Page 1

SERVICE MANUAL

■ LEAD-FREE SOLDER

MODEL

CONTENTS

CODE : 00Z

PN525USM/E

LCD MONITOR

PN-525U

CHAPTER 1. OUTLINE OF THE PRODUCT,

NOMENCLATURE AND FUNCTION . . . . . . . . . . . .1 - 1

CHAPTER 2. CONNECTION, ADJUSTMENT,

OPERATION, AND FUNCTION . . . . . . . . . . . . . . . .2 - 1

CHAPTER 3. DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . .3 - 1

CHAPTER 4. BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 1

CHAPTER 5. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . .5 - 1

CHAPTER 6. HARDWARE DESCRIPTIONS. . . . . . . . . . . . . . . . .6 - 1

CHAPTER 7. CIRCUIT DIAGRAM & PARTS LAYOUT . . . . . . . . .7 - 1

Parts marked with "!" are important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

■ LEAD-FREE SOLDER

The PWB’ s of this model employs lead-free solder. The “LF” marks indicated on the PWB’s and the Service Manual mean “Lead-Free” solder. The

alphabet following the LF mark shows the kind of lead-free solder.

Example:

<Solder composition code of lead-free solder>

Solder composition

Sn-Ag-Cu

Sn-Ag-Bi

Sn-Ag-Bi-Cu

Sn-Zn-Bi

Sn-In-Ag-Bi

Sn-Cu-Ni

Sn-Ag-Sb

Bi-Sn-Ag-P

Bi-Sn-Ag

5mm

Lead-Free

Solder composition

code (Refer to the

table at the right.)

a

(1) NOTE FOR THE USE OF LEAD-FREE SOLDER THREAD

When repairing a lead-free solder PWB, use lead-free solder thread. Never use conventional lead solder thread, which may cause a breakdown or an

accident.

Since the melting point of lead-free solder thread is about 40°C higher than that of conventional lead solder thread, the use of the exclusive-use soldering iron is recommendable.

Solder composition code

a

b

z

i

n

s

p

(2) NOTE FOR SOLDERING WORK

Since the melting point of lead-free solder is about 220°C, which is about 40°C higher than that of conventional lead solder, and its soldering capacity

is inferior to conventional one, it is apt to keep the soldering iron in contact with the PWB for longer time. This may cause land separation or may

exceed the heat-resistive temperature of components. Use enough care to separate the soldering iron from the PWB when completion of soldering is

confirmed.

Since lead-free solder includes a greater quantity of tin, the iron tip may corrode easily. Turn ON/OFF the soldering iron power frequently.

If different-kind solder remains on the soldering iron tip, it is melted together with lead-free solder. To avoid this, clean the soldering iron tip after completion of soldering work.

If the soldering iron tip is discolored black during soldering work, clean

and file the tip with steel wool or a fine filer.

PN-525U LEAD-FREE SOLDER

Page 3

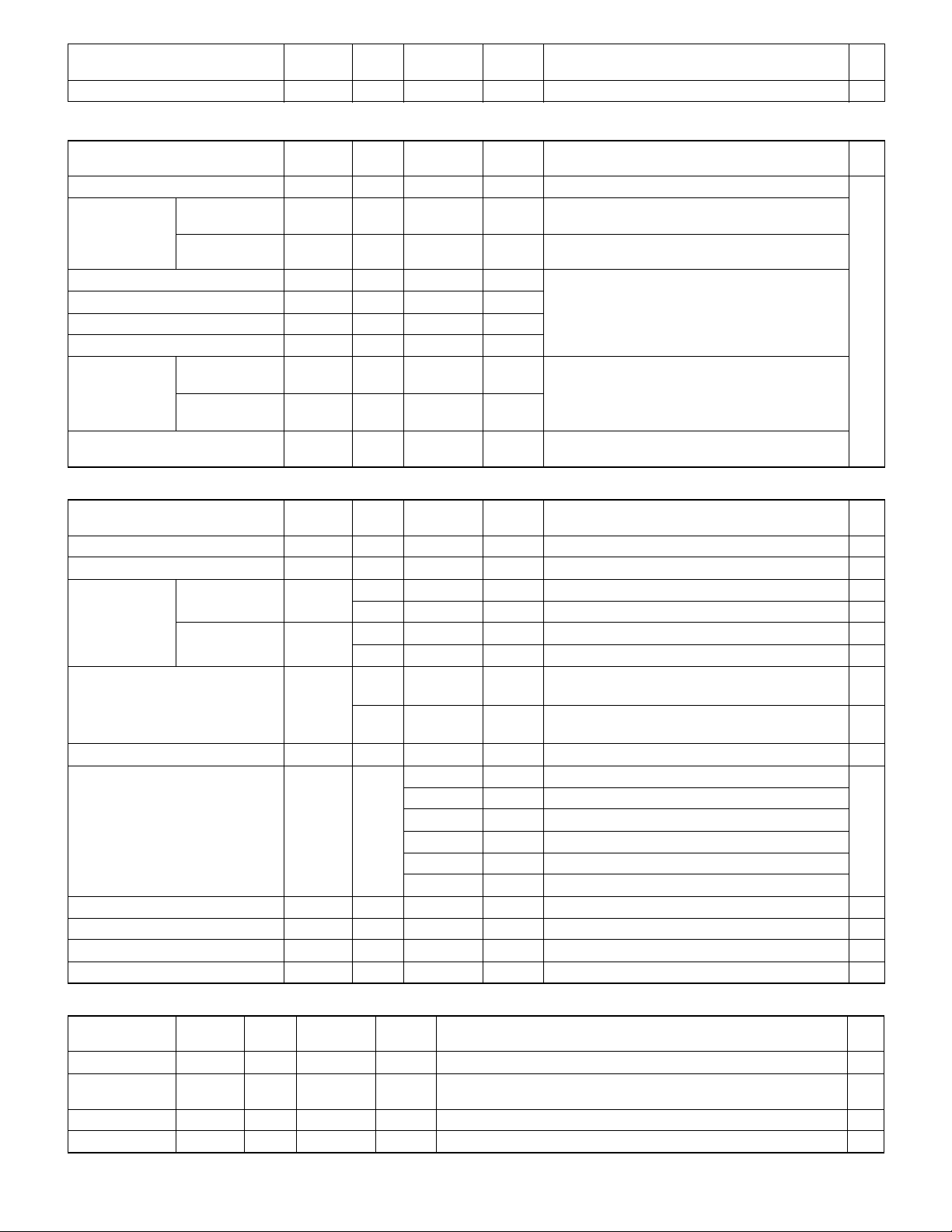

CHAPTER 1. OUTLINE OF THE PRODUCT, NOMENCLATURE AND FUNCTION

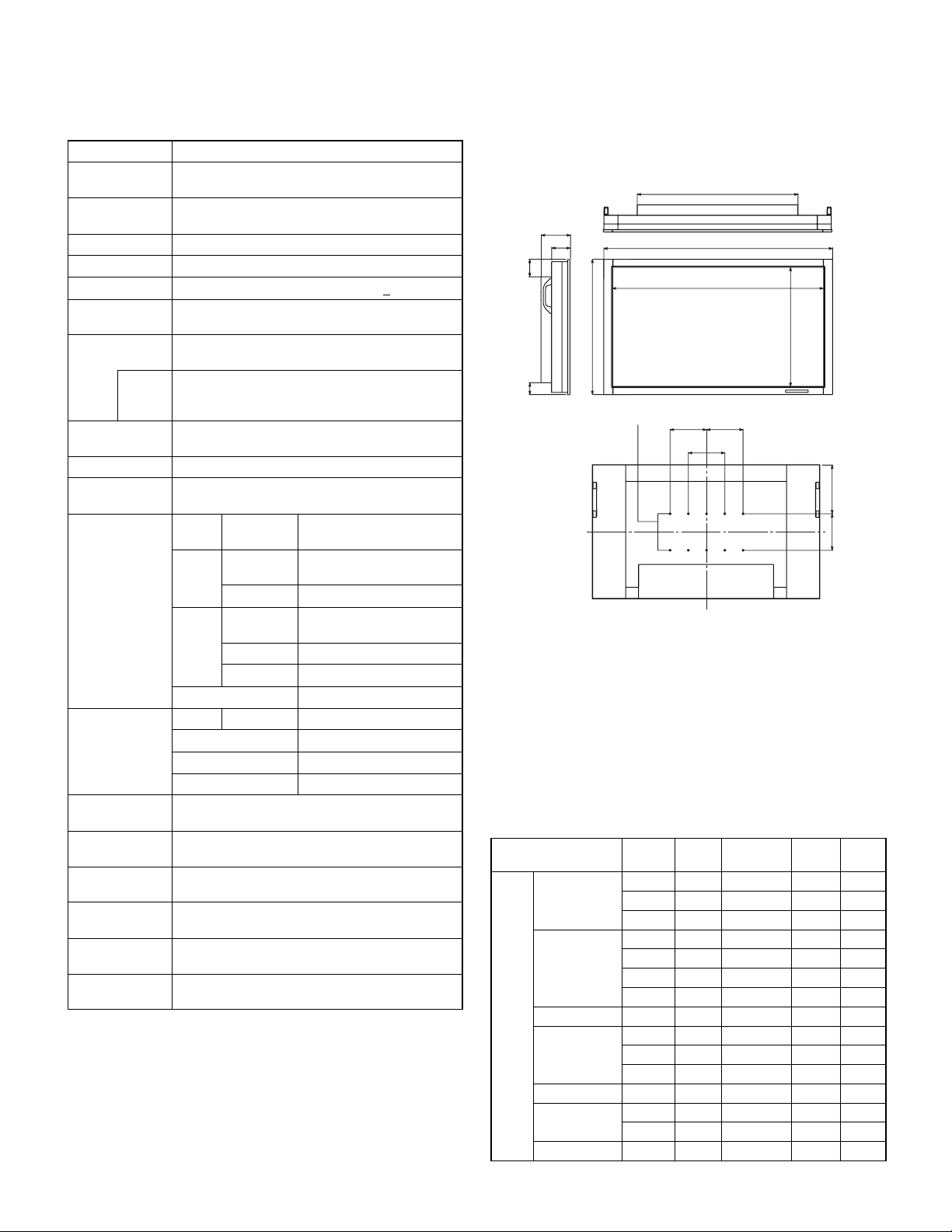

1. SPECIFICATIONS

Model PN-525U

LCD element 52” wide (132.2 cm diagonal)

Max. resolution

(pixels)

Max. colors 16.77 M colors (8 bits/color)

Pixel pitch 0.600mm (H)

Viewing angle 176° right/left/up/down (contrast ratio >

Screen active

area inch (mm)

Computer input

signal

Sync

signal

Video signal

system

Plug and play VESA DDC2B

Power

management

Input terminals PC/AV Digital DVI-D 24 pin

Output terminals PC/AV Digital DVI-D 24 pin

Power

requirement

Operating

temperature

Operating

humidity

Power

consumption

Dimensions

inch (mm)

Weight lbs. (kg) Approx. 97.0 (44)

*1 Cannot be used simultaneously.

*2 Does not support plug and play.

*3 Connection is allowed with an HDCP-compatible device only.

Does not support Repeater control function.

*4 When AUTO INPUT CHANGE is OFF. 11.5 W when it is ON.

ASV low-reflection black TFT LCD

× 1080

1920

× 0.600mm (V)

45-3/8

× 25-1/2 (1152.0 × 648.0)

Digital (DVI 1.0 standard-compliant),

Analog RGB (0.7Vp-p) [75Ω]

Horizontal/vertical separate

(TTL: positive/negative), Sync-on-green,

Composite sync (TTL: positive/negative)

PAL, PAL-60, SECAM, NTSC (3.58MHz),

NTSC (4.43MHz)

VESA DPMS, DVI DMPM

(HDCP compatible)

PC Analog Mini D-sub 15 pin,

× 1, BNC

3 rows

Audio 3.5 mm mini stereo jack

AV Composite

BNC

× 1

video

Component

BNC (Y, Cb/Pb, Cr/Pr)

Audio RCA pin (L/R) × 1

Serial (RS-232C) D-sub 9 pin

× 1

× 1

Audio RCA pin (L/R) × 1

Serial (RS-232C) D-sub 9 pin

Speaker 7W

AC 120 V, 60 Hz

32°F to 104°F (0°C to 40°C)

20% to 80% (no condensation)

325W (Input signal waiting mode: 7.5W

Standby mode: 3.5W)

Approx. 49-3/8

(1,254

×5-7/8 ×29-3/16.

× 149 ×742) (excluding protrusions)

(excluding the temporarystand)

× 1

+ 7W [6Ω]

10)

*3

*1*2

*

1

× 1

,

× 1

*

1

× 1

× 1

■ DIMENSIONAL DRAWINGS

Note: That the values shown are approximate values.

Unit: inch [mm]

34-3/4 [882]

5-7/8 [149]

3-5/8

[92]

3-3/4 [95] 2-5/8 [66]

Opening width (45-9/16 [1157])

29-3/16 [742]

VESA holes

49-3/8 [1254]

7-7/8

[200]

7-7/8 [200]

7-7/8

[200]

Opening height

(25-11/16 [653])

[271]

10-11/16

[200]

7-7/8

When mounting the monitor, be sure to use a wall-mount / ceilingmount bracket they comply with the VESA-compatible mounting

method. SHARP recommends using M6 screws and tighten the screws.

Note that screw hole depth of the monitor is 3/8 inch (10 mm). Loose

holding may cause the product to fall, resulting in serious personal injuries as well as damage to the product. The screw and hole should come

together with over 5/16 inch (8 mm) length of thread. Use the bracket

which applied UL1678 standard, and which can endure at least 4 times

or more the weight of the monitor.

■ COMPATIBLE SIGNAL TIMING (PC)

Screen resolution Hsync Vsync

VESA 640

× 480 31.5kHz 60Hz 25.175MHz oo

37.9kHz 72Hz 31.5MHz oo

37.5kHz 75Hz 31.5MHz oo

× 600 35.1kHz 56Hz 36.0MHz o

800

37.9kHz 60Hz 40.0MHz oo

48.1kHz 72Hz 50.0MHz oo

46.9kHz 75Hz 49.5MHz oo

× 480 31.0kHz 60Hz 33.75MHz oo

848

1024

× 768 48.4kHz 60Hz 65.0MHz oo

56.5kHz 70Hz 75.0MHz oo

60.0kHz 75Hz 78.75MHz oo

× 864 67.5kHz 75Hz 108.0MHz oo

1152

1280

× 768 47.8kHz 60Hz 79.5MHz oo

60.3kHz 75Hz 102.25MHz oo

× 960 60.0kHz 60Hz 108.0MHz oo

1280

Dot

frequency

Analog

signal

Digital

signal

-

PN-525U OUTLINE OF THE PRODUCT, NOMENCLATURE AND FUNCTION

1 – 1

Page 4

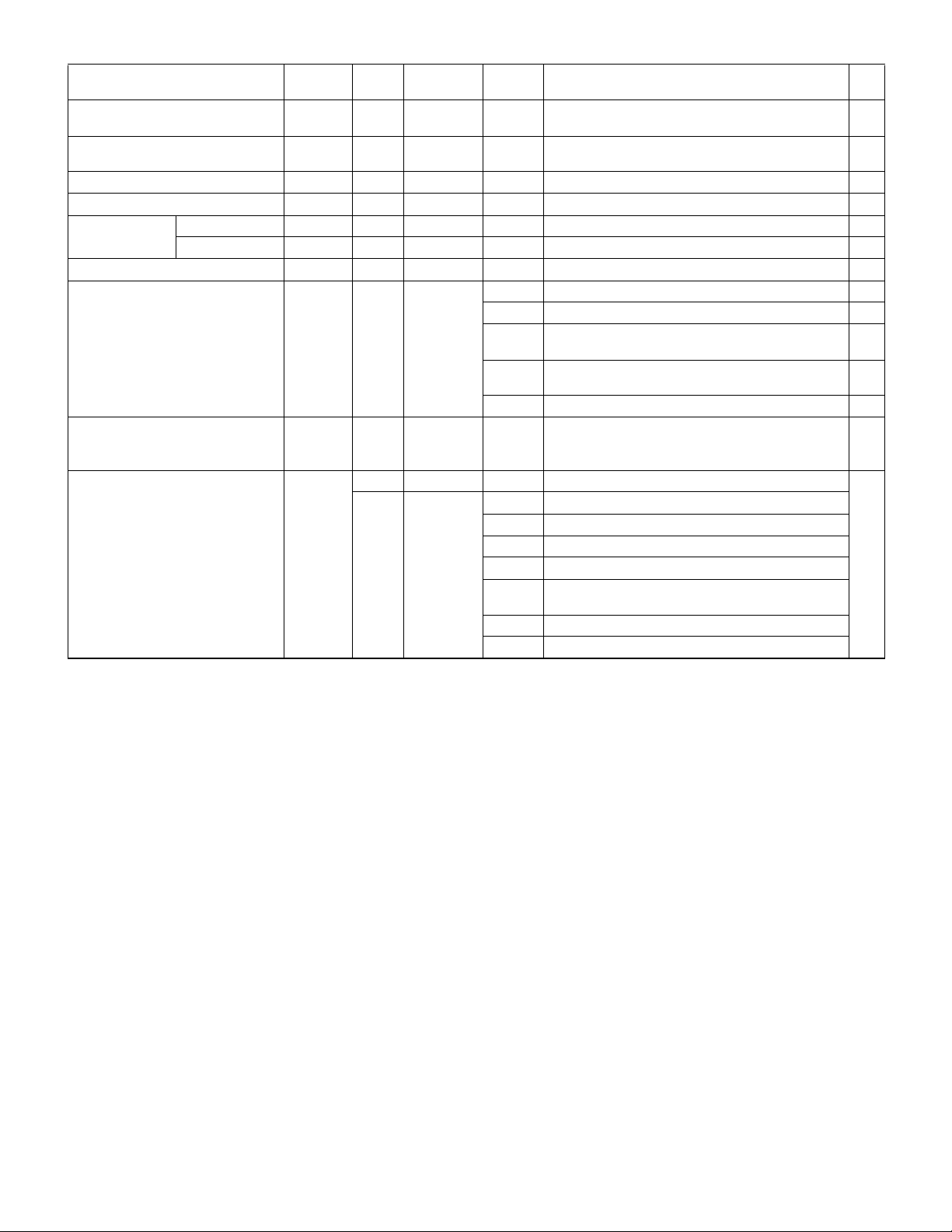

Screen resolution Hsync Vsync

VESA

Wide 1280

US

TEXT

Sun 1024

*1 Displays a reduced image.

* All are compliant only with non-interlaced.

* Depending on the connected PC, images may not be displayed

properly even if the compatible signal described above is input.

* The frequency values for the Sun are reference values.

× 1024 64.0kHz 60Hz 108.0MHz oo

1280

80.0kHz 75Hz 135.0MHz oo

1360

× 768 47.7kHz 60Hz 85.5MHz oo

*

1600 × 1200

1

75.0kHz 60Hz 162.0MHz oo

× 720 44.7kHz 60Hz 74.4MHz oo

1920

× 1080 66.3kHz 60Hz 148.5MHz oo

× 400 31.5kHz 70Hz 28.3MHz oo

720

× 768 48.3kHz 60Hz 64.13MHz o

53.6kHz 66Hz 70.4MHz o

56.6kHz 70Hz 74.25MHz o

1152 × 900 61.8kHz 66Hz 94.88MHz o

71.8kHz 76.2Hz 108.23MHz o

1280 × 1024 71.7kHz 67.2Hz 117.01MHz o

81.1kHz 76Hz 134.99MHz o

1600 × 1000 68.6kHz 66Hz 135.76MHz o

Dot

frequency

Analog

signal

Digital

signal

-

-

-

-

-

-

-

-

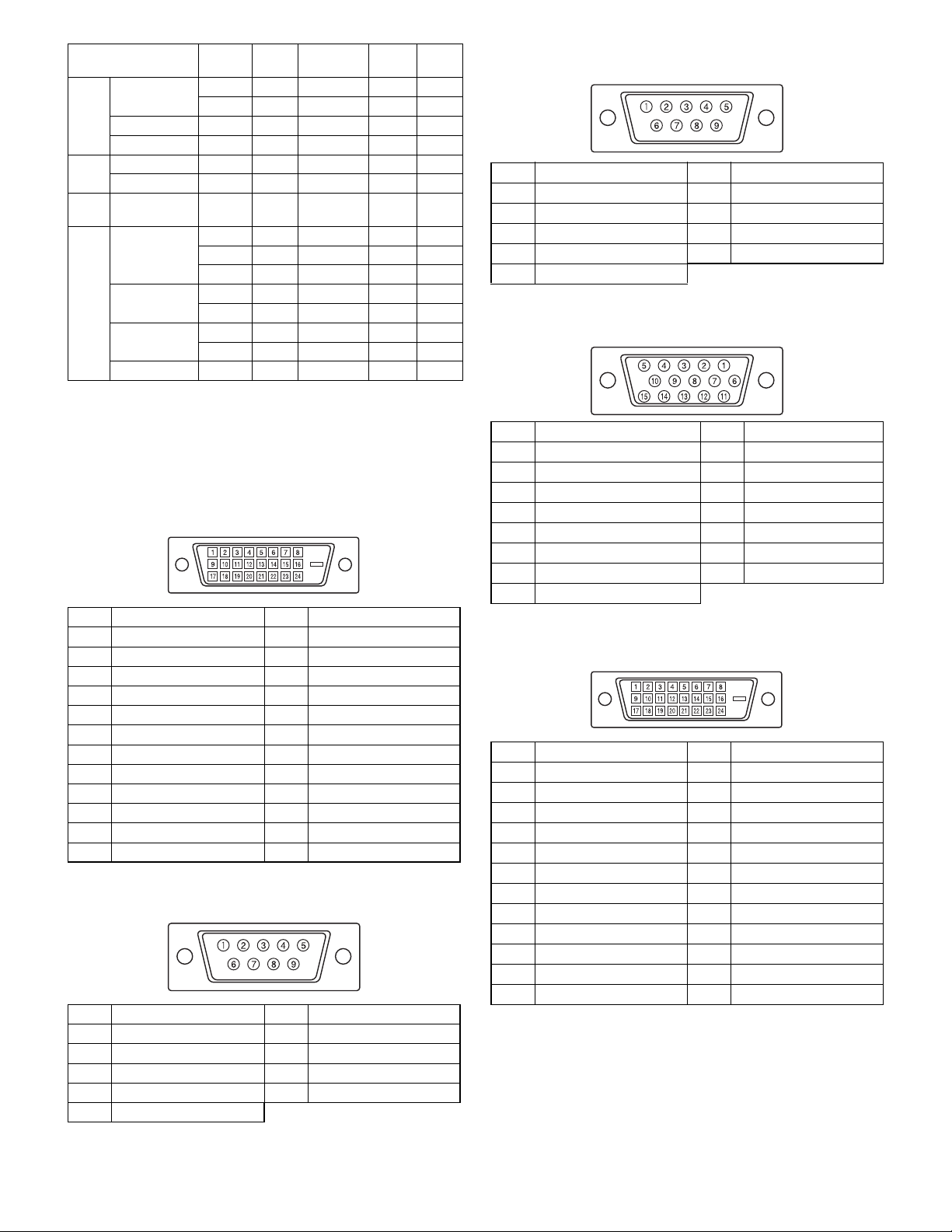

■ PC1/AV1 INPUT TERMINAL PINS

(DVI-D 24 Pin)

No. Function No. Function

1 TMDS data 2- 13 N.C.

2 TMDS data 2

3 TMDS data 2/4 shield 15 GND

4 N.C. 16 Hot-plug detection

5 N.C. 17 TMDS data 0

6 DDC clock 18 TMDS data 0+

7 DDC data 19 TMDS data 0/5 shield

8N.C. 20N.C.

9 TMDS data 1

10 TMDS data 1

11 TMDS data 1/3 shield 23 TMDS clock

12 N.C. 24 TMDS clock−

+ 14 +5V

−

− 21 N.C.

+ 22 TMDS clock shield

+

■ RS-232C INPUT TERMINAL PINS

(D-sub 9 Pin)

No. Function No. Function

1N.C. 6N.C.

2 Transmitted data 7 N.C.

3 Received data 8 N.C.

4N.C. 9N.C.

5GND

■ RS-232C OUTPUT TERMINAL PINS

(D-sub 9 Pin)

No. Function No. Function

1N.C. 6N.C.

2 Received data 7 N.C.

3 Transmitted data 8 N.C.

4N.C. 9N.C.

5GND

■ PC2 RGB INPUT TERMINAL PINS

(Mini D-sub 15 Pin)

No. Function No. Function

1 Red video signal input 9

2 Green video signal input 10 GND

3 Blue video signal input 11 N.C.

4 N.C. 12 DDC data

5 GND 13 Hsync signal input

6 GND for red video signal 14 Vsync signal input

7 GND for green video signal 15 DDC clock

8 GND for blue video signal

+5V

■ PC/AV OUTPUT TERMINAL PINS

(DVI-D 24 Pin)

No. Function No. Function

1TMDS data 2

2TMDS data 2

3 TMDS data 2/4 shield 15 GND

4 N.C. 16 Hot-plug detection

5 N.C. 17 TMDS data 0

6 DDC clock 18 TMDS data 0+

7 DDC data 19 TMDS data 0/5 shield

8N.C. 20N.C.

9TMDS data 1

10 TMDS data 1

11 TMDS data 1/3 shield 23 TMDS clock

12 N.C. 24 TMDS clock−

− 13 N.C.

+ 14 +5V

− 21 N.C.

+ 22 TMDS clock shield

+

−

PN-525U OUTLINE OF THE PRODUCT, NOMENCLATURE AND FUNCTION

1 – 2

Page 5

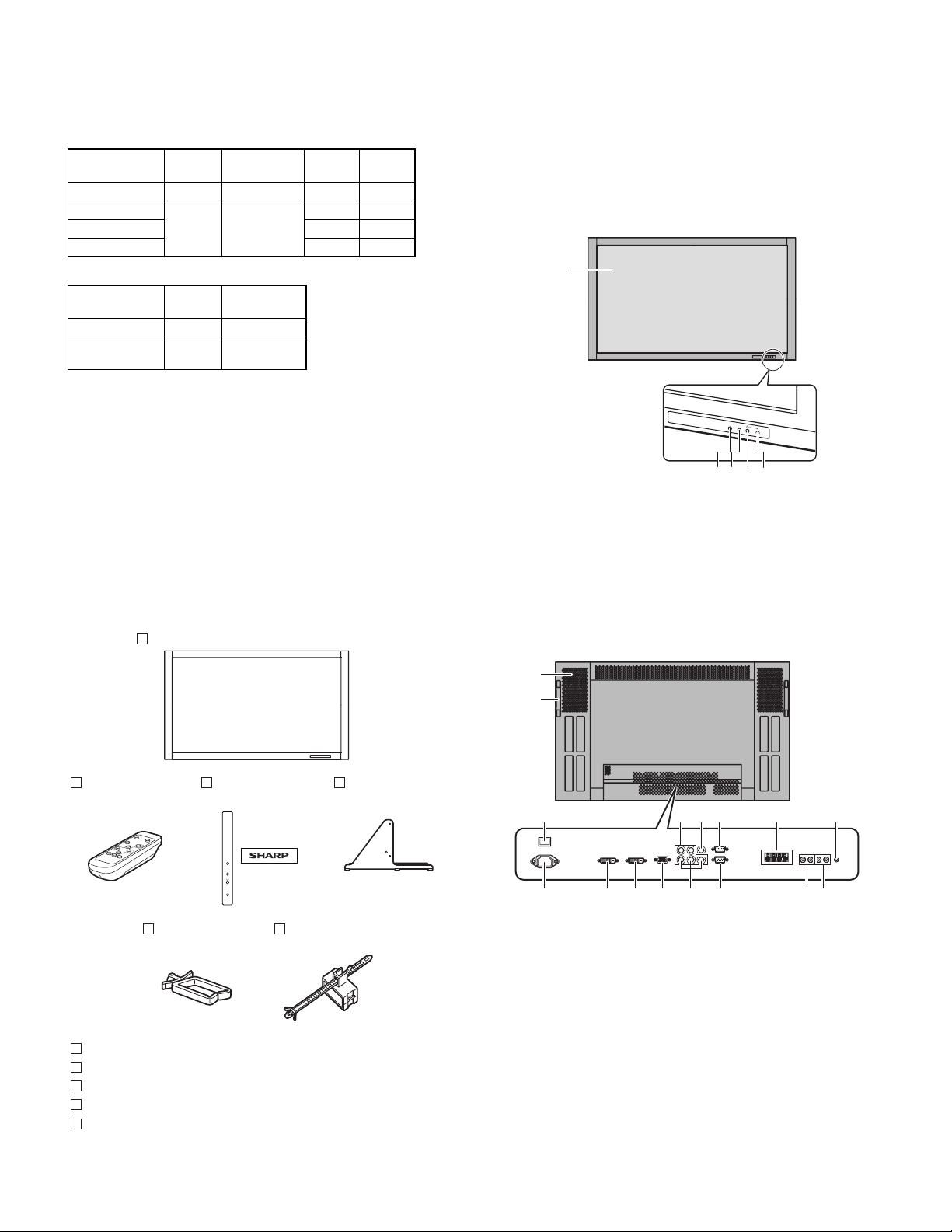

■ POWER MANAGEMENT

ŊŏőŖŕ

This monitor conforms to VESA DPMS and DVI DMPM. Both your video

card and computer must support the same standard in order for the

monitor’s power management function to work.

DPMS: Display Power Management Signaling

DPMS Screen

Power

consumption

Hsync Vsync

ON STATE Display 325W Yes Yes

STANDBY

SUSPEND Yes No

OFF STATE No No

No

display

7.5W

No Yes

DMPM: Digital Monitor Power Management

DMPM Screen

Power

consumption

Monitor ON Display 325W

Active OFF

No

display

7.5W

*When AUTO INPUT CHANGE is OFF. 11.5 W when it is ON.

■ DDC (PLUG AND PLAY)

The monitor supports the VESA DDC (Display Data Channel) standard.

DDC is a signal standard for plug and play between monitors and computers. Information about resolution and other parameters is exchanged

between the two. This function can be used if the computer supports

DDC and it has been configured to detect plug-and-play monitors.

There are several types of DDC, depending on the communication

method used. This monitor supports DDC2B.

2. SUPPLIED ACCESSORIES

Liquid Crystal Display: 1

*Sharp Corporation holds authorship rights to the Utility Disk program.

Do not reproduce it without permission.

*For environmental protection!

Do not dispose of batteries in household waste. Follow the disposal

instructions for your area.

3. PART NAMES AND FUNCTION

■ FRONT VIEW

1

2345

*Use a pointed object such as a pen tip to press the switches at the

front of the monitor.

1 LCD panel

2 Remote control sensor

3 Input switch

4 Power switch

5 Power LED

■ REAR VIEW

Remote control

unit: 1

Cable clamp: 2

Vertical logo

sticker: 2

INPUT

Power cord

Temporary stand: 2

clamp: 1

Power cord (Approx. 13.1 feet [4 m]): 1

“AA” size battery: 2

CD-ROM (Utility Disk for Windows): 1

Operation manual: 1

Blank sticker: 1

Place a blank sticker onto the SHARP logo to cover the logo.

L

K

1689

GJ

H

I23457F

1 Main power switch 9 RS-232C output terminal

(D-sub 9 pin)

2 AC input terminal F RS-232C input terminal

(D-sub 9 pin)

3 PC/AV output terminal (DVI-D) G External speaker terminals

4 PC1 input terminal (DVI-D) H PC/AV audio output terminals

AV1 input terminal (DVI-D) I AV audio input terminals

5 PC2 input terminal

J PC audio input terminal

(Mini D-sub 15 pin)

6 PC3 input terminals (BNC) K Handles

7 AV2 input terminals (BNC) L Vents

8 AV3 input terminal (BNC)

PN-525U OUTLINE OF THE PRODUCT, NOMENCLATURE AND FUNCTION

1 – 3

Page 6

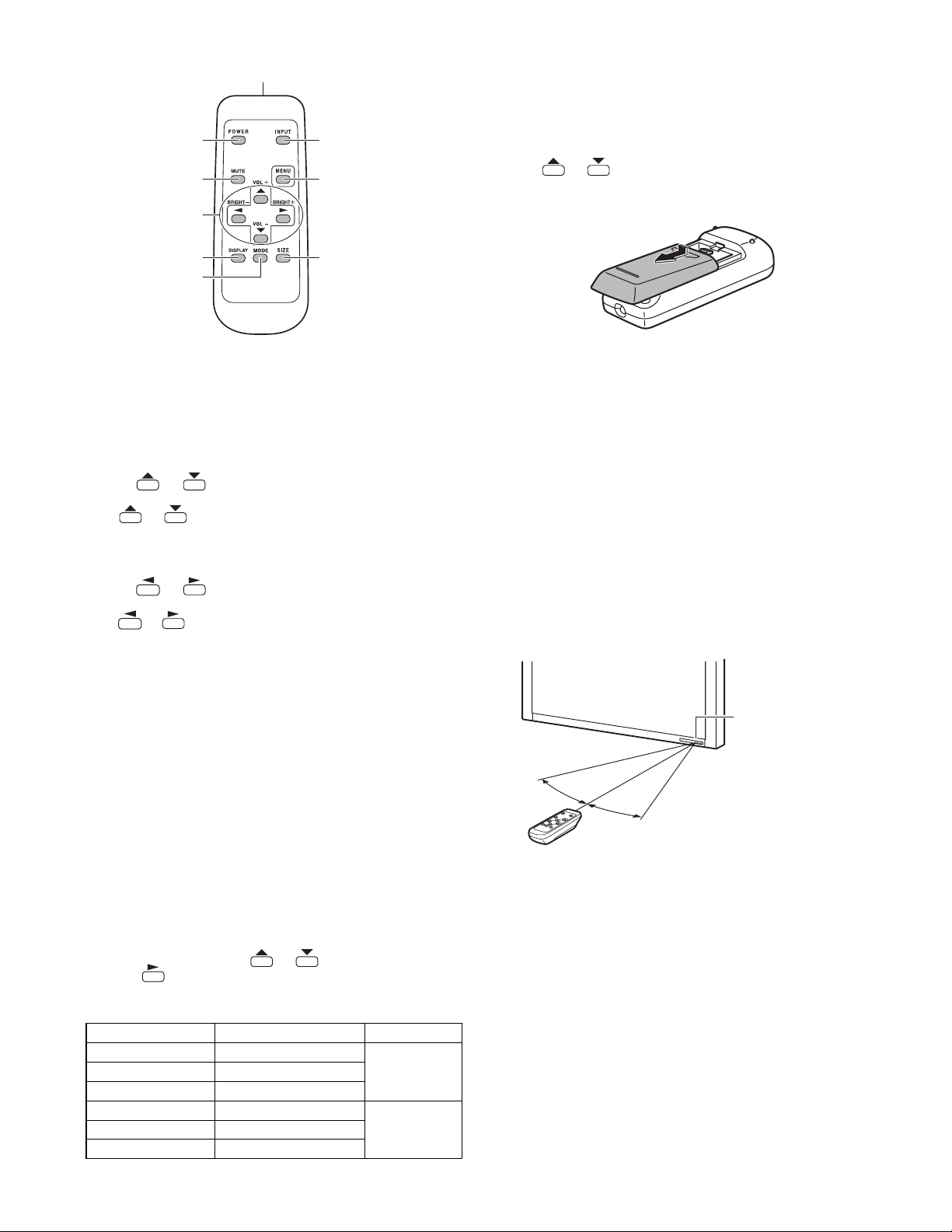

■ Remote Control Unit

2

3

4

1

7

8

*1 Select the terminal for DVI SELECT.

*2 Select the terminal for BNC SELECT.

8MENU button

Displays and turns off the menu screen

9SIZE button

The menu is displayed.

Press or to select the screen size.

■ Setting the batteries

1) Press the cover gently and slide it in the direction of the arrow.

5

9

6

1Signal transmitter

2POWER button

3MUTE button

Turns off the volume temporarily.

Press the MUTE button again to turn the sound back to the previous

level.

4VOL +/- button (Volume adjustment)

Pressing or displays the VOLUME menu when the menu

screen is not displayed.

Press or to adjust the volume of the sound.

*If you do not press any buttons for about 4 seconds, the VOLUME

menu automatically disappears.

BRIGHT

+/− button (Backlight adjustment)

Pressing or displays the BRIGHT menu when the menu

screen is not displayed.

Press or to adjust the brightness.

*If you do not press any buttons for about 4 seconds, the BRIGHT

menu automatically disappears.

Cursor control (S /T/W / X) buttons

5DISPLAY button

Displays monitor information. The display disappears when this button is

pressed again or disappears automatically after approximately

15 seconds.

6MODE button

Each time you press this button, the color mode changes in the following order:

• STD (Standard) JVIVID J sRGB

J STD...

*sRGB applies to PC input only.

sRGB is international standard of color representation specified by

IEC (International Electrotechnical Commission).

Color conversion is made in taking account of liquid crytal’s characteristics and represents color tone close to its original image.

7INPUT button (Input mode selection)

The menu is displayed. Press or to select the input mode,

and press to enter.

*You can select the input terminal by pressing the input switch of

the monitor.

Input mode Video Audio

PC1 DIGITAL

PC2 ANALOG PC2 input terminal

PC3 ANALOG

AV1 DIGITAL

AV2 COMPONENT

*1

PC1 input terminal PC audio input

terminal

*2

*1

PC3 input terminals

AV1 input terminal AV audio input

*2

AV2 input terminals

terminals

AV3 VIDEO AV3 input terminal

2) See the instructions in the compartment and put in the supplied batteries (2 “AA” size batteries) with their plus (

+) and minus (−) sides

oriented correctly.

3) Close the cover.

Note:

• The supplied batteries (2 “AA” size batteries) may become

exhausted faster depending on the storage condition. It is recommended that you replace them with new batteries (commercially

available) earlier than specified.

• If you will not use the remote control for a long time, remove the

batteries.

• Use manganese or alkaline batteries only.

■ Remote control operation range

The operation range of the remote control unit is approx. 16.4 feet (5m)

at an angle of appro

the remote control sensor.

16.4 feet (5 m)

°

10

Caution:

• Do not expose the remote control unit to shock by dropping or stepping on it. This could lead to a malfunction.

• Do not expose the remote control unit to liquids, and do not place it

in an area with high humidity.

• The remote control unit may not work properly if the remote control

sensor is under direct sunlight or strong lighting.

• Objects between the remote control unit and the remote control

sensor may prevent proper operation.

• Replace the batteries when they run low as this may shorten the

remote control’s operation range.

• If a fluorescent light is illuminated near the remote control unit, it

may interfere with proper operation.

• Do not use it with the remote control of other equipment such as air

conditioner, stereo components, etc.

× 10° from the center to the top/bottom/right/left of

Remote control sensor

16.4 feet

(5 m)

16.4 feet (5 m)

°

10

PN-525U OUTLINE OF THE PRODUCT, NOMENCLATURE AND FUNCTION

1 – 4

Page 7

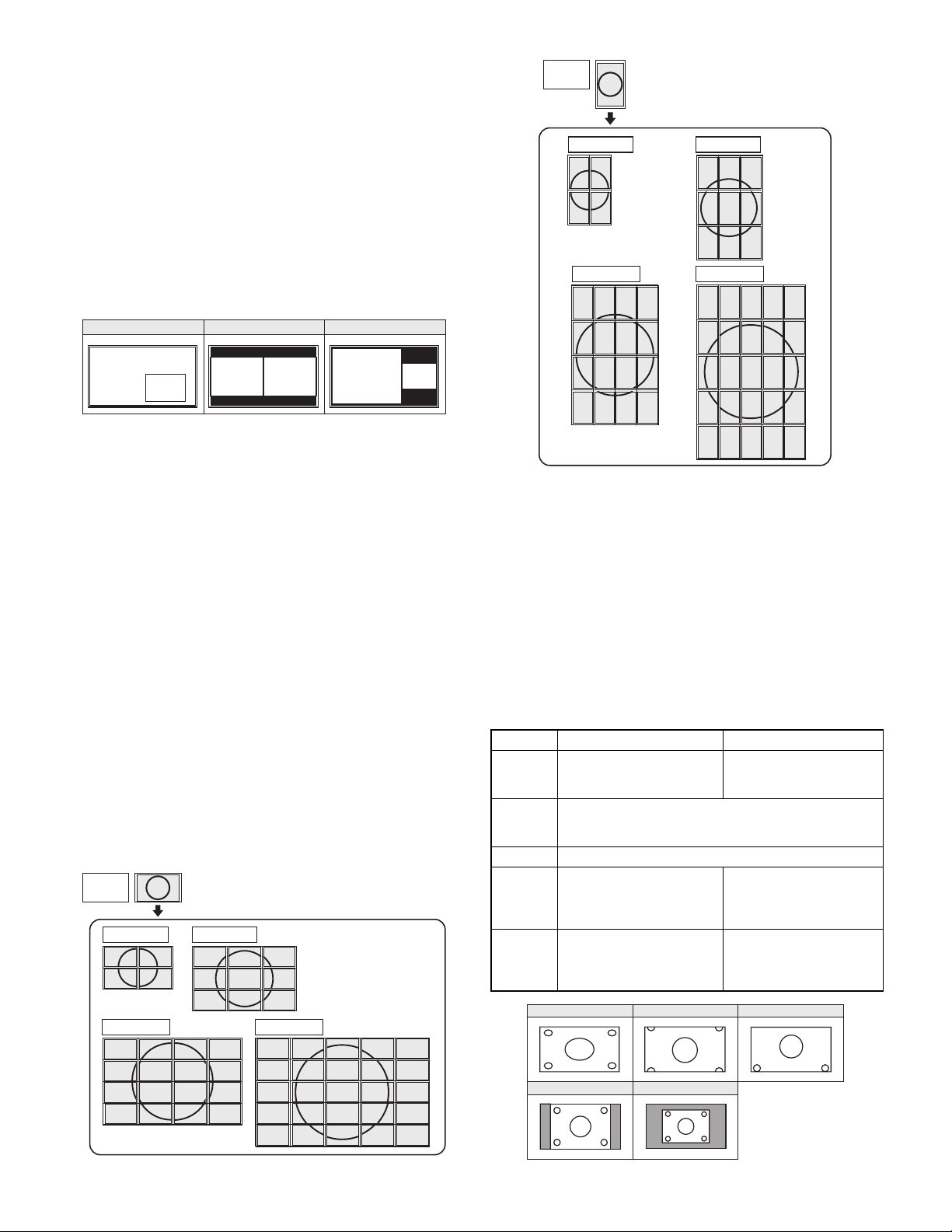

■ Dual screen display

1

3

0

2

012

456

8

9

10

3

7

11

12 13 14 15

012

567

10

11 12

3

8

13

15 16 17 18

20 21 22 23

4

9

14

19

24

012

345

678

1

3

02

0

1

2

4

5

6

8

9

10

3

7

11

12

13

14

15

0

1

2

5

6

7

10

11

12

3813

15

16

17

18

20

21

22

23

4

9

141924

0

1

2

3

4

5

6

7

8

You can display the screens of the PC input signal and AV input signal

simultaneously.

Set this function with “PIP MODES” in the PIP/PbyP menu.

• The currently selected input signal is displayed on the main screen.

• You cannot simultaneously display the screens of signals of the same

type, such as two types of PC input signals or two types of AV input

signals.

PIP : A sub screen is displayed inside a main screen.

PbyP : A main screen and a sub screen are displayed in a line.

PbyP2 : Displays a main screen which measures 1280 pixels in the

longest direction and a sub screen in a line.

In vertical orientation

Original

image

4 monitors

02

1

3

16 monitors 25 monitors

8

12

9 monitors

0

3

6

1

4

7

2

5

8

0

5

10

15

0

4

20

PI P PbyP PbyP2

Main screen

screen

Sub

Main

screen

Sub

screen

Main screen

Note:

• You might infringe on a copyright of the author which is protected

by copyright law when you display the images of the computer

screen and television/VCR simultaneously for profit-making or to

show the image to the public.

• The screen size for dual-screen display is the same as the screen

size for single-screen display. The DotbyDot screen is displayed in

NORMAL size except when it is set as the PIP main screen.

• When dual-screen display is selected, the SCREEN MOTION func-

tion is disabled.

• When dual-screen display is selected, the AUTO INPUT CHANGE

function is disabled.

• When dual-screen display is selected, the screen cannot be

enlarged.

• When dual-screen display is selected, the following adjustments of

ADVANCED are invalid and adjusting is disabled.

3D-NR, MPEG-NR and 3D-Y/C

■ Enlarge

You can align 4, 9, 16, or 25 monitors and integrate them into a single

large screen to display.

Enlarged views of separated images are displayed in each monitor.

In horizontal orientation

Original

image

4 monitors

0

2

16 monitors 25 monitors

012

456

8

12 13 14 15

9 monitors

1

3

910

012

345

678

11

3

7

012

567

10

15 16 17 18

20 21 22 23

11 12

13

PN-525U OUTLINE OF THE PRODUCT, NOMENCLATURE AND FUNCTION

21

2

7

12

17

22

18

23

3813

4

9141924

Sub

screen

1

5

9

13

2

6

10

14

3

711

15

1

6

11

16

Note:

• AV input signals cannot be used for the Enlarge function.

• To integrate 9 or more monitors using PC1 signals, a splitter for the

video signal (commercially available) is required.

• When Enlarge is used, the AUTO INPUT CHANGE function is disabled.

• When connected in PC2/PC3, a splitter for the video signal (commercially available) is required.

• When Enlarge is used, the SCREEN MOTION function is disabled.

■ Switching the screen size

Even when the screen size is changed, the display may remain the

same depending on the input signal.

PC input AV input

WIDE Displays image so it fills the

entire screen.

ZOOM 1 An image with a 4:3 aspect ratio is enlarged to fill the

entire screen without changing the aspect ratio. The

edges of the image may be cut off.

ZOOM 2 Use this size if ZOOM 1 cuts off the subtitles.

NORMAL Displays image so it fills the

screen without changing the

aspect ratio of the input sig-

nals.

DotbyDot Displays the dots of the sig-

nals input from the conne-

cted PC as the correspond-

ing dots on the screen.

WIDE ZOOM1

3

4

8

9

14

19

24

NORMAL

DotbyDot

1 – 5

An image with a 4:3 aspect

ratio is stretched to fill the

entire screen.

Displays the entire image

of the aspect ratio of 4:3

without changing the

aspect ratio.

Displays the dots of the

input signals as the corresponding dots on the

*

screen.

ZOOM2

Page 8

*With a monitor with a screen resolution of 1600 x 1200, selecting Dot-

byDot displays the NORMAL screen.

Note:

• Using this monitor's screen-size switching or dual-screen display

functions to compress or expand the screen for commercial or public viewing in establishments like cafes or hotels may infringe on

the rights of the creators, as protected by Copyright Law, so please

be careful.

• When “Enlarge” is set, the screen size is fixed to “WIDE” mode.

• When dual-screen display is selected, the screen size cannot be

changed.

• The appearance of the original video may change if you select a

screen size with a different aspect ratio than the original image

(e.g. TV broadcast or video input from external equipment).

• When an ordinary non-wide image (4:3) is viewed with the whole

screen using the screen-size switching function of this monitor, the

edge of the image may be lost or appear distorted. If you wish to

respect the creator’s intentions, set the screen size to “NORMAL”.

• When playing commercial software, parts of the image (like subtitles) may be cropped. In this case select the optimal screen size

using the screen-size switching function of this monitor. With some

software, there may be noise or distortion at the edges of the

screen. This is due to the characteristics of the software, and is not

a malfunction.

• Depending on the original image size, black bands may remain at

the edges of the screen.

■ SCHEDULE

You can set the time to switch the monitor on and off.

Set this function with “SCHEDULE” in the OPTION menu.

SCHEDULE

No. POWER DAY OF THE WEEK TIME INPUT

(1)

XXXX/XX/XX XXX XX:XX:XX

(2)

PC2 ANALOG

(3) (4) (5)

Specifies the day of the week to execute the SCHEDULE.

ONLY ONCE:

Executes the SCHEDULE once on the specified day.

Specify the day of the week to execute the SCHEDULE.

EVERY WEEK:

Executes the SCHEDULE on the specified day of the week every

week. Specify the day of the week to execute the SCHEDULE.

Periodic setting such as “Monday through Friday” is also possible.

EVE RY DAY:

Executes the SCHEDULE every day regardless of the day of the

week.

4 TIME

Specifies the time to execute the SCHEDULE.

Set the time on a 24-hour basis.

5 INPUT

Specifies the input mode at power-on. When not specifying, the

screen at the previous power-off appears.

Input modes displayed on “PC1/AV1” depend on DVI SELECT settings.

Input modes displayed on “PC3/AV2” depend on BNC SELECT settings.

Caution:

• Do not switch off the main power after setting the SCHEDULE.

• Specify the correct date and time.

SCHEDULE does not function unless the date and time are specified.

• Check regularly that the set date and time are correct.

Note:

• Up to 8 SCHEDULE items can be registered.

• Setting the SCHEDULE flashes the power LED alternately in red and

orange in standby mode.

• A SCHEDULE that has a large number has precedence over that of a

small number when schedules overlap.

1024x768

V: 60 Hz H: 48.4 kHz

OK…[MENU]

1) Press or to select the SCHEDULE number, and press

.

2) Set the SCHEDULE. (See the description below.)

Press or to select the date and time, and press or

to change the setting.

3) Press .

MENU

SCHEDULE becomes effective.

1

Q : SCHEDULE effective

-

: SCHEDULE not effective

2 POWER

ON : Switches the monitor on at the specified time.

OFF : Switches the monitor off at the specified time and puts the

monitor in standby mode.

3 DAY OF THE WEEK

■ ADVANCED items (AV input)

FLESH TONE

Adjust the hue control.

3D-NR

Reduce the noise of playback images on video.

Setting a higher level reduces more noise. However, it may cause blurring on an image.

MPEG-NR

Reduce block noise caused by digital compression.

3D-Y/C (AV3)

Specify whether to perform 3-dimension Y/C separation.

If dot interference or cross-color is occurring in fast-motion scenes,

selecting “OFF” may improve the image quality.

PN-525U OUTLINE OF THE PRODUCT, NOMENCLATURE AND FUNCTION

1 – 6

Page 9

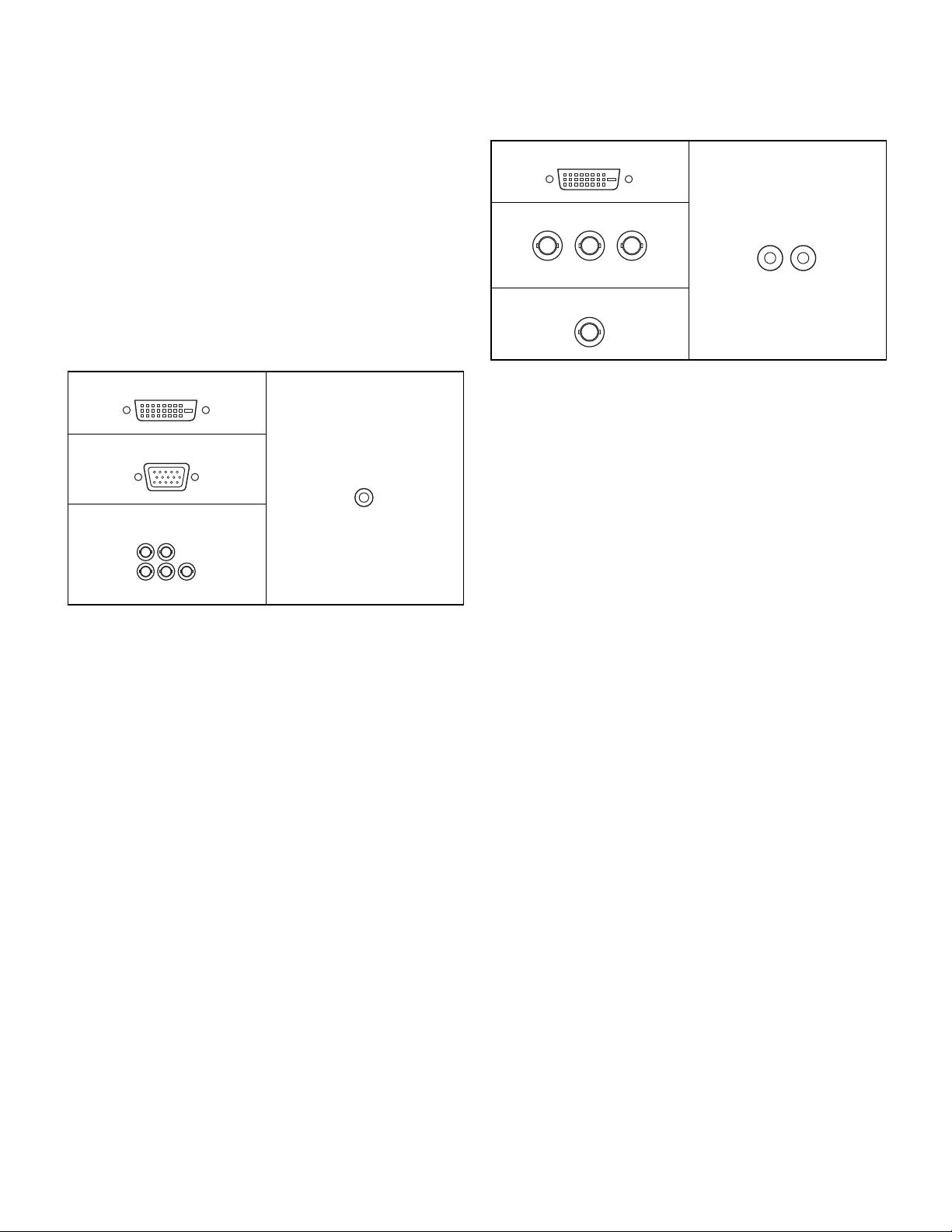

CHAPTER 2. CONNECTION, ADJUSTMENT, OPERATION, AND FUNCTION

1. CONNECTION

1-1. CONNECTING PERIPHERAL EQUIPMENT

Caution:

• Be sure to turn off the main power switch and disconnect the plug

from the power outlet before connecting/disconnecting cables.

Also, read the manual of the equipment to be connected.

• Be careful not to mix up the input terminal with the output terminal

when connecting cables. Mixing up the input and output terminals

may cause malfunctions and the other problems.

(1) Connection with a PC

PC1 input terminal

PC2 input terminal

PC audio input terminal

PC3 input terminals

HV

RGB

• Use a commercially available signal cable (DVI-D 24 pin) for the PC1

input terminal. Set DVI SELECT on the OPTION menu to PC (DIGITAL) when using the PC1 input terminal.

• Use a commercially available signal cable (Mini D-sub 15 pin) for the

PC2 input terminal.

• Use a commercially available signal cable (BNC) for the PC3 input

terminals. Set BNC SELECT on the OPTION menu to PC (ANALOG)

when using the PC3 input terminals.

(2) Connection with AV equipment

AV1 input terminal

AV2 input terminals

Cr/Pr Y Cb/Pb

AV3 input terminal

• Use a commercially available signal cable (DVI-D 24 pin) for the AV1

input terminal. Set DVI SELECT on the OPTION menu to AV (DIGITAL) when using the AV1 input terminal.

• Use a commercially available component cable (BNC) for the AV2

input terminals. Set BNC SELECT on the OPTION menu to AV

(COMPONENT) when using the AV2 input terminals.

• Use a commercially available video cable (BNC) for the AV3 input terminal.

• Use a commercially available audio cable (RCA) for the AV audio

input terminals.

• The AV1 input terminal is compatible with the video signals below:

1920

× 1080p @ 50/59.94/60Hz

1920

× 1080i @ 50/59.94/60Hz

1280

× 720p @ 50/59.94/60Hz

720

× 576p @ 50Hz

720

× 480p @ 59.94/60Hz

640

× 480p @ 59.94/60Hz

• The AV2 input terminals are compatible with the video signals below :

1080i (1125i)/50, 1080i (1125i)/60, 720p (750p)/50, 720p (750p)/60,

576p (625p), 576i (625i), 480p (525p), 480i (525i)

AV audio input terminals

• Use a commercially available audio cable (mini stereo jack) for the

PC audio input terminal. Use an audio cable without resistance.

Note:

• Images may not be displayed properly depending on the computer

(graphics board) to be connected.

• A screen with 1920

rectly on PC3 (BNC). In this case, check the settings of your computer (graphics board) to verify that input signals conform to

specifications of this monitor (Hsync: 66.3 kHz, Vsync: 60 Hz, and

Dot frequency: 148.5 MHz).

• If there is a check box to disable EDID in display control panel,

check it when using PC3 (BNC).

• Use the automatic screen adjustment when a PC screen is dis-

played for the first time using PC2 or PC3, or when the setting of

the PC is changed.

• The screen is adjusted automatically when SELF ADJUST in the

OPTION menu is set to “ON”.

× 1080 resolution may not be displayed cor-

PN-525U CONNECTION, ADJUSTMENT, OPERATION, AND FUNCTION

2 – 1

Page 10

(3) Other terminals

[PC/AV audio output terminals]

• Audio from the equipment connected to the AV audio input terminals

or PC audio input terminal is output. Connect to the audio input terminals of the connected equipment using a commercially available

audio cable (RCA).

• The audio output varies depending on the input mode selection.

• The volume level can be adjusted using the volume adjustment.

• Selecting FIXED of “AUDIO OUTPUT” from the OPTION menu fixes

the volume of sound output from the audio output terminals.

Caution:

• Do not use a power cord other than the one supplied with the monitor.

• Be sure to use a power outlet of AC 120 V (60 Hz).

Using power supply other than the one specified may cause fire.

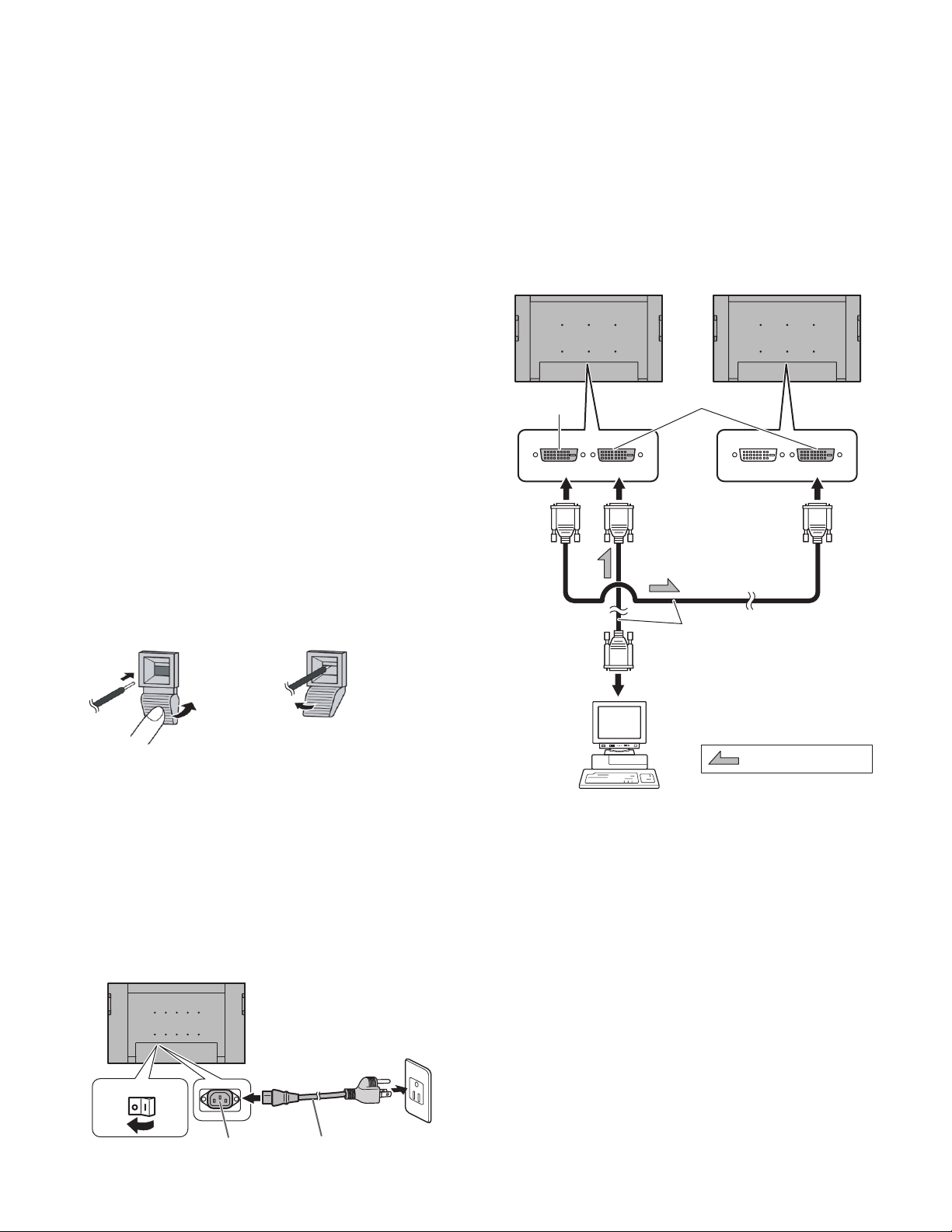

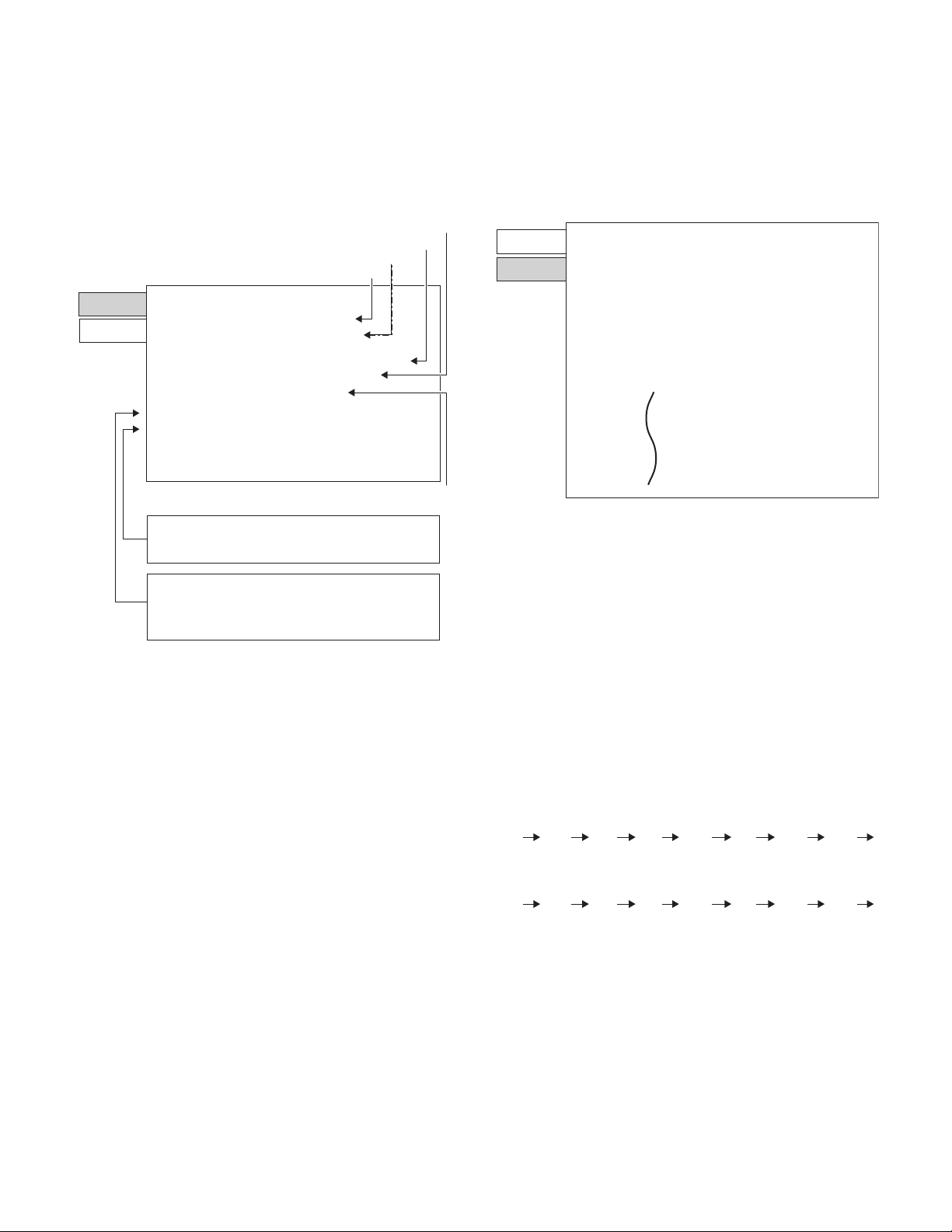

1-4. CONNECTING MULTIPLE MONITORS

You can connect multiple monitors (up to 5 monitors) in a daisy chain by

using the PC1/AV1 input terminals and PC/AV output terminals of this

monitor.

[Connection example]

• Audio signals output from the PC/AV audio output terminals cannot

be adjusted using the AUDIO menu.

[PC/AV output terminals]

Video signals from PC1 and AV1 can be output to HDCP-compatible

external device. Use this terminal when you connect multiple monitors in a daisy chain via DVI cable (commercially available).

Images cannot be output to device that is not HDCP-compatible.

[RS-232C input/output terminals]

You can control the monitor from a PC by connecting a commercially

available RS-232C straight cable between this terminal and the PC.

1-2. CONNECTING EXTERNAL SPEAKERS

Be sure to use external speakers with an impedance of 6 ohms and a

rated input of at least 7W.

1) While pushing the tab, insert the tip of the cable.

2) Release the tab.

12

First monitor Second monitor

PC/AV output

PC1/AV1 input terminals

terminal

Digital signal (DVI) cables

(commercially available)

To PC digital RGB output terminal

Note:

• Be sure to connect the

speakers properly.

• Avoid short circuiting the

+ and − terminals and the left and right

+ and − terminals.

1-3. CONNECTING THE POWER CORD

1) Turn off the main power switch.

2) Plug the power cord (supplied) into the AC input terminal.

3) Plug the power cord (supplied) into the AC power outlet.

Power outlet

Main power switch

1

AC input terminal

2

Power cord (Supplied)

3

PN-525U CONNECTION, ADJUSTMENT, OPERATION, AND FUNCTION

shows the signal flow

Note:

• The length of the signal cables or surrounding environment may

affect the image quality.

• The screen may not display properly when using terminals other

than PC1/AV1 for the input mode. In this case, turn off the power to

all the monitors connected in a daisy chain and then turn the power

on again.

2 – 2

Page 11

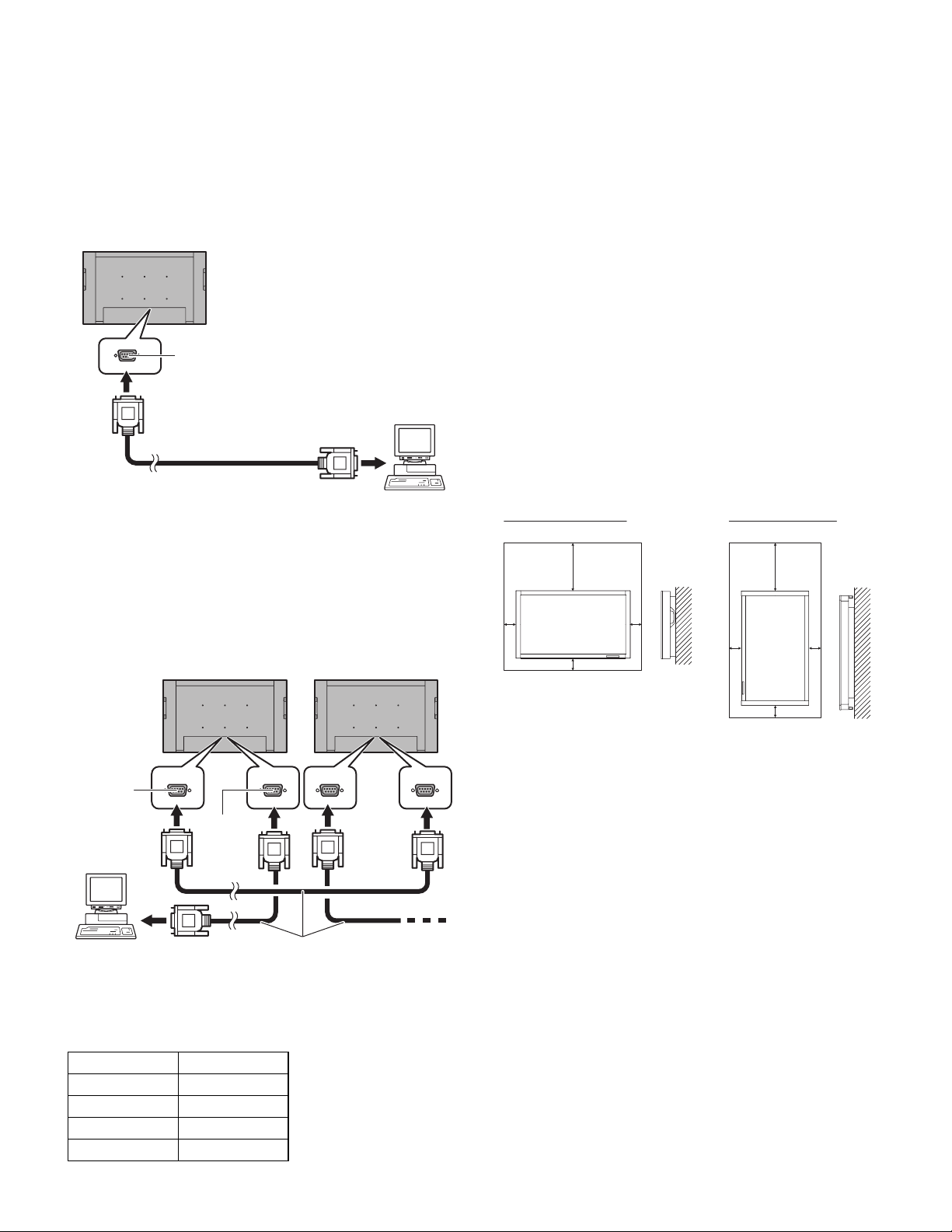

1-5. CONTROLLING THE MONITOR WITH A PC

You can control this monitor from a PC via RS-232C (COM port) on the

PC. You can also connect multiple monitors via a daisy chain by using a

PC. By assigning ID numbers to each monitor, you can make input

mode selection/adjustment or can check the status of

■ PC connection

One-to-one connection with a PC

Connect with RS-232C straight cable between the PC’s COM port

(RS-232C connector) and the RS-232C input terminal on the rear of the

monitor.

RS-232C input terminal

To COM port

RS-232C straight cable

(commercially available)

Daisy chain connection from a single PC (Advanced operation)

Connect with RS-232C straight cable between the PC’s COM port

(RS-232C connector) and the RS-232C input terminal on the rear of the

first monitor.

Next, connect RS-232C straight cable to the first monitor’s RS-232C

output terminal and to the second monitor’s RS-232C input terminal.

Connect in the same way to the third and subsequent monitors.

First monitor Second monitor

a specific

monitor.

PC

1-6. HOW TO INSTALL THE MONITOR

■ Mounting precautions

• Since the monitor is heavy, consult your dealer before installation.

• Installing or moving the monitor must be done by two or more people.

• A stand and mounting bracket compliant with VESA specifications is

required. Do not use any screw holes other than VESA holes for

installation.

• When moving the monitor, be sure to hold it with the handles both on

the rear and the unit bottom. Do not hold the LCD panel. This may

cause product damage, failure, or injury.

• Install the monitor with the surface perpendicular to a level surface. If

necessary, limit the tilt between 0 and 20 degrees downward.

• Mounting the monitor on the wall requires special expertise and the

work must be performed by an authorized SHARP dealer. You should

never attempt to perform any of this work yourself. Our company will

bear no responsibility for accidents or injuries caused by improper

mounting or mishandling.

• This monitor should be used at an ambient temperature between

32 °F (0 °C) and 104 °F (40 °C). Provide enough space around the

monitor to prevent heat from accumulating inside.

For the monitor in

horizontal orientation

7-7/8 [20]

2

[5]

2 [5]

**

2

[5]

For the monitor in

vertical orientation

7-7/8

[20]

2

[5]

2

[5]

RS-232C

output

terminal

RS-232C

input

PC

To COM port

terminal

RS-232C straight cables

(commercially available)

■ Communication conditions

Set the RS-232C communication settings on the PC to match the

monitor’s communication settings as follows:

Baud rate 9,600bps

Data length 8bits

Parity bit None

Stop bit 1bit

Flow control None

Unit: inch [cm]

*The monitor can be installed close to a wall, etc.

However, the monitor emits heat during operation. Be aware that

heat emitted from the monitor may discolour or alter the wall.

If it is difficult to provide such space because the monitor is

installed inside a housing or for other reasons, take other measures

to keep the ambient temperature between 32°F (0 °C) and 104 °F

(40 °C) such as installing a fan in the housing.

• Adhere to the following when installing the monitor in the vertical

orientation. Failing to adhere to the following may cause malfunctions.

-

Install the monitor such that the power LED is located on the

downside.

-

Set the MONITOR on the SETUP menu to PORTRAIT.

• Do not block any ventilation openings. If the temperature inside the

monitor rises, this could lead to a malfunction.

• After mounting, it is recommended to take some measures to pre-

vent the monitor from falling down.

• Do not place the monitor on a device which generates heat.

• Be sure to use a stand or a wall-mount/ceiling-mount bracket

designed or designated for mounting the monitor.

2 [5]

PN-525U CONNECTION, ADJUSTMENT, OPERATION, AND FUNCTION

2 – 3

Page 12

• This monitor is designed to be installed on a concrete wall/ceiling or

pillar. Reinforced work might be necessary for some materials such

as plaster/thin plastic board/wood before starting installation.

This monitor and bracket must be installed on a wall which can

endure at least 4 times or more the weight of the monitor. Install by

the most suitable method for the material and the structure.

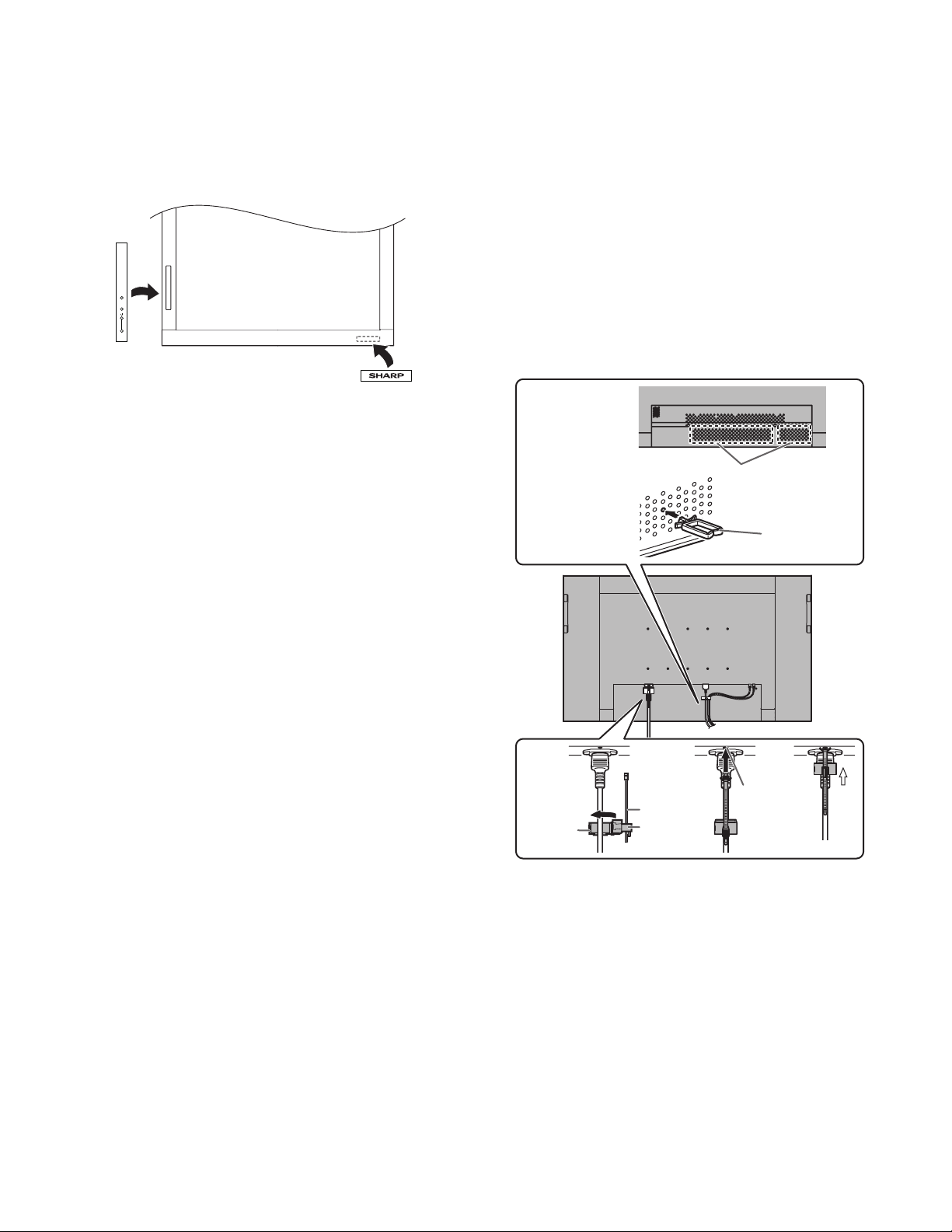

• Use the supplied logo sticker when you install the monitor in vertical orientation.

*

INPUT

*Do not remove the factory-affixed sticker but affix the logo sticker

over it.

Be careful not to cover the remote control sensor or buttons.

■ BINDING CABLES

[Attaching the cable clamp]

The cables connected to the terminals on the back of the monitor can

be neatly bundled using the supplied cable clamps as shown in the illustration.

Caution:

• Verify the position for attaching a cable clamp in advance.

• A cable clamp cannot be removed once it is attached.

[Fastening the power cord]

1) Attach the supplied power cord clamp to the power cord, making

sure the power cord clamp is circular hole-sidedown.

2) Insert the tip of the band into the hole for the power cord clamp.

3) While holding the tail of the band, slide the fastened part toward the

AC input terminal.

Cable clamp

positions

Insert the cable

Cable clamp

attachment

clamp into a hole.

(any hole available)

Cable clamp

123

Hole for

the power

cord clamp

Fastened

part

Band

Power cord

clamp

PN-525U CONNECTION, ADJUSTMENT, OPERATION, AND FUNCTION

2 – 4

Page 13

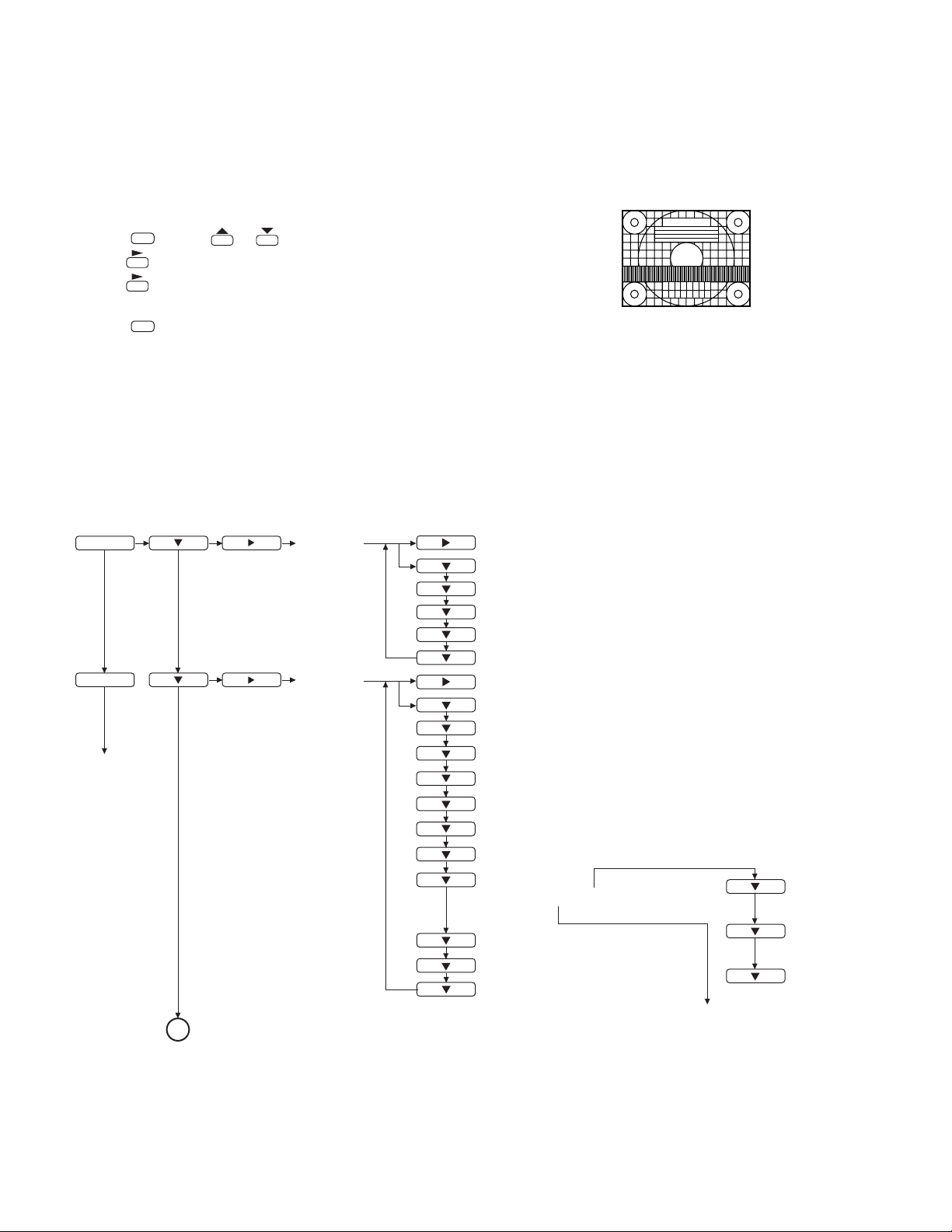

2. ADJUSTMENT METHOD

[ADJUSTMENTS FOR PC SCREEN DISPLAY]

■ Automatic adjustment

When you use the PC2 input terminal or PC3 input terminals to display

a PC screen for the first time, or when you change the setting of the PC,

use the automatic screen adjustment.

1) Switch the input to PC2 or to PC3 and display the adjustment pattern. (See the description below.)

2) Press and use or to display the SCREEN menu.

MENU

3) Press and select “AUTO”.

4) Press .

The automatic adjustment is complete in several seconds.

5) Press twice to close the menu screen.

MENU

Note: If the screen cannot be adjusted properly with one automatic

adjustment, repeat the automatic adjustment two or three times.

Try manual adjustment if necessary.

■ Screen display for adjustment

Before making adjustments in the SCREEN menu or PICTURE menu,

display an image to brighten the entire screen. If you are using a Windows PC, use the adjustment pattern on the supplied CD-ROM.

2-1. SETTINGS AND ADJUSTMENTS

<Opening the adjustment pattern>

1) Load the supplied CD-ROM into the computer's CD-ROM drive.

2) Open the CD-ROM in [My Computer].

3) Double-click [Adj_uty.exe].

The adjustment pattern will appear.

Adjust the screen automatically or manually.

4) When adjustment is finished, press the [Esc] on the computer's keyboard to quit the adjustment program.

5) Eject the CD-ROM from the CD-ROM drive.

Note: If the display mode on the computer you are using is 65,000 col-

ors, the color levels in the color pattern may appear differently or

grayscale may appear to be colored.

(This is due to the specifications of the input signal and is not a

malfunction.)

MENU

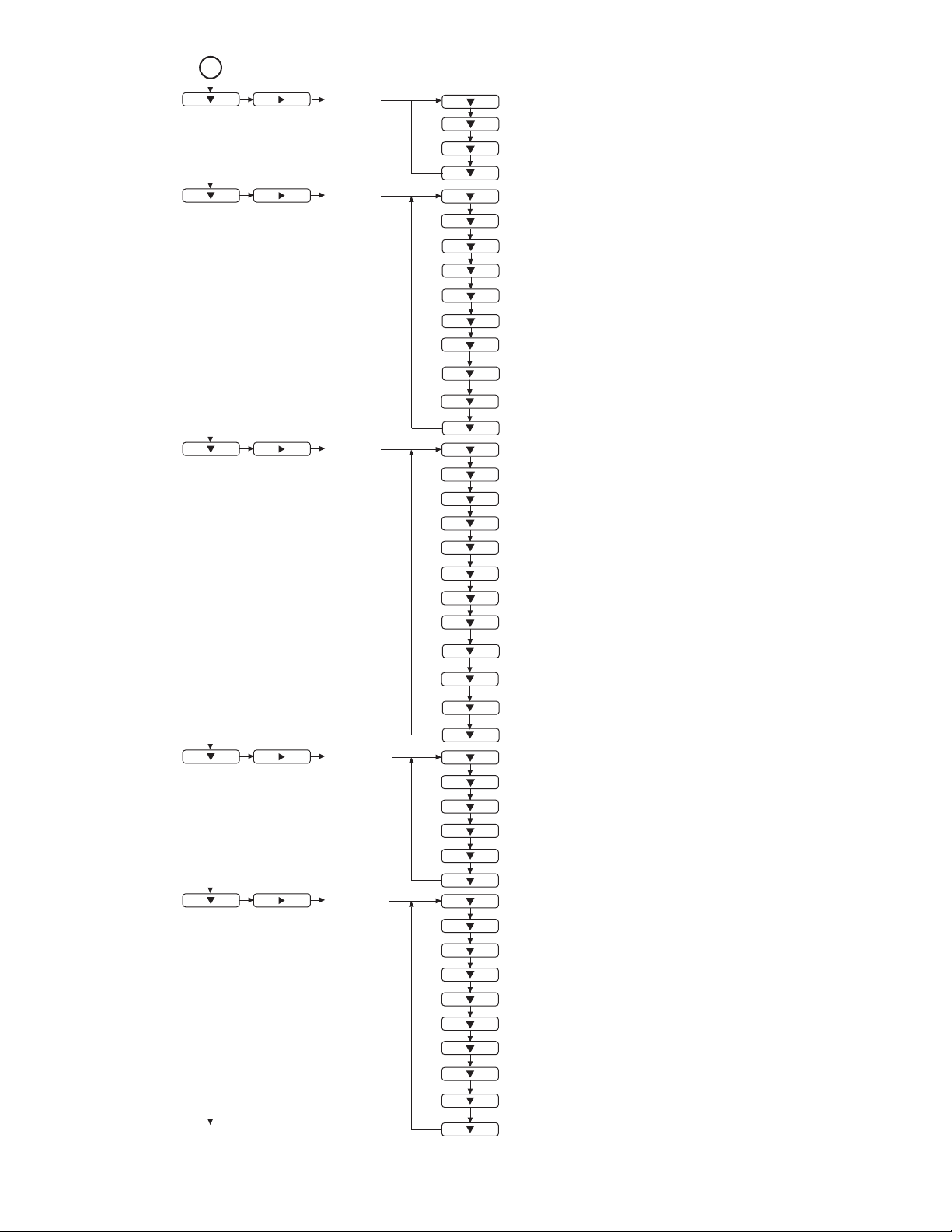

MENU

END

SCREEN

(PC2/PC3)

PICTURE

AUTO

CLOCK

PHASE

H-POS

V-POS

RESET

(Adjust with

(Adjust with

(Adjust with

(Adjust with

(Initialize with

AUTO (PC2/PC3)

CONTRAST

BLACK LEVEL

TINT (AV input)

COLORS (AV input)

SHARPNESS

ADVANCED (AV input)

COLOR MODE

WHITE BALANCE

*

(THRU /PRESET/USER)

COPY TO USER

GAMMA

RESET

(Adjust with

(Adjust with

(Adjust with

(Adjust with

(Adjust with

(Adjust with

(Adjust with

(Adjust with

(Adjust with

(Adjust with

(Initialize with

e and d.)

e and d.)

e and d.)

e and d.)

d.)

e and d.)

e and d.)

e and d.)

e and d.)

e and d.)

e and d.)

e and d.)

e and d.)

d.)

e and d.)

d.)

R-CONTRAST

(Adjust with e and d.)

G-CONTRAST

(Adjust with

e and d.)

B-CONTRAST

(Adjust with

e and d.)

A

PN-525U CONNECTION, ADJUSTMENT, OPERATION, AND FUNCTION

* Input signal level (for PC1 only)

PRESET

(Adjust with

e and d.)

2 – 5

Page 14

A

AUDIO

SETUP

OPTION

TREBLE

BASS

BALANCE

RESET

OSD H-POSITION

OSD V-POSITION

SCREEN MOTION

MOTION TIME 1

MOTION TIME 2

MONITOR

LANGUAGE

ID No. SET

PICTURE FLIP

POWER ON DELAY

DATE/TIME SETTING

SCHEDULE

DVI SELECT

BNC SELECT

QUICK SHOOT

COLOR SYSTEM

AUDIO OUTPUT

480LINES (PC2/PC3)

(Adjust with e and d.)

(Adjust with

(Adjust with

e and d.)

e and d.)

(Initialize with d.)

(Adjust with

(Adjust with

e and d.)

e and d.)

(Adjust with e and d.)

(Adjust with

(Adjust with

(Adjust with

(Adjust with

(Adjust with

(Adjust with

(Adjust with

(Adjust with

(Adjust with

(Adjust with

(Adjust with

e and d.)

e and d.)

e and d.)

e and d.)

e and d.)

e and d.)

e and d.)

e and d.)

e and d.)

e and d.)

e and d.)

(Adjust with e and d.)

(Adjust with

(Adjust with

(Adjust with

e and d.)

e and d.)

e and d.)

ENLARGE

(PC input)

PIP/PbyP

768LINES (PC2/PC3)

SELF ADJUST

POWER MANAGEMENT

AUTO INPUT CHANGE

ENLARGE MODE

ENLARGE POS

BEZEL H

BEZEL V

H-POS

V-POS

PIP MODES

PIP SIZE

PIP H-POS

PIP V-POS

PIP BLEND

PIP SOURCE

SOUND CHANGE

MAIN POS

PbyP2 POS

(Adjust with

(Adjust with

(Adjust with

e and d.)

e and d.)

e and d.)

(Adjust with e and d.)

(Adjust with

(Adjust with

(Adjust with

e and d.)

e and d.)

e and d.)

(Adjust with e and d.)

(Adjust with

(Adjust with

(Adjust with

(Adjust with

(Adjust with

(Adjust with

(Adjust with

(Adjust with

(Adjust with

(Adjust with

(Adjust with

e and d.)

e and d.)

e and d.)

e and d.)

e and d.)

e and d.)

e and d.)

e and d.)

e and d.)

e and d.)

e and d.)

AUTO OFF

(Adjust with

* The menu screen will close automatically if no operation is performed for about 15 seconds.

PN-525U CONNECTION, ADJUSTMENT, OPERATION, AND FUNCTION

2 – 6

e and d.)

Page 15

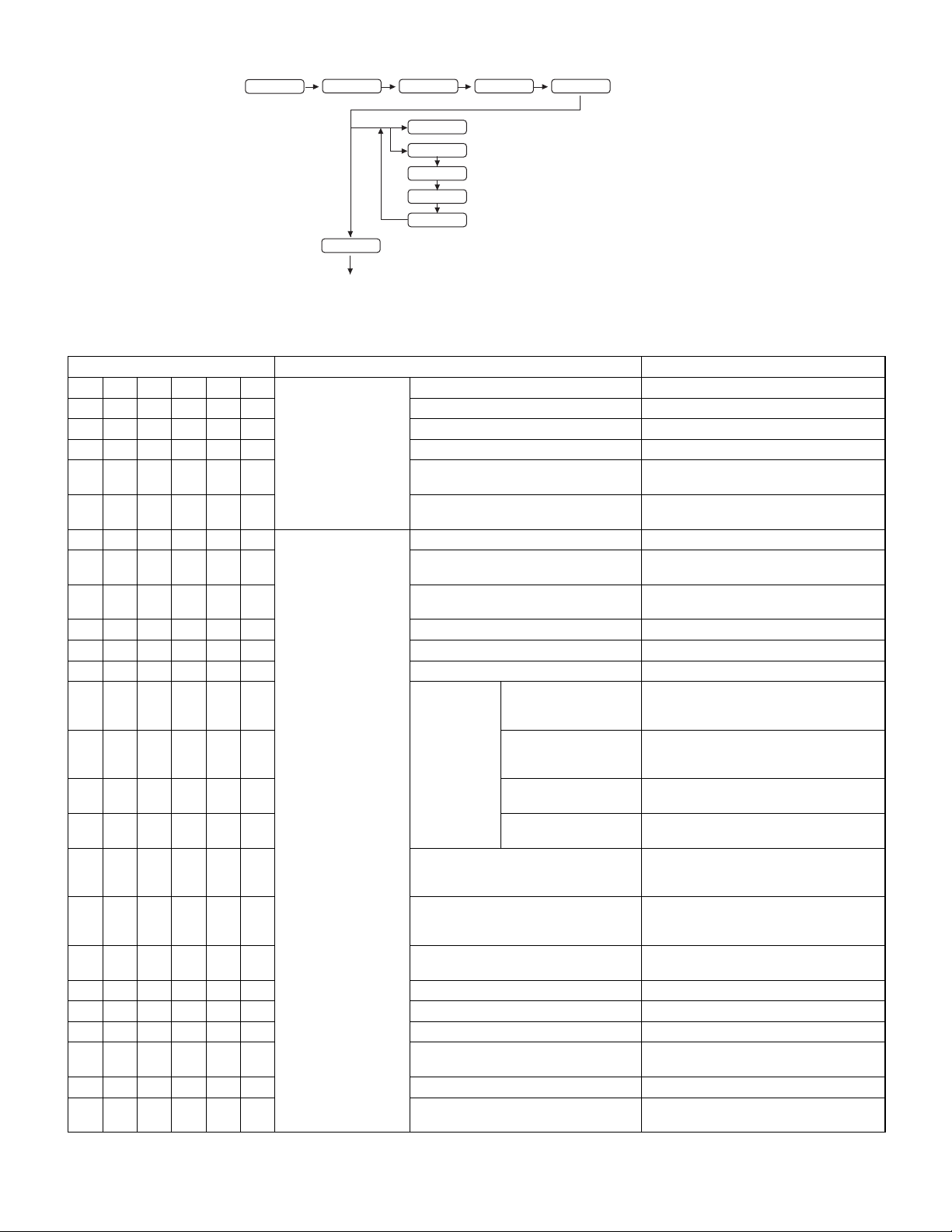

2-2. INITIALIZATION (RESET)/FUNCTIONAL RESTRICTION SETTING

SIZE

(Press about 5 seconds.)

MENU

ALL RESET

ADJUSTMENT LOCK

OSD DISPLAY

LED

RS-232C

(Adjust with

(Adjust with

(Adjust with

(Adjust with

(Adjust with

END

2-3. ADJUSTMENT ITEM LIST

INPUT MODE ITEM ADJUSTMENT

PC1 PC2 PC3 AV1 AV2 AV3 SCREEN AUTO

¥¥ CLOCK 0 ~ 255

¥¥ PHASE 0 ~ 63

¥¥ H-POS 0 ~ 100

¥¥

¥¥

¥¥ PICTURE AUTO

¥¥¥¥¥¥

¥¥¥¥¥¥

¥¥¥ TINT 0 ~ 60

¥¥¥ COLORS 0 ~ 60

¥¥¥¥¥¥ SHARPNESS 0 ~ 24

¥¥¥

¥¥¥

¥¥¥

¥

¥¥¥¥¥¥

¥¥¥¥¥¥

¥¥¥¥¥¥

¥¥¥¥¥¥ R-CONTRAST 0 ~ 512

¥¥¥¥¥¥ G-CONTRAST 0 ~ 512

¥¥¥¥¥¥ B-CONTRAST 0 ~ 512

¥¥¥¥¥¥

¥¥¥¥¥¥ GAMMA 1.8/2.2/2.4

¥¥¥¥¥¥

V-POS Depends on the resolution

Either 0 ~ 200/300/500

RESET OFF

ON

CONTRAST PC1/AV1/AV2/AV3: 0 ~ 60

PC2/PC3: 0 ~ 127

BLACK LEVEL PC1/AV1/AV2/AV3: 0 ~ 60

PC2/PC3: 0 ~ 127

ADVANCED FLESH TONE OFF

LOW

HIGH

3D-NR OFF

LOW

HIGH

MPEG-NR OFF

ON

3D-Y/C OFF

ON

COLOR MODE STD

VIVID

sRGB

WHITE BALANCE THRU (PC1 only)

PRESET

USER

PRESET 3000K ~ 10000K

(500K carve)

COPY TO USER OFF

ON

RESET OFF

ON

e and d.)

e and d.)

e and d.)

e and d.)

e and d.)

*2

PN-525U CONNECTION, ADJUSTMENT, OPERATION, AND FUNCTION

2 – 7

Page 16

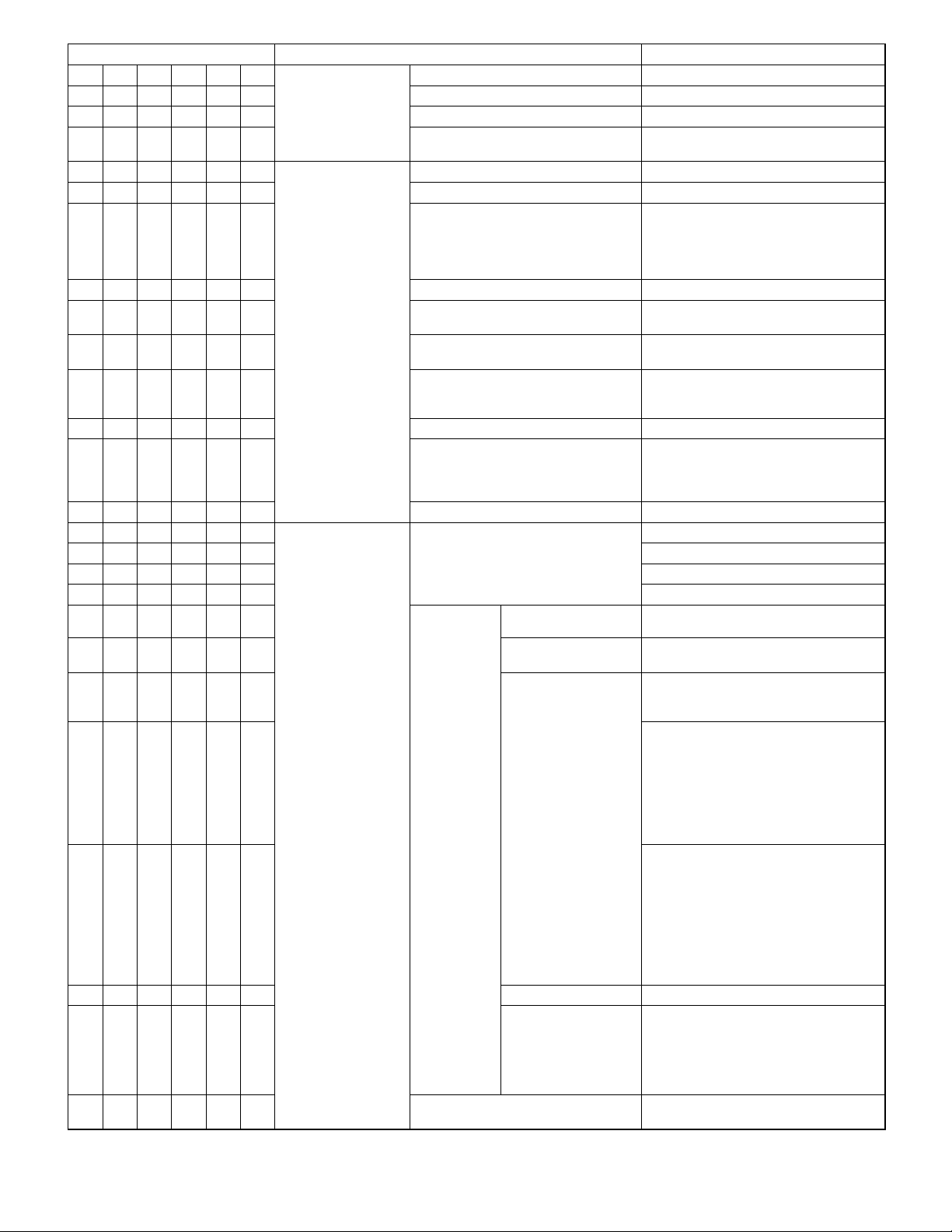

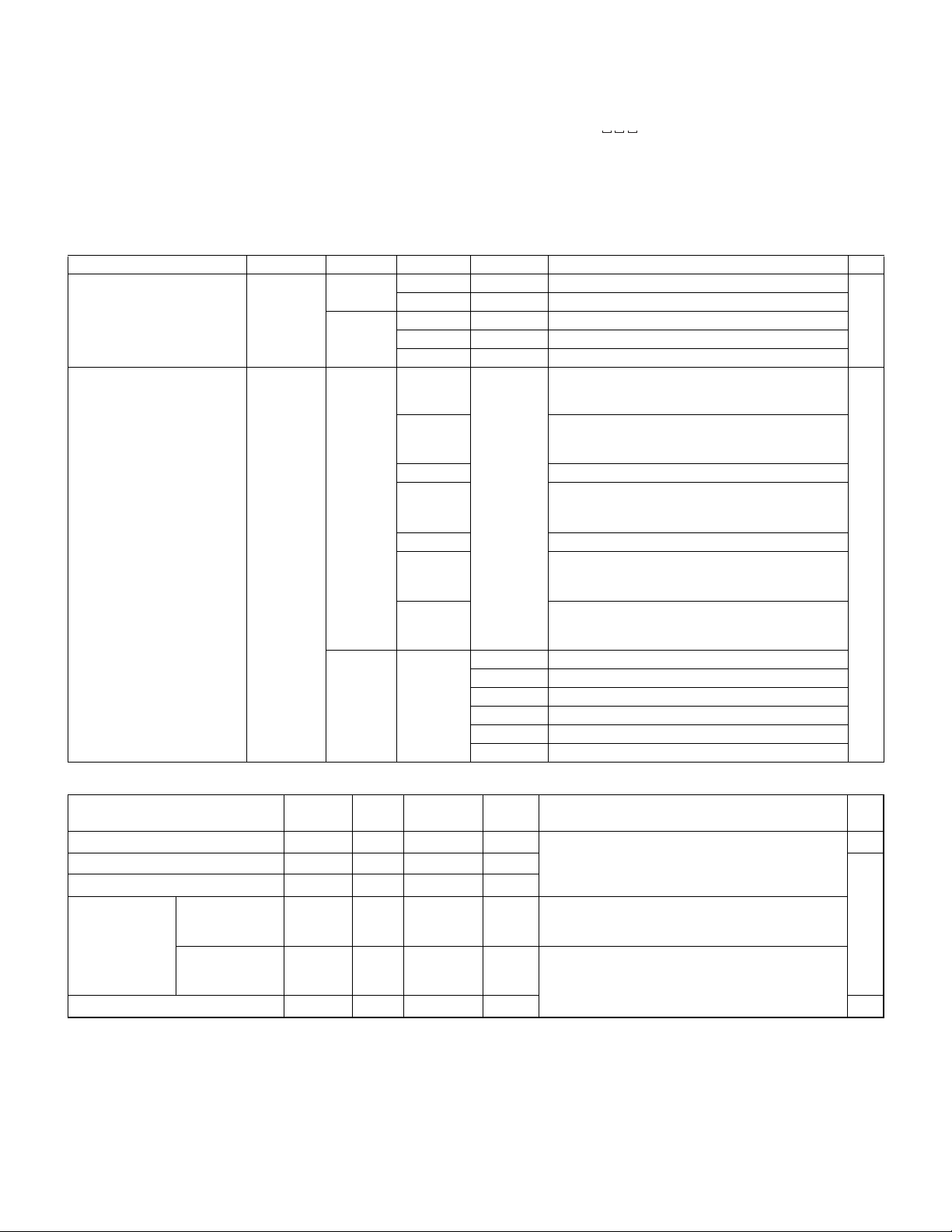

INPUT MODE ITEM ADJUSTMENT

¥¥¥¥¥¥AUDIO TREBLE

¥¥¥¥¥¥ BASS

¥¥¥¥¥¥ BALANCE

¥¥¥¥¥¥

¥¥¥¥¥¥SETUP OSD H-POSITION 0 ~ 100

¥¥¥¥¥¥ OSD V-POSITION 0 ~ 100

¥¥¥¥¥¥

¥¥¥¥¥¥ MOTION TIME 1 0 ~ 20 (H) [Unit: hour]

¥¥¥¥¥¥

¥¥¥¥¥¥

¥¥¥¥¥¥

¥¥¥¥¥¥ ID No. SET 0 ~ 255

¥¥¥¥¥¥

¥¥¥¥¥¥ POWER ON DELAY 0 ~ 60 (S) [Unit: second]

¥¥¥¥¥¥OPTION DATE/TIME SETTING Year: 2007 ~ 2099

¥¥¥¥¥¥ Month: 1 ~ 12

¥¥¥¥¥¥ Day: 1 ~ 28, 29, 30, 31

¥¥¥¥¥¥ Time: 00:00 ~ 23:59

¥¥¥¥¥¥

¥¥¥¥¥¥

¥¥¥¥¥¥

¥¥¥¥¥¥

¥¥¥¥¥¥

¥¥¥¥¥¥ TIME 00:00 ~ 23:59

¥¥¥¥¥¥

¥¥¥¥¥¥

RESET OFF

SCREEN MOTION OFF

MOTION TIME 2 PATTERN1: 10 ~ 990 (S)

MONITOR LANDSCAPE

LANGUAGE ENGLISH/DEUTSCH/FRANCAIS/

PICTURE FLIP STANDARD

SCHEDULE (Set

DVI SELECT PC (DIGITAL)

--- or ¥ )

POWER OFF

DAY OF THE WEEK ONLY ONCE

INPUT ---

−10 ~ 0 ~ +10

−10 ~ 0 ~ +10

−10 ~ 0 ~ +10

ON

PATTERN1

PATTERN2

PATTERN3

PATTERN4

PATTERN2/3/4: 5 ~ 20 (S) [Unit: second]

PORTRAIT

ITALIANO/ESPANOL/PYCCKNÑ/

Japanese

MIRROR

UPSIDE DOWN

ROTATE

--- (Invalidity)

¥ (Effectriely)

ON

EVERY DAY

EVERY WEEK

MON

TUE

WED

THU

FRI

SAT

SUN

--MON

TUE

WED

THU

FRI

SAT

SUN

PC1/AV1

PC2

PC3/AV2

AV3

AV (DIGITAL)

PN-525U CONNECTION, ADJUSTMENT, OPERATION, AND FUNCTION

2 – 8

Page 17

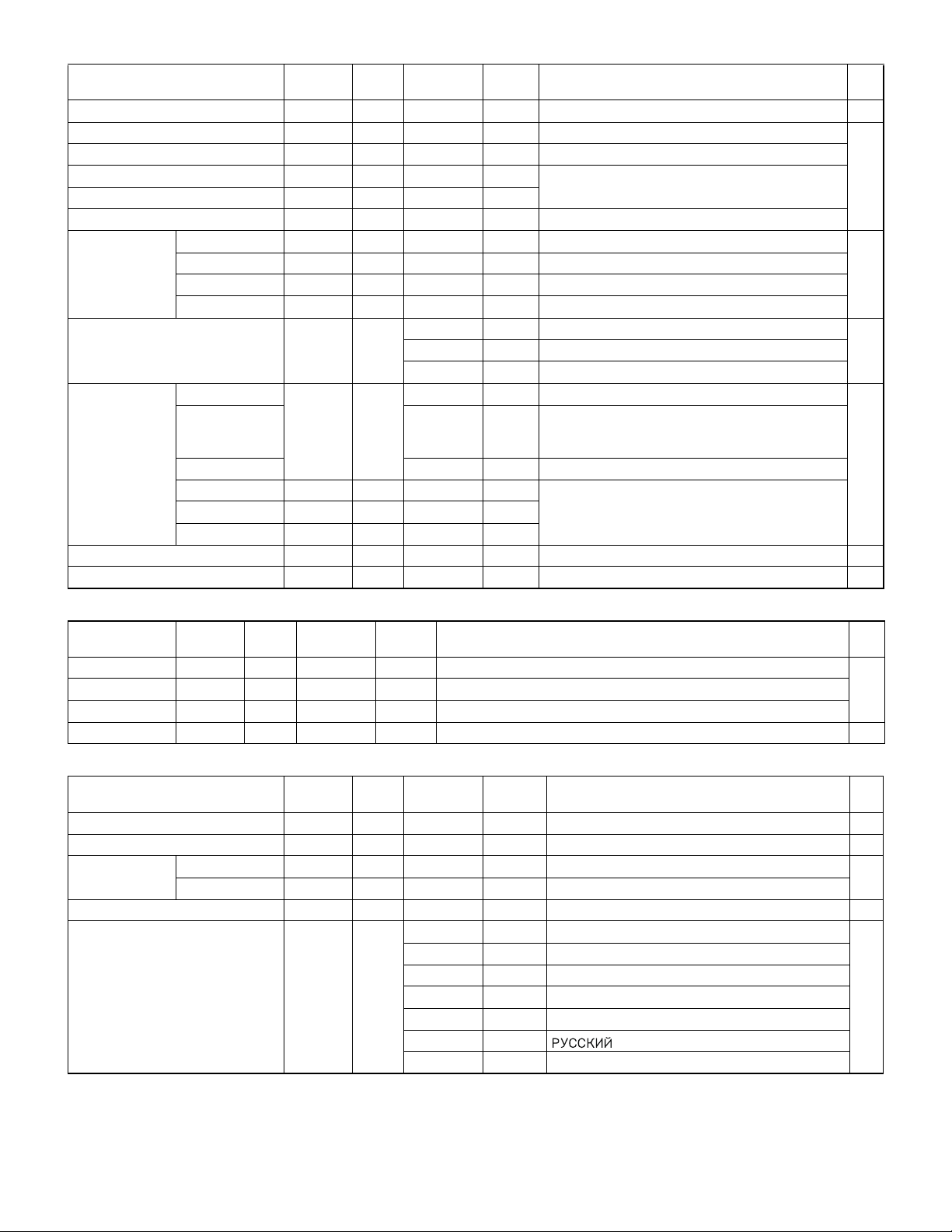

INPUT MODE ITEM ADJUSTMENT

¥¥¥¥¥¥

¥¥¥¥¥¥

¥¥¥¥¥¥

¥¥¥¥¥¥

¥¥

¥¥

¥¥¥¥¥¥

¥¥¥¥¥¥

¥¥¥¥¥¥

¥¥¥

¥¥¥

¥¥¥ BEZEL H 0 ~ 100

¥¥¥ BEZEL V 0 ~ 100

¥¥¥ H-POS infinite

¥¥¥ V-P OS in finite

¥¥¥¥¥¥

¥¥¥¥¥¥ PIP SIZE 1 ~ 12

¥¥¥¥¥¥ PIP H-POS 0 ~ 100

¥¥¥¥¥¥ PIP V-POS 0 ~ 100

¥¥¥¥¥¥ PIP BLEND 0 ~ 15

¥¥¥¥¥¥ PIP SOURCE

¥¥¥¥¥¥

¥¥¥¥¥¥

¥¥¥¥¥¥

¥¥¥¥¥¥

OPTION BNC SELECT PC (ANALOG)

QUICK SHOOT OFF

COLOR SYSTEM AUTO

AUDIO OUTPUT VARIABLE

480 LINES 640

768 LINES 1024

SELF ADJUST OFF

POWER MANAGEMENT OFF

AUTO INPUT CHANGE OFF

ENLARGE ENLARGE MODE OFF

ENLARGE POS 2

PIP/PbyP PIP MODES OFF

SOUND CHANGE MAIN

MAIN POS POS1

PbyP2 POS POS1

AUTO OFF MANUAL

AV (COMPONENT)

ON

PA L

PAL-60

SECAM

NTSC3.58

NTSC4.43

FIXED

× 480

× 480

848

1280

1360

ON

ON

ON

× 2

2

× 3

3

× 4

4

× 5

5

× 2: 0 ~ 3

× 3: 0 ~ 8

3

× 4: 0 ~ 15

4

× 5: 0 ~ 24

5

PIP

PbyP

PbyP2

SUB

POS2

POS2

POS3

AUTO

× 768

× 768

× 768

PN-525U CONNECTION, ADJUSTMENT, OPERATION, AND FUNCTION

2 – 9

Page 18

2-4. 232C CONTROL

(1) Communication procedure

<Command format>

When a command is sent from the PC to the monitor, the monitor operates according to the received command, and sends a response message to the PC.

■ When a command has not been executed

Return code (0DH, 0AH)

RRE

*If an ID number has been assigned

Return code

C1 C2 C3 C4 P1 P2 P3 P4

Command field

(4 prescribed

alphanumerical

characters)

Parameter field

(4 character string

comprised of:

0-9, +, -, space, ?)

Example: VOLM0030

VOLM 30

*Be sure to input 4 characters for the parameter. Pad with spaces

(“ ”) if necessary.

(“[Enter]” is a return code (0DH, 0AH or 0DH))

Wrong : VOLM30 [Enter]

Right : VOLM 30 [Enter]

When inputting a negative value, specify a numerical value in three digits.

Example: AUTR-009

Do not use spaces for MPOS, DATE, and SC01 through SC08. Specify parameters using a specified number of characters.

Example: MPOS010097

If a command has “R” listed for “DIRECTION” in the “RS- 232C command table”, the current value can be returned by using “?” as the

parameter.

Example :

VOLM????

1

From PC to monitor

(How much is current volume setting?)

30

If an ID number has been assigned (For example, ID number

1

From monitor to PC (Current volume setting: 30)

=

1)

VOLM ?1 From PC to monitor

30 001

1

From monitor to PC

<Response code format>

■ When a command has been executed correctly

Return code (0DH, 0AH)

OK

A response is returned after a command is executed.

*If an ID number has been assigned

Space (20H)

O K SPC 0 0 1

ID number of responding monitor

Return code (0DH, 0AH)

Space (20H)

Return code (0DH, 0AH)

RRE SPC 0 0 1

ID number

• “ERR” is returned when there is no relevant command or when the

command cannot be used in the current state of the monitor.

• If communication has not been established for reasons such as a bad

connection between the PC and monitor, nothing is returned (not

even ERR).

• If no monitor has been assigned the designated ID number (e.g. if the

command IDSL0002 [Enter] is used, but no monitor with ID number: 2

is found), no response is returned.

■ If execution of the command is taking some time

Return code (0DH, 0AH)

IWTA

When the following commands are used, “WAIT” is returned.

In this case, a value will be returned if you wait a while. Do not send any

command during this period.

No ID number is attached to WAIT response.

• Commands which return WAIT:

1 When repeater control is used

2 When an IDSL or IDLK command is used

3 When one of the following commands is used:

RSET, INPS, ASNC, WIDE, EMAG, EPOS, PXSL, POWR,

AGIN, MWIN, MWIP, MWPP, ESTG

■ When control via RS-232C is locked (to prevent use) using the

operation lock function

Return code (0DH, 0AH)

ECDKOL

Advanced operation

This section explains commands for daisy chain connection. The basic

communication procedure is the same as in the “One-to-one connection

with a PC” section.

<ID numbers>

You can assign a unique ID number to each monitor. This allows you to

control a particular monitor in a daisy chain of monitors.

You can assign ID numbers either from the menu screen (using the

remote control) or from the PC using RS-232C cable.

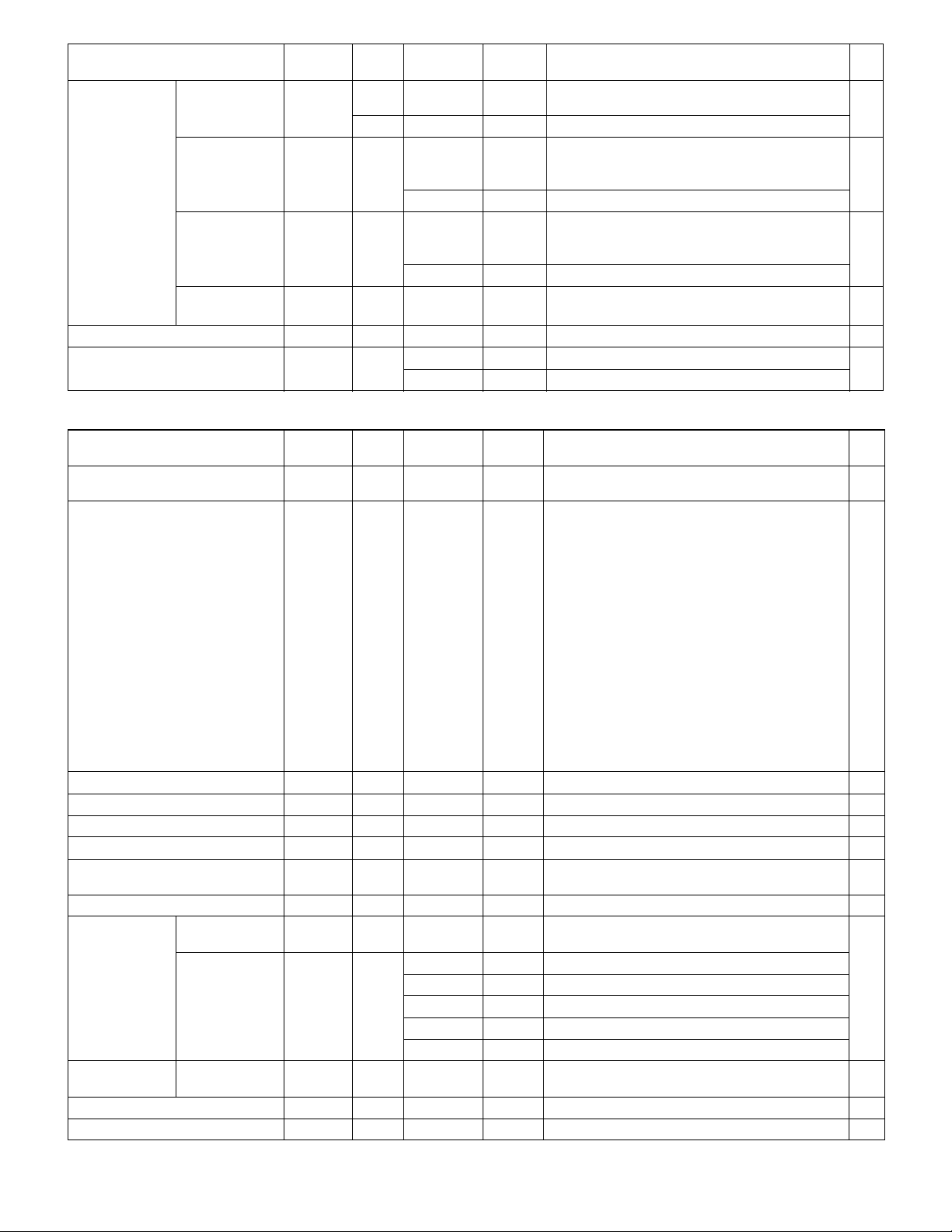

[Example]

ID number: 1

ID number: 2 ID number: 3 ID number: 4

If monitors are connected as shown above, you can execute commands

like “Set the volume of the monitor with ID 4 to 20”.

When controlling monitors linked in a daisy chain by designating ID

numbers, you should basically avoid any duplication of ID numbers.

PN-525U CONNECTION, ADJUSTMENT, OPERATION, AND FUNCTION

2 – 10

Page 19

ID numbers do not have to be assigned in ascending order starting from

the PC. They can also be connected as shown below.

[Example]

ID number: 3 ID number: 2 ID number: 4 ID number: 1

<Commands for ID control>

The command examples shown on this page assume the following connection and ID number set up.

ID number: 1 ID number: 2 ID number: 3 ID number: 4

IDST: A monitor receiving this command sets its own ID number in the

parameter field.

Example: IDST0001

OK 001

1

The ID number of this monitor is set to 1.

Note: You can automatically assign ID numbers by using the IDST

command with the Repeater control.

For example, using the command “IDST001

+” automatically sets

the ID numbers, as shown below.

[Example]

ID number: 1 ID number: 2 ID number: 3 ID number: 4

IDST001

+

1

ID setting command with repeater control

WAIT

OK 001

OK 002

OK 003

OK 004

1

“OK” response from ID number : 1

1

“OK” response from ID number : 2

1

“OK” response from ID number : 3

1

“OK” response from ID number : 4 (End)

IDSL: The parameter of this command sets the ID number of the monitor.

The monitor is subject to the next command.

Example:

IDSL0002

WAIT

OK 002

VOLM0030

WAIT

OK 002

VOLM0020

OK 001

1

The next command is for the monitor with ID number : 2.

1

Searching for monitor with ID number : 2

1

Found monitor with ID number : 2

1

Sets volume of monitor with ID number : 2 to 30.

1

Processing

1

OK response from monitor with ID number : 2

1

Sets volume to 20.

1

The volume of the monitor

with ID number : 1

(the one directly connected

to the PC) is set to 20.

*

*The IDSL command is effective only once, for the immediately

succeeding command.

IDSL: The parameter of this command sets the ID number of the monitor.

The monitor is subject to all subsequent commands.

Example:

IDLK0002

1

Following commands are for the monitor with ID number : 2.

1

WAIT

OK 002

VOLM0030

WAIT

Searching for monitor with ID number : 2

1

Found monitor with ID number : 2

1

Sets volume of monitor

with ID number : 2 to 30.

1

Processing

*

OK 002

VOLM0020

1

Sets volume of monitor

with ID number : 2 to 20.

*

WAIT

OK 002

1

IDLK0000

WAIT

OK 002

Canceling fixed ID number setting

1

Canceling IDLK

1

Cancelation complete

VOLM0010

1

OK 001

The volume of the monitor with ID number: 1

(the one directly connected to the PC) is set to 10.

(IDLK is canceled.)

*The IDLK command remains effective until it is canceled, or power

is shut off.

IDCK: Provides screen display of the ID number currently assigned to a

monitor, and the ID number currently set for IDLK (if any).

Example:

(After executing IDLK0002)

1

IDCK0000

ID:001 IDLK:002

(Parameter has no meaning.)

1

Returned response. The ID number is also displayed on the monitor screen.

IDCK000

+

1

Repeater control

(If a command is used with repeater control, ID

designation using IDSL or IDLK is canceled.)

WAIT

ID:001 IDLK:000

ID:002 IDLK:000

ID:003 IDLK:000

ID:004 IDLK:000

<Repeater control>

This system has a function to allow setting of multiple monitors connected in a daisy chain using a single command. This function is called

repeater control. You can use Repeater control function without assigning ID numbers.

[Example]

Set 1 Set 2 Set 3 Set 4

If monitors are connected as shown above, you can execute a command like “Set all monitors’ input settings to PC1 DIGITAL”.

PN-525U CONNECTION, ADJUSTMENT, OPERATION, AND FUNCTION

2 – 11

Page 20

<Repeater control command>

Repeater control is achieved by setting the FOURTH CHARACTER of

the parameter to “

+”.

Example:

VOLM030

+ 1 Sets volume of all monitors to 30.

In repeater control, responses are returned by all the connected monitors.

If you want to determine that a value has been returned by a specific

set, assign ID numbers to each monitor in advance.

When some monitors do not return their responses, the probable cause

is that the monitors could not receive the command or command processing is not complete. Do not send a new command.

Example:

(When 4 monitors are connected, and assigned ID numbers: 1 through 4)

VOLM030

+

WAIT

OK 001

OK 002

OK 003

1

OK 004

If 4 monitors are connected in a chain, reliable operation can be ensured by sending a new command only

after a reply has been returned by 4th (last) monitor.

Repeater control can also be used for reading settings.

Example:

VOLM??? +

WAIT

10 001

20 002

30 003

Volume settings for all monitors are returned.

30 004

Note:

• If repeater control is used during ID designation (IDSL, IDLK),

the ID designation is canceled.

• Commands that use parameters consisting of more than four characters can not be controlled by repeater control.

<Communication interval>

• After OK or ERR is returned, you must send the following commands.

To set a timeout for the command response, specify 10 seconds or

longer.

• Provide an interval of 100 ms or more between the command

response and the transmission of the next command.

VOLM0020

OK

Interval of 100 ms or more

INPS0001

WA I T

OK

PN-525U CONNECTION, ADJUSTMENT, OPERATION, AND FUNCTION

2 – 12

Page 21

2) RS-232C command table

<How to read the command table>

Command : Command field

Direction : W: When the “Parameter” is set in the parameter field, the command functions as described under “Control/Response Contents”.

R : The returned value indicated under “Reply” can be obtained by setting “????”, “ ?” or “???

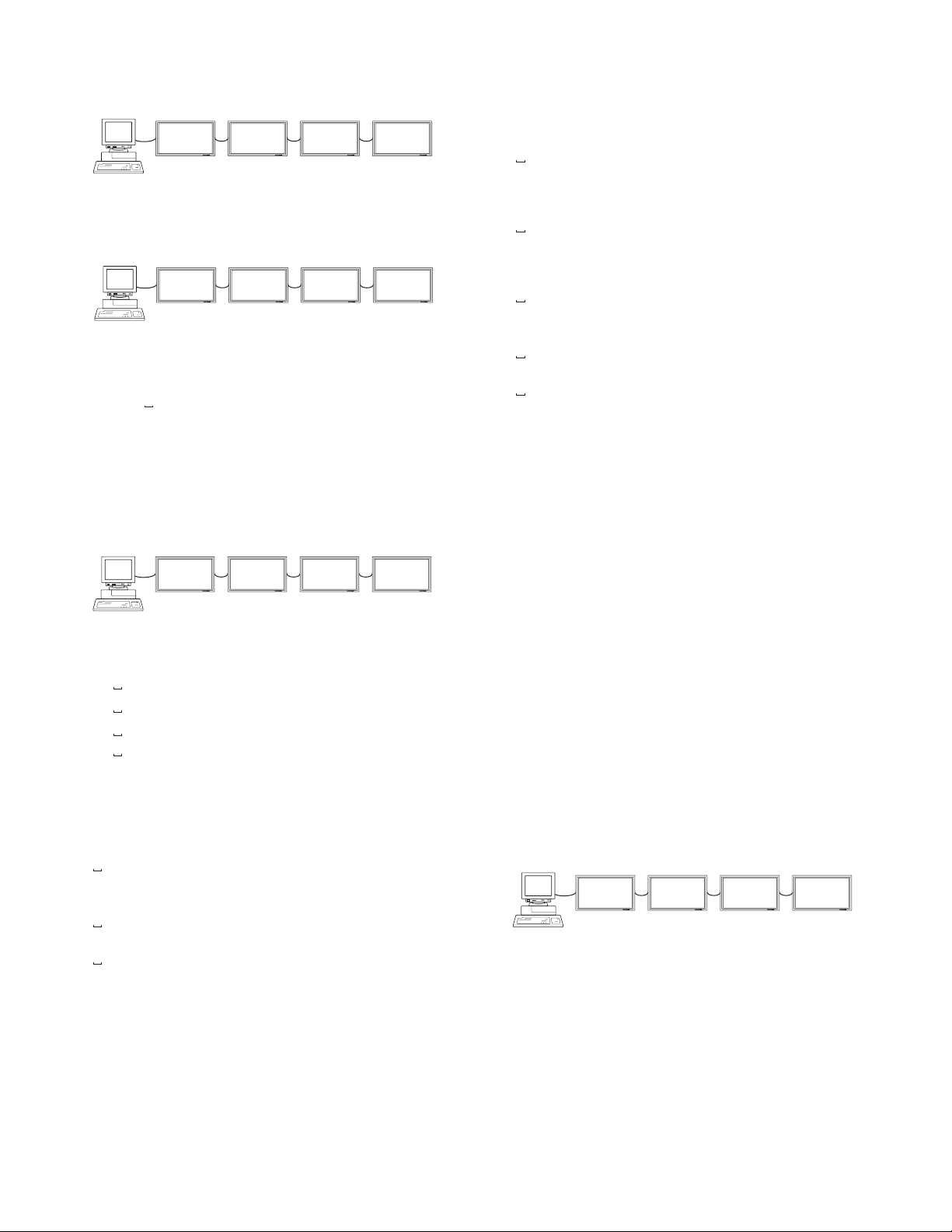

field.

Parameter : Parameter field

Reply : Response (Returned value)

* : “Yes” indicates commands which can be used in power standby mode.

Note: To specify the horizontal/vertical positions for vertical orientation, specify the values for horizontal orientation.

+” (repeater control) in the parameter

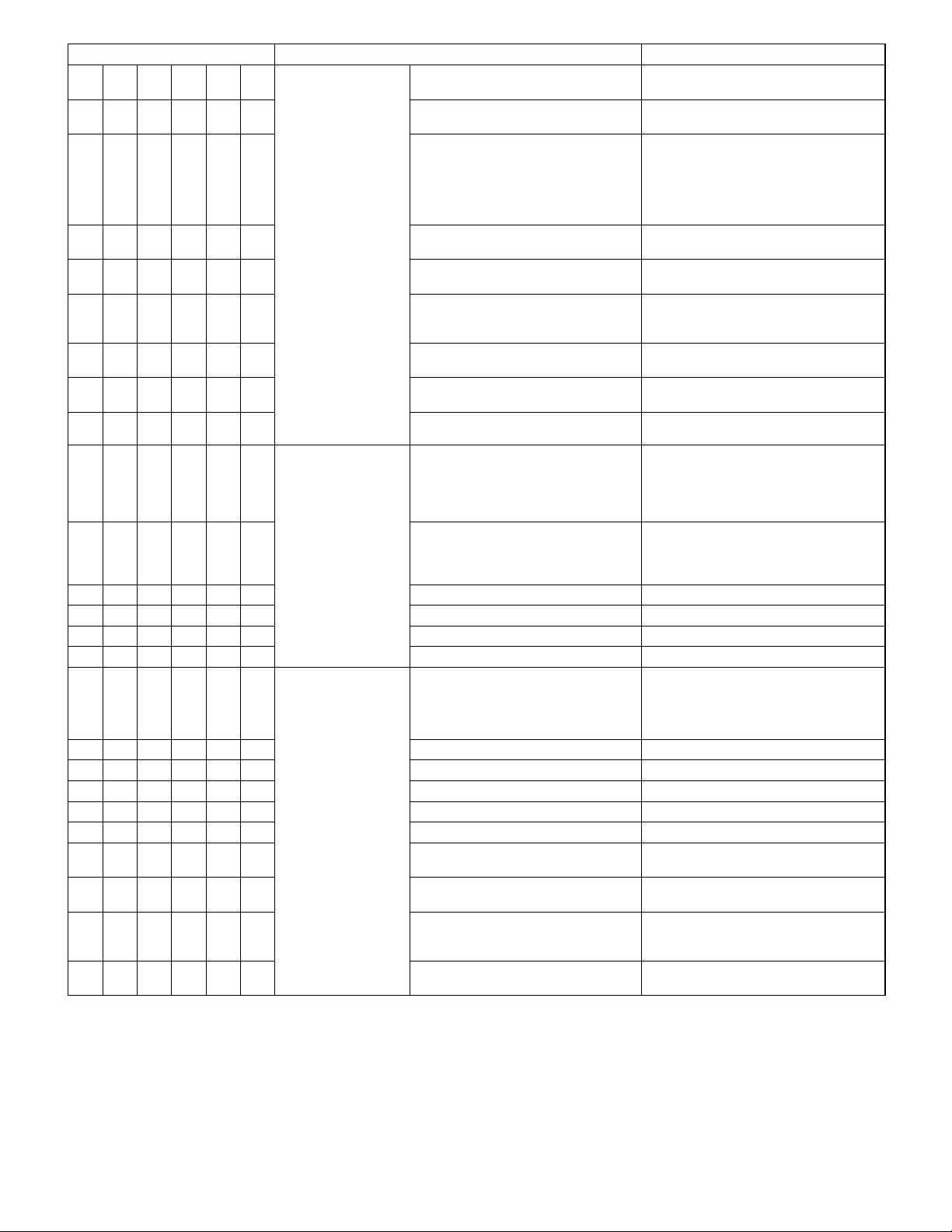

■ Power control/Input mode selection

Function Command Direction Parameter Reply Control/Response contents *

POWER CONTROL POWR W 0 Switches to standby mode. o

1 Returns from standby mode.

R 0 Standby mode

1 Normal mode

2 Input signal waiting mode

INPUT MODE SELECTION INPS W 0 Toggle change for input mode

1 PC1 DIGITAL

2PC2 ANALOG

3 AV2 COMPONENT

4 AV3 VIDEO

6PC3 ANALOG

7AV1 DIGITAL

R 1 PC1 DIGITAL

2PC2 ANALOG

3 AV2 COMPONENT

4 AV3 VIDEO

6PC3 ANALOG

7AV1 DIGITAL

Terminals not selected in DVI SELECT/BNC

SELECT cannot be selected.

“ERR” when AV (DIGITAL) is selected for DVI

SELECT.

“ERR” when PC (ANALOG) is selected for BNC

SELECT.

“ERR” when AV (COMPONENT) is selected for BNC

SELECT.

“ERR” when PC (DIGITAL) is selected for DVI

SELECT.

o

■ SCREEN menu (PC2/PC3)

Function Command

AUTO ASNC W 1

CLOCK CLCK WR 0-255 0-255

PHASE PHSE WR 0-63 0-63

POSITIONING POSITION OF

THE LONGEST

DIRECTION

POSITION OF

THE SHORTEST

DIRECTION

RESET ARST W 1

HPOS WR 0-500 0-500 A maximum value depends on a resolution.

VPOS WR 0-100 0-100

Direc-

PN-525U CONNECTION, ADJUSTMENT, OPERATION, AND FUNCTION

Parameter Reply Control/Response contents *

tion

2 – 13

-

-

-

Page 22

■ PICTURE menu

Function Command

AUTO AGIN W 1 When the input mode is PC2, PC3.

CONTRAST CONT WR 0-60 0-60 0-127 on PC2/PC3. o

BLACK LEVEL BLVL WR 0-60 0-60 0-127 on PC2/PC3.

TINT TINT WR 0-60 0-60 When the input mode is AV.

COLOR COLR WR 0-60 0-60

SHARPNESS SHRP WR 0-24 0-24

ADVANCED FLESH TONE FLES WR 0-2 0-2 0: OFF, 1: LOW, 2: HIGH o

3D-NR TDNR WR 0-2 0-2 0: OFF, 1: LOW, 2: HIGH

MPEG-NR MPNR WR 0-1 0-1 0: OFF, 1: ON

3D-Y/C YCSP WR 0-1 0-1 0: OFF, 1: ON

COLOR MODE BMOD WR 0 0 STD o

WHITE

BALANCE

GAMMA GAMM WR 0-2 0-2 0: 1.8, 1: 2.2, 2: 2.4 o

RESET ARST W 2

THRU CTMP WR 0 0 When the input mode is PC1. o

PRESET 1-15 1-15 From 1: approximately 3,000K to 15: approximately

USER 99 99

R-CONTRAST CRTR WR 0-512 0-512 “ERR” when CTMP is not set to 99.

R-CONTRAST CRTG WR 0-512 0-512

B-CONTRAST CRTB WR 0-512 0-512

Direc-

tion

Parameter Reply Control/Response contents *

2 2 VIVID

3 3 sRGB (When the input mode is PC)

10,000K

(500K steps)

-

-

■ AUDIO menu

Function Command

TREBLE AUTR WR

BASS AUBS WR

BALANCE AUBL WR

RESET ARST W 3

Direc-

tion

Parameter Reply Control/Response contents *

−10-10 −10-10 o

−10-10 −10-10

−10-10 −10-10

■ SETUP menu

Function Command

SCREEN MOTION SCSV WR 0-4 0-4 0: OFF, 1-4: PATTERN 1-4 o

MOTION TIME 1 MTIM WR 0-20 0-20 o

MOTION TIME 2 PATTERN 1 MINT WR 10-990 10-990 Per 10 seconds o

PATTERN 2-4 MINT WR 5-20 5-20 Per second

MONITOR STDR WR 0-1 0-1 0: LANDSCAPE, 1: PORTRAIT o

LANGUAGE LANG WR 14 14 ENGLISH o

Direc-

tion

Parameter Reply Control/Response contents *

1 1 DEUTSCH

22FRANÇAIS

33ITALIANO

44ESPAÑOL

55

66

日本語

-

PN-525U CONNECTION, ADJUSTMENT, OPERATION, AND FUNCTION

2 – 14

Page 23

Function Command

ID NUMBER ID NO. SETTING IDST W 0-255 Sets the monitor’s ID number. (“0” means “no ID num-

ID NO. SETTING

(ONCE)

ID NO. SETTING

(SUBSEQUENT)

ID CHECK IDCK W 0 ID: xxx

PICTURE FLIP PFIL WR 0-3 0-3 0: OFF, 1: MIRROR, 2: UPSIDE DOWN, 3: ROTATE o

Power On Delay PWOD WR 0 0 OFF o

IDSL W 1-255 Sets a monitor ID number.

IDLK W 1-255 Sets a monitor ID number.

Direc-

Parameter Reply Control/Response contents *

tion

ber”.)

R 0-255 Returns the monitor’s ID number.

This ID number is only effective for the command

immediately after this command.

0 Clears the ID number if one has been designated.

This ID number is effective for the next and all subsequent commands after this command.

0 Clears the ID number if one has been designated.

Displays monitor's own ID number and the selected

IDLK: yyy

1-60 1-60 ON

ID number on the screen.

■ OPTION menu

o

o

o

o

Function Command

DATE/TIME SETTING DATE WR AABBCCD-

SCHEDULE SC01~

DVI SELECT DVSL WR 0-1 0-1 0: PC (DIGITAL), 1: AV (DIGITAL) o

BNC SELECT BNSL WR 0-1 0-1 0: PC (ANALOG), 1: AV (COMPONENT) o

QUICK SHOOT (PC) QSPC WR 0-1 0-1 0: OFF, 1: ON o

QUICK SHOOT (AV) QSAV WR 0-1 0-1 0: OFF, 1: ON o

COLOR SYSTEM CSYS WR 0-5 0-5 0: AUTO, 1: PAL, 2: PAL-60, 3: SECAM, 4: NTSC3.58,

AUDIO OUTPUT AOUT WR 0-1 0-1 0: VARIABLE, 1: FIXED o

INPUT RESOLU-

TION (PC)

INPUT RESOLUTION (AV)

SELF ADJUST AADJ WR 0-1 0-1 0: OFF, 1: ON o

POWER MANAGEMENT PMNG WR 0-1 0-1 0: OFF, 1: ON o

RESOLUTION

CHECK

PIXEL SETTING

(PC2, PC3)

RESOLUTION

CHECK

C08

PXCK R

PXSL WR 1 1 V: 768) 1360 × 768

RESO R

Direc-

WR ABCDEF-

Parameter Reply Control/Response contents *

tion

DEE

FGGH

2 2 V: 768) 1280

3 3 V: 768) 1024

5 5 V: 480) 848

6 6 V: 480) 640

AABBCCDDEE

ABCD-

EFFGG

H

-

-

AA: Year, BB: Month, CC: Day, DD: Time, EE: Minute o

Schedule of a specified number

=

A: Schedule 0

B: Power 0

C: Day of the week 1 0

D: Day of the week 2 0

E: Day of the week 3 0

F: Time 00-23

G: Minute 00-59

H: Input 0

5: NTSC4.43

Returns current resolution in the form of hhh, vvv.

Not effective, 1 = Effective

= OFF, 1 = ON

= Only once,

= Every week,

1

= Every day

2

= Sunday,

= Monday through

1

= Saturday, 9 = Not exist

6

= Sunday,

= Monday through

1

= Saturday, 9 = Not exist

6

= Not specified,

= PC1/AV1, 2 = PC2,

1

= PC3/AV2, 4 = AV3

3

-

× 768

× 768

× 480

× 480

480i, 480p, 1080i, 720p, 1080p, VGA, etc.

-

o

PN-525U CONNECTION, ADJUSTMENT, OPERATION, AND FUNCTION

2 – 15

Page 24

Function Command

AUTO INPUT CHANGE AINC WR 0-1 0-1 0: OFF, 1: ON o

Direc-

tion

Parameter Reply Control/Response contents *

■ ENLARGE menu (When the input mode is PC)

Function Command

ENLARGE MODE EMAG WR 0-4 0-4 0: OFF, 1: 2

BEZEL WIDTH WIDT H OF THE

IMAGE POSITION (2

IMAGE POSITION (3

IMAGE POSITION (4

IMAGE POSITION (5

ENLARGED

SCREEN

POSITIONING

ENLARGE/IMAGE POSITION

SETTING

SHORTER SIDE

WIDTH OF THE

LONGER SIDE

× 2) EPOS WR 0-3 0-3 Refer to “■ Enlarge”

× 3) EPOS WR 0-8 0-8

× 4) EPOS WR 0-15 0-15

× 5) EPOS WR 0-24 0-24

THE LONGEST

DIRECTION

THE SHORTEST

DIRECTION

BEZH WR 0-100 0-100

BEZV WR 0-100 0-100

EPSH WR -999-999 -999-999 The setting range depends on the ENLARGE MODE

EPSV WR -999-999 -999-999

ESTG WR XXYY XXYY XX: Enlarge mode (Same as EMAG),

Direc-

tion

Parameter Reply Control/Response contents *

× 2, 2: 3 × 3, 3: 4 × 4, 4: 5 × 5

setting and the IMAGE POSITION.

YY: Image Position (Same as EPOS)

■ PIP/PbyP menu

Function Command

PIP MODES MWIN WR 0-3 0-3 0: OFF, 1: PIP, 2: PbyP, 3: PbyP2 o

PIP SIZE MPSZ WR 1-12 1-12 o

PIP POS T H E L O N G E S T

DIRECTION

THE SHORTEST

DIRECTION

PIP V/H-POS MPOS W 0-100,

PIP BLEND MWBL WR 0-15 0-15 o

PIP SOURCE MWIP WR 1 1 PC1 DIGITAL o

SOUND CHANGE MWAD WR 1-2 1-2 1: MAIN, 2: SUB o

MAIN POS (Main screen) MWPP WR 0-1 0-1 0: POS1, 1: POS2 o

PbyP2 POS (Sub screen) MW2P WR 0-2 0-2 0: POS1, 1: POS2, 2: POS3 o

AUTO OFF MOFF WR 0-1 0-1 0: MANUAL, 1: AUTO o

MHPS W 0-100 o

MVPS W 0-100 o

Direc-

Parameter Reply Control/Response contents *

tion

R 0-100 o

R 0-100 o

0-100

R 0-100,

0-100

2 2 PC2 ANALOG

33AV2 COMPONENT

44AV3 VIDEO

6 6 PC3 ANALOG

7 7 AV1 DIGITAL

Specify the position in MPOSxxxyyy format.

(xxx: Longer side, yyy: Shorter side position)

Returns a response in (xxx,yyy) format.

(xxx: Longer side, yyy: Shorter side position)

-

o

o

■ Initialization/Functional Restriction Setting (FUNCTION) menu

Function Command

ALL RESET RSET W 0

ADJUSTMENT

LOCK

OSD DISPLAY LOSD WR 0-1 0-1 0: ON, 1: OFF o

LED OFLD WR 0-1 0-1 0: ON, 1: OFF o

ALCK WR 0-2 0-2 0: OFF o

Direc-

tion

Parameter Reply Control/Response contents *

PN-525U CONNECTION, ADJUSTMENT, OPERATION, AND FUNCTION

2 – 16

-

Page 25

■ Others

Function Command

SCREEN SIZE (PC) WIDE WR 1-5 1-5 1: WIDE, 2: NORMAL, 3: DotbyDot, 4: ZOOM1,

SCREEN SIZE (AV) WIDE WR 1-5 1-5 1: WIDE, 2: ZOOM1, 3: ZOOM2, 4: NORMAL,

VOLUME VOLM WR 0-31 0-31 o

MUTE MUTE WR 0-1 0-1 0: OFF, 1: ON

INFORMATION MODEL INF1 R Value o

SERIAL NO SRNO R Value o

BRIGHT VLMP WR 0-31 0-31 Brightness o

TEMPERATURE SENSOR DSTA R 0 Internal temperature normal o

TEMPERATURE ACQUISITION ERRT R Value Temperature at temperature sensors 1 through 3 are

CAUSE OF LAST STANDBY MODE STCA W 0 Initialization o

Direc-

Parameter Reply Control/Response contents *

tion

5: ZOOM2

5: DotbyDot

1 Internal temperature abnormal (Standby mode) o

2 Internal temperature abnormal (Temperature is nor-

mal now, but it was abnormal during operation.)

3 Internal temperature abnormal

(Brightness of the backlight decreases.)

4 Temperature sensor abnormal o

returned in the following forms:

[Sensor 1], [Sensor 2], [Sensor 3]

R 0 No detectable error has occurred

1 Standby mode by POWER button

2 Main power “OFF” by the main power switch

3 Standby mode by RS-232C

4 Waiting mode by No Signal

(Incl: VESA DPMS/DMPM)

6 Standby mode by abnormal temperature

8 Standby mode by SCHEDULE setting

o

o

-

o

o

o

PN-525U CONNECTION, ADJUSTMENT, OPERATION, AND FUNCTION

2 – 17

Page 26

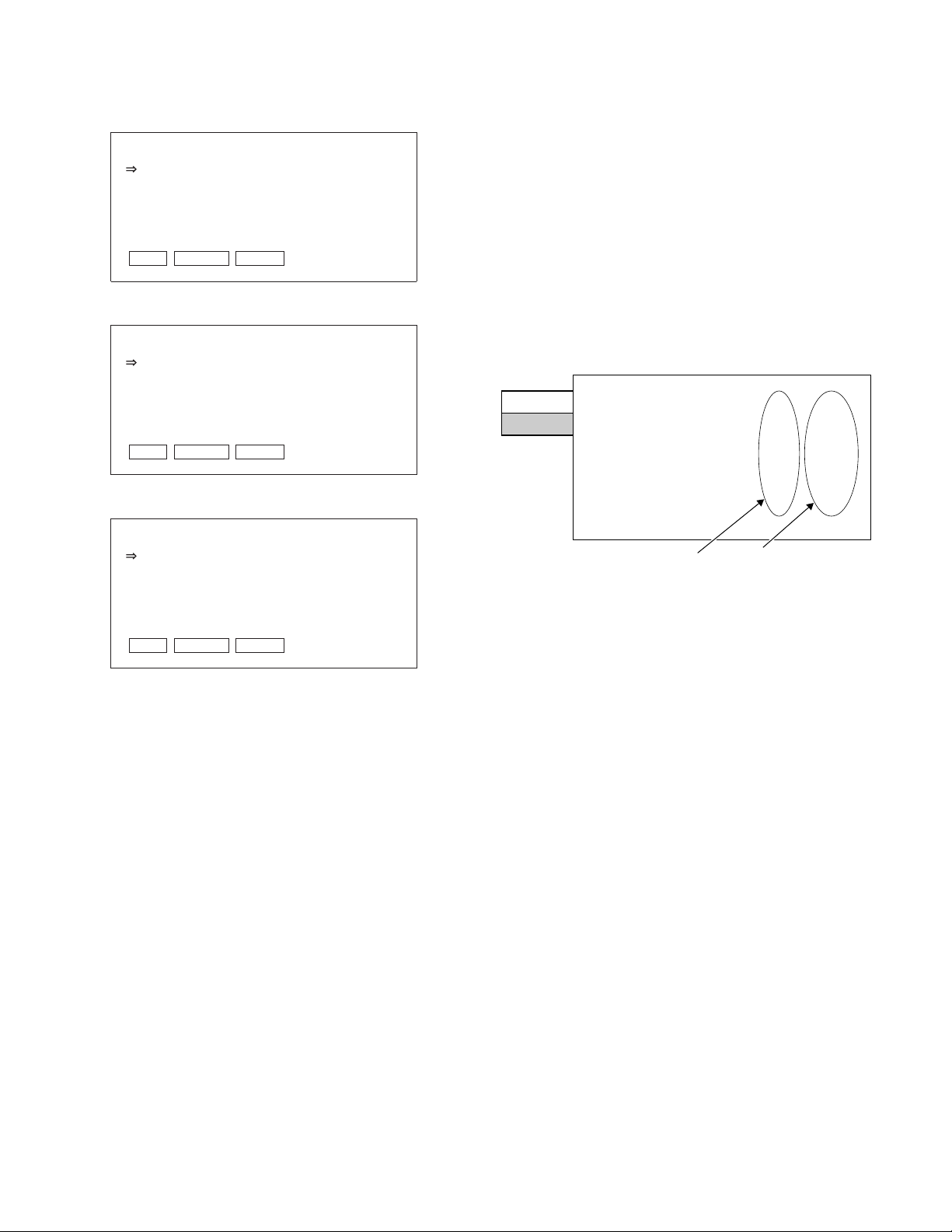

3. SERVICE MENU

g

SERVICE MENU 1:

Used to display the model name, the manufacturing No., the firmware

version/checksum, and the usage time.

[Operating procedures]

1) Press [SIZE] button for 5sec, and press [1] [ 4 ] [3] [ 2 ] buttons in

this sequence. “SERVICE MENU1” is displayed.

Firmware checksum

Firmware version

Serial number

Model name

SERVICE1

SERVICE2

SERVICE MENU1 1/1

MODEL

S/N

FIRM VERSION

CHECK SUM

USAGE TIME

WHITE BALANCE CHECK

CALIBRATION CHECK

㧦

PNXXXXX

㧦

㧦

XXXXX (XXXXXXXX)

㧦

OK

㧦

XXXXXH

㧦

XXXXXXXX

XXXX

㧦

PC AV

PC2 PC3 AV2 AV3N AV3P

END[MENU]

Use time

• PC2/PC3/SOG SYNC THRESHOLD LEVEL :

Do not change the setting.

• HARDWARE CHECK SETTING:

Do not change the setting.

• AUTO INPUT CHANGE DELAY :

Do not change the setting.

[Operating procedures]

1) With “SERVICE MENU1” displayed, select “SERVICE2” with [ 4 ]

button and press [3] button.

SERVICE MENU2 1/2

SERVICE1

SERVICE2

ʋ

AGING

CALIBRATION

FACTORY RESET

MODEL TYPE

HARDWARE CHECK

WHITE BALANCE SETTING

COMPONENT PHASE

=>

=>

=>

< XX >

=>

=>

=>

When the calibration set value becomes the default

value, it is displayed.

(It is not displayed usually.)

When the white balance set value becomes the default

value by replacement of the PWB or the panel, it is

displayed.

(It is not displayed usually.)

*Immediately after turning on the power, “CALCULATING” is displayed

for the checksum for a while, and the result is dipslayed.

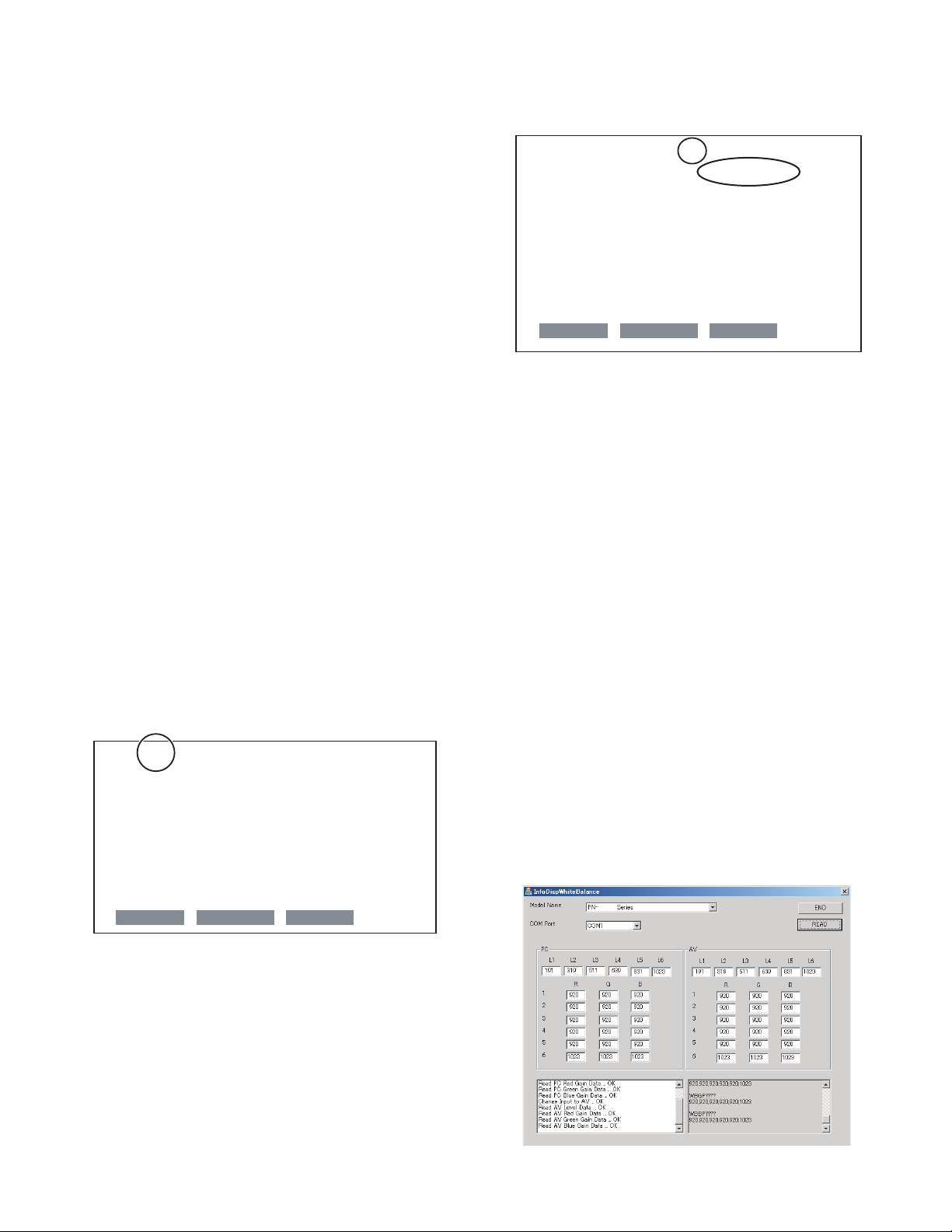

SERVICE MENU 2:

• AGING:

AGING. Refer to “3-1. AGING”.

• CALIBRATION :

Used to adjust automatically the gain and the offset of PC/components/composite. Refer to “3-2. Calibration”.

• FACTORY RESET :

Used to reset the user adjustment values, the usage time, and the

operation logs to the factory setting. Refer to “3-3. FACTORY

RESET”.

• MODEL TYPE :

Used to select the destination. JP: Japanese model, US: North America model, EU: A European model

After changing the MODEL TYPE, execute ALL RESET.

(Refer to “2-2. INITIALIZATION (RESET)/FUNCTIONAL RESTRICTION SETTING”)

• HARDWARE CHECK :

Used to display the hardware detection result. Refer to “3-4. HARDWARE CHECK”.

• WHITE BALANCE SETTING:

Refer to “3-5. WHITE BALANCE SETTING”.

• COMPONENT PHASE :

Do not change the setting.

2) Select setting item with [ 2 ] [ 4 ] button.

3) Adjust it with the [1] [3] button.

When the item with => mark press [3] button and advances to the

next screen.

4) Press [MENU] button to return to the previous screen sequentially,

terminating the operation.

3-1. AGING

(1) Operating procedures

1) Enter the “SERVICE MENU 2” mode.

2) Select [AGING] with [ 2 ] [ 4 ] buttons, and press [3] button.

3) Select [AGING1] or [AGING2] with [ 2 ] [ 4 ] buttons, and press [3]

button. The aging is started.

AGING1: Every time when [3] button is pressed, the whole screen

color is changed.

Dark

Dark

blue

green

AGING2: The whole screen color is changed every 2 sec.

Dark

Dark

blue

4) To terminate aging, turn off the main power source. (The power button of the remote controller or the machine cannot terminate aging.)

*AGING3 must not be used.

reen

Dark

red

Dark

red

Blue Green Red White Black

Blue Green Red White Black

PN-525U CONNECTION, ADJUSTMENT, OPERATION, AND FUNCTION

2 – 18

Page 27

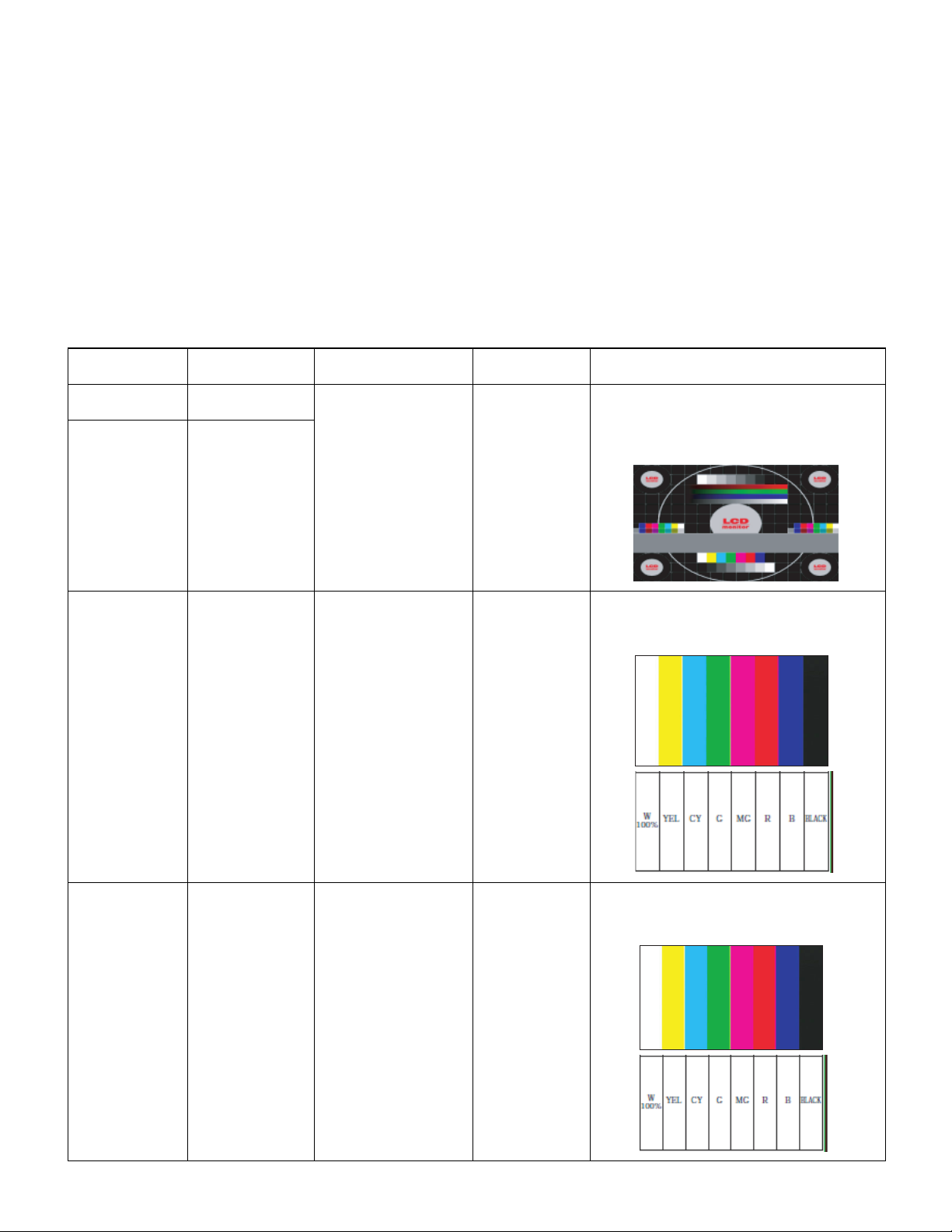

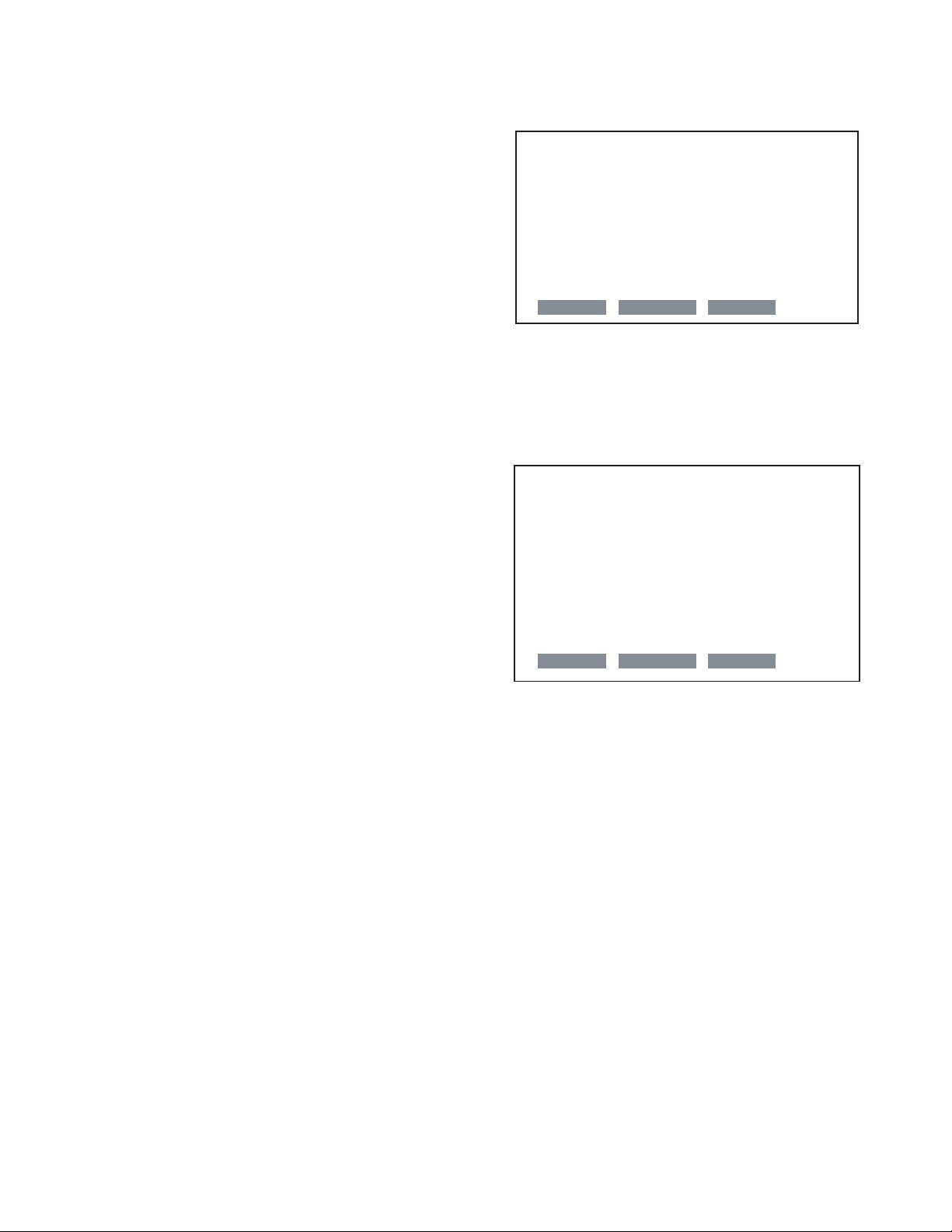

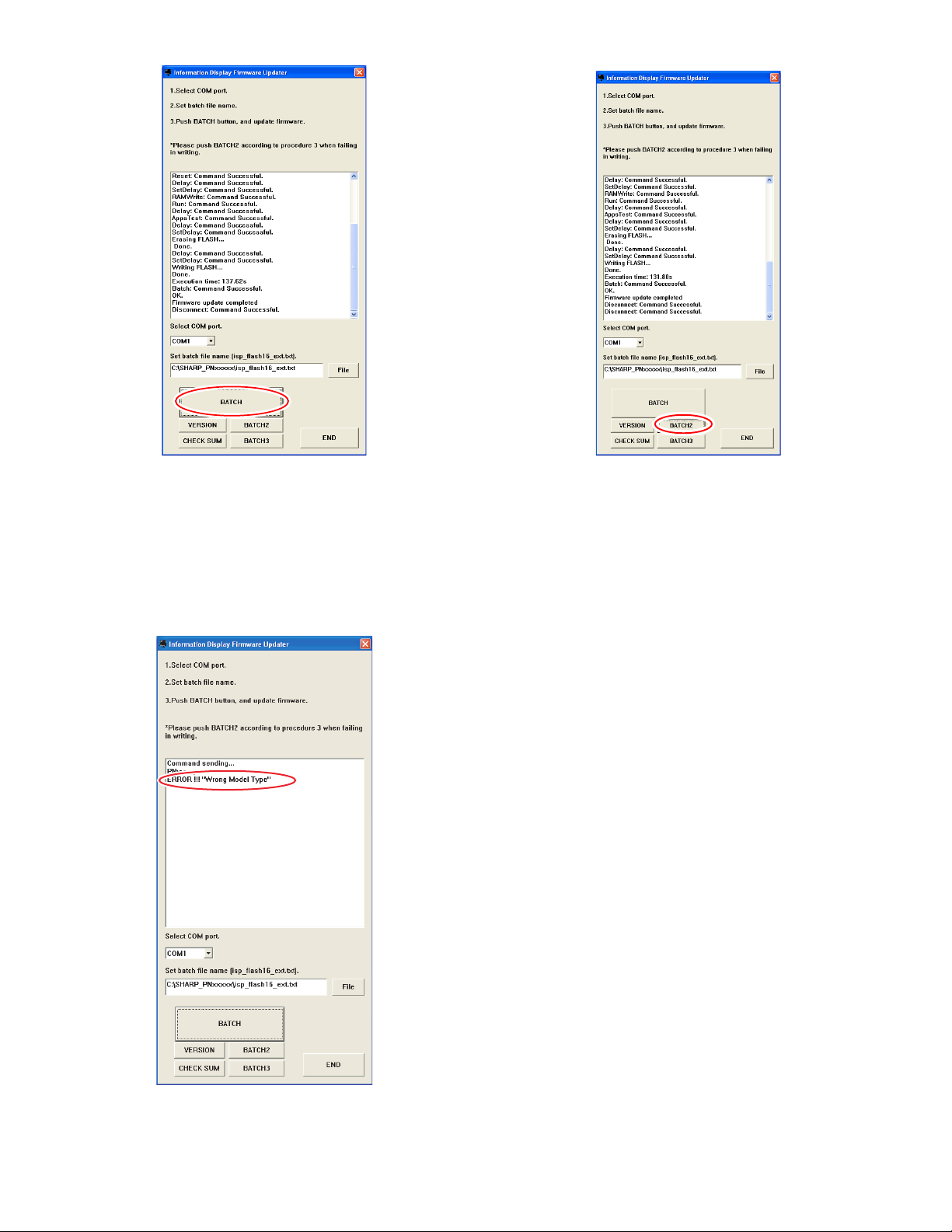

3-2. CALIBRATION

Adjusts the offset and the gain of an A/D converter by the following input mode.

• PC2 ANALOG mode (D-sub terminal)

• PC3 ANALOG mode (BNC terminal)

• AV2 COMPONENT mode (component terminal)

• AV3 VIDEO mode (composite terminal)

(1) Operating procedures

1) Select the input mode to be adjusted with [INPUT] button.

2) The video signal for adjustment is displayed on the screen.

Note:

• Be sure to use the following video signal to perform the adjustment.

• Since PC2 ANALOG (D-sub terminal) and PC3 ANALOG (BNC terminal) differ in the calibration results, be sure to adjust them with their own

input mode.

Input mode Signal type

PC2 ANALOG PC ANALOG signal

(D-sub terminal)

PC3 ANALOG PC ANALOG signal

(BNC terminal)

AV2 COMPONENT COMPONENT signal Y level: 0.7 Vp-p

Input signal level (Adjusted

standard value)

RGB level: 0.7 Vp-p 1920x1080 60Hz

(Pedestal to white level)

Pb/Pr level: 0.7 Vp-p

signal timing Input image

or

XGA (1024x768)

60Hz

1080i 60Hz Full color bar (White 100%, color saturation 100%)

The adjustment image displayed by executing

“Adj_uty.exe” in the CD-ROM packed together with

the product.

(Or a video image with 0 to 255 gradations of RGB

White)

*Recommended signal generator:

VG-849, VG-859 made by Astro Design.

AV3 VIDEO VIDEO (NTSC3.58)

signal

0.714 Vp-p

(Pedestal to white level)

PN-525U CONNECTION, ADJUSTMENT, OPERATION, AND FUNCTION

NTSC3.58 Full color bar (White 100%, color saturation 100%)

2 – 19

*Recommended signal generator:

VG-849, VG-859 made by Astro Design.

Page 28

3) Enter the “SERVICE MENU 2” mode.

4) Select [CALIBRATION] with [ 2 ] [ 4 ] buttons, and press [3] button. The CALIBRATION screen is displayed.

• CALIBRATION screen when PC2/PC3 ANALOG mode

CALIBRATION PC (ANALOG)

AUTO CALIBRATION

ADC OFFSET1 R: 511 B:G: 511 511

ADC OFFSET2 R: 128 G : B:128 128

ADC GAIN R : 511 511 511G: B: