriorated.

(6) The input pulse is defective. A • See Cause (4) of Phenomenon 1.

(7) The roll paper is of poor

quality.

5. Paper

cannot be

loaded.

The end of the

roll paper

cannot be

(1) The leading edge of paper roll

is improperly cut .

inserted into the

paper guide

section.

(2) A piece of paper is blocking

the paper guide path.

Checkpoints and

Checking Method

A • Verify that nothing is

• Clean the heating elements

attached to the heating

elements of the printhead.

B • Verify that the heating

• If the heating elements are

elements of the printhead

are not damaged.

B • See Cause (2) of Phenomemon 1.

A • Verify that nothing is

• Clean the surface of each

attached to the surface of

each platen roller.

A • Verify that the surface of

• If deformation is found,

each platen roller is not

deformed.

A • See Cause (1) of Phenomenon 2.

B • See Cause (2) of Phenomenon 2.

A • Verify that the head up

• Set the head up lever to

lever is set to the correct

position.

A • Make sure the H-springs

• If they are not correctly

are correctly installed and

not deformed.

• If the H/C frame is warped,

not warped.

A • See Cause (2) of Phenomenon 3.

B • Verify that the heating

• If any deterioration is

elements of the printhead

have not deteriorated.

A • Verify that the specified-roll

• Use the specified quality

paper is being used.

• Check the paper for proper

color development and

excessive dust.

A • Check that the leading

• If the leading edge of the

edge of the paper roll is

properly cut and is not

folded.

A • Verify that no piece of

• Remove the paper.

paper is blocking the paper

path.

Repair Method

of the printhead.

damaged, replace the

thermal head.

platen roller.

replace the corresponding

platen roller ass’y.

the printing position.

installed, reinstall properly.

Replace any deformed

H-spring with a new one.

replace the head mounting

deck ass’y.

found, replace the thermal

head.

paper.

paper roll is improperly cut,

cut it properly and insert

into the printer again.

Note:

When removing the piece

of paper be sure not to

damage the printhead and

platen roller with any tools.

Page 11

Phenomenon Condition Cause Level

6. Paper is not

fed.

Roll paper is not

fed, and printing

(1) Roll paper feeding is

defective.

is repeated on

the same line.

(2) A foreign substance is

attached to part of the power

transmission mechanism unit,

or any of the gears in the unit

are damaged.

(3) The paper feed motor is

damaged.

(4) The paper feed motor drive

signal is defective.

7. The paper

feed pitch is

The line spacing

is not uniform.

(1) Roll paper is not being fed

correctly.

not uniform.

(2) The feeding load of a paper

roll exceeds the specification.

(3) Paper is jammed in the paper

guide.

(4) The paper feed motor drive

signal is defective.

(5) The head up lever position is

not correct.

8. Paper end

detection is

not corrected.

Although paper

exists in the

paper guide

(1) The paper end detector is

defective.

path, the out-ofpaper state

continues.

When paper is

removed from

the paper guide

path, the printer

does not enter

the out-of-paper

(1) A piece of paper or foreign

substance is blocking the

paper path.

(2) The paper end detector is

defective.

state.

Checkpoints and

Checking Method

A • Verify that the specified roll

• Use the specified roll paper.

paper (width, thickness,

and diameter) is being

used.

• Verify that the roll paper is

• Load the roll paper

loaded properly in the

paper supplying device.

B • Verify that no foreign

• Tension: ≤50g-cm

• If any foreign matter is

matter attached to any part

of the power transmission

mechanism unit and that

• If any of the gears are

no gears are damaged.

B • Check the resistance at

• If any abnormality is found,

each coil of the

corresponding paper feed

motor

Resistance: Approx.

Resistance:90Ω±10%

B • Verify that the

• If the drive signal is not

corresponding paper feed

motor drive signal is

normal.

A • See Cause (1) of

Phenomenon 6.

• Check the platen roller for

• If deformed, replace the

deformation.

A • See Cause (2) of

Phenomenon 6.

• The paper roll isn’t set

• Reset the paper roll properly.

properly.

• The paper roll doesn’t meet

• Use a paper roll which

the specification in size.

B • Paper is jammed in the

• Remove paper. At this

paper guide.

B • See Cause (4) of Phenomenon 6.

A • See Cause (1) of Phenomenon 4.

B • Check the signal level on

• If the signal level is

the paper end detection

circuit board.

B • Verify that nothing is

• If anything is blocking the

blocking the paper path.

B • See Cause (1) of Phenomenon 8.

Repair Method

correctly.

attached, remove it.

damaged, replace them.

replace the paper feed

motor.

output or is not within the

specified range, adjust the

drive circuit.

platen roller with a new one.

meets the specification in

size.

time, use caution to

prevent damage to the

platen roller.

abnormal, replace the

paper guide ass’y.

paper path, remove it.

Page 12

Phenomenon Condition Cause Level

9. Roll paper is

not taken up.

Roll paper is fed

but not taken up.

(1) The paper take up shaft is

worn or damaged.

(2) SP gear, C-spring or pulley is

worn or doesn’t rotate

smoothly.

(3) Some of the gear teeth are

worn or damaged.

(4) The paper take up belt is worn

or stretched.

10. Paper

cannot be

taken up

properly.

Because the

tension to take

up the roll paper

is weak, the

diameter of the

paper taken up

becomes larger.

(1) The paper take up shaft is

worn or damaged.

(2) SP gear, C-spring or pulley is

worn or doesn’t rotate

smoothly.

(3) Paper roll swerves. B • Verify that the paper take

(4) Some of the gear teeth are

worn or damaged.

(5) The paper take up belt is worn

or stretched.

Checkpoints and

Checking Method

B • Verify that the paper take

up shaft is not worn or

damaged.

B • Check paper winding parts

for wear and damage.

Repair Method

• If any wear or damage is

found, replace the paper

take up shaft.

• If wear or damage is found,

replace the part with a new

one.

B • Verify that no teeth are

worn or damaged.

• If any of the gear teeth are

worn or damaged, replace

the gear.

B • Verify that the paper take

up belt is not worn or

stretched.

• If the paper take up belt is

worn or stretched, replace

it.

B • See Cause (1) of Phenomenon 9.

B • Replace SP gear, C-spring or pulley with new one.

• If any deformation or warp

up frame sub ass’y is not

deformed or warped.

is found, replace the paper

take up frame sub ass’y.

B • See Cause (3) of Phenomenon 9.

B • See Cause (4) of Phenomenon 9.

Page 13

CHAPTER 6 DISASSEMBLY AND ASSEMBLY

• This chapter mainly outlines the procedure for disassembling the

printer. It is advisable to reinstall the printer in the reverse order

from disassembly, referring to "Cautions t o be taken when installing."

• Some easy steps have been omitted.

• Only part names are described without indicating their part codes.

For the part codes, refer to the Parts Guide.

[Cautions to be taken when working on the printer]

1) The parts which need to be greased are indicated in "Cautions to

be taken when reinstalling." Whenever such a part is replaced

with a new one, grease it before installing.

1 REMOVE THE CUTTER45 and

H-COVER45

1

Lubrication interval (rough guide)

• Every 6 months

• Every 2 years or 2,000,000 lines of printing

• Part s code of lubricant

Lubricant type PARTS CODE PRICE RANK

G36 00BB703600001 AU

2) Use caution not to have the gear chipped or deformed when

removing or reinstalling.

3) Do not touch directly the printing head.

4) Be sure to wear an earth band to ground your body.

[PARTS LIST]

No. PARTS NAME Q’ty

CUTTER45

H-COVER45

SCREW (M2×8)

CAUTION LABEL

1

1

3

1

3

4

2

Fig. 1

[DISASSEMBLY METHOD]

1) Remove the CUTTER45 and H-COVER45 :

Using a Phillips screwdriver, remove the three SCREWs

Remove the CUTTER45

The H-COVER45

and H-COVER45 .

carries the "CAUTION" label .

.

Page 14

2 REMOVE THE MANUAL CUTTER

3

2

[DISASSEMBLY METHOD]

1) Remove the G-COVER45

Using a screwdriver, raise the two tabs of the G-COVER45

and remove the G-COVER45 from the PRINTER FRAME45

.

1

Fig. 2

4

[PARTS LIST]

No. PARTS NAME Q’ty

PRINTER FRAME45

G-COVER45

SCREW (M2 × 8)

PT-COVER

2) Remove the SCREWs

Insert a flat-bladed screwdriver into the slit shown in the fig-

ure below.

Apply force into the direction indicated by the arrow, to raise

the tang and pull out the PT-COVER upward.

. Remove the PT-COVER .

1

1

3

1

Along the right side in the slit,

(A)

2

Fig. 3

1

Insert a screwdriver (-) here.

PT-COVER

Fig. 4

Page 15

3 REMOVE THE HEAD UNIT

1

E

5

4

6

4

A

1

E

A

2

[PARTS LIST]

No. PARTS NAME Q’ty

H-SPRING

HEAD UP LEVER

E-RING

SCREW (M3 × 6)

THERMAL HEAD

H/C FRAME

Use caution not to touch the heating element of the HEAD

and PWB.

2

1

1

2

1

1

3

Fig. 5

[DISASSEMBLY METHOD]

1) Remove the H-SPRINGs on the right and left sides of the

printer frame.

<Note> Pinch the H-SPRING at point E with long-nose pliers

2) Remove the HEAD UP LEVER

3) Remove the E-RING

4) Remove the H/C FRAME UNIT (Part of the assembly of the

THERMAL HEAD

<Note> Use caution not to damage or deform the H/C FRAME

5) Remove the two SCREWs

and remove it taking care not to deform the rib of the

HOUSING A.

H-spring

Pinch here with long-nose pliers.

Fig. 6

.

.

and H/C FRAME ).

UNIT by inadvertently hitting them with the ROLLERs

and gears.

and remove the THERMAL HEAD

from the H/C FRAME .

[GREASING]

Apply grease on the two mounting areas A of the H/C FRAME .

Page 16

[Cautions to be taken when reinstalling]

1. Adju sti ng the HEAD position

Whenever the THERMAL HEAD

adjust its position for the H/C FRAME

is replaced with a new one,

.

• Procedure:

1) The screw hole for fixing the HEAD

is made a slot as shown in the figure below. First, align

the screw hole in the HEAD

slot and temporarily secure it with the SCREW

2) Install the H/C FRAME UNIT

3) Adjust the HEAD position and make sure that heating

element of the HEAD

performing a printing test. Do not adjust the Head position

during printing; otherwise the HEAD might break down

due to friction.

<Procedure for adjusting HEAD position>

(1) Insert a flat-bladed screwdriver into the adjustment

hole C in the H/C FRAME

ward little by little with the screwdriver until it reaches

the desired position, and secure it with the SCREW

(tightening torque: 6.5 kgf-cm).

2. Direction of H-SPRING

Install the H-SPRINGs so that the hooks point outward.

1

is most properly positioned, by

in the H/C FRAME

with the bottom area of the

on the HOUSING .

. Adjust the HEAD up-

3. HEAD cable

Install the 9-pin connector to the right end of the THERMAL

HEAD

Use caution to make a good connection or a deformed connector when connecting the THERMAL HEAD

bles.

.

4. Installing HEAD UP LEVER and H-SPRING ("J" side)

and the 10-pin connector to the left end.

4

6

The number of pins on the

PWB unit:10P

The number of pins on the

PWB unit:9P

Fig. 8

1)

and HEAD ca-

5

4

H/C frame unit

H-SPRING ("J" side)

2

1

1

Fig. 7

2)

2

3

1

3)

Fig. 9

Page 17

4 REMOVE THE PLATEN ROLLER

5

6

1

2

3

Fig. 10

4

3

2

1

[DISASSEMBLY METHOD]

1) Remove the E-RING and the PF-GEAR .

2) Remove the E-RINGs (for bushing)

.

3) Remove the PLATEN ROLLER "J"

and the PT-HOLDER .

. Remove the BUSHINGs

, PLATEN ROLLER "R"

[Cautions to be taken when reinstalling]

1. How t o tell PLATEN ROLLER "J" fr om PLATEN ROLLER "R"

As shown in the figure below, the PLATEN ROLLER "J" has

a black line on it.

The two PLATEN ROLLERs have different polishing directions

of the rubber roller. Pay attention to the direction when installing

them.

( PLATEN ROLLER "J" )( PLATEN ROLLER "R" )

[PARTS LIST]

No. PARTS NAME Q’ty

E-RING

PF-GEAR

BUSHING

PLATEN ROLLER "J"

PLATEN ROLLER "R"

PT-HOLDER

E-RINGs (for bushing)

2. LUBRICATIONS

Apply grease on the PLATEN ROLLER "J"

ROLLER "R"

below.

( PLATEN ROLLER "R" )

( PLATEN ROLLER "J" )

, and PT-HOLDER in the points indicated

( PT-HOLDER )

4

4

Apply grease (G36)

on the

PLATEN HOLDER

shaft, 4 mm in width.

2

2

2

1

1

1

2

, PLATEN

Apply grease (G36)

inside the bushing.

without black line with black line

Fig. 11

Fig. 12

Page 18

5 REMOVE THE GEARS

5

Fig. 13

[PARTS LIST]

11

10

9

8

4

3

1

2

No. PARTS NAME Q’ty

IDLE GEAR-L

SCREW (M3 × 5)

WASHER

TIMING BELT

PULLEY GEAR

SPOOL UNIT

SCREW (M2×6)

PULLY

C-SPRING

SP-GEAR

IDLE GEAR-S

2

4

1

1

1

1

1

1

1

1

1

[DISASSEMBLY METHOD]

<RIGHT SIDE>

1) Remove the IDLE GEAR-L

2) Remove the SCREW

3) Remove the TIMING BELT

4) Remove the PULLEY GEAR

5) Remove the SCREW

<LEFT SIDE>

1) Remove the IDLE GEAR-L

<SPOOL UNIT>

1) Remove the E-RING

2) Remove the PULLEY

IDLE GEAR-S

and WASHER .

.

.

, C-SPRING , SP-GEAR and

.

[Cautions to be taken when reinstalling]

1. Please note the posi tion of the WASHER when securing the

.

.

.

.

WASHER

PULLEY

GEAR

The PRINTER

FRAME 45's shaft

2. LUBRICATIONS

Apply grease (G-36) on the IDLE GEAR-L

, SP-GEAR , and PRINTER FRAME (45) in the areas

indicated below.

( IDLE GEAR-L )

Apply grease on the gear teeth

contact and inside the shaft hole.

to with the SCREW .

SCREW

WASHER

Fig. 14

SCREW

WASHER

, PULLEY GEAR

( PULLY GEAR )

Apply grease inside the

gear shaft hole.

Apply grease on the gear shaft

and inside the shaft hole.

Apply grease

sufficiently.

( PRINTER FRAME45 )( SP GEAR )

Apply grease on

the shafts.

Fig. 15

Page 19

6 REMOVE THE HARDWARE PARTS

1

3

5

5

5

[PARTS LIST]

No. PARTS NAME Q’ty

MICRO S/W UNIT

PWB UNIT

SCREW (M2 × 12)

MOTOR

SCREW (M3 × 6)

SCREW (M3 × 5)

1

1

1

2

4

1

2

4

6

4

Fig. 16

[DISASSEMBLY METHOD]

<MICRO SWITCH>

1) Remove the connector cable of the MICRO S/W UNIT from

the connector CON5 (2 pins) of the PWB UNIT

2) Remove the SCREW

and the MICRO S/W UNIT .

.

<JOURNAL SIDE MOTOR>

1) Remove the connector cable of t he MOTOR from the connector CON5 (6 pins) of the PWB UNIT

2) Remove the two SCREWs

and the MOTOR .

.

<RECEIPT SIDE MOTOR>

1) Remove the connector cable of t he MOTOR from the connector CON7 (6 pins) of the PWB UNIT

2) Remove the two SCREWs

and the MOTOR .

.

<PWB UNIT>

1) Remove the SCREW and the PWB UNIT .

[Cautions to be taken when reinstalling]

1. Wire the MICRO SWITCH UNIT cable as shown below.

Secure the MICRO S/W UNIT

ing torque: 4.0 kgf-cm).

3

2. Wire each cable as shown below.

Push the cables into the grooves.

Journal motor

cable

Twist the

cable.

with the SCREW (tighten-

Wire the MICRO SWITCH

cable as shown in the figure.

Fig. 17

Earth cable

Receipt motor cable

Twist the

cable.

CN2

CN6

CN3

CN7

CN5

Micro switch cable

Fig. 18

Page 20

7 REMOVE OTHER PARTS

1

Fig. 19

[DISASSEMBLY METHOD]

1) Remove the two FEED ROLLERs from the PRINTER

FRAME (45).

2) Remove the SCREW (M3×5)

3) Remove the STOPPER

2. LUBRICATION

Apply grease (G-36) on the mounting areas of the FEED ROLLER.

and remove the SP-GUIDE .

from the PRINTER FRAME (45).

2

3

4

[PARTS LIST]

No. PARTS NAME Q’ty

FEED ROLLER

SP-GUIDE

SCREW (M3×5)

STOPPER

2

1

1

1

Apply grease

Fig. 20

Page 21

8 GREASING POINTS WHEN

INSTALLING SPOOL

2

grease

grease

[PARTS LIST]

No. PARTS NAME Q’ty

1

SPOOL

G/WHEEL

1

1

Fig. 21

• Apply grease (G-36) in the points indicated in the figure.

1) Left end of the SPOOL

2) SP ANGLE in the area to which the right end of the SPOOL

is fitted.

Page 22

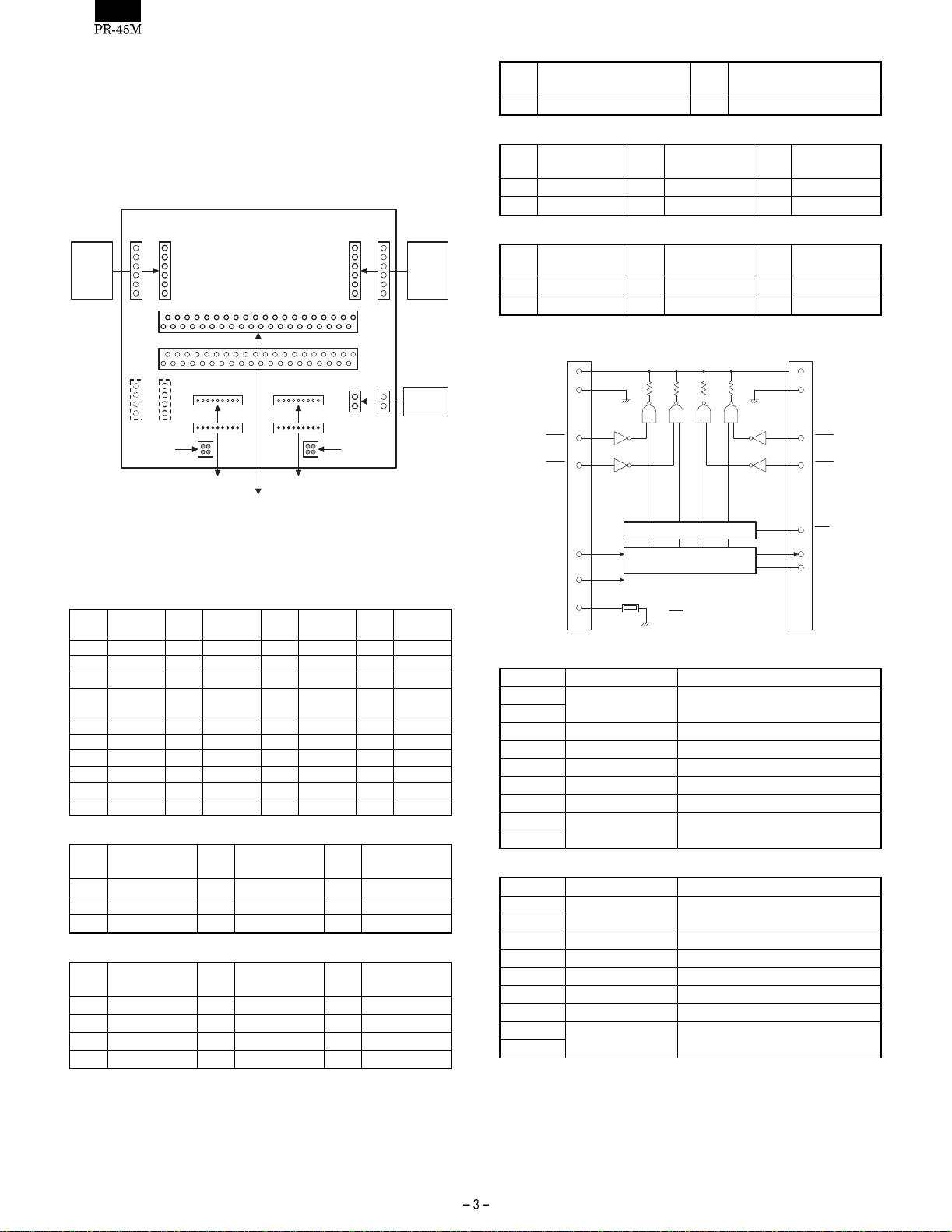

CHAPTER 7. PWB LAYOUT

CON6

16

1

CON4

1

6

C3

CON2

19

PD1

4

3

1

2

CON1

19

R1 R2 R3 R4

CON7

16

40

CON5

CON3

PD2

4

3

1

2

C1

R5

C21

1

2

Page 23

PR-45M

1 Exteriors

39

7

30

18

36

4

28

40

6

31

25

41

35

36

37

22

15

6

21

3

24

6

6

20

10

38

8

32

2

19

33

10

34

18

24

40

9

11

12

17

13

14

16

1

10

21

6

42

15

6

20

22

15

5

4

27

23

43

26

29

26

RCPS0216

– 1 –

Page 24

1 Exteriors

NO. PARTS CODE

LX-BZ6786BHZZ

1

GCOVH2467BHZZ

2

RHEDZ2003RCZZ

3

MSPRT6740BHZZ

4

LFRM-2352BHZZ

5

XBPSD30P06KS0

6

NGERH2317BHZZ

7

LFRM-2353BHZZ

8

NGERH6644BHZZ

9

LX-BZ6787BHZZ

10

NGERH6643BHZZ

11

MSPRD6741BHZZ

12

NBLTH6630RCZZ

13

NPLYB2325BHZZ

14

XRESJ25-04000

15

XWSSD60-05000

16

NGERH6645BHZZ

17

XBPSD30P06K00

18

MLEVP6715BHZZ

19

NGERH6641BHZZ

20

LBSHB6643BHZZ

21

NGERH6640BHZZ

22

MLEVP6711BHZZ

23

XRESJ60-08000

24

TCAUH6696BHZZ

25

RMOTS2319BHZZ

26

CPWBF2785BHZZ

27

QSW-M5048CHZZ

28

QCNW-7731BHZZ

29

XJBSD20P12000

30

GCOVH7146BHZZ

31

PGUMM2377RCZZ

32

LHLDR6832BHZZ

33

PGUMM2376RCZZ

34

GCOVH2468BHZZ

35

LX-BZ6785BHZZ

36

PCUT-2324BHZZ

37

PGIDM2393BHZZ

38

PGIDH2394BHZZ

39

QCNW-7904BHZZ

40

QCNW-7847BHZZ

41

QCNW-7846BHZZ

42

LBNDJ2003SCZZ

43

DUNTK4877BHZZ

101

PR-45M

PRICE

NEW

MARK

PART

RANK

RANK

AB C Screw (M2×5)

AM N E PT-cover

BF N B TH/head

AF C H/S spring

AX N D Head frame

AA C Screw (M3×6KS)

AR N C Spool

AS N D SP guide

AF C Idle gear-S

AB C Screw (M3×5)

AT C SP-gear

AF C C spring

AG C Timing belt

AF C Pulley

AA C E type ring (2.5mm)

AB C Washer

AF C Pulley gear

AA C Screw (M3×6K)

AF C Stopper

AE C Idle gear-L

AE N C Bushing

AE C PF gear

AG C Lever

AA C E type ring (6mm)

AD D Guide label

BC N B Motor

BC N E PWB unit

AH B Switch, cover

AE C Switch wire

AA C Screw (2×12)

AH N D G-cover 45

AN N C Platen roller J

AF C PT-holder

AN N C Platen roller R

AK N D H-cover 45

AB C Screw (M2×6)

AG N C Cutter 45

AF N C Feed roller

AK N C G/wheel

AE N C Eaerth wire

AT N C Head cable B (10pin)

AT N C Head cable A (9pin)

AA C Cable band (80mm)

AL E Micro s/w unit (include No.28,29)

DESCRIPTION

2 PWB unit

NO. PARTS CODE

QCNCM7207BH4J

1

QCNCM7176BH0I

2

QCNCM7176BH0J

3

QCNCM7176BH0F

4

QCNCM6865BH0B

5

VRD-RC2EY221J

6

VRD-RC2EY393J

7

VRD-RC2EY473J

8

VHPGP2S40J/-1

9

RC-KZ1054CCZZ

10

VCEAGU1HW106M

11

(Unit)

CPWBF2785BHZZ

901

PRICE

NEW

MARK

PART

RANK

RANK

AQ C Connector (40P)(6229ZiF DIP) [CON1]

AD C Connector (Key)(53014-0910) [CON2]

AQ N C Connector (10P)(53014-1010) [CON3]

AD N C Connector (6P)(53014-0610) [CON6]

AB C Connector (2P)(5267-02A) [CON5]

AA C Resistor (1/4W 220Ω ±5%) [R2,4]

AA C Resistor (1/4W 39KΩ ±5%) [R1,3]

AA C Resistor (1/4W 47KΩ ±5%) [R5]

AK B Photo sensor (GP2S40J) [PD1,2]

AB C Capacitor (50WV 0.1µF) [C2,3]

AB C Capacitor (50WV 10µF) [C1]

BC N E PWB unit

DESCRIPTION

– 2 –

Page 25

COPYRIGHT 2000 BY SHARP CORPORATION

All rights reserved.

Printed in Japan.

No part of this publication may be re produced,

stored in a retrieval system, or transmitted.

In any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise,

without prior wr itten permission of the publis her.

SHARP CORPORATION

Information Systems Group

Quality & Reliability Control Center

Yamatokoriyama, Nara 639-1103, Japan

2000 December Printed in Japan

Loading...

Loading...