Data Sheet

LRS1338A-1

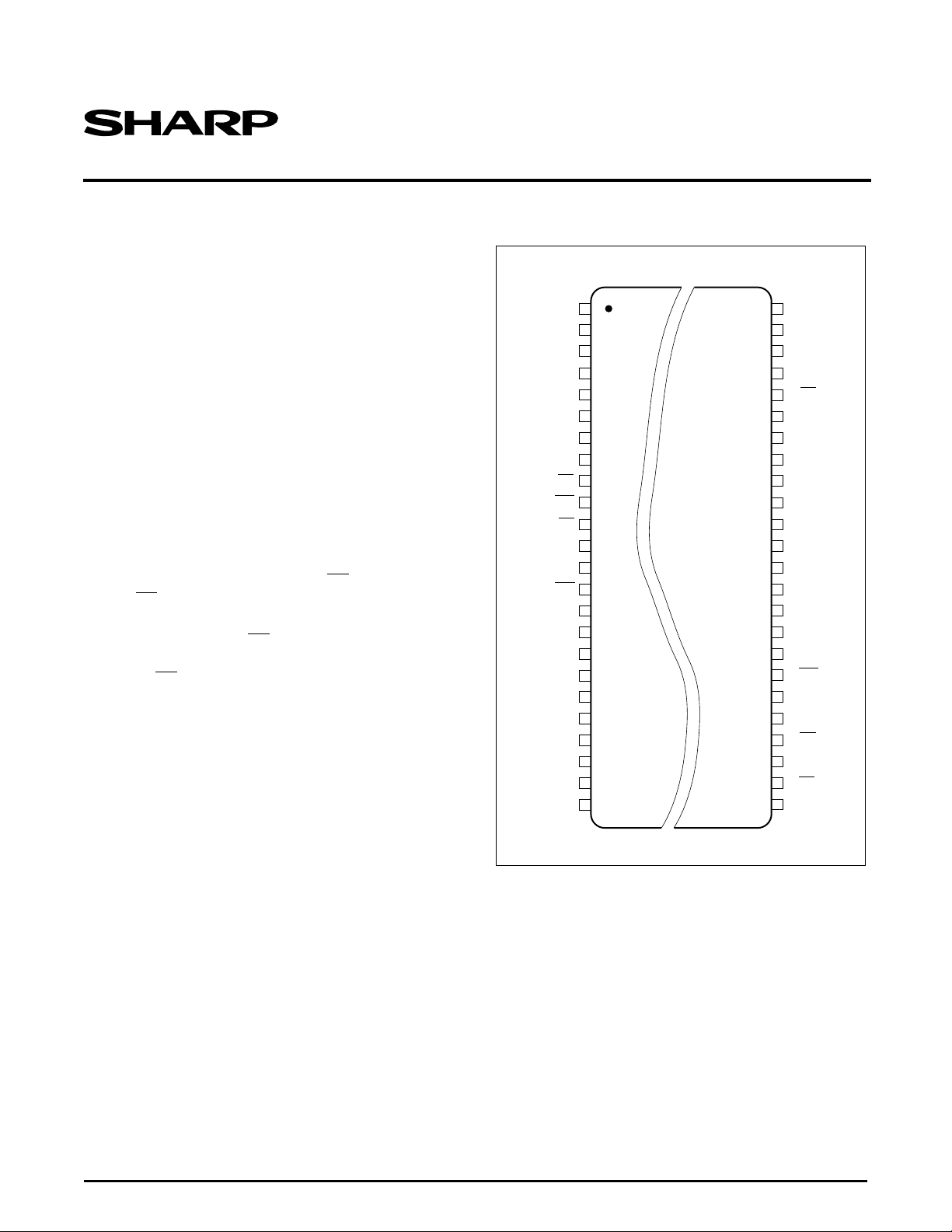

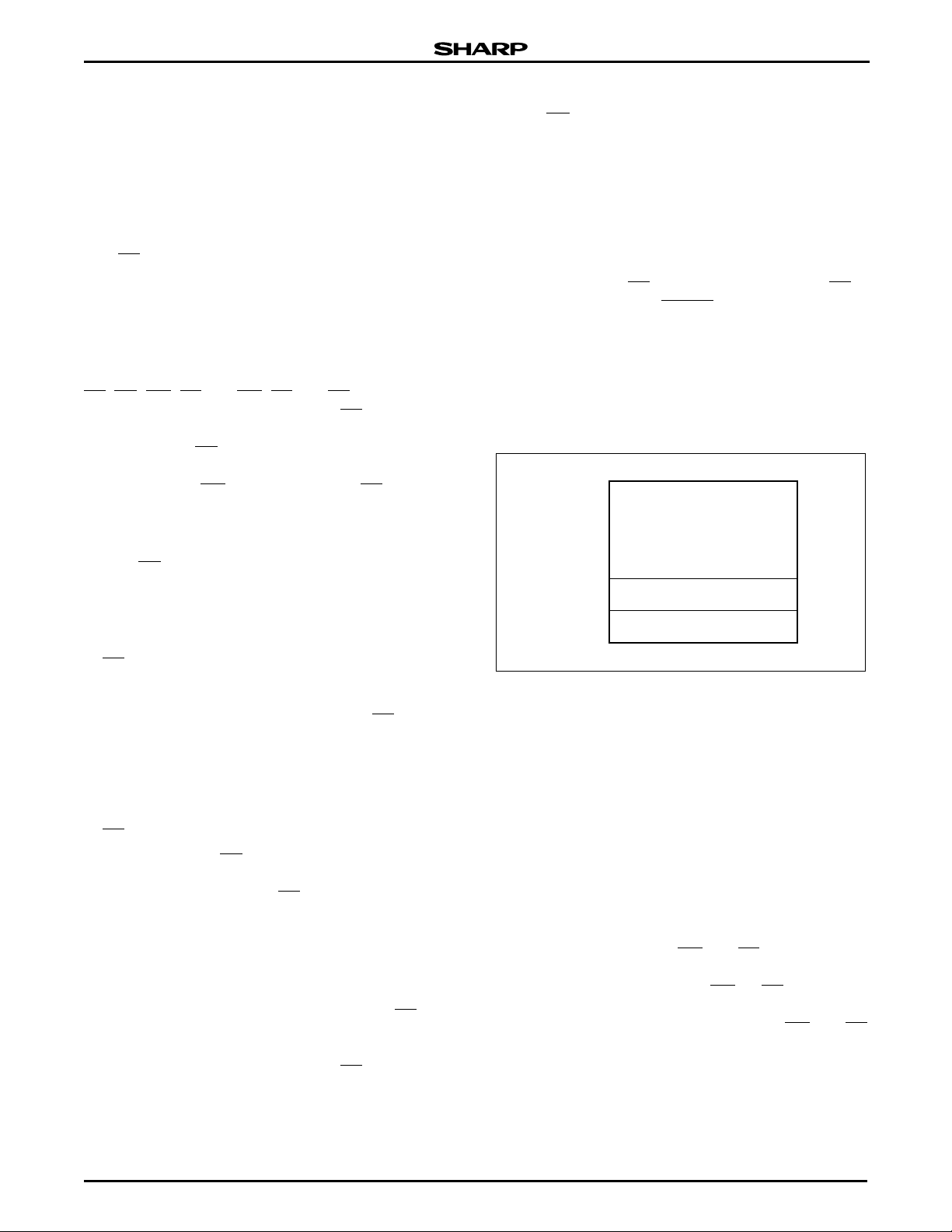

TOP VIEW48-PIN TSOP

2

3

4

5

8

9

S-A

9

/F-A

8

S-A12/F-A

11

S-A13/F-A

12

S-A14/F-A

13

48

45

42

6

7S-A

10

/F-A

9

S-A11/F-A

10

47

46

I/O

14

S-CE

I/O

15

I/O

13

10

11

12

I/O

7

13

44

I/O

3

43

I/O

10

I/O

6

14

15

16

17

18

19

20

39

36

41

40

38

37

I/O

1

S-WE

I/O

8

S-A7/F-A

6

S-A6/F-A

5

S-A8/F-A

7

F-A18

F-A17

F-WP

S-A

5

/F-A

4

I/O

0

F-OE

I/O

5

I/O

4

I/O

12

I/O

9

1

S-A

15

/F-A

14

S-A16/F-A

15

S-A17/F-A

16

21

22

23

24S-A

0

S-A2/F-A

1

S-A4/F-A

3

S-A3/F-A

2

34

F-CE

35

GND

31

33

32

30

29

S-A

1

/F-A

0

F-RP

F-WE

S-OE

F-V

PP

S-V

CC

F-V

CC

I/O

11

I/O

2

27

28

26

25

LRS1338A

Stacked Chip

8M Flash Memory and 2M SRAM

FEATURES

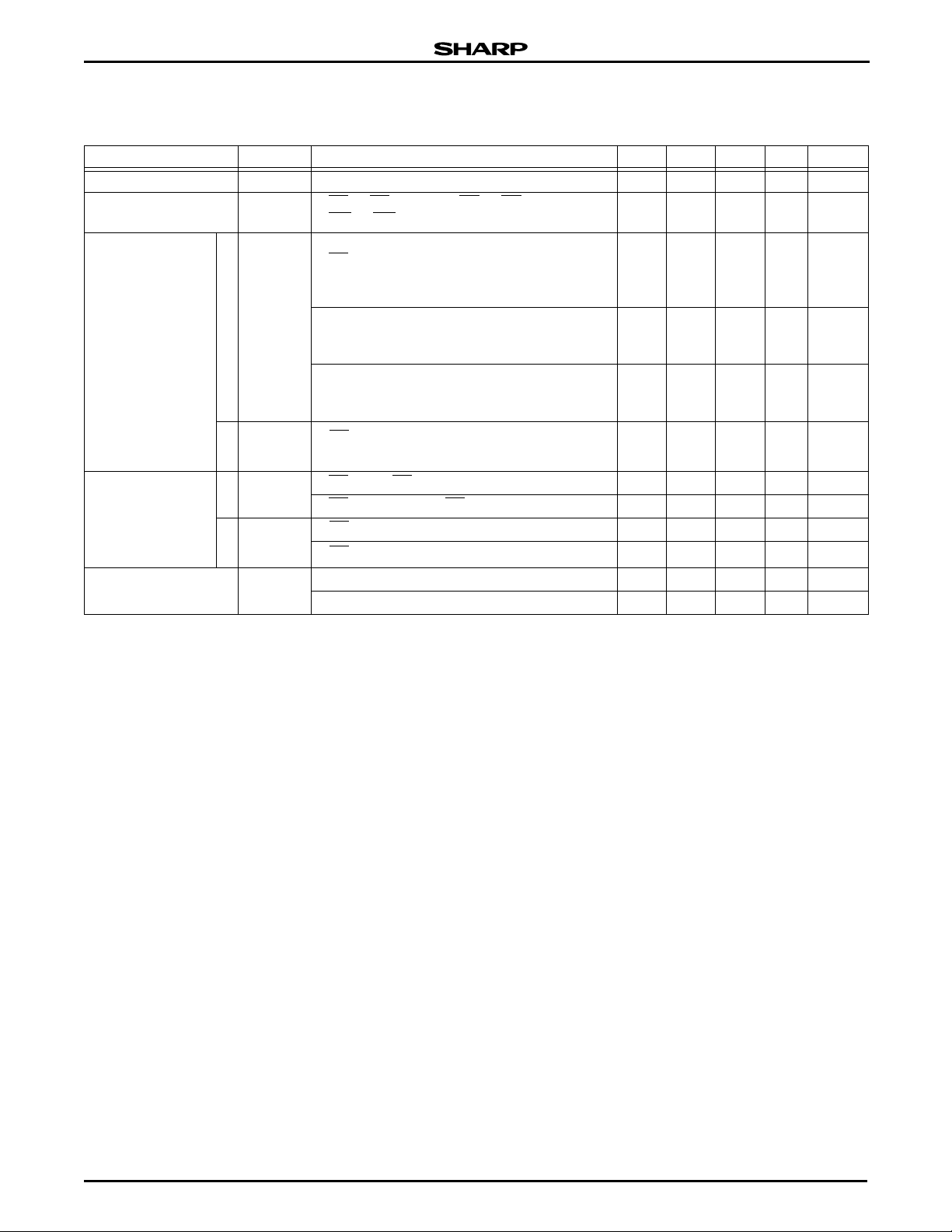

PIN CONFIGURATION

• Flash memory and SRAM

• Stacked die chip scale package

• 48-pin TSOP (TSOP48-P-1014) plastic package

• Power supply: 2.7 V to 3.6 V

• Operating temperature: -40°C to +85°C

• Access time (MAX.):

– Flash memory: 120 ns

– SRAM: 85 ns

• Operating current (MAX.):

–Flash memory

– Read: 25 mA (t

– Word write: 57 mA (F -V

– Block erase: 42 mA (F-V

– SRAM: 25 mA (t

• Standby current

2

CYCLE

CYCLE

= 200 ns)

≥ 3.0 V)

CC

≥ 3.0 V)

CC

= 200 ns)

– Flash memory: 20 µA MAX. (F-CE ≥ F-VCC - 0.2 V,

F-RP

≤ 0.2 V, F-VPP ≤ 0.2 V)

–SRAM:

– 40 µA MAX. (S-CE

• Fully static operation

• Three-state output

NOTES:

1. Block erase and word write operations of flash memory with

2. Total standby current is the summation of flash’s memory standby

DESCRIPTION

as 524,288 × 16-bit flash memory and 262,144 × 8-bit

static RAM in one package. It is fabricated using silicongate CMOS process technology.

S-CE

< -30°C are not supported.

T

A

current and SRAM’s one.

The LRS1338A is a combination memory organized

≥ S-VCC - 0.2 V)

– 0.6 µA TYP. (T

A

≥ S-VCC - 0.2 V)

= 25°C, S-VCC = 3 V,

Figure 1. LRS1338A Pin Configuration

Data Sheet 1

LRS1338A Stacked Chip (8M Flash & 2M SRAM)

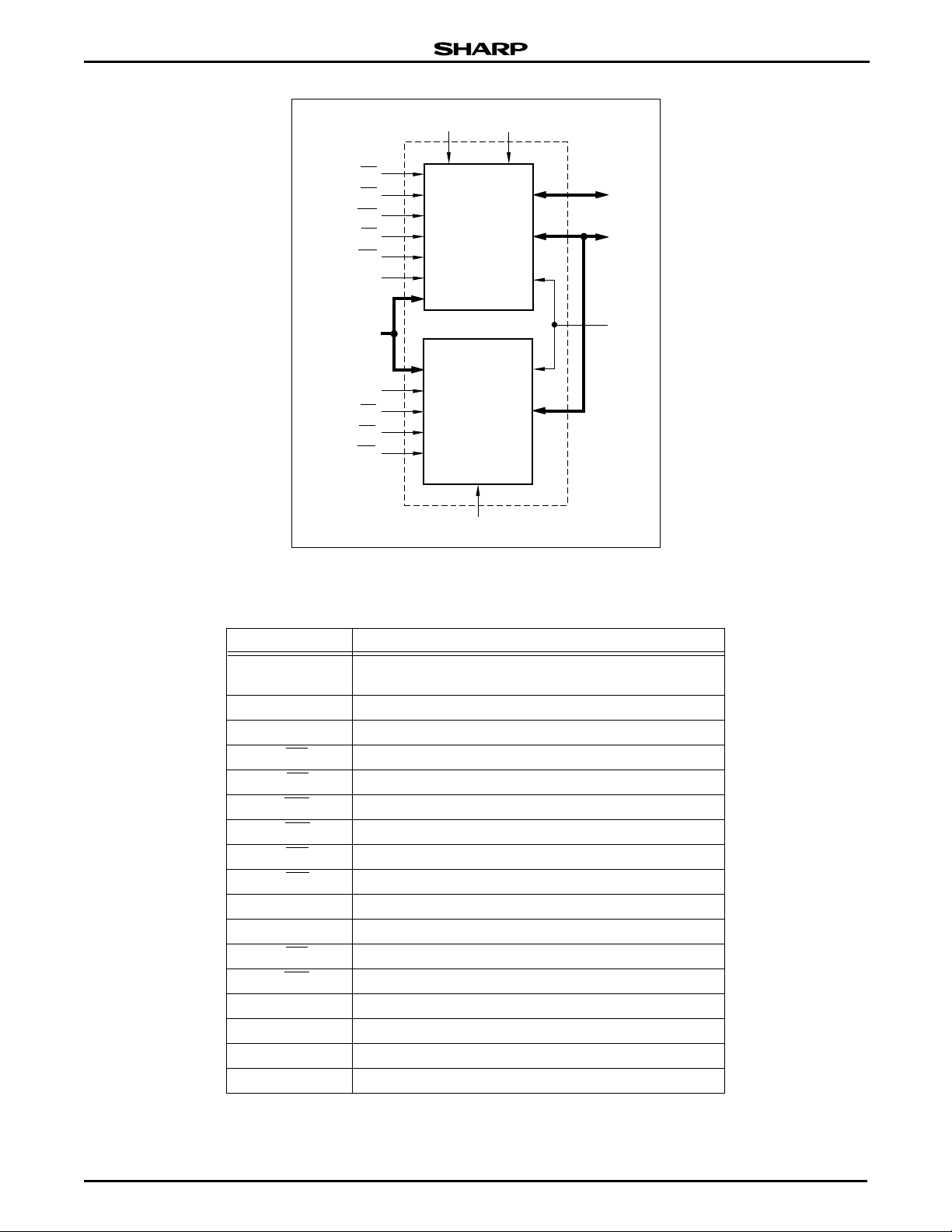

CC

SRAM

S-V

F-V

CC

F-CE

F-OE

F-WE

F-RP

F-WP

, F-A

F-A

17

S-A1 to S-A

F-A

to F-A

0

S-A

S-CE

S-OE

S-WE

F-V

524,288 x 16 BIT

FLASH MEMORY

18

17

,

16

0

262,144 x 8 BIT

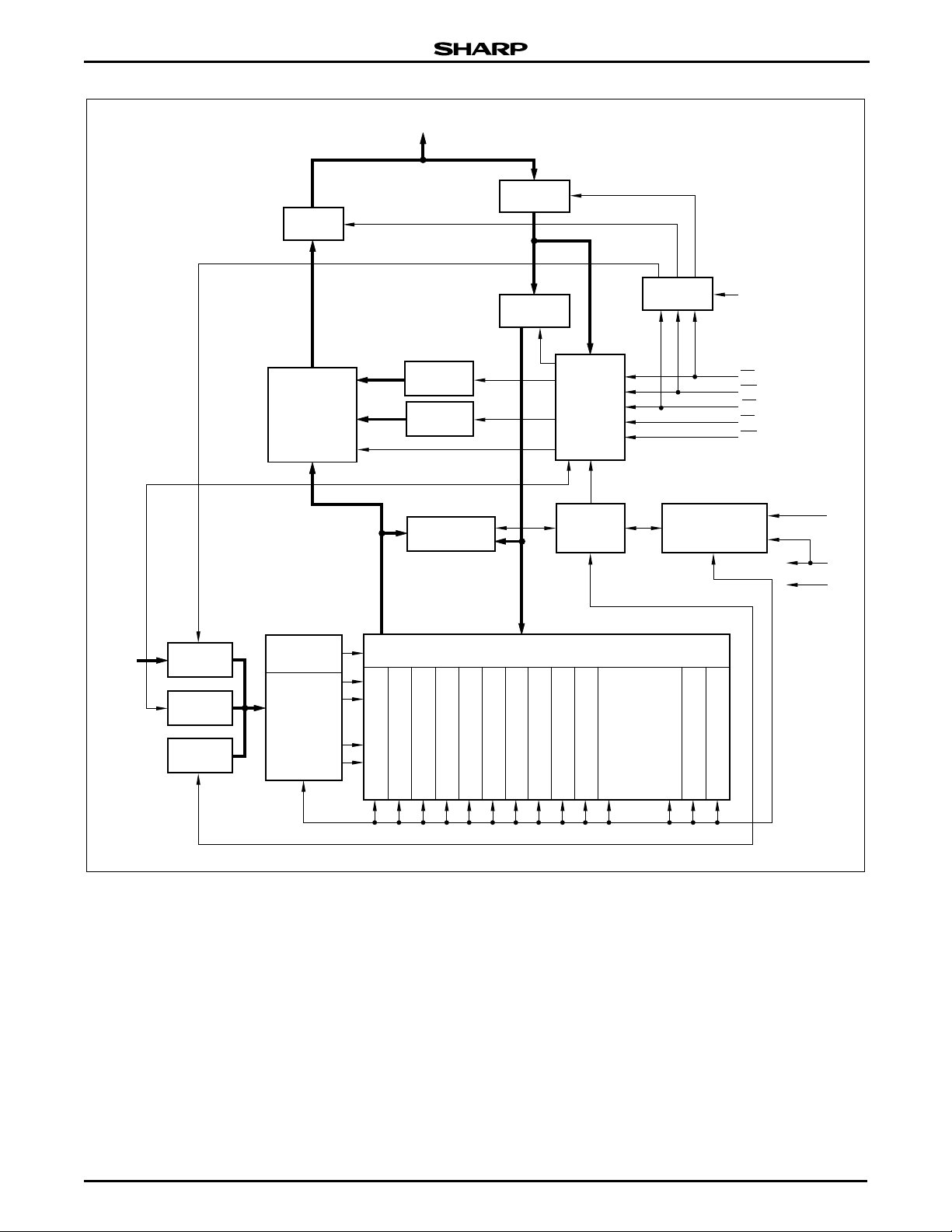

Figure 2. LRS1338A Block Diagram

PP

I/O8 to

I/O

15

I/O0 to

I/O

7

GND

LRS1338A-2

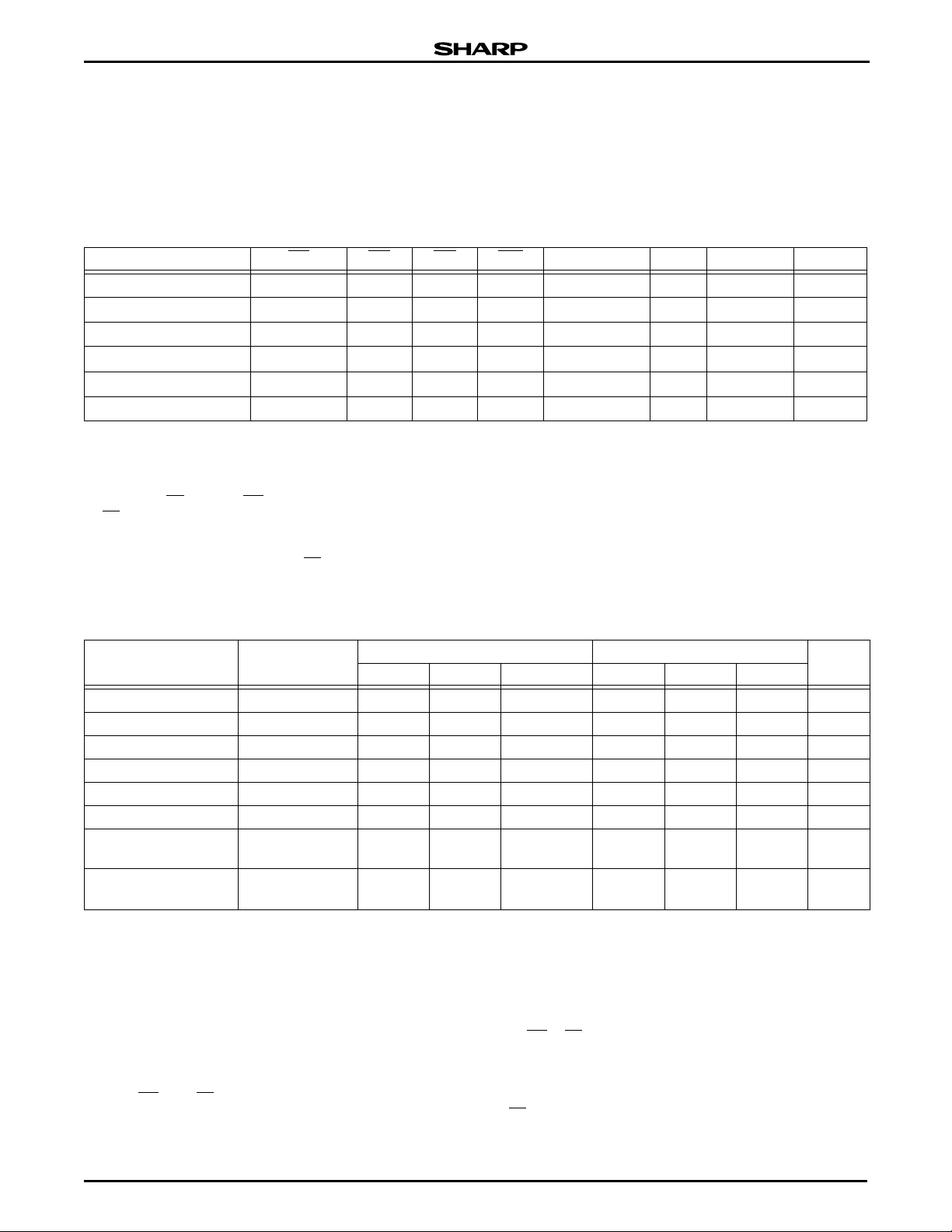

Table 1. Pin Descriptions

PIN DESCRIPTION

S-A

to S-A

1

F-A0 to F-A

S-A

F-A

17

F-CE

S-CE

F-WE

S-WE

F-OE

S-OE

I/O

0

I/O

to I/O

8

F-RP

F-WP

F-V

F-V

S-V

0

to F-A

to I/0

CC

PP

CC

17

Common Address Input Pins

16

Address Input Pin for SRAM

Address Input Pin for Flash Memory

18

Chip Enable Input Pin for Flash Memory

Chip Enable Input Pin for SRAM

Write Enable Input Pin for Flash Memory

Write Enable Input Pin for SRAM

Output Enable Input Pin for Flash Memory

Output Enable Input Pin for SRAM

Common Data Input/Output Pins

7

Data Input/Output Pins for Flash Memory

15

Reset/Deep Power Down Input Pin for Flash Memory

Write Protect Pin for Flash Memory’s Boot Block

Power Supply Pin for Flash Memory

Power Supply Pin for Flash Memory Write/Erase

Power Supply Pin for SRAM

GND Common Ground

2 Data Sheet

Stacked Chip (8M Flash & 2M SRAM) LRS1338A

GENERAL DESIGN GUIDELINES

Supply Po wer

Maximum difference (between F-VCC and S-VCC) of

the voltage is less than 0.3 V.

Power Supply and Chip Enable of Flash

Memory and SRAM

It is forbidden that both F-CE and S-CE should be

LOW simultaneously. If the two memories are active

together, they many not op erate nor mally du e to inter ference noi ses or dat a collis ion on I/O bus. Bot h F-V

CC

and S-VCC need to be applied by the recommende d

supply voltage at the same time except SRAM data

retention mode.

SRAM Data Retention

SRAM data retention is capable in three ways.

SRAM power switching betwee n a system bat tery an d

a backup battery needs careful device decoupling from

Flash Memory to prevent SRAM supply voltage from

falling lower than 2.0 V by a Flash Mem ory peak current caused by transitio n of F la sh Mem or y supp ly vol tage or of control signals (F-CE

CASE 1: FLASH MEMORY IS IN STANDBY MODE

(F-V

= 2.7 V TO 3.6 V)

CC

• SRAM inputs and input/outputs except S-CE

be applied with voltages in the range of -0.3 V to

S-V

+ 0.3 V or to be open (HIGH-Z).

CC

• Flash Memory inputs and input/outputs except F-CE

and RP need to be applied with voltages in the range

of -0.3 V to S-V

+ 0.3 V or to be open (HIGH-Z).

CC

, F-OE, and RP).

need to

CASE 2: FLASH MEMORY IS IN DEEP POWER

DOWN MODE (F-V

• SRAM inputs and input/outputs except S-CE

= 2.7 V TO 3.6 V)

CC

need to

be applied with voltages in the range of -0.3 V to

S-V

+ 0.3 V or to be open.

CC

• Flash Memory inputs and input/outputs except RP

need to be applied with voltages in the range of -0.3 V

to S-V

be at the same level as F-V

+ 0.3 V or to be open (HIGH-Z). RP needs to

CC

or to be open.

CC

CASE 3: FLASH MEMORY POWER SUPPLY IS

TURNED OFF (F-V

• Fix RP

LOW level before tu rning off Flash memo ry

CC

= 0 V)

power supply.

• SRAM inputs and input/outputs except S-CE

need to

be applied with voltages in the range of -0.3 V to

S-V

+ 0.3 V or to be open (HIGH-Z).

CC

• Flash Memory inputs and input/outputs except RP

need to be applied with voltages in the range of

-0.3 V to S-V

+ 0.3 V or to be open (HIGH-Z).

CC

Power Up Sequence

When turning on Flash memory power supply, keep

RP

LOW. After F-VCC reaches ove r 2.7 V, keep RP

LOW for more than 100 ns.

Device Decoupling

The power supply needs to be designed c arefully

because one of the SRAM and the F lash Me mor y is in

standby mode when the other is active. A careful

decoupling of power supplies is necessary between

SRAM and Flash Memory. Note peak current caused

by transition of control signals (F-CE

, S-CE).

Table 2. Truth Table

F-CE F-OE F-WE F-RP S-CE S-OE S-WE ADDRESS MODE

L L H H H X X X Flas h read Output I

L H H H H X X X Flash read HIGH-Z I

LHLHHXX XFlash write Input I

H X X X L L H X SRAM read Output I

H X X X L H H X SRAM read HIGH-Z I

H X X X L X L X SRAM write Input I

H X X H H X X X Standby HIGH-Z I

X X X L H X X X Deep power down HIGH-Z I

NOTES:

1. F-CE

2. X can be V

3. Refer to DC Characteristics. When F-V

4. Do not use in a timing that both F-OE

should not be LOW when S-CE is LOW simultaneously.

or VIH for control pins and addresses, and V

for F-VPP. See DC Characteristics for V

tents can be read, but not altered.

IL

or V

and V

PPLK

≤ V

PP

and F-WE is LOW level.

PPLK

voltages.

PPH

, memory con-

PPLK

PPH

5. F-RP

6. Command writes involving block erase, write, or lock-bit configura-

7. Refer to Table 6 for valid D

1,2

to

I/O

0

I/O

at GND ± 0.2 V ensures the lowest deep power down current.

tion are reliably executed whe n F-V

block erase or word w rite operations wit h VIH < F-RP < VHH or

T

<-30°C produce spurious results and should not be attempted.

A

during a write operation.

IN

CURRENT NOTE

15

CC

CC

CC

CC

CC

CC

SB

SB

= V

PP

and F-VCC=V

PPH

3, 4

5

4, 6, 7

5

CC1

Data Sheet 3

LRS1338A Stacked Chip (8M Flash & 2M SRAM)

ABSOLUTE MAXIMUM RATINGS

PARAMETER SYMBOL RATINGS UNIT NOTES

Supply voltage V

Input voltage V

Operating temperature T

Storage temperature T

voltage V

V

PP

CC

IN

OPR

STG

PP

Input voltage RP

NOTES:

1. The maximum applicable voltage on any pins with respect to GND.

2. Except V

3. Except RP

4. -2.0 V undershoot is allowed when the pulse width is less than 20 ns.

5. +14.0 V overshoot is allowed when the pulse width is less than 20 ns.

PP

.

.

-0.2 to +4.6 V 1, 2

-0.3 to VCC +0.3 V 1, 3, 4

-40 to +85 °C

-65 to +125 °C

-0.2 to +12.6 V 1, 5

-0.5 to +12.6 V 1, 4, 5

RECOMMENDED DC OPERATING CONDITIONS

TA = -40°C to +85°C

PARAMETER SYMBOL MIN. TYP. MAX. UNIT NOTES

Supply voltage V

Input voltage

CC

V

IH

V

IL

V

HH

2.7 3.0 3.6 V

2.0 VCC + 0.3 V 1

-0.3 0.8 V 2

11.4 12.6 3

NOTES:

1. V

is the lower one of S-VCC and F-VCC.

CC

2. -2.0 V undershoot is allowed when the pulse width is less than 20 ns.

3. This voltage is applicable to F-RP

pin only.

PIN CAPACITANCE

TA = 25°C, f = 1 MHz

PARAMETER SYMBOL CONDITION MIN. TYP. MAX. UNIT

Input capacitance* C

I/O capacitance* C

NOTE: *

Sampled by not 100% tested.

IN

I/O

VIN = 0 V 20 pF

V

= 0 V 22 pF

I/O

4 Data Sheet

Stacked Chip (8M Flash & 2M SRAM) LRS1338A

DC ELECTRICAL CHARACTERISTICS

TA = -40°C to + 85°C, VCC = 2.7 V to 3.6 V

PARAMETER SYMBOL CONDITION MIN. TYP. MAX. UNIT NOTES

Input leakage current I

Output leakage current I

Operating supply

current

I

Flash

I

SRAM

I

Standby current

Flash

I

SRAM

Output voltage

NOTES:

1. This value is read current (I

2. Sampled but not 100% tested.

3. This value is operation current (I

4. This value is operation current (I

5. This value is operation current (I

VOL,

V

CCR

CC

CC

VIN = 0V to V

LI

F-CE, S-CE = VIH or F-OE, S-OE = VIH or

LO

, S-WE = VIH, V

F-WE

CC

= 0 V to V

I/O

CC

-1.5 1.5 µA

-1.5 1.5 µA

Read current, F-VPP ≤ F-VCC,

≤ 0.2 V, VIN ≥ VCC – 0.2 V or

F-CE

V

≤ 0.2 V

IN

= 200 ns, I

t

CYCLE

Summation of V

rent, and V

F-V

≥ 3.0 V

CC

PP

Summation of V

lock-bits current, and V

Block lock-bits current. F-V

= 0 mA

I/O

Byte Write or set l ock-bi t c ur-

CC

Byte Write or set lock-bit current.

Block Erase or Clear Block

CC

Block Erase or Clear

PP

≥ 3.0 V

CC

S-CE = 0.2 V, VIN ≥ VCC – 0.2 V or VIN ≥ 0.2 V

t

CYCLE

F-CE = VIH, RP = V

SB

F-CE

S-CE = V

SB

S-CE

= 200 ns, I

≥ VCC – 0.2 V, RP ≤ 0.2 V 20 µA 7

IH

≥ VCC – 0.2 V 0.6 40 µA 9, 10

= 0 mA

I/O

IH

IOL = 2.0 mA 0.4 V

I

OH

+ I

CCW

CCE

CC1

= 1.0 mA 2.4 V

OH

) of flash memory.

PPR

+ I

) of flash memory.

PPW

+ I

) of flash memory.

PPE

) of SRAM.

6. This value is standby current (I

7. This value is deep power down current (I

flash memory.

8. This value is standby current (I

9. This value is standby current (I

10.Reference values at V

CCS

SB1

SB

= 3.0 V and TA = +25°C

CC

25 mA 1

57 mA 2, 3

42 mA 2, 4

25 mA 5

2.0 mA 6

3.0 mA 8

+ I

) of flash memory.

PPS

CCD

) of SRAM

) of SRAM.

+ I

PPD

) of

Data Sheet 5

LRS1338A Stacked Chip (8M Flash & 2M SRAM)

FLASH MEMORY*

New Features

The LRS1388A flash memory ma intain s backw ards

compatibility with SHARP’s LH28F 800B G- L.

• SmartVoltage technolog y

• Enhanced suspend capabilities

• Boot block architecture

Please note the following important differences:

• V

has been lowered to 1.5 V to support 3.0 V

PPLK

block erase and word write operations. Designs that

switch V

sure that the V

• Allow V

off during read ope rations should ma ke

PP

connection to 3.0 V.

PP

voltage transitions to GND.

PP

Product Overview

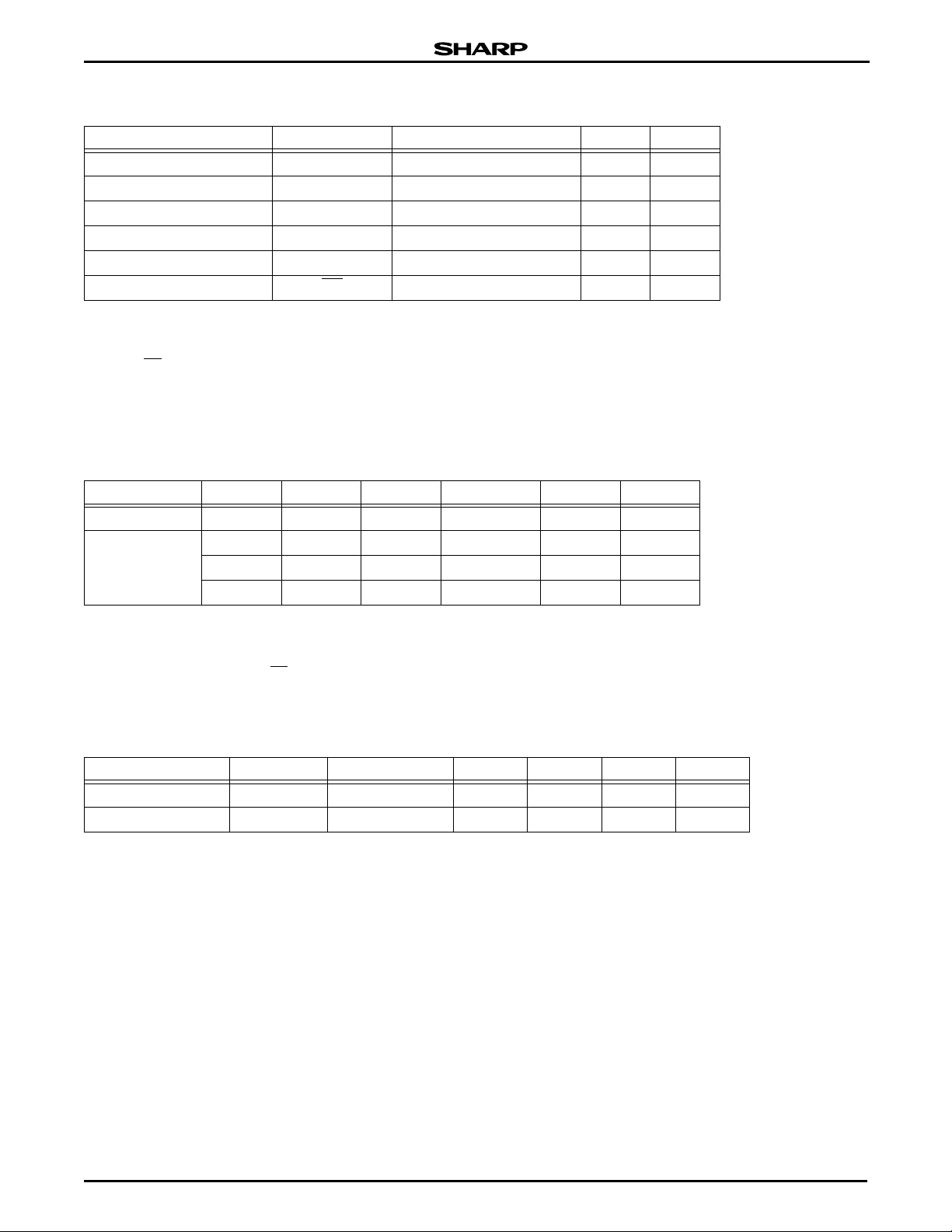

The LRS1338A is a high-performance 8M SmartVoltage flash memory organized as 512K-word of 16

bits. The 512K-word of data is arranged in two 4K-word

boot blocks, six 4K-word paramete r blocks and fifteen

32K-word main blocks wh ich are individuall y erasable

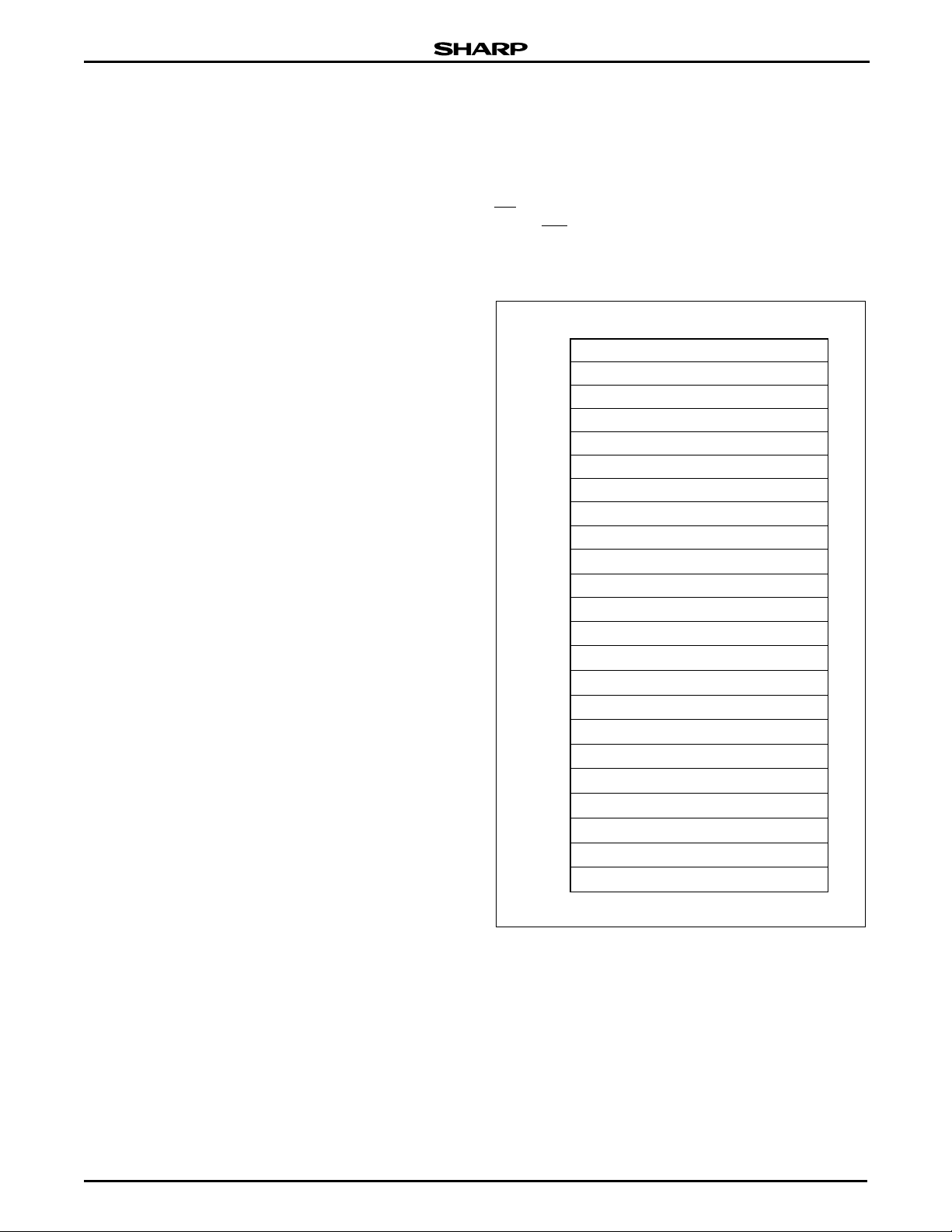

in-system. The memory map is shown in Figure 4.

SmartVoltage technolog y provides a choice of V

and VPP combinations, as shown in Table 3, to meet

system performance and power expectatio ns. In add ition to flexible erase and program voltages, the dedicated V

V

PP

≤ V

pin gives complete data protection when

PP

.

PPLK

Table 3. VCC and VPP Voltage Combinations

V

Voltage VPP Voltage

CC

2.7 V to 3.6 V 2.7 V to 3.6 V

Internal V

and VPP detection circuitry automati-

CC

cally configures the device for optimized read and write

operations.

CC

A Command User Interface (CUI) serves as the

interface between the system processor and internal

operation of the devi ce. A valid command seque nce

written to the CUI initiates device automation. An internal Write State Machine (WSM) automatically executes

the algorithms and timings necessary for block erase

and word write operations.

A block erase o perati on erases on e of the de vi ce’s

32K-word blocks typically within 1.14 se conds, 4Kword blocks typically with in 0 .38 s ec on ds ind epe nden t

of other blocks. Each block can be independently

erased 100,000 times. Block erase suspend mode

allows system software to suspend block erase to read

or write data from any other block.

Writing memory data is performed in word increments

of the device’s 32K-word blocks typically within 44.6 µs,

4K-word blocks typically within 45.9 µs. Word write suspend mode enables the system to read data or execute

code from any other fl as h me mor y array location.

The boot blocks can be locked for the WP

pin. Block

erase or word write fo r boot b lock mus t not be car ried

out by WP

to LOW and RP to VIH.

The status register indicates when the WSM’s block

erase or word write operation is finished.

The access time is 120 ns (t

cial temperature range (-40°C to +85°C) and V

) over the commer-

AVQV

CC

sup-

ply voltage range of 2.7 V to 3.6 V.

The Automatic Power Savi ngs (APS) feature substantially reduces activ e current when the devic e is in

static mode (addresses not switching). In APS mode,

the typical I

When CE

standby mode is enabled. When the RP

current is 1 mA at 3.3 V VCC.

CCR

and RP pins are at VCC, the ICC CMOS

pin is at GND,

deep power-down mode is enabled which minimi zes

power consumption a nd provide s write pr otection during reset. A reset time (t

) is required from RP

PHQV

switching HIGH until output s are valid. Likewise, the

device has a wake time (t

writes to the CUI are recognized. With RP

) from RP HIGH until

PHEL

at GND, the

WSM is reset and the status register is cleared.

NOTE: *

mands, voltage, etc. refer only to the Flash portion of this chip.

In the Flash Me mory sectio n all referenc e to pins, com -

6 Data Sheet

Stacked Chip (8M Flash & 2M SRAM) LRS1338A

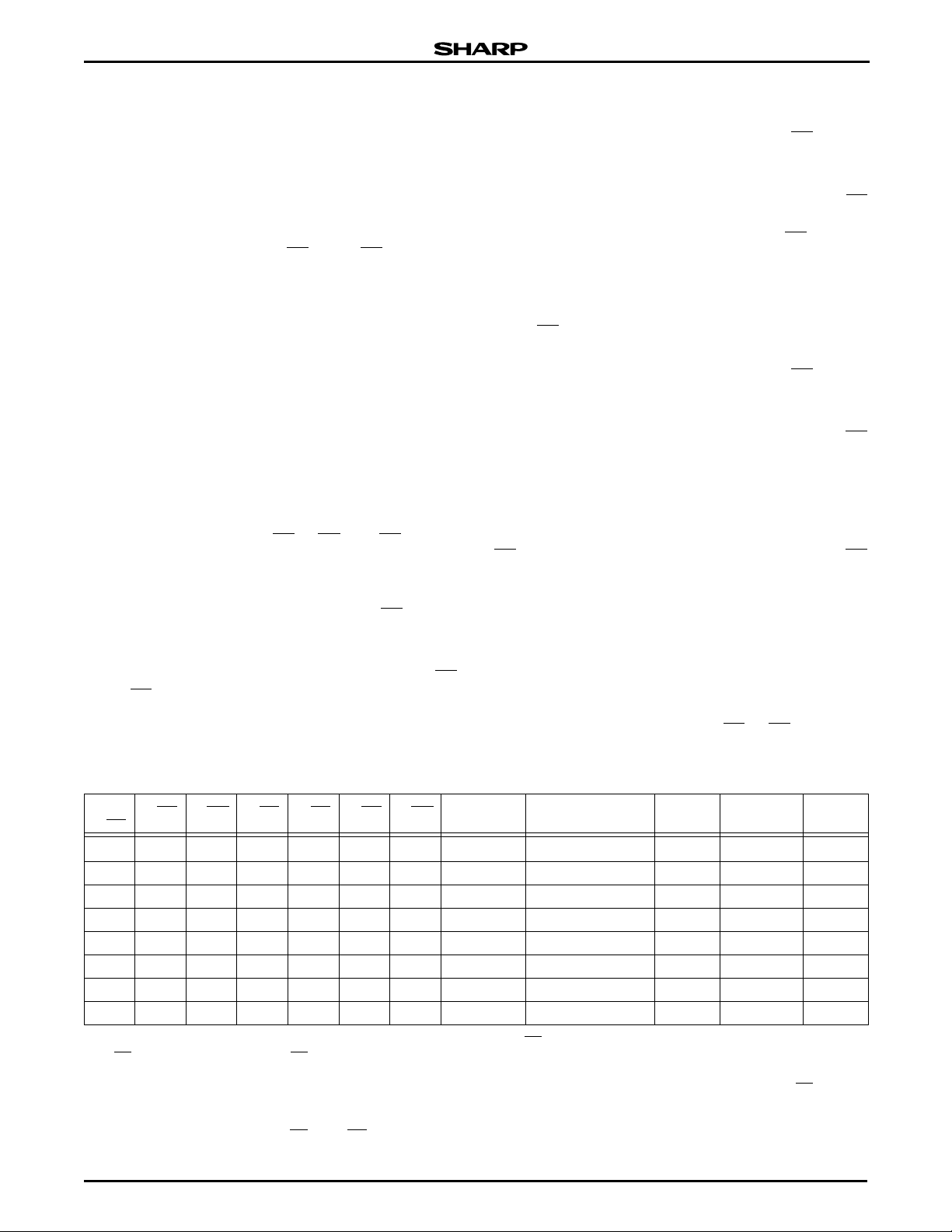

- I/O

I/O

0

15

INPUT

BUFFER

OUTPUT

BUFFER

A0 - A

I/O

15

BLOCKS

LOGIC

PROGRAM/ERASE

VOLTAGE

SWITCH

DATA

REGISTER

IDENTIFIER

REGISTER

OUTPUT

MULTIPLEXER

18

INPUT

BUFFER

ADDRESS

LATCH

ADDRESS

COUNTER

Y

DECODER

X

DECODER

. . .

STATUS

REGISTER

DATA

COMPARATOR

BOOT BLOCK 0

BOOT BLOCK 1

PARAMETER BLOCK 0

PARAMETER BLOCK 1

PARAMETER BLOCK 2

PARAMETER BLOCK 3

COMMAND

USER

REGISTER

WRITE

STATE

MACHINE

Y GATING

32K-WORD

MAIN BLOCK 0

MAIN BLOCK 1

PARAMETER BLOCK 4

PARAMETER BLOCK 5

V

CC

CE

WE

OE

RP

WP

MAIN BLOCK 13

MAIN BLOCK 14

V

PP

V

CC

GND

. . .

LRS1338A-3

Figure 3. Flash Memory Block Diagram

Data Sheet 7

LRS1338A Stacked Chip (8M Flash & 2M SRAM)

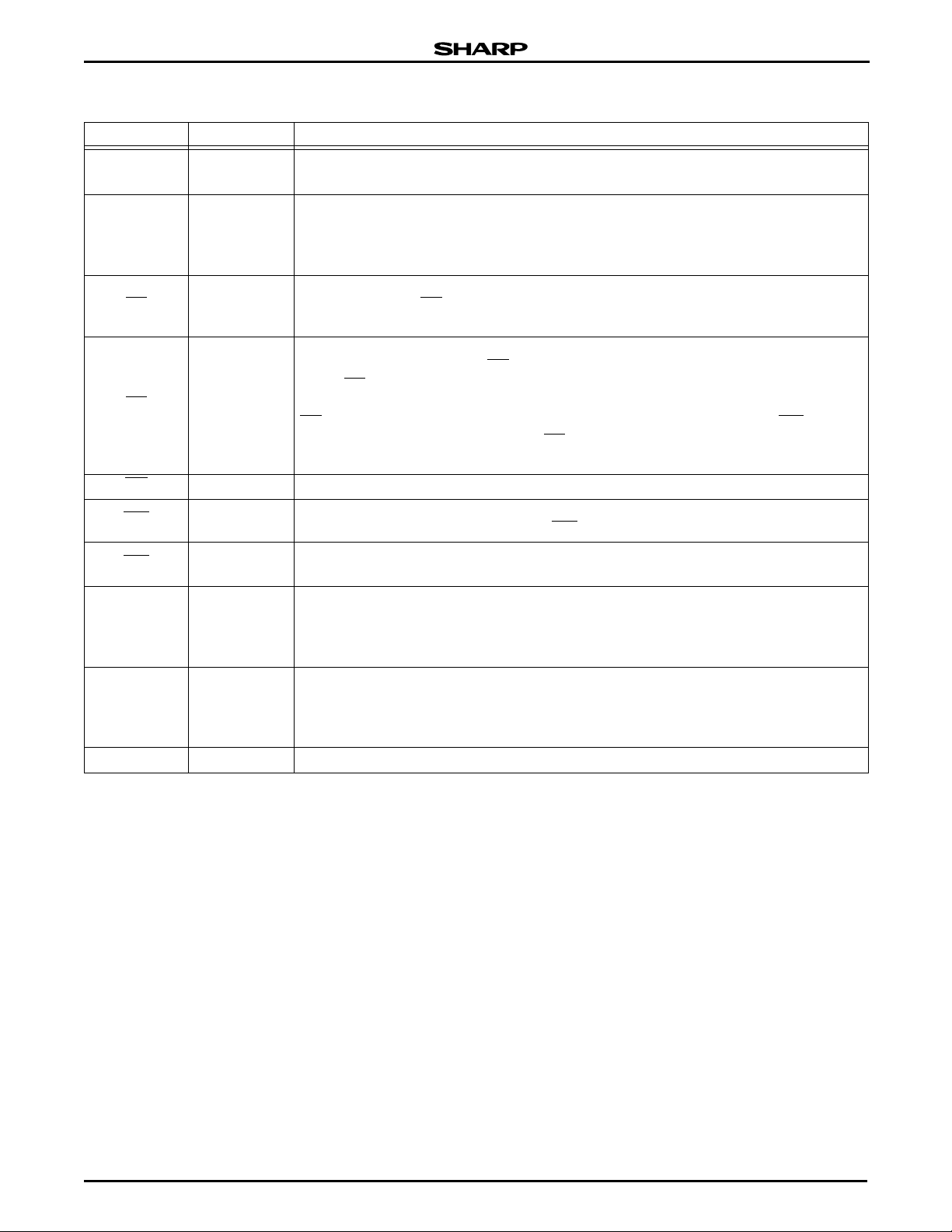

Table 4. Flash Pin Descriptions

SYMBOL TYPE NAME AND FUNCTION

A

0

- A

18

Input

ADDRESS INPUTS: Inputs for addresses during read and write operations.

Addresses are internally latched during the write cycle.

DATA INPUT/OUTPUTS: Inputs da ta an d co mman ds du ring C UI wr ite cycl es ; ou t-

I/O

- I/O

0

15

Input/Output

puts data during memory array, status register, and identifier code read cycles. Data

pins float to HIG H- imp edan ce wh en the chi p is dese le ct ed or ou tp uts a r e di sabl e d.

Data is internally la tc he d dur in g a writ e cycle .

CHIP ENABLE: Activates the device’s control logic, input buffers, decoders, and

CE

Input

sense amplifiers. CE-HIGH deselects the device and reduces power consumption

to standby levels.

RESET/DEEP POWER-DOWN: Puts the device in deep power-down mode and

RP

Input

resets internal automation. RP

LOW, RP

inhibits write operations which provides data protection during power

transitions. Exit from deep power-down sets the device to read array mode. With

RP

= VHH, block erase or word write can operate to all blocks without WP state.

Block erase or word write with V

-HIGH enables normal operation. When driven

IH

not be attempted.

OE

WE

WP

Input OUTPUT ENABLE: Gates the device’s outputs during a read cycle.

Input

Input

WRITE ENABLE: Controls writes to the CIU and array blocks. Addresses and data

are latched on the rising edge of the WE

WRITE PROTECT: Master control for boot blocks locking. When V

blocks cannot be erased and programmed.

BLOCK ERASE an d WORD WRITE P OWER SUPPLY: For erasin g array bloc ks or

V

PP

Supply

writing words. With V

and word write with an invalid V

PP

≤ V

, memory contents cannot be altered. Block erase

PPLK

PP

results and should not be attempted.

DEVICE POWER SUPPLY: Do not float any power pins. With V

V

CC

Supply

write attempts to the flash memory are inhibited. Device operations at invalid

V

voltage (see ‘DC Characteristics’) produce spurious results and should not

CC

be attempted.

GND Supply GROUND: Do not float any ground pins.

< RP < VHH produce spurious results and should

pulse.

, locked boot

IL

(see ‘DC Characteristics’) produce spurious

CC

≤ V

LKO

, all

8 Data Sheet

Stacked Chip (8M Flash & 2M SRAM) LRS1338A

7

7F000

7FFFF

7EFFF

FE000

7DFFF

7D000

7CFFF

7C000

7BFFF

7B000

7AFFF

7A000

79FFF

79000

78FFF

78000

77FFF

70000

6FFFF

68000

67FFF

58000

57FFF

60000

5FFFF

50000

4FFFF

48000

47FFF

40000

3FFFF

38000

37FFF

30000

2FFFF

28000

27FFF

20000

1FFFF

18000

17FFF

10000

0FFFF

08000

07FFF

00000

8

9

10

11

12

13

14

32K-WORD MAIN BLOCK

632K-WORD MAIN BLOCK

532K-WORD MAIN BLOCK

4 32K-WORD MAIN BLOCK

332K-WORD MAIN BLOCK

232K-WORD MAIN BLOCK

132K-WORD MAIN BLOCK

032K-WORD MAIN BLOCK

54K-WORD PARAMETER BLOCK

44K-WORD PARAMETER BLOCK

34K-WORD PARAMETER BLOCK

24K-WORD PARAMETER BLOCK

14K-WORD PARAMETER BLOCK

04K-WORD PARAMETER BLOCK

14K-WORD BOOT BLOCK

0

4K-WORD BOOT BLOCK

TOP BOOT

32K-WORD MAIN BLOCK

32K-WORD MAIN BLOCK

32K-WORD MAIN BLOCK

32K-WORD MAIN BLOCK

32K-WORD MAIN BLOCK

32K-WORD MAIN BLOCK

32K-WORD MAIN BLOCK

LRS1338A-4

Principles of Operation

The LRS1388A SmartVoltage flash memory

includes an on-chip W SM to manage bloc k erase and

word write functions. It allows for: 100% TTL-level control inputs, fixed power supplies during block erasure,

word write, and minimal processor overhead with

RAM-like interface timings.

After initial device power-up or return from deep

power-down mode (see ‘Bus Operatio n’), the device

When V

altered. The CUI, with two-step bloc k erase or word

write command sequences, provides protec tion from

unwanted operations even when high voltage is

applied to V

V

is below the write lockout voltage V

CC

RP

is at VIL. The device’s boot blocks locking capability for WP

vertent code or data alteration by block erase and

word write operations.

≤ V

PP

. All write functions are d isabled when

PP

, memory contents cannot be

PPLK

provides additional protection from inad-

defaults to re ad array mode . Manipulation of external

memory control pins allow array read, standby, and

output disable operations.

Status register and identifier codes can be accessed

through the CUI indep endent of the F-V

High voltage on F-V

enables successful block era-

PP

voltage.

PP

sure and word writing. All functions associated with

altering m emory co ntents — block erase, word write,

status, and identifier codes — are accessed via the CUI

and verified through the status register.

Commands are written using standard microprocessor write timings. The CUI contents serve as input to

the WSM, which controls the block erase and word

write. The internal algorithms are regulated by the

WSM including pulse repetition , internal verif ication,

and margining of d ata. Addresses a nd data are internally latched during write cycles. Wr iting the appropriate command outputs array data, accesses the

identifier codes or outputs status register data.

Interface software that initiates and polls progress of

block erase and word write can be stored in any block.

This code is copied to and executed from system RAM

during flash memory updates. After successful completion, reads are again possible via the Read Array command. Block erase suspend allows system software to

suspend a block erase to read/write dat a from/to blocks

other than that which is suspended. Word writ e suspend allows system software to suspend a word write to

read data from any other flash memory array location.

DATA PROTECTION

Depending on the appl ication, the syst em designer

may choose to make the V

(available only when memor y block erases or word

writes are required) or hardwir ed to V

accommodates either design practice and encourages

optimization of the processor-memory interface.

Data Sheet 9

power supply switchable

PP

. The device

PPH

Figure 4. Memory Map

LKO

or when

LRS1338A Stacked Chip (8M Flash & 2M SRAM)

RESERVED FOR

FUTURE IMPLEMENTATION

DEVICE CODE

MANUFACTURER CODE

7FFFF

00001

00000

1338A-5

Bus Operation

The local CPU reads and writes f lash memory insystem. All bus cycles to or from the flash memory conform to standard microprocessor bus cycles.

READ

Information can be read from any block, identifier

codes or status register independent of the V

age. RP

can be either VIH or VHH.

The first task is to write the appropriate read mode

command (Read Array, Read Identifier Codes, or Read

Status Register) to the CUI. Upon initial device powerup or after exit from deep power-down mode, the device

automatically resets to read array mode. Five control

pins dictate the data flow in and out of the component:

CE

, OE, WE, RP and WP. CE and OE must be drive n

active to obtain data at the outputs. CE

is the device

selection control, and when active enables the selected

memory device. OE

is the data output (I/O0 - I/O15) control and when active drives the selected memory data

onto the I/O bus. WE

V

or VHH. Figure 12 illustrates a read cycle.

IH

must be at VIH and RP must be at

OUTPUT DISABLE

With OE

puts are disabled. Output pins (I/O

at a logic-HI GH le ve l ( VIH), the device out-

- I/O15) are placed

0

in a HIGH impedance state.

PP

volt-

As with any automated device, it is important to

assert RP

during system reset. When the system

comes out of reset, i t ex pec ts to re ad f ro m fl ash m emory. Automated flash memories provide status information when accessed during block erase or word write

modes. If a CPU reset occur s with no flash memory

reset, proper CPU initialization may not occur because

the flash memory may be provid ing status in formation

instead of arr ay data. SHARP ’s flash memories allow

proper CPU initialization following a system reset

through the use of RP

controlled by the same RESET

input. In this appl ication, RP is

signal that resets the

system CPU.

READ IDENTIFIER CODES OPERATION

The read identifier codes operation outputs the manufacturer code and devic e codes, the system CP U can

automatically match the device with its proper algorithms.

STANDBY

CE

at a logic HIGH level (VIH) places the device in

standby mode which substantially reduces device

power consumption. I/O

a HIGH-impedance st ate independent of OE

- I/O15 outputs are placed in

0

. If deselected during block erase or word write, the device continues functioning, and consuming active power until

the operation completes.

DEEP POWER-DOWN

RP

at VIL initiates the deep power down mode.

In read modes, RP

-LOW deselects the memory,

places output driver s in a HIGH-impedance s tate and

turns off all internal circuits. RP

a minimum of 1 00 ns. Time t

must be held LOW for

is required after

PHQV

return from power-down until initial memory access

outputs are valid. After this wake-up interval, normal

operation is restored. The CUI is reset to read array

mode and status register is set to 80H.

During block erase or word write modes, RP

-LOW

will abort the operation. Memory contents being altered

are no longer valid; the data may be partially erased or

written. Time t

HIGH (V

) before another command can be written.

IH

is required after RP goes to logic

PHWL

Figure 5. Device Identifier Code Memory Map

WRITE

Writing commands to the CUI enable reading of

device data and identifier codes. T hey also control

inspection and clearing of the status register.

When V

CC

= V

and VPP = V

CC1

, the CUI add i-

PPH

tionally controls block erasure and word write. The

Block Erase comman d requ ires ap propr iate com man d

data and an address within the block to be erased. The

Word Write command requires the command and

address of the location to be written.

The CUI does not occupy an addressable memory

location. It is wri tten wh en WE

and CE are active. The

address and data needed to execute a command ar e

latched on the rising edge of WE

or CE (whichever

goes HIGH first). Standard microprocessor write timings are used. F igure 13 a nd 14 illustrat e WE

and CE

controlled write operations.

10 Data Sheet

Stacked Chip (8M Flash & 2M SRAM) LRS1338A

COMMAND DEFINITIONS

When VPP ≤ V

, Read oper ation s from t he statu s

PPLK

Device operations are selected by writ ing specific com-

mands into the CUI. Tabl e 6 defines these comma nds.

register, identifier codes or blocks are enabled. Placing

V

on VPP enables successful block erase and word

PPH

write operations.

Table 5. Bus Operations

MODE RP

Read V

Output Disable V

Standby V

Deep Power-Down V

Read Identifier Codes V

Write V

NOTES:

1. Refer to ‘DC Characteristics’. When V

2. X can be V

See ‘DC Characteristics’ for V

3. Never hold OE

at GND ± 0.2 V ensures the lowest deep power-down current.

4. RP

5. See ‘Read Identifier Codes Command’ for read identifier code data.

6. Command writes involving block erase or word write are reliably executed when V

Block erase or word write with V

7. Refer to Table 6 for valid D

or VIH for control pins and addresses, and V

IL

LOW and WE LOW at the same time.

or V

IH

HH

or V

IH

HH

or V

IH

HH

IL

or V

IH

HH

or V

IH

HH

PP

and V

PPLK

< RP < VHH produce spurious results and should not be attempted.

IH

during a write operations.

IN

CE OE WE ADDRESS V

V

IL

V

IL

V

IH

V

IL

V

IH

V

IH

V

IH

XX X XHIGH Z

XXX X XHIGH Z4

≤ V

PPH

V

IL

V

IL

, memory contents can be read, but not altered.

PPLK

voltages.

V

V

PPLK

IL

IH

or V

PPH

V

IH

V

IL

for VPP.

I/O0 - I/O15NOTES

PP

XXD

OUT

1, 2, 3

XXHIGH Z

See Figure 3 X 5

XXDIN3, 6, 7

= V

PP

and VCC = V

PPH

CC1

.

1

4

OPER.2ADDR.3DATA

4

NOTES

COMMAND

Read Array/Reset

Read Identifier Codes

Table 6. Command Definitions

BUS CYCLES

REQUIRED

FIRST BUS CYCLE SECOND BUS CYCLE

OPER.

2

ADDR.

3

DATA

1 Write X FFH

2 Write X 90H Read IA ID 5

≥

Read Status Register 2 Write X 70H Read X SRD

Clear Status Register 1 Write X 50H

Block Erase 2 Write BA 20H Write BA D0H 6

Word Write 2 Write WA 40H or 10H Write WA WD 6, 7

Block Erase and Word

Write Suspend

Block Erase and Word

Write Resume

NOTES:

1. Commands other than those shown in table are reserved by SHARP for

future device implementations and should not be used.

2. BUS operations are defined in Table 5.

3. X = Any valid address within the device; IA = Identifier Code Address, see Figure 5.

BA = Address within the block being erased; WA = Address of memory location to be written.

4. SRD = Data read from status register. See Table 9 for a description of the status register bits.

WD = Data to be written at location WA. Data is latched on the rising edge of WE

ID = Data read from identifier codes.

5. Following the Read Identifier Codes command, read operations access manufacturer and device codes.

See ‘Read Identifier Codes Command’ for read identifier code data.

6. When WP

Attempts to issue a block erase or word write to a locked boot block while RP

7. Either 40H or 10H are recognized by the WSM as the word write setup.

= VIL, RP must beat VHH to enable block erase or word write operations.

1WriteXB0H 6

1WriteXD0H 6

or CE (whichever goes HIGH first).

= VIH.

Data Sheet 11

Loading...

Loading...