PREPARED BY:

DATE:

A-

t SPEC.No: DG-996011

APPROVED BY: DATE: ELECTRONIC COMPONENTS GROUP

Jd B /‘YY

( SPECIFICATION 1 Opto-Electronic Devices Division

/

DEVICE SPECIFICATION FOR

SHARP CORPORATION

REPRESENTATIVE DIVISION:

Y

.

Light Emitting Diode

MODEL No.

LTlZE4OA

1. These specification sheets include materials protected under the copyright of Sharp Corporation (“Sharp”).

Please do not reproduce or cause anyone to reproduce them without Sharp5 consent.

2. When using this product, please observe the absolute maximum ratings and the instructions for use outlined

in these specification sheets, as well as the precautions mentioned below. Sharp assumes no responsibility

for any damage resulting corn use of the product which does not comply with the absolute maximum ratings

and the instructions included in these specification sheets, and the precautions mentioned below.

(Precautions)

(1) This products is designed for use in the following application areas;

* OA equipment * Audio visual equipment * Home appliance

* Telecommunication equipment (Terminal) * Measuring equipment

* Tooling machines * Computers

I

If the use of the product in the above application areas is for equipment listed in paragraphs

(2) or (3), please be sure to observe the precautions given in those respective paragraphs.

(2) Appropriate measures, such as fail-safe design and redundant design considering

the safety design of the overall system and equipment, should be taken to ensure reliability

and safety when this product is used for equipment which demands high reliability and

safety in function and precision, such as ;

* Transportation control and safety equipment (aircraft, train, automobile etc.)

* Traffic signals * Gas leakage sensor breakers l Rescue and security equipment

* Other safety equipment

L

(3) Please do not use this product for equipment which require extremely high reliability

and safety in fimction and precision, such as ;

* Space equipment * Telecommunication equipment (for trunk lines)

l

Nuclear power control equipment * Medical equipment

c

. (4) Please contact and consult with a Sharp sales representative if there are any questions

regarding interpretation of the above three paragraphs.

-I

1

1

1

3. Please contact and consult with a Sharp sales representative for any questions about this product.

DATE:

CUSTOMER’S APPROVAL

DATE:

BY:

PRESENTED BY:

M.Katoh,

Department General Manager of

Engineering Dept.,111

Opto-Electronic Devices Division

Electronic Components Group

SHARP CORPORATION

I

J .i L.

i __,

MODEL Nd. ‘- _. -

LTlZE40A Smdkation

1. Application

This specification applies to the light emitting diode device Model No. LTl ZE4OA.

[AlInGaP (dicing or scribe/brake type/Yellow green) chip LED device]

.DG-g96011.-. . Feb/22/9!

PAGE -

LTl ZE40A l/14

2. Outline dimensions and temkal connections

3. Ratings and characteristics

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3- 1. Absolute maximum ratings

3-2. Electra-optical characteristics

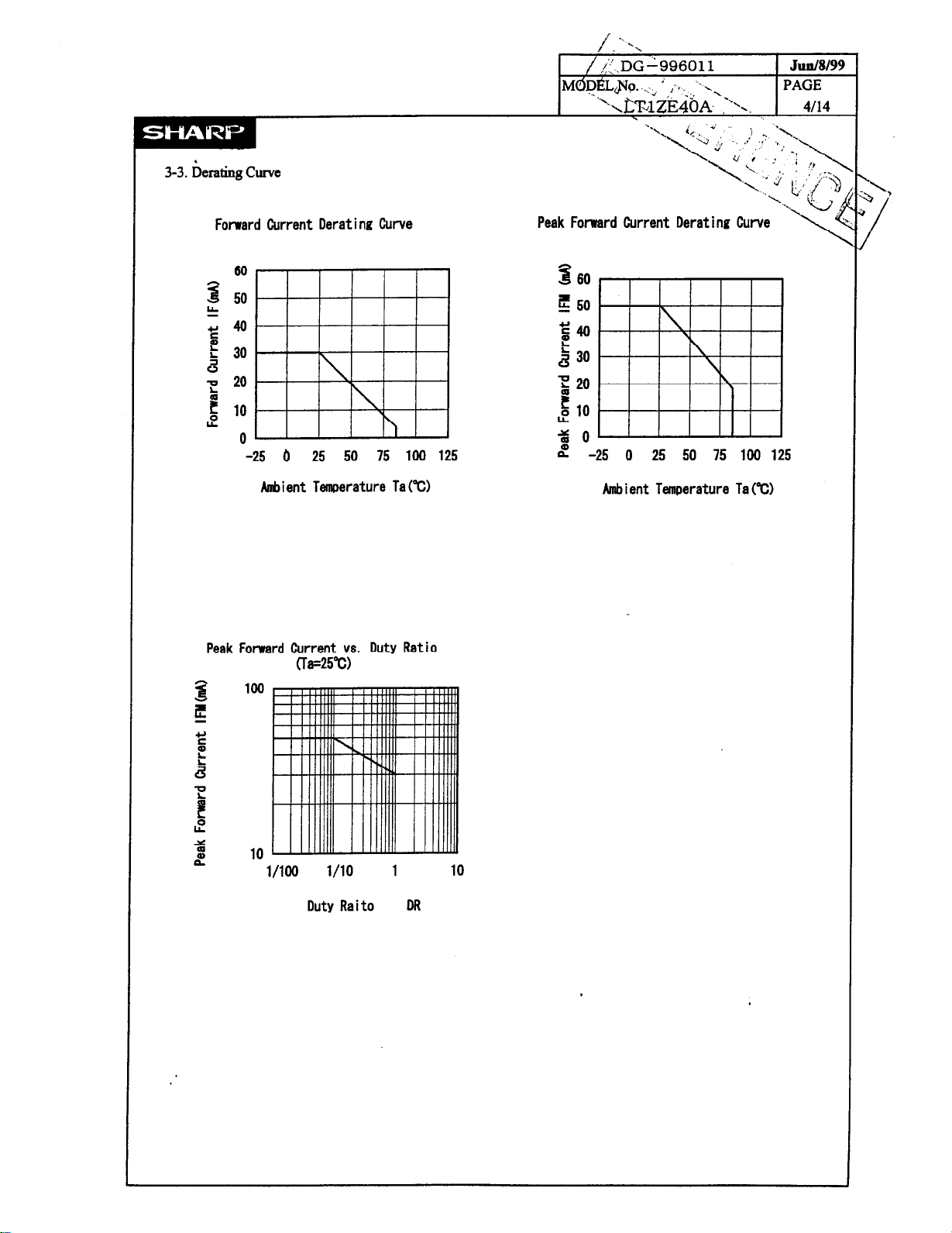

3-3. Derating Curve

3-4. Characteristics Diagram

4. Reliability

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1. Test items and test conditions

4-2. Failure judgement criteria

5. incoming inspection

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5- 1. Inspection method

5-2. Description of inspection and criteria

6. Taping specification

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1. Taping

6-2. Label

6-3. Luminous intensity rank

6-4. Dominant wavelength raak

...*.*..**...~.......,~f~ to the attached sheet Page2.

Refer to the attached sheet Page 3-5.

Refer to the attached sheet Page 6.

Refer to the attached sheet Page 7.

Refer to the attached sheet Page 8- 11.

7. Packing Specification

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...*

7- 1. Dampproof package

7-2. Storage conditions

7-3. Treatment after opening

8. Soldering

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8- 1. Reflow soldering

8-2. Manual soldering

9. Precautions for use

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9- 1. Precautions matters for designing circuit

9-2. Cleaning method

10. Ekironment

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

lo- 1. Ozonosphere destructive chemicals.

10-2. Bromic non-burning materials

Refer to the attached sheet Page 12.

Refer to the attached sheet Page 13.

Refer to the attached sheet Page 14.

Refer to the attached sheet Page 14.

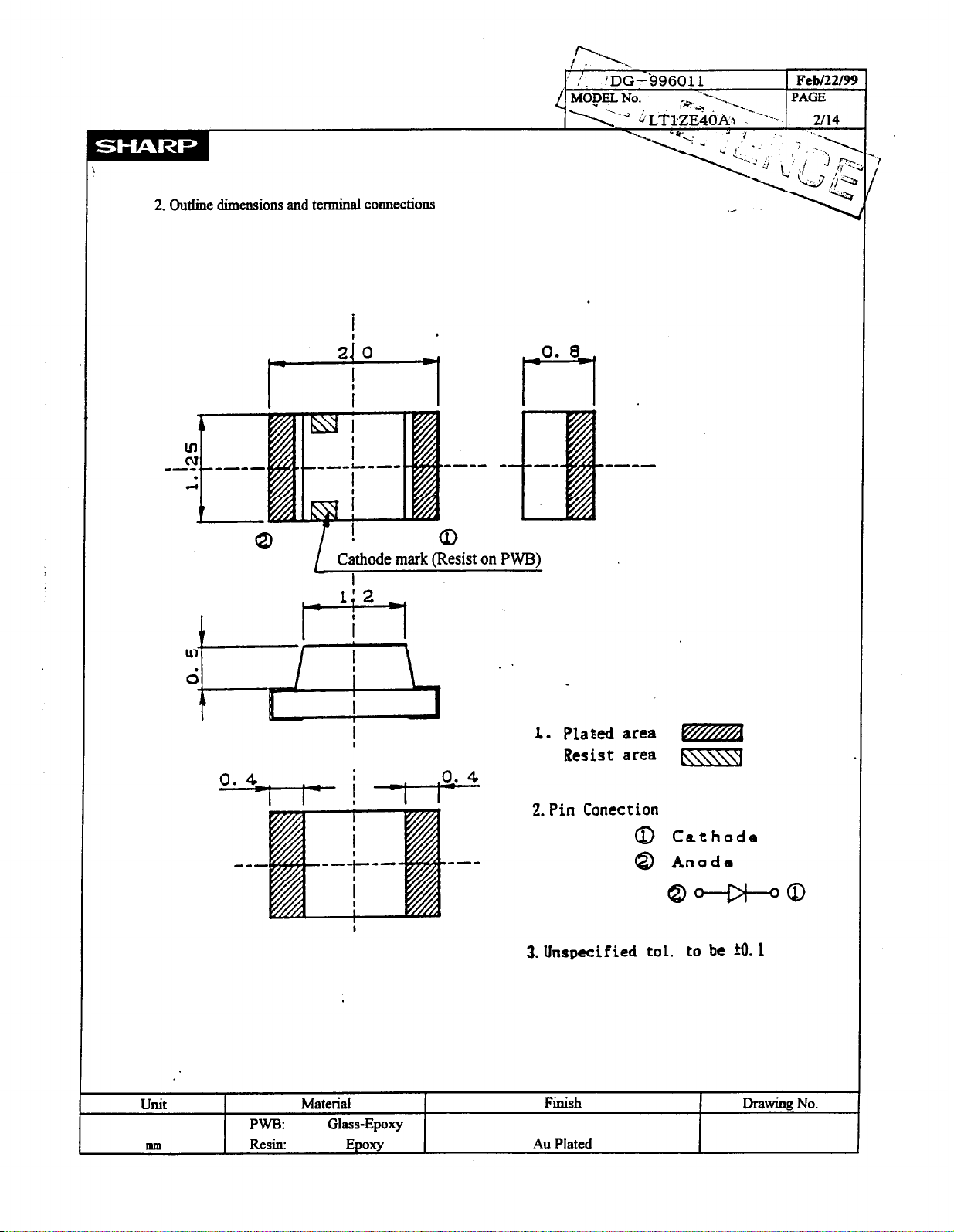

2. Outliue dimensions and terminal connections

Febl2219’

unit

mm

j---

0. 4 .

I I- h-l=

.

---

Material

PWB: Glass-Epoxy

Resin:

I

Epoxy

1. Plabzd area m

Resist area m

2. Pin Conection

0 Cathode

e-w

@ Anode

43-o

3. Unspecified tol. to be ktl. 1

Finish

Au Plated

Drawiug No.

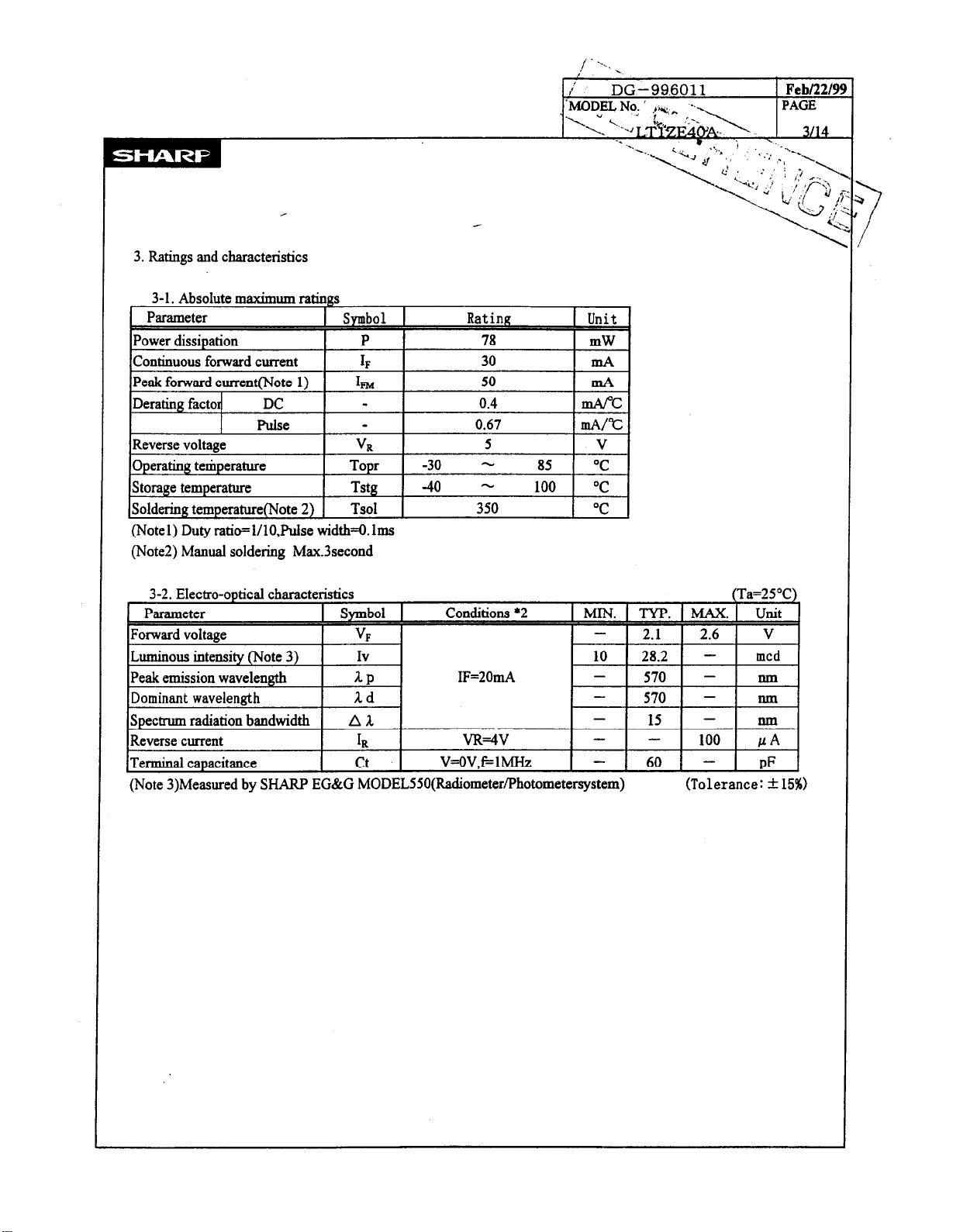

3. Ratings and characteristics

/ _.. _

/

I

DG-99.6011

ifDDEl, No. ’ ,,-, _

-‘.

‘-\U \.‘yi t * :.-- \

-.

.._

. . .

Febl22/99-

PAGE

3/14

(Notel) Duty ratio=l/lO,Puise width=O.lms

(Note2) Manual soldering Max.3second

(Note 3)Measured by SHARP EG&G MODELSSO(Radiometer/Photometersystem) (Tolerance: f 15%)

L

Forward Current Derating Curve

60

-25 b 25 50

Anbient Temperature Ta("c)

Peak Fotward Current vs. Duty Ratio

cTa=25"c)

l/100 l/10 1

Duty Raito DR

75 100 125

10

Loading...

Loading...