Sharp LRS13023 Datasheet

®

PRODUCT SPECIFICATIONS

Integrated Circuits Group

LRS1302

Stacked Chip

8M Flash and 1M SRAM

(Model No.: LRS13023)

Spec No.: EL116039

Issue Date: June 11, 1999

SHARP

l

Handle this document carefully for it contains material protected by international

copyright law. Any reproduction, full or in part, of this material is prohibited

without the express written permission of the company.

l

When using the products covered herein, please observe the conditions written herein

and the precautions outlined in the following paragraphs. In no event shall the

company be liable for any damages resulting from failure to strictly adhere to these

conditions and precautions.

(1)

LRS13023

The products covered herein are designed and manufactured for the following

application areas. When using the products covered herein for the equipment

listed in Paragraph (2). even for the following application areas, be sure

to observe the precautions given in Paragraph (2). Never use the products

for the equipment listed in Paragraph (3).

- Office electronics

* Instrumentation and measuring equipment

- Machine tools

- Audiovisual equipment

- Home appliances

* Communication equipment other than for trunk lines

(2) Those contemplating using the products covered herein for the following

equipment which demands high reliability, should first contact a sales

representative of the company and then accept responsibility for incorporating

into the design fail-sale operation, redundancy, and other appropriate measures

for ensuring reliability and safety of the equipment and the overall system.

* Control and safety devices for airplanes, trains, automobiles, and other

transportation equipment

* Mainframe computers

- Traffic control systems

* Gas leak detectors and automatic cutoff devices

- Rescue and security equipment

* Other safety devices and safety equipment,etc.

(3) Do not use the products covered herein for the following equipment which

demands extremely high performance in terms of functionality, reliability, or

accuracy.

- Aerospace equipment

- Communications equipment for trunk lines

- Control equipment for the nuclear power industry

- Medical equipment related to life support, etc.

(4) Please direct all queries and comments regarding the interpretation of the

above three Paragraphs to a sales representative of the company.

l

Please direct all queries regarding the products covered herein to a sales

representative of the company.

-

SHARP

LRS13023

Part 1 Overview

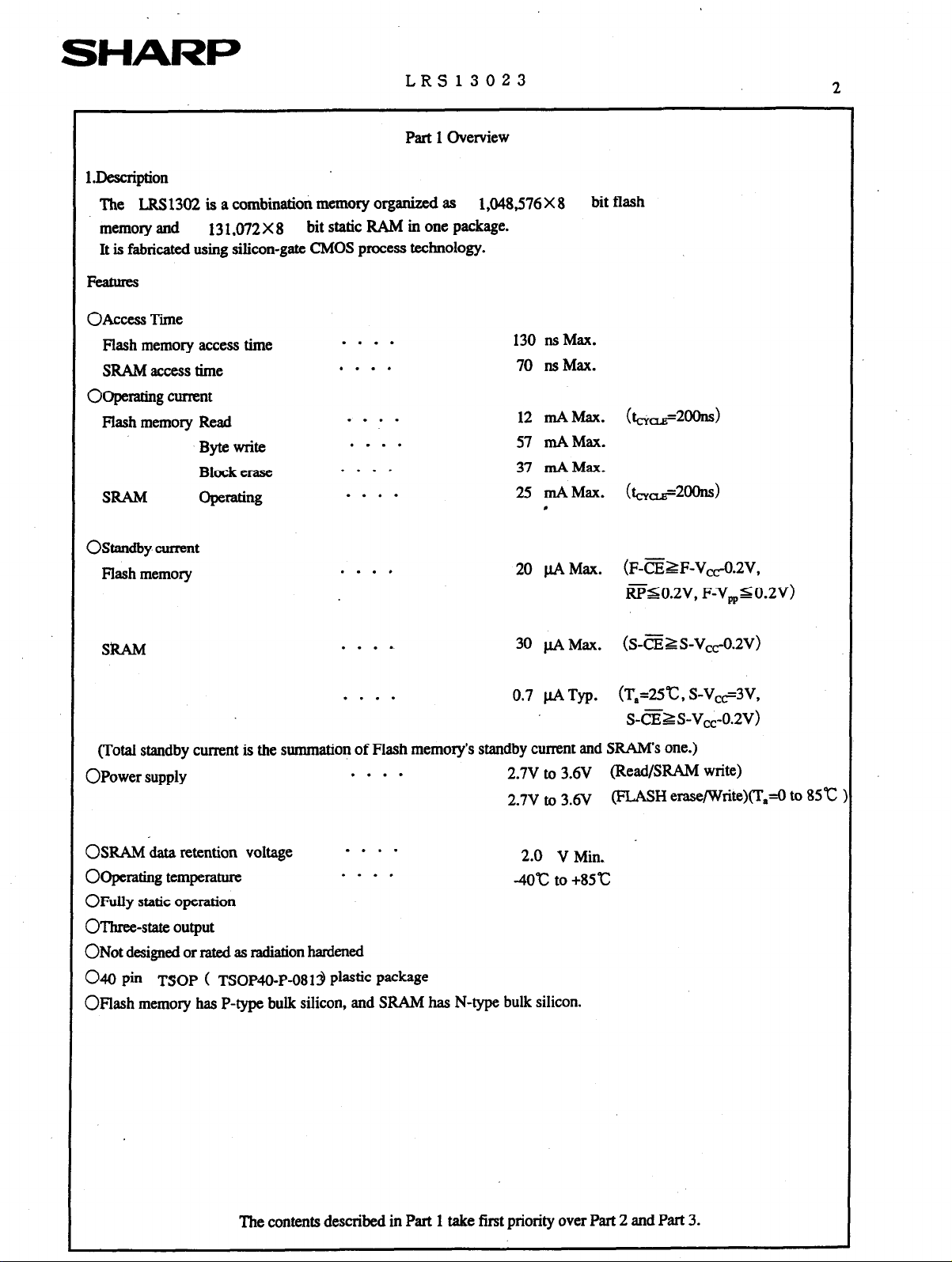

l.Description

The LRS1302 is a combination memory organized as

memory and

It is fabricated using silicon-gate CMOS process technology.

Features

OAccess Time

Flashmemoryaccesstime

SRAM access time

OOpemtingcurrent

Flash memory Read

SRAM

131,072X8

Byte write

Block erase

operatin%

bit static RAM in one package.

- * * *

. . . .

. . . .

. . . .

. . . .

- - * *

1448,576 X 8

130 nsMax.

70 nsMax.

12 mAMax. (t&ti2OOns)

57 r&Max.

37 mAMax.

25 mA Max. hcxJz.=2=)

,

bit flash

2

ostandbycurrent

Flash memory

Sk4M

(Total standby curnat is the summation of Flash memory’s standby current and SRAM’s one.)

OPower supply

OSRAM data retention voltage

OOperating temperature

OFully static operation

oThree-state output

ONot designed or rated as radiation hardened

040 pin TSOP ( TSOP~O-p-0819 plastic package

OFlash memory has P-type bulk silicon, and SRAh4 has N-type bulk silicon.

. . . .

. . . .

. . . .

. . . .

. . . .

20 @ Max. (F-EZF-Vc,0.2V,

EbO.2V, F-V&O.2V)

30 pA Max. (S-EZS-Vc,0.2V)

0.7 @ Typ. (T,=25”c, S-V,-3V,

S-CErs-Vcc-0.2V)

2.7V to 3.6V @ead/SRAM write)

2.7~ to 3.6~ @LASH erase/write)(T,=O to 85c

2.0 V Min.

40°C to +85”c

The contents described in Part 1 take first priority over Part 2 and Part 3.

-

SHARP

LRS13023

Part 1 Overview

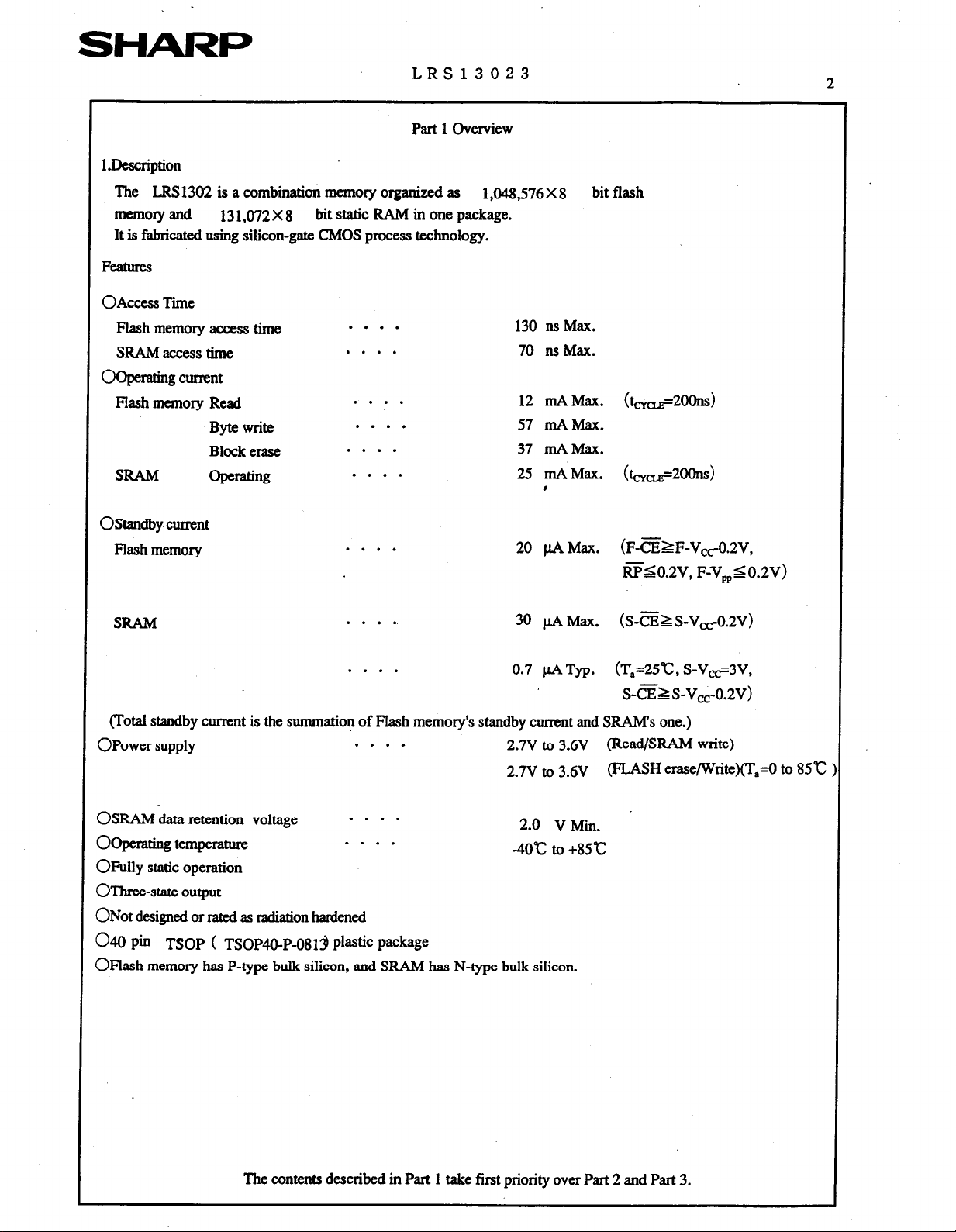

l.Description

The LRS1302 is a combination memory organized as

memory and

It is fabricated using silicon-gate CMOS process technology.

OAccess Time

Flashmemoryaccesstime

SRAM access time

OOpemtingcment

Flash memory Read

SRAM Operating

131,072X8

Byte write

Block erase

bit static RAM in one package.

- * * *

. . . .

. . . .

. . . .

. . . .

- - * *

1,048,576X 8 bit flash

130 nsMax.

70 nsMax.

12 mAMax. (t&ti2Oons>

57 mAMax.

37 mAMax.

25 mAMax.

,

hcxJ&oons)

2

ostandbycurrent

Flash memory

Sk4M

(Total standby current is the summation of Flash memory’s standby current and SRAM’s one.)

3Power supply

3SRAM data retention voltage

3Operating temperature

IFully static operation

3Three-state output

JNot designed or rated as radiation hardened

240 Pin TSOP ( TSOP~O-p-0819 plastic package

IFlash memory has P-type bulk silicon, and SRAM has N-type bulk silicon.

. . . .

. . . .

. . . .

. . . .

. . . .

20 pA Max. (F-EZF-Vc,0.2V,

EbO.2V, F-V&O.2V)

30 @ Max. (S-=ZS-Vc,0.2V)

0.7 @ Typ. (T,=25”c, S-V,-3V,

s-CEZS-vcc-0.2v)

2.7V to 3.6V @ead/SPAM write)

2.7~ to 3.6~ (FLASH erase/write>Cr,=O to 85c

2.0 V Min.

40°C to +85”c

The contents described in Part 1 take first priority over Part 2 and Part 3.

m

.

SHARI=

LRS13023

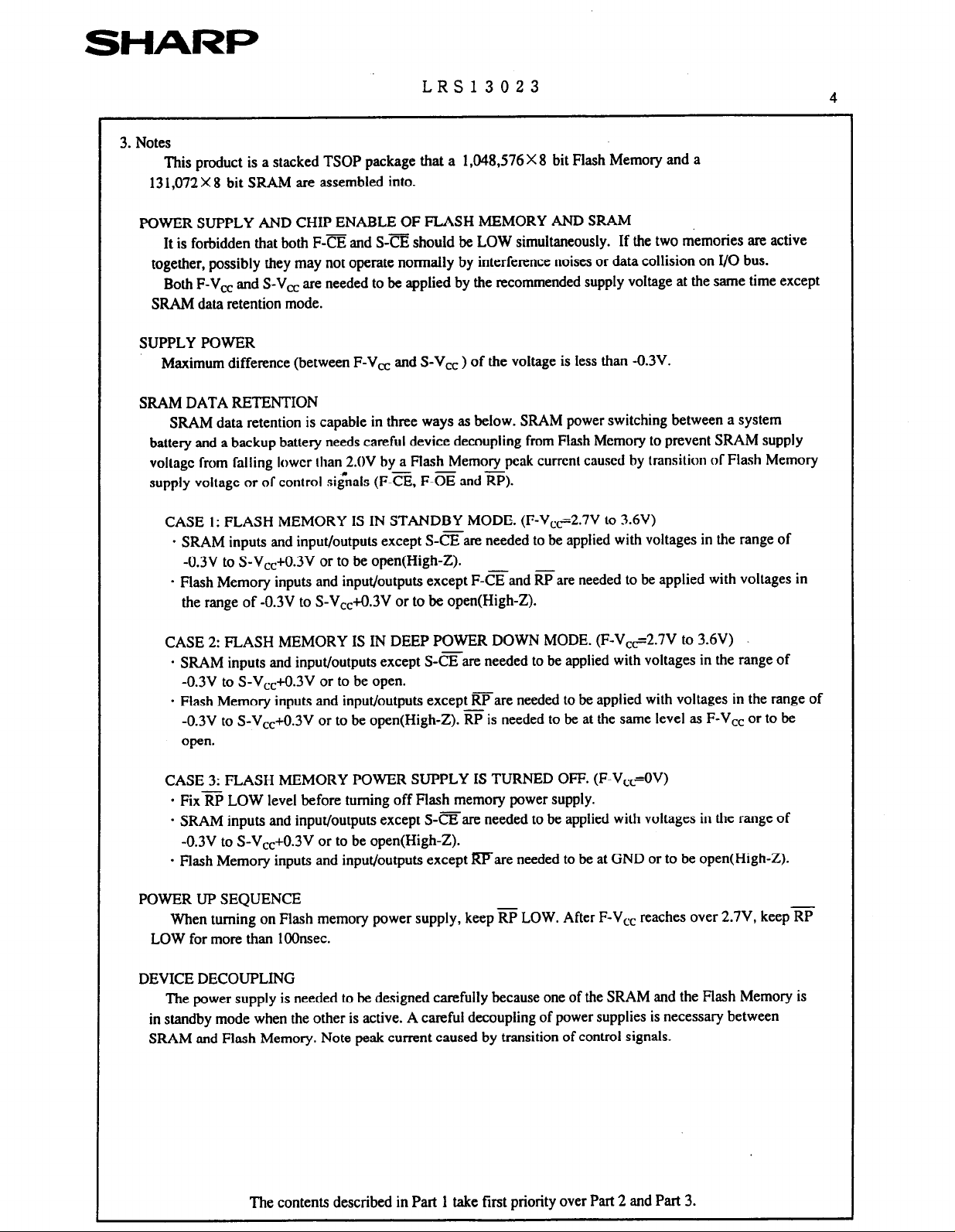

3. Notes

This product is a stacked TSOP package that a 1,048,576X 8 bit Flash Memory and a

13 1,072 X 8 bit SRAM are assembled into.

POWER SUPPLY AND CHIP ENABLE OF FLASH MEMORY AND SRAM

It is forbidden that both F-E and S-E should be LOW simultaneously. If the two memories are active

together, possibly they may not operate normally by interference noises or data collision on I/O bus.

Both F-V, and S-V, are needed to be applied by the recommended supply voltage at the same time except

SRAM data retention mode.

SUPPLY POWER

Maximum difference (between F-V,

SRAM DATA RETENTION

SRAM data retention is capable in three ways as below. SRAM power switching between a system

battery and a backup battery needs careful

voltage from

supply voltage or of control si{nals (F-B, F-?% and RP).

CASE I: FLASH MEMORY IS IN STANDBY MODE. (F-Vcc=2.7V to 3.6V)

* SRAM inputs and input/outputs except S-mare needed to be applied with voltages in the range of

-0.3V to S-Vcc+O.3V or to be open(High-Z).

* Flash Memory inputs and input/outputs except F-eand Gare needed to be applied with voltages in

the range of -0.3V to S-V,,+O.3V or to be open(High-Z).

failing

lower han

2.OV by a Flash Memory peak current caused by transition of Flash Memory

and S-V, ) of the voltage is less than -0.3V.

device

decoupling from Flash Memory to prevent SRAM

4

supply

CASE 2: FLASH MEMORY IS IN DEEP POWER DOWN MODE. (F-Vcc=2.7V to 3.6V)

* SRAM inputs and input/outputs except S-mare needed to be applied wilh voltages in the range of

-0.3V to S-V,c+O.3V or to be open.

* Flash Memory inputs and input/outputs except mare needed to be applied with voltages in the range of

-0.3V to S-Vc,+O.3V or to be open(High-Z). RP is needed to be at the same level as F-V,, or to be

open.

CASE 3: FLASH MEMORY POWER SUPPLY IS TURNED OFF. (F-VcpOV)

* Fix- LOW level before turning off Flash memory power supply.

* SRAM inputs and input/outputs except S-mare needed to be applied with voltages in the range of

-0.3V to S-V,c+O.3V or to be open(High-Z).

- Flash Memory inputs and input/outputs except mare needed to be at GND or to be open(High-Z).

POWER UP SEQUENCE

When turning on Flash memory power supply, keep i@ LOW. After F-V,, reaches over 2.7V, keep RP

LOW for more than 1OOnsec.

DEVICE DECOUPLING

The power supply is needed to be designed carefully because one of the SRAM and the Flash Memory is

in standby mode when the other is active. A careful decoupling of power supplies is necessary between

SRAM and Flash Memory. Note peak current caused by transition of control signals.

The contents described in Part 1 take first priority over Part 2 and Part 3.

SHARP

LRS13023

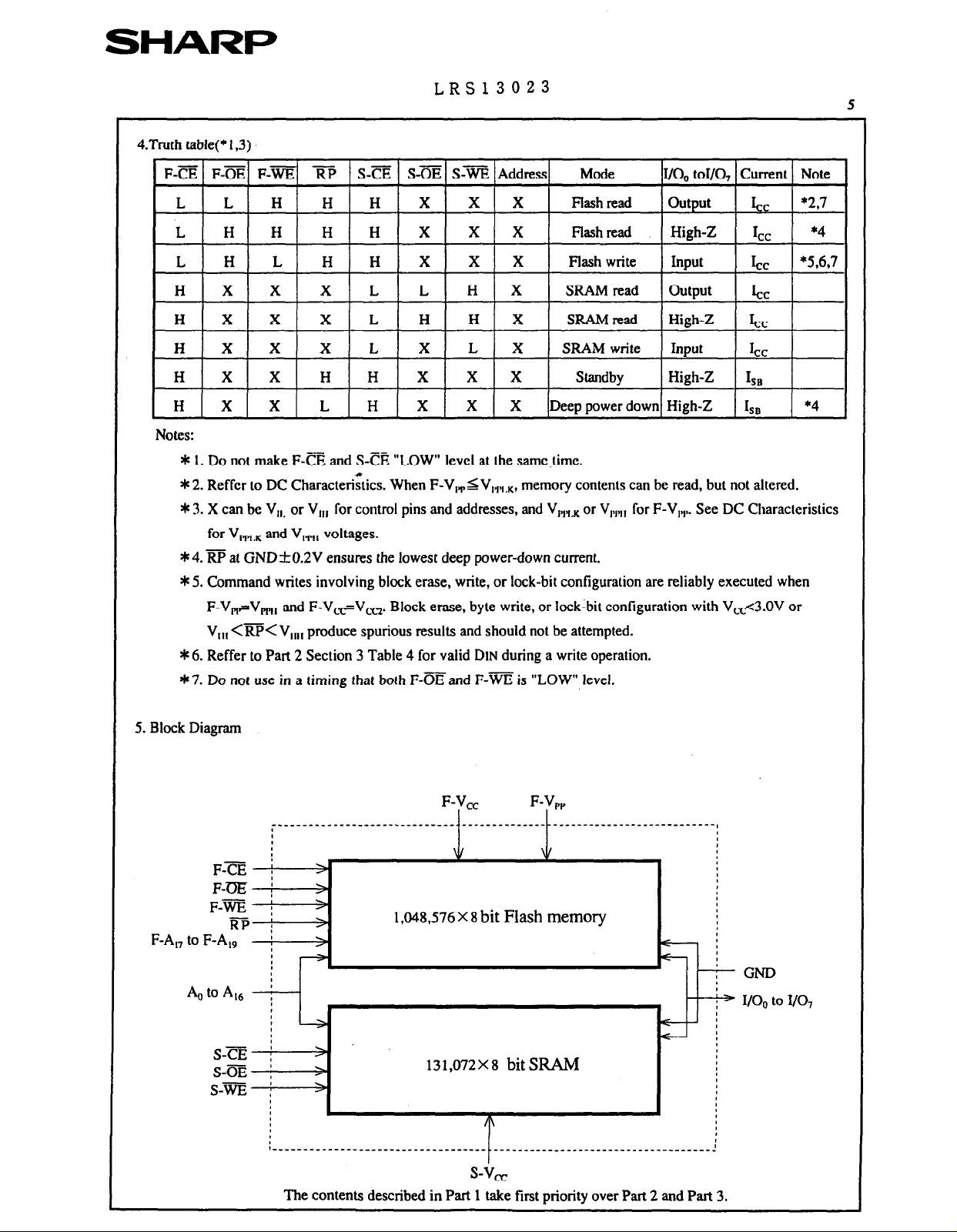

4.Truth table(* 1.3)

F-a F-m F-m RP S-a S-m S-m Address Mode I/O, toI/O, Current Note

LLHHHXXX Flash read output

LHHHHXXX Flash read High-Z I,, *4

LHLHHXXX Flash write Input

HXXXLLHX SRAM read output Ice

HXXXLHHX sR4M read High-Z I,,

HXXXLXLX SRAM write Input I

HXXHHXXX Standby High-Z Iss

HXXLHXXX Deep power down High-Z Isa *4

Notes:

* 1. Do not make F-C? and S-C8 “LOW” level at the samc,limc.

* 2. Reffcr to DC Character&tics. When F-V&V,,.,.,, memory contents can be read, but not altered.

* 3. X can be V,,, or V,,, for control pins and addresses, and V,,nx or VI,,,,, for F-V,,,,. See DC Characteristics

for V,,,k and V,,.,, voltages.

* 4. i@ at GND f0.2V ensures the lowest deep power-down current.

* 5. Command writes involving block erase, write, or lock-bit configuration are reliably executed when

F-V,,=V,, and F-V,@,. Block erase, byte write, or lock-bit conliguration with Vcc<3.0V or

V,,, <m< V,,,, produce spurious results and should not be attempted.

* 6. Reffer to Part 2 Section 3 Table 4 for valid DIN during a write operation.

$7. Do not

use in

a timing that both F-mand F-WE is “LOW” level.

EC

kc

cc

5

*2,7

*5,6,7

5. Block Diagram

F-n i

F-GE / >

F-m j

RP ;

F-A,, to F-A,, !

&to&, ;

S-TE /

S-FE

s-m ;

F-V, F-V,,

____________________----------.------------------------------------------

9

w v

3

>

>

>

4

I

>

>

>

1,048,576 X 8

131,072X8

bit Flash memory

bit SR4M

I

e- ;

e

0

>

The contents described in Part 1 take first priority over Part 2 and Part 3.

SHARP

LRS13023

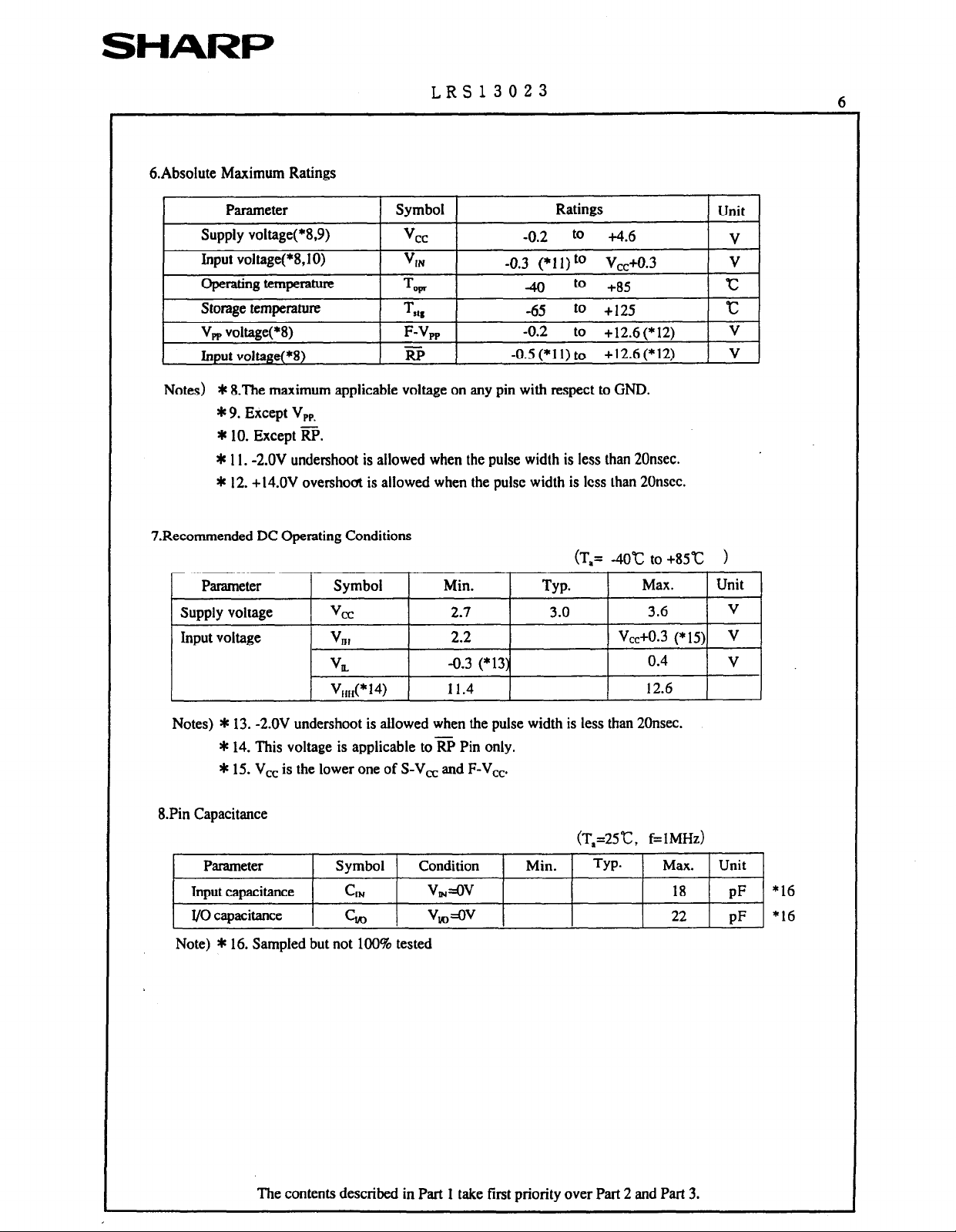

6.Absolute Maximum Ratings

Notes) * 8.The maximum applicable voltage on any pin with respect to GND.

* 9. Except Vrp,

* 10. Except @.

* 11. -2.OV undershoot is allowed when the pulse width is less than 20nsec.

* 12. +14.OV overshoot is allowed when the pulse width is less than 2Onscc.

7.Recommended DC Operating Conditions

CT,= -40°C to +85”c )

Parameter Symbol Min.

Supply voltage

Input voltage

vc-2

V”,

VU.

v,,,,(* 14)

2.7 3.0 3.6

2.2 V,,+O.3 (*15) V

-0.3 (*13:

11.4 12.6

TYP.

Max. Unit

V

0.4

V

6

Notes) * 13. -2.OV undershoot is allowed when the pulse width is less than 2Onsec.

* 14. This voltage is applicable toi@ Pin only.

* 15. V, is the lower one of S-V, and F-V,,.

8.Pin Capacitance

(T,=25”c, f=lMHz)

Parameter Symbol Condition

Input capacitance

I/O capacitance

Note) * 16. Sampled but not 100% tested

Gi

CIA3

v,=ov

v,=ov

Min. TYP.

Max. Unit

18

22

PF

PF

*16

*16

The contents described in Part 1 take first priority over Part 2 and Part 3.

SHARP

LRS13023

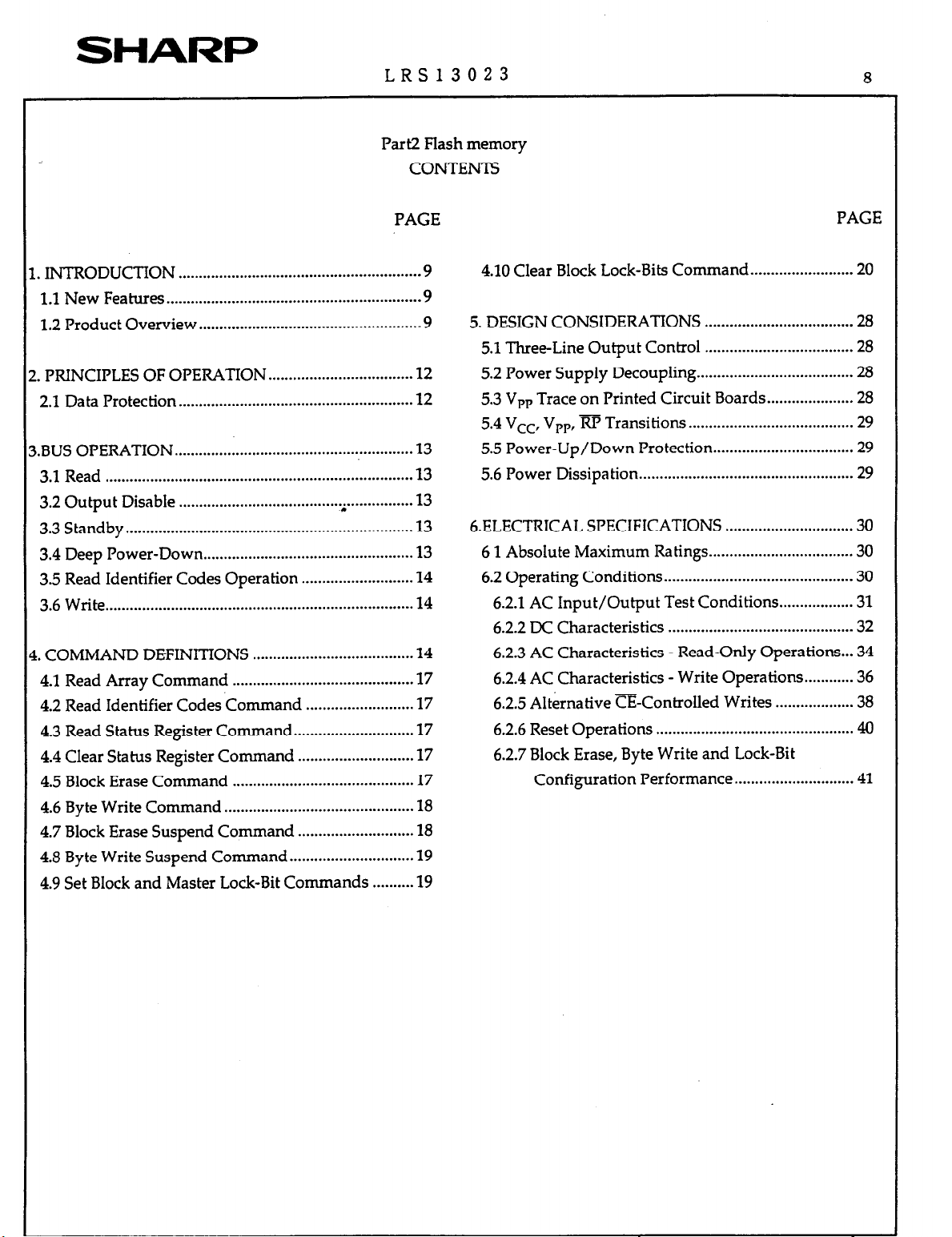

Part2 Flash memory

CONTENTS

8

PAGE

.. INTRODUCTION

1.1 New Features.. ...........................................................

1.2 Product Overview

!. PRINCIPLES OF OPERATION

2.1 Data Protection

I.BUS OPERATION.. ........................................... .

3.1 Read

3.2 Output Disable

3.3 Standby

3.4 Deep Power-Down

3.5 Read Identifier Codes Operation

3.6 Write ...........................................................................

I. COMMAND DEFINITIONS

4.1 Read Array Command

4.2 Read Identifier Codes Command .........................

4.3 Read Status Register Command..

4.4 Clear Status Register

4.5 Block Erase Command

4.6 Byte Write Command ..............................................

4.7 Block Erase Suspend Command

4.8 Byte Write Suspend Command.. ...........................

4.9 Set Block and Master Lock-Bit Commands

........................................................................... 13

...................................................................... 13

........................................................... 9

......................................................

...................................

.........................................................

............

........................................

...................................................

.......................................

............................................ 17

Command

............................................ 17

;............... 13

........................... 14

..........................

...........................

...........................

.........

-9

9

12

12

13

13

14

14

.17

.17

.17

18

.18

.19

-19

PAGE

4.10 Clear Block Lock-Bits

5. DESIGN CONSIDERATIONS .................................... 28

5.1 Three-Line Output Control .................................... 28

5.2 Power Supply

5.3 V,, Trace on Printed Circuit Boards.. ................... 28

5.4 V,,, V,,, i?is Transitions.. ......................................

5.5 Power-Up/Down Protection.. ................................ 29

5.6 Power Dissipation.. .................................................. 29

6.ELECTRICAL SPECIFICATIONS ............................... 30

6 1 Absolute Maximum

6.2 Operating Conditions..

6.2.1 AC Input/Output Test Conditions.. ................ 31

6.2.2 DC Characteristics .............................................

6.2.3 AC Characteristics - Read-Only Operations

6.2.4 AC Characteristics - Write Operations..

6.2.5 Alternative a-Controlled Writes ................... 38

6.2.6 Reset Operations ................................................ 40

6.2.7 Block Erase, Byte Write and Lock-Bit

Configuration Performance.. ...........................

Decoupling.. .................................... 28

Command.. ....................... 20

29

Ratings.. ................................. 30

............................................ 30

32

... 34

.36

.........

41

SHARP

LRS13023

Part2 Flash memory

CONTENTS

8

PAGE

.. INTRODUCTION

1.1 New Features.. ...........................................................

1.2 Product Overview

!. PRINCIPLES OF OPERATION

2.1 Data Protection

I.BUS OPERATION.. ........................................... . ............ 13

3.1 Read

3.2 Output Disable

3.3 Standby

3.4 Deep Power-Down

3.5 Read Identifier Codes Operation

3.6 Write ...........................................................................

I. COMMAND DEFINITIONS

4.1 Read Array Command

4.2 Read Identifier

4.3 Read Status Register Command..

4.4 Clear Status Register Command

4.5 Block Erase Command

4.6 Byte Write Command

4.7 Block Erase Suspend

4.8 Byte Write Suspend

4.9 Set Block and Master Lock-Bit Commands

........................................................................... 13

...................................................................... 13

...........................................................

......................................................

...................................

.........................................................

........................................

...................................................

....................................... 14

............................................ 17

Codes Command

............................................ 17

.............................................. 18

Command

Command..

;............... 13

........................... 14

.........................

..........................

...........................

...........................

...........................

.........

9

-9

9

12

12

13

14

.17

.17

.17

.18

.19

-19

PAGE

4.10 Clear Block Lock-Bits Command.. ....................... 20

.........

28

.36

5. DESIGN CONSIDERATIONS ....................................

5.1 Three-Line Output Control .................................... 28

5.2 Power Supply

5.3 V,, Trace on Printed

5.4 V,,, V,,, i?is Transitions.. ...................................... 29

5.5 Power-Up/Down

5.6 Power Dissipation..

6.ELECTRICAL SPECIFICATIONS ............................... 30

6 1 Absolute Maximum

6.2 Operating Conditions..

6.2.1 AC Input/Output

6.2.2 DC Characteristics ............................................. 32

6.2.3 AC Characteristics - Read-Only Operations ... 34

6.2.4 AC Characteristics - Write Operations..

6.2.5 Alternative a-Controlled Writes ................... 38

6.2.6 Reset Operations ................................................ 40

6.2.7 Block Erase, Byte Write and Lock-Bit

Configuration Performance.. ........................... 41

Decoupling.. .................................... 28

Circuit Boards.. ................... 28

Protection.. ................................ 29

.................................................. 29

Ratings.. ................................. 30

............................................ 30

Test Conditions.. ................ 31

SHARP

LRS13023

INTRODUCTION

his datasheet contains LRS1302 specifications.

iection 1 provides a flash memory overview. Sections

!, 3,4, and 5 describe the memory organization and

unctiordity. Section 6 covers electrical specifications.

..l New Features

The LRS1302 SmartVoltage Flash memory maintains

)ackwards-compatibility with SHARP’s 28F008SA.

Cey enhancements over the 28F008SA include:

SmartVoltage Technology

*Enhanced Suspend Capabilities

Jn-System Block Locking

30th devices share a compatible, status register, and

oftware command set. These similarities enable a

clean upgrade from the 28FOO8SA to LRS1302. When

upgrading, it is important to note the following

iifferences:

-Because of new feature support, the two devices

have different device codes. This allows for

software optimization.

.VPpLK has been lowered from 6SV to 1.5V to

support 2.7V-3.6V block erase, byte write, and

lock-bit configuration operations. Designs

switch VPP off during read operations should make

sure that the VP, voltage transitions to GND.

*To take advantage of SmartVoltage technology,

allow VP, connection to 2.7V-3.6V.

that

SmartVoltage technology provides a choice of Vcc and

VP, combinations, as shown in Table 1, to meet system

performance and power expectations. V, at 2.7V to

3.6V eliminates the need for a separate 12V converter.

In addition to flexible erase and program voltages, the

dedicated VPP pm gives complete data protection

when VP, I VP,,.

Table 1. V,, and VP, Voltage Combinations Offered

;_.

2,7V to 3.6V(‘l) 2.7V to 3.6V

NOTE’ ’

‘1. FLASH Erase/Write(T*=O”C to 85°C)

Internal Vcc and

automatically configures the device for optimized read

and write operations.

A Command User Interface (CUT) serves as the

interface between the system processor and internal

operation of the device. A valid command sequence

written to the CUT initiates device automation. An

internal Write State Machine (WSM) automatically

executes the algorithms and timings necessary for

block erase, byte write, and lock-bit configuration

operations.

A block erase operation erases one of the device’s

64Kbyte blocks typically within 1.8 second

independent of other blocks. Each block can be

independently erased 100,000 times (1.6 million block

erases per device). Block erase suspend mode allows

system software to suspend block erase to read or

write data from any other block.

by SmartVoltage Technology

Vcc Voltage VPP Voltage

VW

detection Circuitry

9

I

I.2 Product Overview

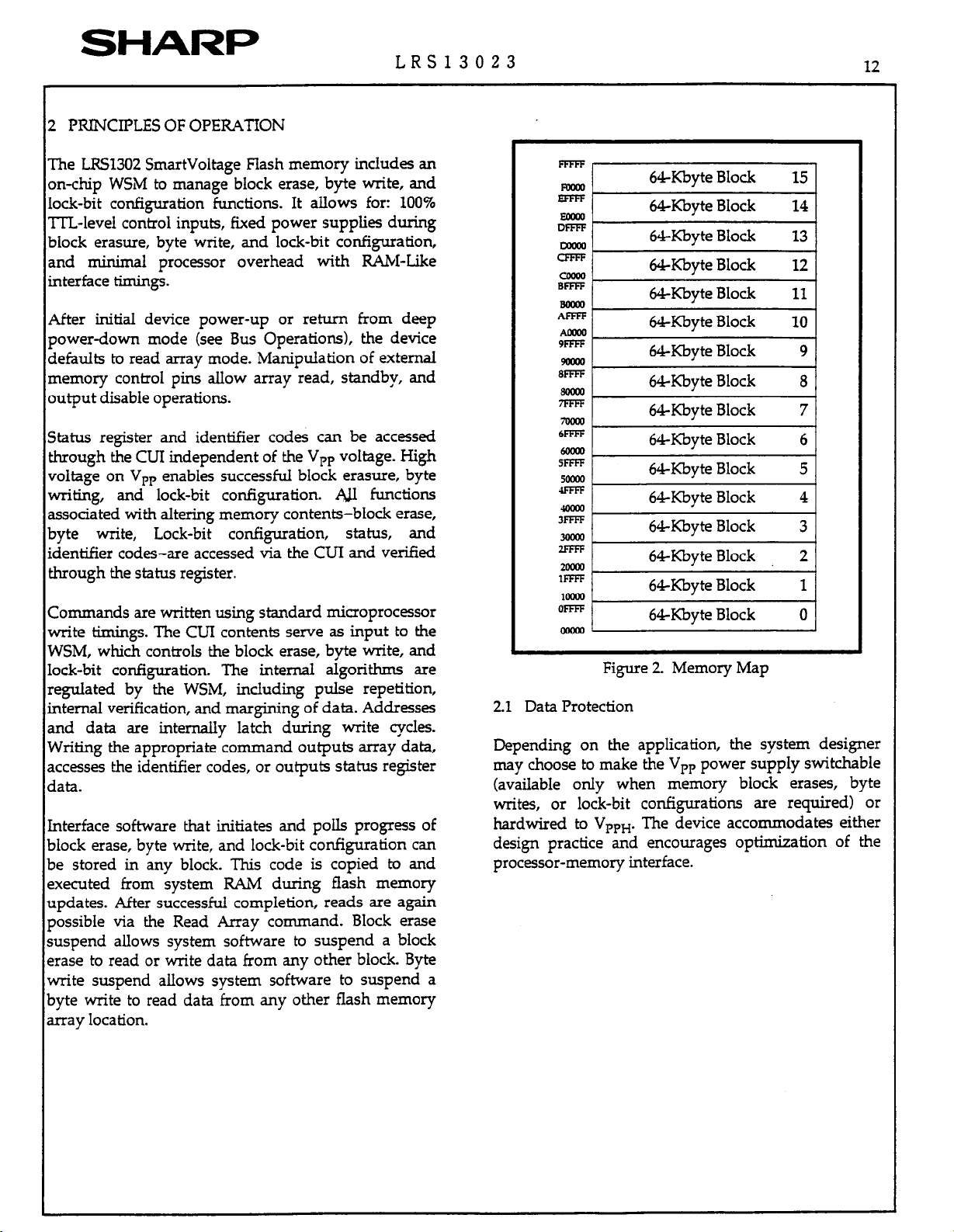

The LRS1302 is a high-performance &Mbit

;martVoltage Flash memory organized as 1 Mbyte of 8

>its. The 1 Mbyte of data is arranged in sixteen

&Kbyte blocks which are individually erasable,

o&able, and unlockable in-system. The memory map

s shown in Figure 2.

Writing memory data is performed in byte increments

typically within 17 us. Byte write suspend mode

enables the system to read data or execute code from

any other flash memory array location.

1

SHARP

LRS13023

10

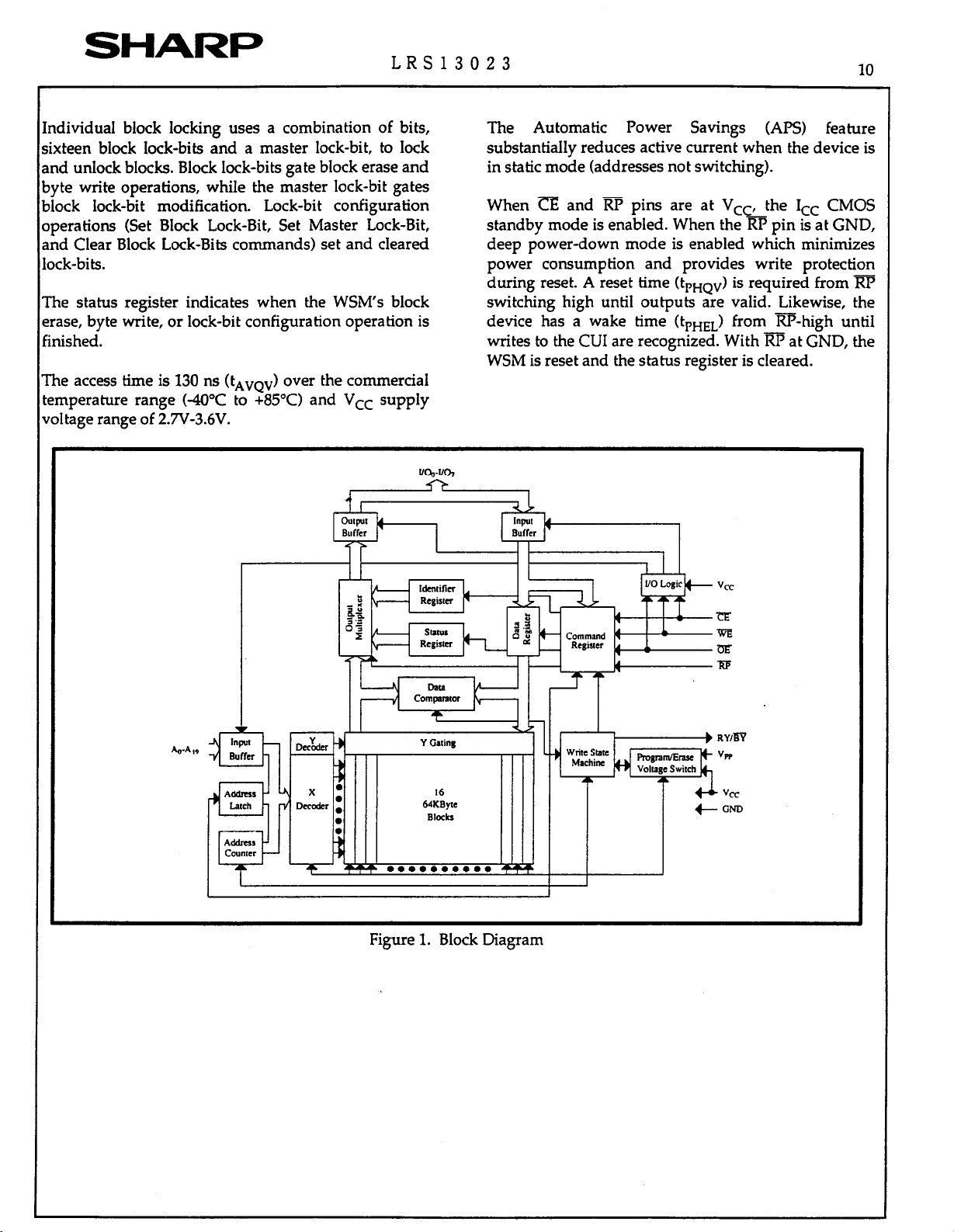

~Individual block locking uses a combination of bits,

‘sixteen block lock-bits and a master lock-bit, to lock

land unlock blocks. Block lock-bits gate block erase and

‘byte write operations, while the master lock-bit gates

~block lock-bit modification. Lock-bit configuration

loperations (Set Block Lock-Bit, Set Master Lock-Bit,

and Clear Block Lock-Bits commands) set and cleared

lock-bits.

The status register indicates when the WSM’s block

erase, byte write, or lock-bit configuration operation is

finished.

The access time is 130 ns (tAvQv) over the commercial

temperature range (-40°C to +BS’C) and V,, supply

voltage range of 2.7V-3.6V.

The Automatic Power Savings (AI%) feature

substantially reduces active current when the device is

in static mode (addresses not switching).

When a and RF pins are at V,,, the I,, CMOS

standby mode is enabled. When the RP pin is at GND,

deep power-down mode is enabled which minimizes

power consumption and provides write protection

during reset. A reset time (tPHqv) is required from RP

switching high until outputs are valid. Likewise, the

device has a wake time (tpHEL) from m-high until

writes to the CUI are recognized. With RP at GND, the

WSM is reset and the status register is cleared.

4 x :

occcdc.r .

16

64KByle

.

BlOCb

Figure 1. Block Diagram

SHARP

Svm

f40-419

I/O&O~

CE

Rp

OE

_. _-

WE

bP

Vcc

GND

rote: V,-,

LRS13023

Table 2. Pin Descriptions

Type

INPUT

INPUT/

OUTPUT

INPUT

INPUT

INPUT

INPUT

SUPPLY

SUPPLY

SUPPLY GROUND: Do not float any ground pins.

,P, n, m and WE mean F-V,,, F-V,,, F-a, Fa and F-WE.

ADDRESS INPUTS: Inputs for addresses during read and write operations. Addresses

are internally latched during a write cycle.

DATA INPUT/OUTPUTS: Inputs data and commands during CUI write cycles; outputs

data during memory array, status register, and identifier code read cycles. Data pins

float to high-impedance when the chip is deselected or outputs are disabled. Data is

internally latched during a write cycle.

CHIP ENABLE: Activates the device’s control logic, input buffers, decoders, and sense

amplifiers. a-high deselects the device and reduces power consumption to standby

levels.

RESET/DEEP POWER-DOWN: Puts the device in deep power-down mode and resets

internal automation. m-high enables normal operation. When driven low, p inhibits

write operations which provides data protection during power transitions. Exit from

deep power-down sets the device to read array mode. Ris at V,, enables setting of the

master lock-bit and enables configuration of block lock-bits when the master lock-bit is

-

set. RP=V,,, overrides block lock-bits thereby enabling block erase and byte write

operations to locked memory blocks. Block erase, byte write, or lock-bit configuration

with V,,<RI’cV& produce spurious results and should not be attempted.

OUTPUT ENABLE: Gates the device’s outputs during a read cycle.

WRITE ENABLE: Controls writes to the CUI and array blocks. Addresses

latched

BLOCK ERASE, BYTE WRITE, LOCK-BIT CONFIGURATION POWER SUPPLY: For

erasing array blocks, writing bytes, or configuring lock-bits. With VPP5VPPLK, memory

contents cannot

invalid VP, (see DC Characteristics) produce spurious results and should not be

attempted.

DEVICE POWER SUPPLYDo not float any power pins. With VCCIVLKO, all write

attempts to the flash memory are inhibited. Device operations at invalid Vcc voltage (see

DC Characteristics) produce spurious results and should not be attempted. Block erase,

byte write and lock-bit configuration operations with V,,<3.OV are not supported.

on

the rising edge of the WE pulse.

be altered. Block erase, byte write, and lock-bit configuration with an

Name and Function

and

11

data are

SHARI=

2 PRINCIPLES OF OPERATION

LRS13023

12

The LRS1302 SmartVoltage Flash memory includes an

on-chip WSM to manage block erase, byte write, and

lock-bit configuration functions. It allows for: 100%

TTL-level control inputs, fixed power supplies during

block erasure, byte write, and lock-bit configuration,

and minimal processor overhead with RAM-Like

interface timings.

After initial device power-up or return from deep

power-down mode (see Bus Operations), the device

defaults to read array mode. Manipulation of external

memory control pins allow array read, standby, and

output disable operations.

Status register and identifier codes can be accessed

through the CUI independent of the VP, voltage. High

voltage on V,, enables successful block erasure, byte

writing, and lock-bit configuration. All functions

associated with altering memory contents-block erase,

byte write, Lock-bit configuration, status, and

identifier codes-are accessed via the CUI and verified

through the status register.

Commands are written using standard microprocessor

write timings. The CUI contents serve as input to the

WSM, which controls the block erase, byte write, and

lock-bit configuration. The internal algorithms are

regulated by the WSM, including pulse repetition,

internal verification, and margining of data. Addresses

and data are internally latch during write cycles.

Writing the appropriate command outputs array data,

accesses the identifier codes, or outputs status register

data.

Interface software that initiates and polls progress of

block erase, byte write, and lock-bit configuration can

be stored in any block. This code is copied to and

executed from system RAM during flash memory

updates. After successful completion, reads are again

possible via the Read Array command. Block erase

suspend allows system software to suspend a block

erase to read or write data from any other block. Byte

write suspend allows system software to suspend a

byte write to read data from any other flash memory

array location.

I

I

Aoooo

9FFFF

9oMw)

SFFFF

8oooO

7FFFF

7owo

6FFFF

t5wlo

SFFFF

2Izzz

I

I

mm

OFFFF

ooom

2.1 Data Protection

Depending on the application, the system designer

may choose to make the V,, power supply switchable

(available only when memory block erases, byte

writes, or lock-bit configurations are required) or

hardwired to V,,,.

design practice and encourages optimization of the

processor-memory interface.

64Kbyte Block

64-Kbyte Block

64Kbyte Block 4 1

64Kbyte Block

64Kbyte Block 0

Figure 2. Memory Map

The device accommodates either

15 I

10 I

l/

SHARI=

LRS13023

When VPPIVPPLK, memory contents cannot be altered.

The CUI, with two-step block erase, byte write, or

lock-bit configuration command sequences, provides

protection from unwanted operations even when high

voltage is applied to VP+. All write functions are

disabled when V,,

VLKO or when RP is at Vl,. The device’s block locking

capability provides additional protection from

inadvertent code or data alteration by gating erase and

byte write operations.

3 BUS OPERATION

The local CPU reads and writes flash memory

in-system. All bus cycles to or from the flash memory

:onform to standard microprocessor bus cycles.

3.1 Read

Information can be read from any block, identifier

:odes, or status register independent of the VP,

voltage. RP can be at either Vl, or V,,.

The first task is to write the appropriate read mode

:ommand (Read Array, Read Identifier Codes, or Read

status Register) to the CUI. Upon initial device

Tower-up or after exit from deep power-down mode,

:he device automatically resets to read array mode.

Four control pins dictate the data flow in and out of

:he component: CE, OE, WE, and m. CE and m must

>e driven active to obtain data at the outputs. m is the

device selection control, and when active enables the

ielected memory device. m is the data output

I/O&O,) control and when active drives the

ielected memory data onto the I/O bus. WE must be

it VI, and m must be at V,, or V,,. Figure 12

llustrates a read cycle.

1.2 Output Disable

Mith 0lY at a logic-high level (Vt,), the device outputs

Ire disabled. Output pins I/0,-1/0, are placed in a

high-impedance state.

is below the write lockout voltage

.c

---

13

3.3 Standby

n at a logic-high level (V,,) places the device in

standby mode which substantially reduces device

power consumption. I/O&O, outputs are placed in

a high-impedance state independent of OE. If

deselected during block erase, byte write, or lock-bit

configuration, the device continues functioning, and

consuming active power until the operation completes.

3.4 Deep Power-Down

i?Ij at V,, initiates the deep power-down mode.

In read modes, m-low deselects the memory, places

output drivers in a high-impedance state and turns off

all internal circuits. RP must be held low for a

minimum of 100 ns. Time tPHQv is required after

return from power-down until initial memory access

outputs are valid. After this wake-up interval, normal

operation is restored. The CUI is reset to read array

mode and status register is set to 80H.

During block erase, byte write, or lock-bit

configuration modes, m-low will abort the operation.

Memory contents being altered are no longer valid; the

data may be partially erased or written. Time tpHWL is

required after Rp goes to logic-high (VI,) before

another command can be written.

As with any automated device, it is important to assert

Rp during system reset. When the system comes out of

reset, it expects to read from the flash memory.

Automated flash memories provide status information

when accessed during block erase, byte write, or

lock-bit configuration modes. If a CPU reset occurs

with no flash memory reset, proper CPU initialization

may not occur because the flash memory may be

providing status information instead of array data.

SHARP’s flash memories allow proper CPU

initialization following a system reset through the use

of the i?l? input. In this application, Rp is controlled by

the same m signal that resets the system CPU.

SHARP

LRS13023

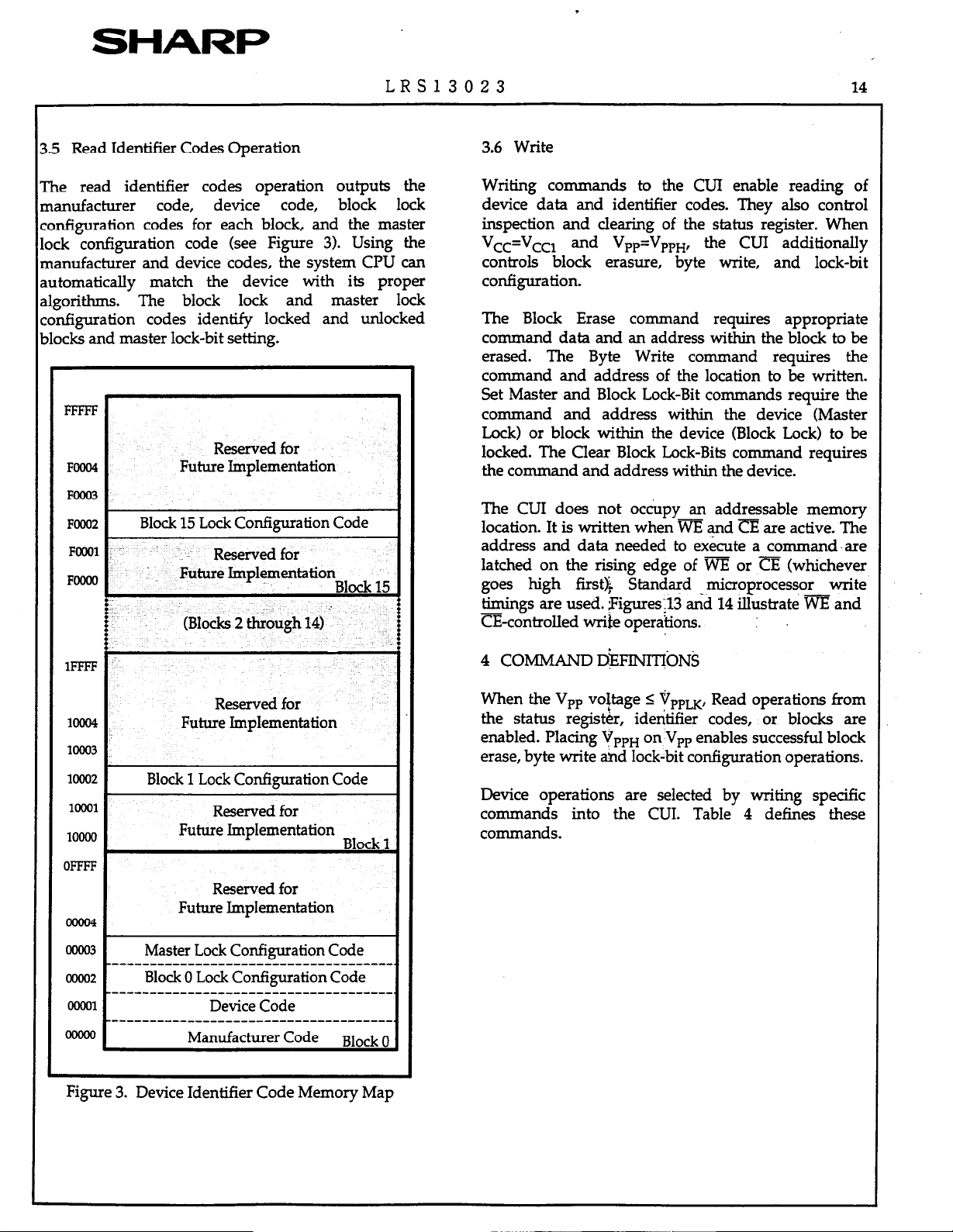

1.5 Read Identifier Codes Operation

The read identifier codes operation outputs the

nanufacturer code, device code, block lock

:onfiguration codes for each block, and the master

ock configuration code (see Figure 3). Using the

nanufacturer and device codes, the system CPU can

u,rtomatically match the device with its proper

algorithms. The block lock and master lock

:onfiguration codes identify locked and unlocked

~1ock.s and master lock-bit setting.

Reserved for

FOO04

FOOO3

FOOOZ 1

FOOOl

FOOOO

Future Implementation

Block 15 Lock Configuration Code

Reserved for

Future Implementation

Block 1

(Blocks 2 through 14) ’

14

3.6 Write

Writing commands to the CUI enable reading of

device data and identifier codes. They also control

inspection and clearing of the status register. When

V,--=Vccl and VPP=VPPH, the CUI additionally

controls block erasure, byte write, and lock-bit

configuration.

The Block Erase command requires appropriate

command data and an address within the block to be

erased. The Byte Write command requires the

command and address of the location to be written.

Set Master and Block Lock-Bit commands require the

command and address within the device (Master

Lock) or block within the device (Block Lock) to be

locked. The Clear Block Lock-Bits co

mmand requires

the command and address within the device.

The CUI does not occupy an addressable memory

location. It is written when WE and a are active. The

address and data needed to execute a command-are

latched on the rising edge of WE or CE (whichever

goes high first& Stand,ard microprocessor write

timings are used. jQures:13 and 14 illustrate WE and

m-controlled write operahons.

:

IFFFF

Reserved for

looo4

1ooo3

I

Future Implementation

Block 1 Lock Configuration Code

OFFFF

Reserved for

Future Implementation

oooo4

oooo3

moo2

ooml

Master Lock Configuration Code

------------------------------------.

Block 0 Lock Configuration Code

~~~~~~~~----__-__---________________(

--------_-__________----------------.

Device Code

Manufacturer Code

Block

Figure 3. Device Identifier Code Memory Map

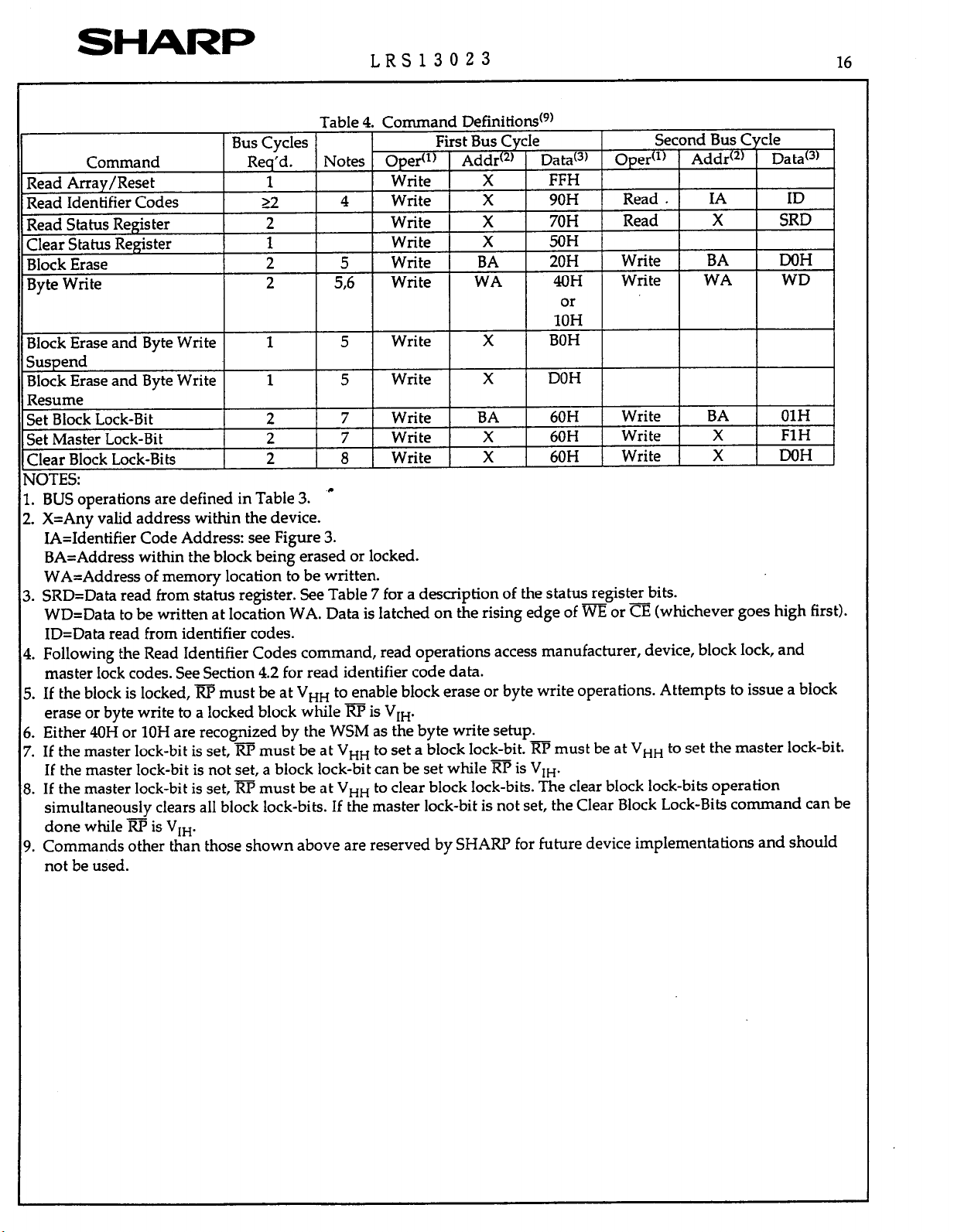

4 COMMAND D&INITlON~

When the VP, voftage I VPPLK, Read operations from

the status register, identifier codes, or blocks are

enabled. Placing VP,, on.Vpp enables successful block

erase, byte write and lock-bit configuration operations.

Device operations are selected by writing specific

commands into the CUI. Table 4 defines these

commands.

SHARP

LRS13023 15

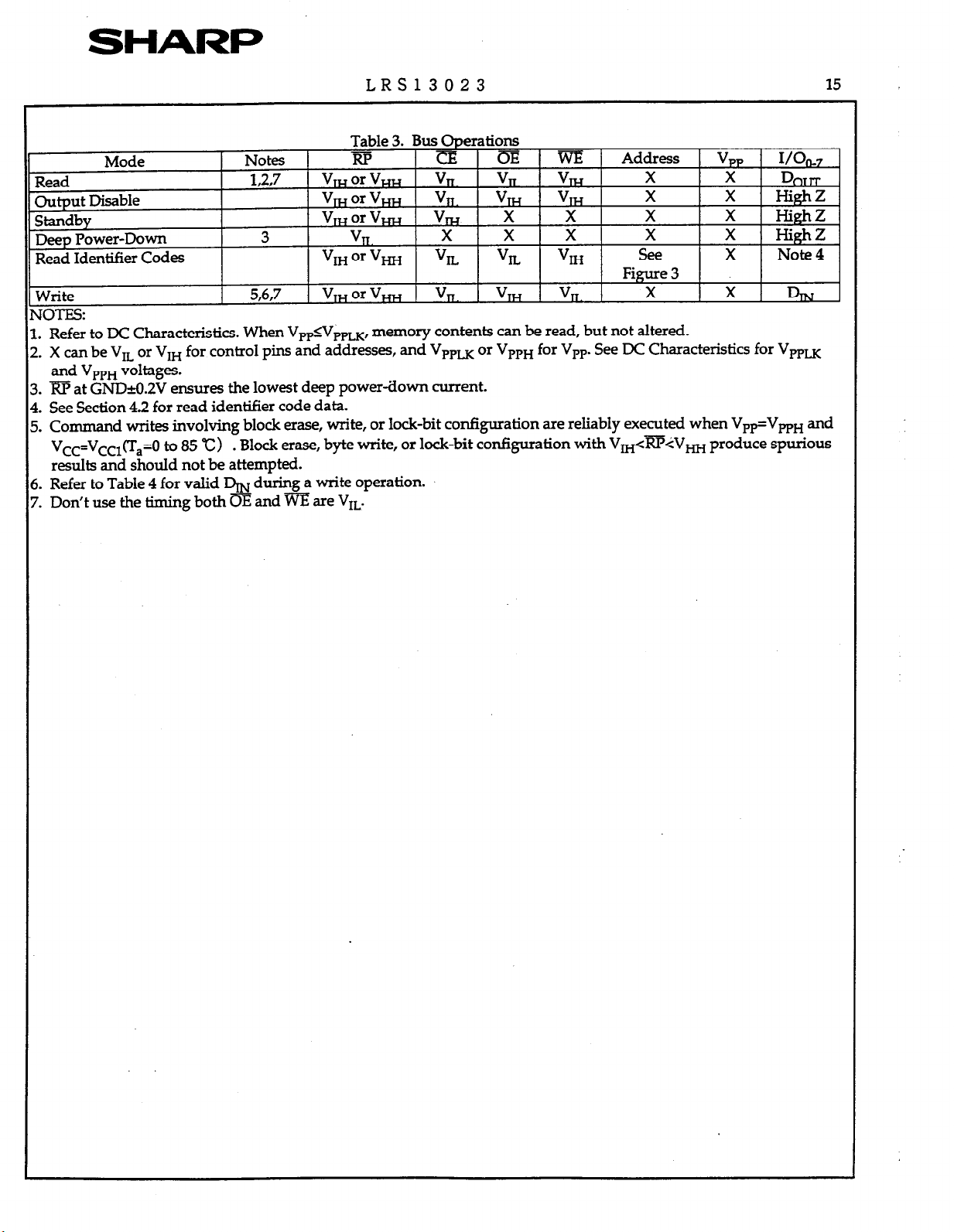

NOTES:

1. Refer to DC Characteristics. When VPPIVPP,,

2. X can be VI, or V,, for control pins and addresses, and VP,, or VP,, for VP,. See DC Characteristics for VW,

and V,,, voltages.

3. i@ at GND&.2V ensures the lowest deep power-down current.

4. See Section 4.2 for read identifier code data.

5. Command writes involving block erase, write, or lock-bit configuration are reliably executed when VPp=VppH and

Vcc=VccIU~=O to 85 “c)

results and should not be attempted.

6. Refer to Table 4 for valid h during a write operation.

7. Don’t use the timing both m and m are VIM

. Block erase, byte write, or lock-bit configuration with V,<mkV, produce spurious

memory contents can be read, but not altered.

SHARI=

LRS13023

16

Table 4. Commanc - - ___._. ~_ _

RIW f-vr1c.c

Command

Read Array/Reset

Read Identifier Codes

Read Status Register

Clear Status Register 1

Block Erase 2 5

Byte Write

Req’d . Notes

1

22

2

2

56

Ope# ) Addrc2) 1 DataQ) Oper(l) 1 Addrt2) 1 Datac3)

Write X

4 Write X 90H

Write X 70H

Write X 5UH

Write BA 20H

Write WA 40H

I I I I

Block Erase and Byte Write

Suspend

Block Erase and Byte Write

Resume

Set Block Lock-Bit 2 7 Write BA 60H

Set Master Lock-Bit 2

Clear Block Lock-Bits 2 8 Write

NOTES:

1. BUS operations are defined in Table 3. ”

2. X=Any valid address within the device.

IA=Identifier Code Address: see Figure 3.

BA=Address within the block being erased or locked.

WA=Address of memory location to be written.

3. SRD=Data read from status register. See Table 7 for a description of the status register bits.

WD=Data to be written at location WA. Data is latched on the rising edge of WE or CE (whichever goes high first).

ID=Data read from identifier codes.

4. Following the Read Identifier Codes command, read operations access manufacturer, device, block lock, and

master lock codes. See Section 4.2 for read identifier code data.

5. If the block is locked, i?i? must be at V,,

erase or byte write to a locked block while m is VII+

6. Either 40H or 10H are recognized by the WSM as the byte write setup.

7. If the master lock-bit is set, m must be at V,,

If the master lock-bit is not set, a biock lock-bit can be set while i?is is V,,.

8. If the master lock-bit is set, RP must be at V,, to clear block lock-bits. The clear block lock-bits operation

simultaneously clears all block lock-bits. If the master lock-bit is not set, the Clear Block Lock-Bits command can be

done while RR 1s Vl,.

9. Commands other than those shown above are reserved by SHARP for future device implementa lions and should

not be used.

-.

1

1

5 Write

5 Write

7 Write X 60H

to enable block erase or byte write operations. Attempts to issue a block

to set a block lock-bit. RP must be at V,, to set the master lock-bit.

1 Definitions(9)

Fist Bus Cycle Second Bus Cycle

---- I

FFH

Read. IA ID

_. ----

or I

10H

X BOH

X

X 60H Write X DOH

DOH

Read X

Write BA

Write WA WD

I I

Write BA OlH

Write X FlH

I

SRD

DOH

I

SHARP

.

LRS13023

:.l Read Array Command

Jpon initial device power-up and after exit from deep

jowerdown mode, the device defaults to read array

node. This operation is also initiated by writing the

lead Array command. The device remains enabled for

eads until another command is written. Once the

nternal WSM has started a block erase, byte write or

sck-bit configuration, the device will not recognize

he Read Array command until the WSM completes its

lperation unless the WSM is suspended via an Erase

luspend or Byte Write Suspend command. The Read

bray command functions independently of the VP,

poltage and m can be V,, or V,,.

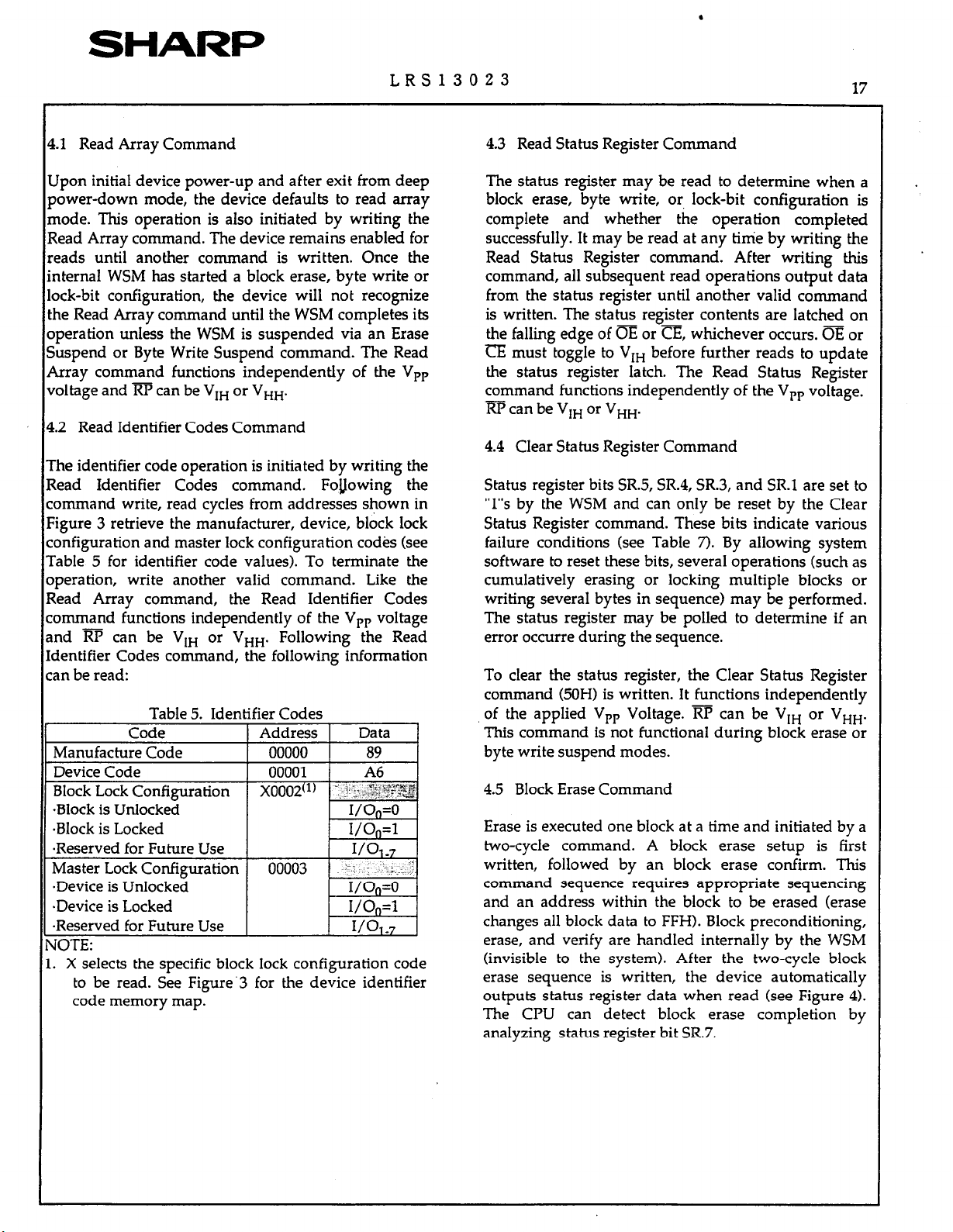

,.2 Read Identifier Codes Command

‘he identifier code operation is initiated by writing the

Lead Identifier Codes command. Following the

ommand write, read cycles from addresses shown in

‘igure 3 retrieve the manufacturer, device, block lock

onfigura tion and master lock configuration codes (see

‘able 5 for identifier code values). To terminate the

Nperation, write another valid command. Like the

Lead Array command, the Read Identifier Codes

ommand functions independently of the VP, voltage

-

nd RP can be V,, or V,,. Following the Read

dentifier Codes command, the following information

an be read:

Table 5. Identifier Codes

17

4.3 Read Status Register Command

The status register may be read to determine when a

block erase, byte write, or, lock-bit configuration is

complete and whether the operation completed

successfully. It may be read at any time by writing the

Read Status Register command. After writing this

command, all subsequent read operations output data

from the status register until another valid command

is written. The status register contents are latched on

the falling edge of OE or CE, whichever occurs. OE or

iZ must toggle to V,,

the status register latch. The Read Status Register

command functions independently of the VP, voltage.

Rp can be V,, or V,,.

4.4 Clear Status Register Command

Status register bits SR.5, SR.4, SR.3, and SR.1 are set to

“1”s by the WSM and can only be reset by the Clear

Status Register command. These bits indicate various

failure conditions (see Table 7). By allowing system

software to reset these bits, several operations (such as

cumulatively erasing or locking multiple blocks or

writing several bytes in sequence) may be performed.

The status register may be polled to determine if an

error occurre during the sequence.

To clear the status register, the Clear Status Register

command (50H) is written. It functions independently

of the applied VP, Voltage. RP can be V,, or V,,.

This command is not functional during block erase or

byte write suspend modes.

before further reads to update

Block Lock Configuration

.Block is Unlocked

*Block is Locked

-Reserved for Future Use

Master Lock Configuration

SDevice is Unlocked

,Device is Locked

,Reserved for Future Use

IOTE:

. X selects the specific block lock configuration code

to be read. See Figure’3 for the device identifier

code memory map.

4.5 Block Erase Command

Erase is executed one block at a time and initiated by a

two-cycle command. A block erase setup is first

written, followed by an block erase confirm. This

command sequence requires appropriate sequencing

and an address within the block to be erased (erase

changes all block data to FFH). Block preconditioning,

erase, and verify are handled internally by the WSM

(invisible to the system). After the two-cycle block

erase sequence is written, the device automatically

outputs status register data when read (see Figure 4).

The CPU can detect block erase completion by

analyzing status register bit SR.7.

Loading...

Loading...