Page 1

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 2

Global LCD Panel Exchange Center

www.panelook.com

RECORDS OF REVISION

MODEL No : LQ315T3LZ23

SPEC No : LD-17408

Date Revised No. PAGE SUMMARY NOTE

2005.05.10 - - 1st Issue

2005.05.17 A

P.12

Changed the sentence P.10

Deleted the sentence

(When vertical period is very long, ~)

Added the vertical frequency

2nd Issue

(Reliability and lifetime ~ -> Display works ~)

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 3

Global LCD Panel Exchange Center

1. Application

This specification applies to the color TFT-LCD module LQ315T3LZ23.

* These specification sheets are proprietary products of SHARP CORPORATION (“SHARP”) and include materials

protected under copyright of SHARP. Do not reproduce or cause any third party to reproduce them in any form or by

any means, electronic or mechanical, for any purpose, in whole or in part, without the express written permission of

SHARP.

* In case of using the device for applications such as control and safety equipment for transportation (aircraft, trains,

automobiles, etc.), rescue and security equipment and various safety related equipment which require higher

reliability and safety, take into consideration that appropriate measures such as fail-safe functions and redundant

system design should be taken.

* Do not use the device for equipment that requires an extreme level of reliability, such as aerospace applications,

telecommunication equipment (trunk lines), nuclear power control equipment and medical or other equipment for

life support.

* SHARP assumes no responsibility for any damage resulting from the use of the device which does not comply with

the instructions and the precautions specified in these specification sheets.

www.panelook.com

LD- 17408-1

* Contact and consult with a SHARP sales representative for any questions about this device.

2. Overview

This module is a color active matrix LCD module incorporating amorphous silicon TFT (T

composed of a color TFT-LCD panel, driver ICs, control circuit, power supply circuit, inverter circuit and back light

system etc. Graphics and texts can be displayed on a 1366×RGB×768 dots panel with 16,777,216 colors by

using LVDS (Low Voltage Differential Signaling) to interface, +5V of DC supply voltages and supply voltage for

back light.

This module also includes the DC/AC inverter to drive the CCFT . (+24V of DC supply voltage)

And in order to improve the response time of LCD, this module applies the O/S (over shoot) driving technology for

the control circuit .In the O/S driving technology, signals are being applied to the liquid crystal according to a

pre-fixed process as an image signal of the present frame when a difference is found between image signal of the

previous frame and that of the current frame after comparing them.

By using the captioned process, the image signals of this LCD module are being set so that image response can be

completed within one frame, as a result, image blur can be improved and clear image performance can be realized.

3. Mechanical Specifications

Parameter Specifications Unit

Display size

Active area 697.69 (H) x 392.26 (V) mm

Pixel Format 1366 (H) x 768 (V)

Pixel pitch 0.51075(H) x 0.51075 (V) mm

Pixel configuration R, G, B vertical stripe

Display mode Normally black

Unit Outline Dimensions *1 780.0(W) x 450.0(H) x Max 48.0(D) mm

Mass 6.4 +/- 0.3 kg

Surface treatment Anti-glare, low reflection coating

Hard coating: 2H

Haze: 23 +/- 5%

80.04 (Diagonal

31.5 (Diagonal

1pixel = R + G + B dot

(

)

)

)

hin Film Transistor). It is

cm

inch

pixel

(*1 )Outline dimensions are shown in Fig.1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 4

Global LCD Panel Exchange Center

4. Input Terminals

4-1. TFT panel driving

CN1 (Interface signals and +5V DC power supply)

Using connector :FI-X30SSL-HF (Japan Aviation Electronics Ind. , Ltd.)or

SM30B-LDYGLS-01(Japan Solderless Terminals MGF. Co., Ltd)

Mating connector :FI-X30H,FI-X30C or FI-X30M (Japan Aviation Electronics Ind. , Ltd.)

Mating LVDS transmitter:THC63LVDM83A or equivalent device

Pin No. Symbol Function Remark

1 VCC +5VPower Supply

2 VCC +5VPower Supply

3 VCC +5VPower Supply

4 VCC +5VPower Supply

5 GND

6 GND

7 GND

8 GND

9 SELLVDS

10 NC

11 GND

12 RIN013 RIN0+

14 GND

15 RIN116 RIN1+

17 GND

18 RIN219 RIN2+

20 GND

21 CLKIN22 CLKIN+

23 GND

24 RIN325 RIN3+

26 GND

27 R/L

28 U/D

29 Reserved

30 Reserved

Note

【

】

1. Shield case on the module’s back surface connects the GND of internal circuit.

2. It is recommend to connect all the GND terminals because of stable operation.

www.panelook.com

(Shown in Fig.1)

Select LVDS data order 【Note1

Negative (-) LVDS differential data input

Positive (+) LVDS differential data input

Negative (-) LVDS differential data input

Positive (+) LVDS differential data input

Negative (-) LVDS differential data input

Positive (+) LVDS differential data input

ClockSignal(-)

ClockSignal(+)

Negative (-) LVDS differential data input

Positive (+) LVDS differential data input

Horizontalshiftdirection

Verticalshiftdirection

【

【

Note 2

Not Available

Not Available

Note 2

】

】

】

LD- 17408-2

Pull up

DefaultH:3.3V

LVDS

LVDS

LVDS

LVDS

LVDS

LVDS

LVDS

LVDS

LVDS

LVDS

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 5

Global LCD Panel Exchange Center

r

)

)

)

㪣㪚㪛㩷㪧㪘㪥㪜㪣

㪈㪊 㪍㪍㬍㪊㩿㪩㪞㪙㪀㬍㪎㪍㪏

㪁㫇 㪸㫅 㪼㫃㩷㪹㪸㪺 㫂

㪪㫆 㫌㫉㪺 㪼㩷 㪛 㫉㫀㫍㪼 㫉

㪞㪸㫋㪼㩷㪛㫉㫀㫍㪼㫉

㪚㫆 㫅 㫋㫉㫆 㫃㩷 㪧㪮㪙

㪠㫅 㫍㪼 㫉㫋㪼 㫉

㪙㪸 㪺㫂㩷㪣 㫀㪾㪿 㫋㩿㪚 㪚㪝 㪫㪀

㪠㫅 㫇㫌 㫋㩷 㪪㫀㪾㫅㪸 㫃

㪧㫆 㫎㪼 㫉㩷㪪 㫌㫇㫇㫃㫐

㪧㫆 㫎㪼 㫉㩷㪪 㫌㫇㫇㫃㫐

㪠㫅 㫇㫌 㫋㩷 㪪㫀㪾㫅㪸 㫃

www.panelook.com

LD- 17408-3

【

Note1

SELLVDS

】

Transmitte

Pin No Data

51 TA0

52 TA1

54 TA2

55 TA3

56 TA4

3 TA5

4 TA6

6 TB0

7 TB1

11 TB2

12 TB3

14 TB4

15 TB5

19 TB6

20 TC0

22 TC1

23 TC2

24 TC3

27 TC4

28 TC5

30 TC6

50 TD0

2 TD1

8 TD2

10 TD3

16 TD4

18 TD5

25 TD6

SELLVDS

=L(GND)

R0(LSB)

R1

R2

R3

R4

R5

G0(LSB)

G1

G2

G3

G4

G5

B0(LSB)

B1

B2

B3

B4

B5

NC NC

(RSV1) (RSV1)

DE DE

R6 R0(LSB)

R7(MSB) R1

G6 G0(LSB)

G7(MSB) G1

B6 B0(LSB)

B7(MSB) B1

(NA) (NA)

=H(3.3V) or Open

R2

R3

R4

R5

R6

R7(MSB

G2

G3

G4

G5

G6

G7(MSB

B2

B3

B4

B5

B6

B7(MSB

㪚㪣㪢㪠㪥㪂

㪚㪣㪢㪠㪥㪄

㪩㪠㪥㪇㪄

㪩㪠㪥㪇㪂

㪩㪠㪥㪈㪄

㪩㪠㪥㪈㪂

㪩㪠㪥㪉㪄

㪩㪠㪥㪉㪂

㪩㪠㪥㪊㪄

㪩㪠㪥㪊㪂

㪩㪆㪣

㪬㪆㪛

㪪㪜㪣㪣㪭㪛㪪

㪝㫉㪸㫄㪼

㪦㪆㪪㫊㪼㫋

㪫㪼㫄㫇㩷㪊

㪫㪼㫄㫇㩷㪉

㪫㪼㫄㫇㩷㪈

㪂㪌㪭㩷㪛㪚

㪭

㪦㪥

㪭

㪙㪩㪫

㪂㪉㪋㪭㩷㪛㪚

㪂㪈㪉㪭㩷㪛㪚

㪚㪥㪈㪚㪥㪉

㪚㫆㫅㫋㫉㫆㫃㩷㪪㫀㪾㫅㪸㫃

㪧㫆㫎㪼㫉㩷㪪㫌㫇㫇㫃㫐

㪚㫀㫉㪺㫌㫀㫋

㪚㪥㪊

㪚㪥㪋㪃㪌

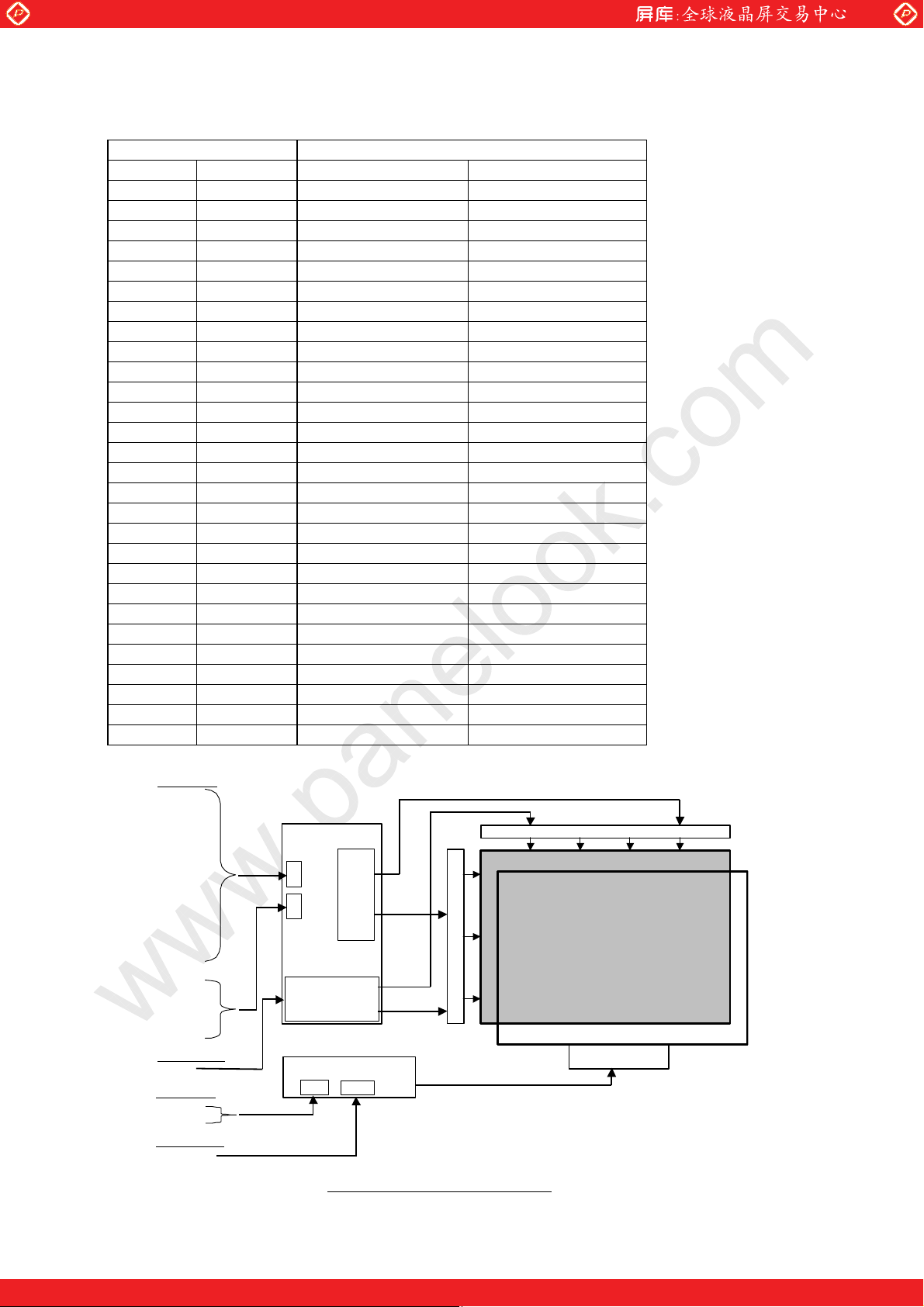

Block Diagram (LCD Module)

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 6

LD- 17408-4

Internal circuits

R7

䱊

R0

8

LCD side)

-

(TFT

B7

G7

䱊

䱊

B0

G0

8

8

ENAB

CK

www.panelook.com

↑

TTL

LVDS

PLL

䯵

side

TV

䯴

Rx1IN0+(13)

8

www.panelook.com

Global LCD Panel Exchange Center

G7

G0

Rx1CLKIN+(22)

Rx1IN0-(12)

Rx1IN1+(16)

Rx1IN1-(15)

Rx1IN2+(19)

Rx1IN2-(18)

Rx1IN3+(25)

Rx1IN3-(24)

↑

LVDS

8

8

R7

B7

䱊

R0

䱊

B0

䱊

TTL

ENAB

Rx1CLKIN-(21)

PLL

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

CLK

Corresponding Transmitter:THC63LVDM83R(THine) etc.

controller

Interface block diagram

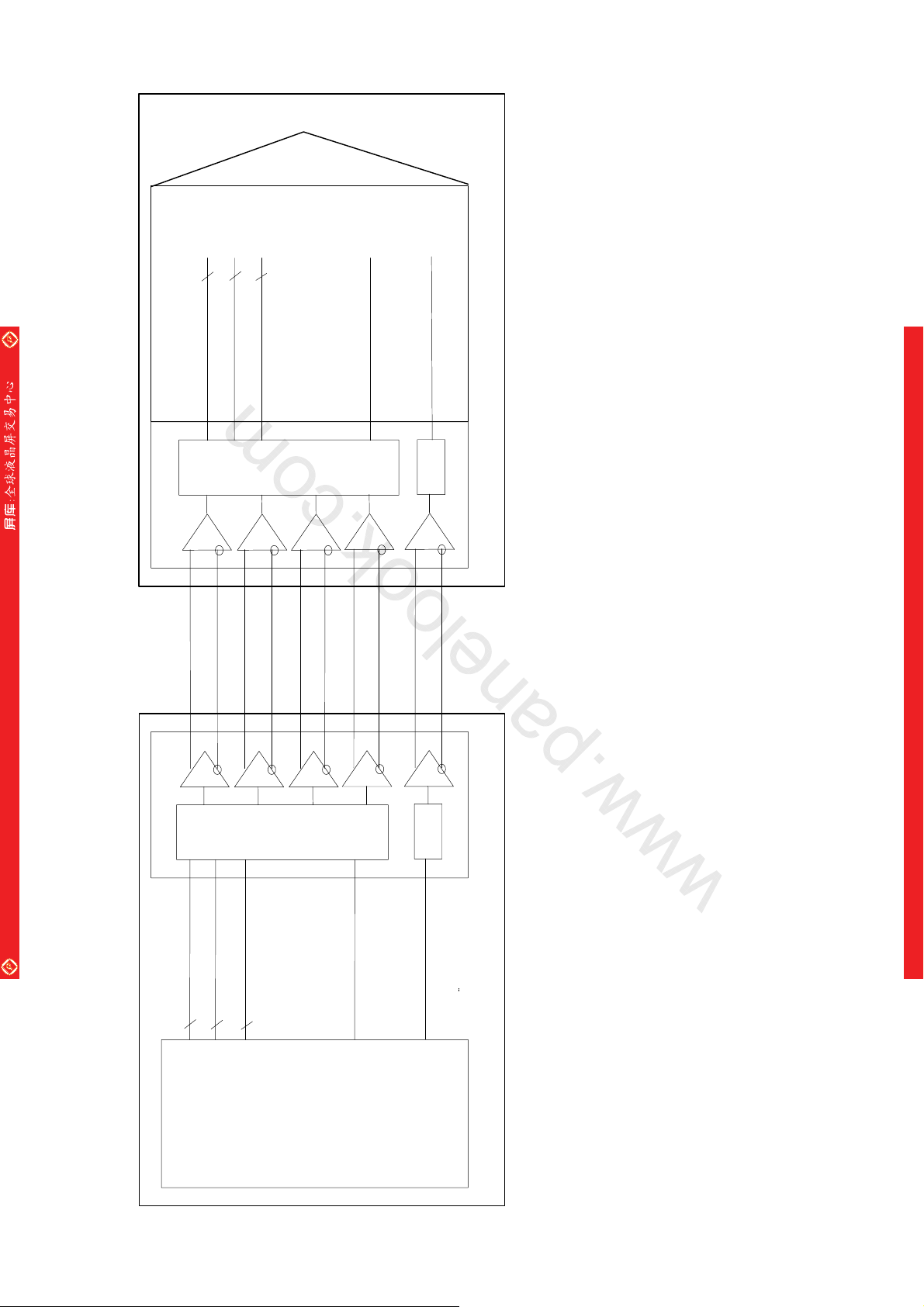

Page 7

Global LCD Panel Exchange Center

NAN

NAN

NAN

NAN

SELLVDS= Low(GND)

CLKIN+

CLKIN-

www.panelook.com

LD- 17408-5

1 cycle

RIN0+

RIN0-

RIN1+

RIN1-

RIN2+

RIN2-

RIN3+

RIN3-

SELLVDS= High(3.3V) or Open

CLKIN+

G0 R5 R4 R3 R2 R1 R0 R0R1 G0

B1 B0 G5 G4 G3 G2 G1 G1G2 B1

DE

A

A

B7 B6 G7 G6 R7 R6 R6R7

B5 B4 B3 B2 B2B3

DE

1 cycle

CLKIN-

RIN0+

RIN0-

RIN1+

RIN1-

RIN2+

RIN2-

RIN3+

RIN3-

DE: Display Enable

NA: Not Available (Fixed Low)

G2 R7 R6 R5 R4 R3 R2 R2R3 G2

B3 B2 G7 G6 G5 G4 G3 G3G4 B3

DE

A

A

B1 B0 G1 G0 R1 R0 R0R1

B7 B6 B5 B4 B4B5

DE

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

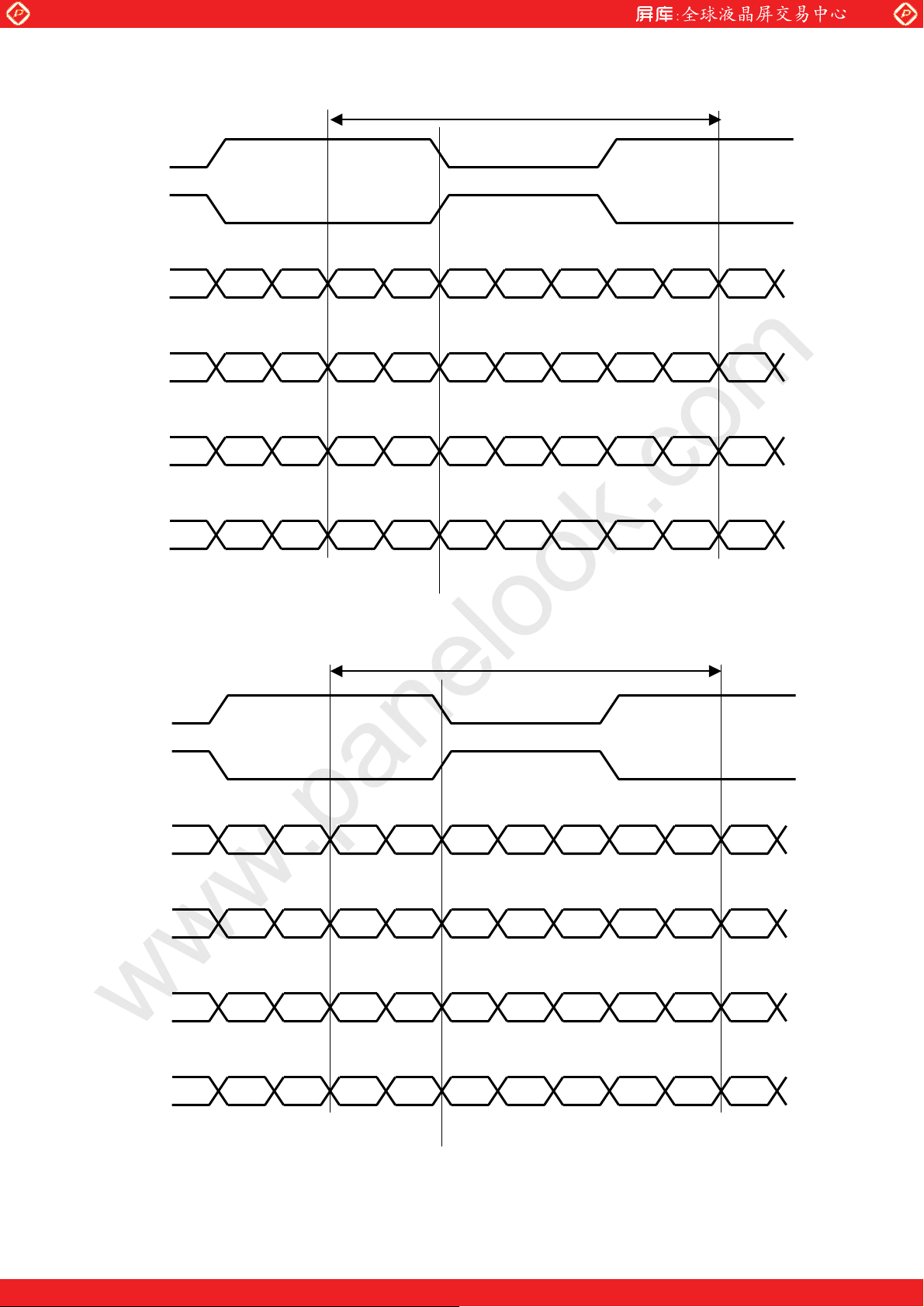

Page 8

Global LCD Panel Exchange Center

Note 2

【

】

Normal (Default)

R/L:L(GND)U/D:L(GND)

CN1 CN1

www.panelook.com

R/L:H(3.3V)U/D:L(GND)

Horizontal reverse image

LD- 17408-6

Vertical reverse image Horizontal and vertical reverse image

R/L:L(GND)U/D:H(3.3V) R/L:H(3.3V)U/D:H(3.3V)

CN1

CN1

CN2(O/S control) -(Shown in Fig 1)

OS Driving Pin No and function

Using connector : SM07B-SRSS-TB-A (JST)

Mating connector : SHR-07V-S or SHR-07V-S-B(JST

)

Pin No. Symbol Function Default

1 Frame Frame frequency setting

H:60Hz, L:50Hz

Pull down0V : (GND)

2 O/S set O/S operation setting H:O/S_ON, L:O/S_OFF Pull down0V : (GND)

3 TEST Fix to Low level usually. Pull down0V : (GND)

4 Temp3 Data3 of panel surface temperature Pull down0V : (GND)

5 Temp2 Data2 of panel surface temperature Pull down0V : (GND)

6 Temp1 Data1 of panel surface temperature Pull down0V : (GND)

7 GND

* L: Low level voltage (GND) H: High level voltage(3.3V)

【

Note

In case of O/S set setting ”L”(O/S_OFF), it should be set the “Temp1~3” and “Frame” to “L”.

】

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 9

Global LCD Panel Exchange Center

a

t

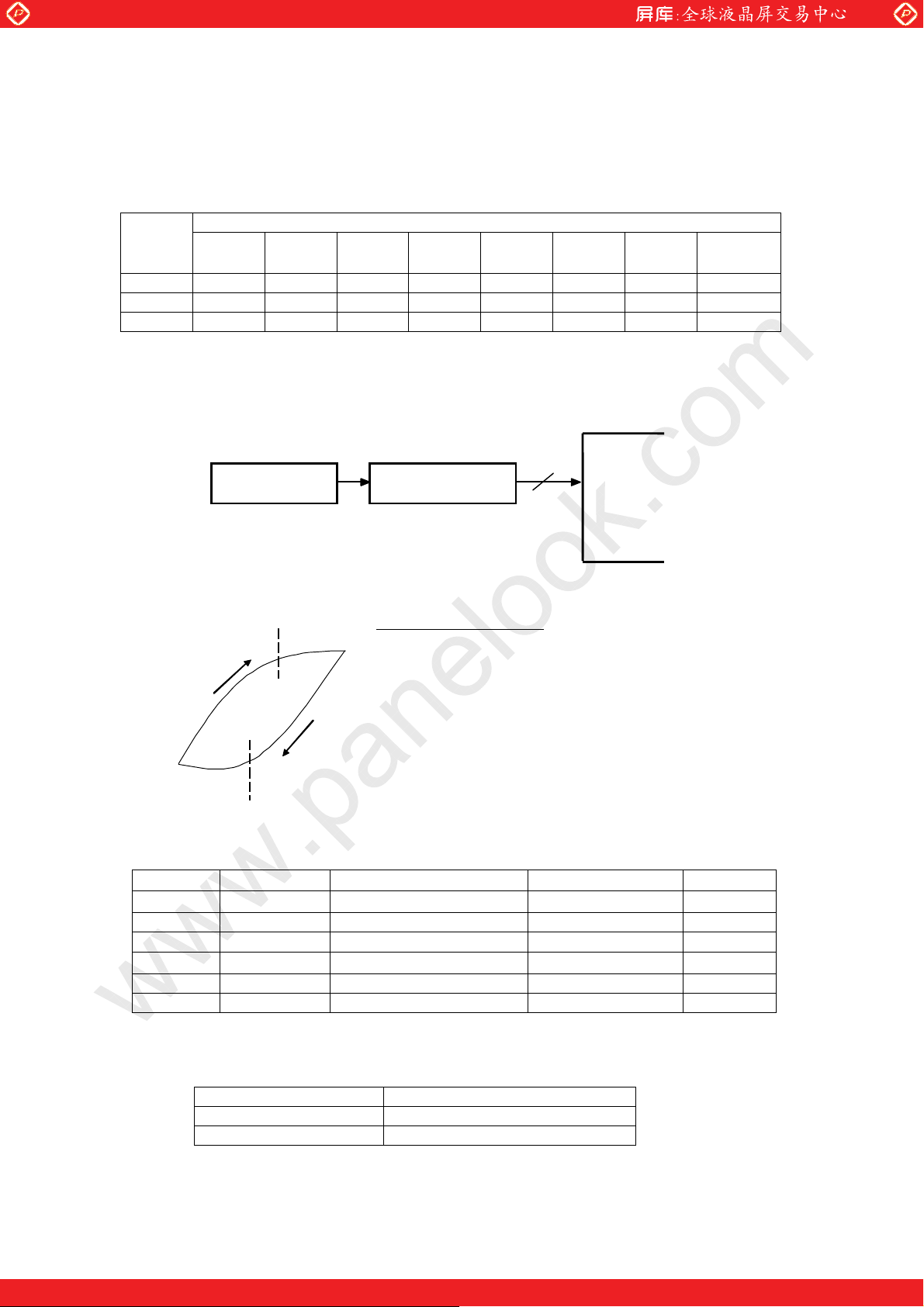

According as the surface temperature of the panel, enter the optimum 3 bit signal into pin No.4,5,6.

Measuring the correlation between detected temperature by the sensor on PWB in users side and actual surface

temperature of panel at center , convert the temperature detected by the sensor to the surface temperature of

panel to enter the 3 bit temperature data.

Pin no.

0-5℃ 5-10℃ 10-15

4 L L L L H H H H

5 L L H H L L H H

6 L H L H L H L H

* L: Low level voltage (GND) H: High level voltage(3.3V)

*For overlapping temperatures (such as 5℃,10℃,15℃,20℃,25℃, 30℃,35℃) select the optimum parameter,

judging from the actual picture image.

www.panelook.com

Surface temperature of panel

℃

15-20

℃

20-25

℃

25-30

30-35℃ 35℃ and

℃

LD- 17408-7

above

Temperature

sensor

Microcomputer

䊶Convert temperature data below

1. serial temp. data 㹢 parallel temp.㩷 dat

2. measurement point temp. data

㹢 panel surface temp. data

3bi

LCD I/F

OS Driving ref. circuit

Domain B

Domain A

Domain A

Domain B

There is a LM70(product by NS) etc. as a temperature sensor.

Please perform temperature compensation between a measurement point

and panel surface temperature with a microcomputer.

hysteresis about the change of setting temperature.

Moreover, please give

4-2. Backlight driving

CN3 (Inverter control) Using connector: S6B-PH-SM3-TB(JST) Mating connector: PHR-6 (JST)

Pin No.

1

Symbol

V

ON Inverter ON/OFF 24k ohm

Function Input Impedance Remark

Note 1

【

】

2 Reserved Not Available -

3 Reserved Not Available -

4

V

Brightness Control 100k ohm

BRT

【

Note 2

】

5 Reserved Not Available -

6 GND GND

* GND of an inverter board is not connected to GND of a module chassis and a liquid crystal panel drive part.

Note 1】 Inverter ON/OFF

【

Input voltage Function

3~5V Inverter: ON

0~1V Inverter: OFF

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 10

Global LCD Panel Exchange Center

Note 2】 Brightness Control

【

PWM Brightness is controlled by analog input voltage (0V to 5V) .

Input voltage Function

5V Brightness Control : Dark

0V Brightness Control : Bright

Reference】The characteristic of the V

【

Input voltage (V

BRT

0V 0%

0.5V 15%

1.0V 30%

1.5V 41%

2.0V 52%

2.5V 62%

3.0V 70%

3.5V 78%

4.0V 84%

4.5V 90%

5.0V 94%

* The measurement shall be executed more than 60 minutes after adjusting dimming voltage.

www.panelook.com

LD- 17408-8

vs. dimming level

BRT

Dimming level

)

(luminance)

CN4,CN5 (Inverter Power input Pin layout) Using connector: B10B-PH-SM3-TB (JST)

Mating connector: PHR-10 (JST)

Pin No. Symbol Function

1 V

2 V

3 V

4 V

5 V

+24V

INV

+24V

INV

+24V

INV

+24V

INV

+24V

INV

6 GND 7 GND 8 GND 9 GND -

10 GND -

*GND of an inverter board is not connected to GND of a module chassis and a liquid crystal panel drive part.

4-3. Lamp characteristics

The back light system is direct type with 18 CCFTs (Cold Cathode Fluorescent Tube).

The characteristics of the lamp are shown in the following table. The value mentioned below is at the case of one

CCFT.

CCFT type : CFL2753A/CFL(STANLEY ELECTRIC CO.,LTD)

CFL15E361Y728P5S30A (NEC Lighting, Ltd)

Item Symbol Min. Typ. Max. Unit Remarks

Life time TL 60000 - - Hour

Note 1】Lamp life time is defined as the time when brightness becomes 50% of the original value in the

【

continuous operation under the condition of Ta=25 ℃ and brightness control(V

BRT

【

=0V).

Note 1

】

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 11

Global LCD Panel Exchange Center

5. Absolute Maximum Ratings

Parameter Symbol Condition Ratings Unit Remark

Input voltage

(for Control)

5V supply voltage

(for Control)

Input voltage

(for Inverter)

24V supply voltage

(for Inverter)

Storage temperature Tstg - -25 ~ +60

Operation temperature

(Ambient)

【Note 1】SELLVDS, R/L, U/D, Frame, O/S set, TEST, Temp1, Temp2, Temp3

【Note 2】Humidity 95%RH Max.(Ta≦40 ℃)

Maximum wet-bulb temperature at 39 ℃ or less.(Ta>40 ℃)

【

Note

The management temperature of each part is shown in reference(page23,24)

】

www.panelook.com

VI

VCC

VBRT

VON

V

INV

Topa - 0 ~ +50

Ta=25

Ta=25

Ta=25

Ta=25

℃

℃

℃

℃

-0.3 ~ 3.6 V

0 ~ + 6 V

0 ~ + 6 V

0 ~ +29 V

No condensation.

℃

℃

LD- 17408-9

Note 1

【

【

Note 2

】

】

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 12

Global LCD Panel Exchange Center

V

6. Electrical Characteristics

6-1. Control circuit driving

Parameter Symbol Min. Typ. Max. Unit Remark

+5V supply

voltage

Supply voltage Vcc +4.5 +5.0 +5.5 V

Current

dissipation

Permissible input ripple

voltage

High VTH - - 100 mV Differential input

threshold voltage

Low V

Input Low voltage VIL 0 - 1.0 V

Input High voltage VIH 2.3 3.3 3.6 V

Input leak current (Low)

Input leak current (High)

Terminal resistor RT - 100 -

Note】VCM: Common mode voltage of LVDS driver.

【

Note 1

【

】

Input voltage sequences Dip conditions for supply voltage

0 < t1 ≦ 10ms a) 2.7V

10ms ≦ t2-1 ≦ 20ms td ≦ 10ms

t2-2 ≧ 10ms b) Vcc < 2.7V

0 < t3 ≦ 1s Dip conditions for supply voltage is

t4 ≧ 1s based on input voltage sequence.

t5 ≧ 200ms

0.9VCC

0.1Vcc

cc

Data1

Data2

t1

t2-1

t2-2

t5

ON

www.panelook.com

【

Icc - 0.8 1.8 A

VRP - - 100 mVP-P Vcc = +5.0V

TL -100 - - mV

IIL1 - - 100 µA

I

IL2 - - 400 µA

IIH1 - - 100 µA

I

IH2 - - 400 µA

Ω

Vcc < 4.5V

≦

0.9Vcc

0.1Vcc

t3

0.1Vcc

t4

td

【

V

CM = +1.2V

【

【

V

【

V

【

V

【

V

【

Differential input

V

7

.

2

LD- 17408-10

Ta=2 5

Note 1

Note 2

Note 6

Note 3

I = 0V

Note 4

I = 0V

Note 5

I =3.3V

Note 4

I =3.3V

Note 5

V

5

.

4

℃

】

】

】

】

】

】

】

】

Vcc

Back light:Vinv

ata1:CLKIN±,RIN0±,RIN1±, RIN2±, RIN3

※ D

ata2:R/L,U/D,SELLVDS,Frame,O/Sset,Temp1,2,3

※ D

OFF

OFF

±

DATA2 sequence is recommended above figure.

However, even if the sequence is out of recommended timing, display works normally.

Note

【

】

About the relation between data input and back light lighting, it based on the above-mentioned input sequence.

When back light is switched on before panel operation or after a panel operation stop, it may not display normally.

But this phenomenon is not based on change of an incoming signal, and does not give a damage to a liquid crystal

display.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 13

Global LCD Panel Exchange Center

Note 2】Typical current situation: 256 gray-bar pattern (Vcc = +5.0V)

【

The explanation of RGB gray scale is seen in section 8.

www.panelook.com

LD- 17408-11

RGB

GS0

RGB

GS1

RGB

GS2

....

RGB

GS254

RGB

GS255

Vcc=5.0V

CK=82.0MHz

Th=20.67μs

Note 3】R/L, U/D, SELLVDS, TEST, Frame, O/Sset, Temp1, Temp2, Temp3

【

Note 4】R/L, U/D

【

Note 5】SELLVDS, Frame, O/Sset, Temp1, Temp2, Temp3

【

Note 6】CLKIN±, RIN0±,RIN1±, RIN2±, RIN3

【

6-2. Inverter driving for back light

±

The back light system is direct type with 18 CCFTs .

Parameter Symbol Min. Typ. Max. Unit Remark

Current dissipation IINV - 4.2 6.5 A

24V

+

Supply voltage1 VINV1 22.5 24.0 25.5 V

Supply voltage2

Permissible input ripple

voltage

INV2 22.5 24.0 27.0 V

V

RF - - 200 mV

V

Input voltage (Low) VONL 0 - 1.0 V

Input voltage (High) VONH 3.0 - 5.0 V

Brightness control voltage V

0 -> 5 V

BRT

INV = 24.0V

V

BRT = 0V, V

V

BRT = 0V, V

V

Note 1

【

V

BRT = 0V, V

Note 1,2

【

VINV = 24V

p-p

ON

ON

】

ON

】

Ta=25

=5V

=5V

=0V

℃

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 14

Global LCD Panel Exchange Center

Note 1】Inverter sequences

【

22.5V

0V

Vinv

V

ON

t1 t2

0〜1V

t3

www.panelook.com

22.5〜25.5V

3〜5V

0〜5V

t4

22.5V

t5 t6

0〜1V

LD- 17408-12

0V

t1,t6≧100Ps

t2,t3,t4,t5≧0

V

BRT

0V

0V

*For the reduction of rush current, t1 should be more than 100us.

*Regarding t1, please input the V

*There is no problem whether the V

signal after lighting the lamps.

BRT

signal is "H"(turning on) or "L"(turning off) under the supplying Vinv

ON

condition.

Note2

【

】

The definition of Vin voltage(27V) is only available with the condition of Von=0V(Inverter off).

In case of Von=5V(Inverter on), Vin voltage is defined as equal or less than 25.5V.

7. Timing characteristics of input signals

7-1. Timing characteristics

Timing diagrams of input signal are shown in Fig.2,3

Parameter Symbol Min. Typ. Max. Unit Remark

Clock

Data enable

signal

Frequency 1/Tc

Horizontal period

TH 1560 1696 1940 clock

65

17.0 20.67 - µs

Horizontal period (High) THd 1366 1366 1366 clock

778 806 972 line Vertical period TV

82 85 MHz

47 50 63 Hz

Vertical period (High) TVd 768 768 768 line

Note

【

】

1. It is recommend making sure that length of vertical period is an integral multiple of horizontal length of

period. Otherwise, the screen may not display properly.

DE

DATA

(R,G,B)

DE

1366

Tc

TH

THd

1 2

1 2 768

TV

1366

767

TVd

Fig.2

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 15

Global LCD Panel Exchange Center

7-2 LVDS signal characteristics

CLK-

Vdiff=0 Vdiff=0

CLK+

RINx-

RINx+

tpd0

tpd1

tpd2

tpd3

tpd4

tpd5

tpd6

www.panelook.com

LD- 17408-13

tCLK

The item Symbol min. typ. max. unit

Clock Frequency 1/tclk 65 82 85 MHz

Delay time, CLK rising edge

tpd0

to serial bit position 0

Delay time, CLK rising edge

tpd1

to serial bit position 1

Delay time, CLK rising edge

tpd2

to serial bit position 2

tpd3

tpd4

Data

position

Delay time, CLK rising edge

to serial bit position 3

Delay time, CLK rising edge

to serial bit position 4

Delay time, CLK rising edge

tpd5

to serial bit position 5

Delay time, CLK rising edge

tpd6

to serial bit position 6

Delay time, CLK rising edge

tpd7

to serial bit position 7

7-3. Input data signal and display position on the screen

R1 G1 B1 R2 G2 B2

(1、1) (1,2)

-0.25 0 0.25

1*tclk/7-0.25 1*tclk/7 1*tclk/7+0.25

2*tclk/7-0.25 2*tclk/7 2*tclk/7+0.25

3*tclk/7-0.25 3*tclk/7 3*tclk/7+0.25

ns

4*tclk/7-0.25 4*tclk/7 4*tclk/7+0.25

5*tclk/7-0.25 5*tclk/7 5*tclk/7+0.25

6*tclk/7-0.25 6*tclk/7 6*tclk/7+0.25

7*tclk/7-0.25 7*tclk/7 7*tclk/7+0.25

1・1 1・2 1・3

2・12・2

3・1

768・1

R G B

DisplayPositionofData(V,H)

1・1366

768・1366

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 16

Global LCD Panel Exchange Center

k

8. Input Signal, Basic Display Colors and Gray Scale of Each Color

www.panelook.com

LD- 17408-14

Colors &

Gray scale

Blac

Blue

Green

Cyan

Red

Basic Color

Magenta

Yellow

White

Black GS0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Darker GS2 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Brighter GS253 1 0 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Gray Scale of Red

Red GS255 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Gray

R0 R1 R2 R3 R4 R5 R6 R7 G0 G1 G2 G3 G4 G5 G6 G7 B0 B1 B2 B3 B4 B5 B6 B7

Scale

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

−

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1

−

0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0

−

0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

−

1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

−

1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1

−

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0

−

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

−

GS1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

×

×ÈÈÈÈ

ØÈÈÈÈ

GS254 0 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Ø

Data signal

Black GS0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

GS1 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

×

Darker GS2 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0

×ÈÈÈÈ

ØÈÈÈÈ

Brighter GS253 0 0 0 0 0 0 0 0 1 0 1 1 1 1 1 1 0 0 0 0 0 0 0 0

Gray Scale of Green

GS254 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0

Ø

Green GS255 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0

Black GS0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

GS1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0

×

Darker GS2 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0

×ÈÈÈÈ

ØÈÈÈÈ

Brighter GS253 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 1 1 1 1 1 1

Gray Scale of Blue

GS254 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1

Ø

Blue GS255 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1

0 : Low level voltage, 1 : High level voltage.

Each basic color can be displayed in 256 gray scales from 8 bit data signals. According to the combination of total

24 bit data signals, the 16,777,216 colors display can be achieved on the screen.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 17

Global LCD Panel Exchange Center

9. Optical characteristics

Ta=25℃, Vcc = +5.0V, V

INV = +24.0V, V

Parameter Symbol Condition Min. Typ. Max. Unit Remark

Viewing angle

Horizontal

range

Vertical

Contrast ratio CRn 600 800 -

θ

θ

θ

θ

21

22

11

12

www.panelook.com

=0V Timing characteristics of input signals: Typical value

BRT

70 85 - Deg.

CR≧10

70 85 -

Deg.

LD- 17408-15

Note1,4

【

Note2,4

【

】

】

Response time (1)

Response time (2)

Chromaticity

white

black

red

green

blue

Wd1

Wr1

Wr2

Wd2

x 0.242 0.272 0.302 y 0.247 0.277 0.307 x - 0.300 -

y - 0.280 - -

=0 deg.

x 0.610 0.640 0.670 -

θ

y 0.300 0.330 0.360 x 0.250 0.280 0.310 y 0.570 0.600 0.630 x 0.120 0.150 0.180 y 0.030 0.060 0.090 -

- 6 -

- 6 -

- 12 20

- 12 20

Gamma - - 2.2 - -

Luminance

Luminance

uniformity

white Y

black Y

white

black

L1

- 0.9 1.35

L2

W

δ

B

δ

Measurement condition : Set the value of V

to maximum luminance of white.

BRT

550 700 -

- - 1.25 -

- - 1.6 -

*The measurement shall be executed more than 60 minutes after lighting at rating.

ms

ms

cd/m

【

【

2

Note3-1,4,5

Note3-2,4,5

Note 4

【

Note 6

【

】

】

】

】

Note】The optical characteristics are measured using the following equipment.

【

Detector

EZ-CONTRAST

(

)

400mm

Field=1

Middle of the screen

TFT-LCD Module

(θ=0°)

Middle of the screen

TFT-LCD Module

Response time : BM-5A

Viewing angle range : EZ-CONTRAST

Luminance, Chromaticity, Contrast : SR-3

Fig.3 Measurement method of optical characteristic

Detector(BM-5A/SR-3

°

(θ=0°)

)

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 18

Global LCD Panel Exchange Center

g

()

Note 1】Definitions of viewing angle range :

【

Note 2】Definition of contrast ratio :

【

The contrast ratio is defined as the following.

θ

12

www.panelook.com

Normal line

22

θ

6 o’clock direction

θ

11

θ

LD- 17408-16

21

Luminance(brightness) with all pixels white

Contrast Ratio

=

Luminance(brightness) with all pixels black

Note 3】Definition of response time 1

【

3-1. Response time (1)

The response time (Wd1 and Wr1) is defined as the following figure and shall be measured by switching the

input signal for “any level of gray (GS0, GS32, GS64, GS96, GS128, GS160, GS192, GS224 and GS255)” and

“any level of gray (GS0, GS32, GS64, GS96, GS128, GS160, GS192, GS224 and GS255)”.

GS0 GS32 GS64 GS96 GS128 GS160 GS192 GS224 GS255

GS0

GS32

GS64

GS96

GS128

GS160

GS192

GS224

GS255

tr:0-32 tr:0-64 tr:0-96 tr:0-128 tr:0-160 tr:0-192 tr:0-224 tr:0-255

td:32-0 tr:32-64 tr:32-96 tr:32-128 tr:32-160 tr:32-192 tr:32-224 tr:32-255

td:64-0 td:64-32 tr:64-96 tr:64-128 tr:64-160 tr:64-192 tr:64-224 tr:64-255

td:96-0 td:96-32 td:96-64 tr:96-128 tr:96-160 tr:96-192 tr:96-224 tr:96-225

td:128-0 td:128-32 Td:128-64 td:128-96 tr:128-160 tr:128-192 tr:128-224 tr:128-255

td:160-0 td:160-32 Td:160-64 td:160-96 td:160-128 tr:160-192 tr:160-224 tr:160-255

td:192-0 td:192-32 Td:192-64 td:192-96 td:192-128 td:192-160 tr:192-224 tr:192-255

td:224-0 td:224-32 Td:224-64 td:224-96 td:224-128 td:224-160 td:224-192 tr:224-255

td:255-0 td:255-32 Td:255-64 td:255-96 td:255-128 td:255-160 td:255-192 td:255-224

t*:x-y...response time from level of gray(x) to level of gray(y)

Wr1 = 6(tr:x-y)/36 , Wd1 = 6(td:x-y)/36

3-2. Response time (2)

The response time (Wd2 and Wr2) is the maximum value defined as the following figure and shall be

measured by switching the input signal for “any level of gray (bright)” and “any level of gray (dark)”.

any level of gray

(bright)

100%

90%

Output

10%

0%

Photodetector

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

any level of gray

(dark)

any level of gray

(bri

ht)

time

Destination luminance

Destination luminance

www.panelook.com

Page 19

Global LCD Panel Exchange Center

Note 4】This shall be measured at center of the screen.

【

Note 5】This value is valid when O/S driving is used at typical input time value.

【

Note 6】Definition of luminance uniformity ;

【

White uniformity is defined as the following with five measurements.(A〜E)

www.panelook.com

LD- 17408-17

B

,

W

δ

δ

maximum luminance of five point(brightness)

=

minimum luminance of five point(brightness)

342

A㩷

B㩷

6831024

C㩷

pixel

D㩷

E㩷

10. Display Quality

The display quality of the color TFT-LCD module shall be compliance with the incoming inspection standard.

11. Handling Precautions of the module

a) Be sure to turn off the power supply when inserting or disconnecting the cable.

b) This product is using the parts(inverter, CCFT etc) which generate the high voltage. Therefore, during

operating, please don't touch these parts.

c) Brightness control voltage is switched for “ON” and “OFF”, as shown in Fig.4. Voltage difference generated

by this switching, ΔV

INV, may affect a sound output, etc. When the power supply is shared between the

inverter and its surrounding circuit. So, separate the power supply of the inverter circuit with the one of its

surrounding circuit.

192㩷

384㩷

576㩷

pixel

VINV

IINV

㰱V

㩷

0V㩷

㩷

0A㩷

INV

㩷

PWM

control signal

ON㩷 ON㩷OFF㩷

Fig.4 Brightness control voltage

Since inverter board’s GND is not connected to the frame of the LCD module, please connect it with the

Customer’s GND of inverter power supply.

d) Be sure to design the cabinet so that the module can be installed without any extra stress such as warp or

twist.

e) Since the front polarizer is easily damaged, pay attention not to scratch it.

f) Since long contact with water may cause discoloration or spots, wipe off water drop immediately.

g) When the panel surface is soiled, wipe it with conventional Display cloth such as absorbent cotton or other

soft cloth.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 20

Global LCD Panel Exchange Center

h) Since the panel is made of glass, it may break or crack if dropped or bumped on hard surface. Handle with

care.

i) Since CMOS LSI is used in this module, take care of static electricity and take the human earth into

consideration when handling.

j) The module has some printed circuit boards (PCBs) on the back side, take care to keep them form any stress

or pressure when handling or installing the module; otherwise some of electronic parts on the PCBs may be

damaged.

k) Observe all other precautionary requirements in handling components.

l) When some pressure is added onto the module from rear side constantly, it causes display non-uniformity

issue, functional defect, etc.. So, please avoid such design.

m) When giving a touch to the panel at power on supply, it may cause some kinds of degradation. In that case,

once turn off the power supply, and turn on after several seconds again, and that is disappear.

n) When handling LCD modules and assembling them into cabinets, please be noted that long-term storage in

the environment of oxidization or deoxidization gas and the use of such materials as reagent, solvent,

adhesive, resin, etc. which generate these gasses, may cause corrosion and discoloration of the LCD

modules.

o) Do not rub or strike the screen with anything hard as this may scratch, mar, or damage the screen

permanently. Dust the TV by wiping the screen and the cabinet with a soft, clean cloth. If the screen requires

additional cleaning, use a clean, damp cloth ; DO NOT USE liquid cleaners or aerosol cleaners.

p) Because of seeing the light from the screw part in the bezel surface, please consider not to be a problem with

cabinet design.

www.panelook.com

LD- 17408-18

12. Packing form

a) Piling number of cartons: 3 maximum

b) Packing quantity in one carton: 5 pcs

c) Carton size: 820 mm(W) x 420 mm(D) x 730m(H)

d) Total mass of one carton filled with full modules: 50kg(Max)

Packing form figures are shown in Fig.4

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 21

Global LCD Panel Exchange Center

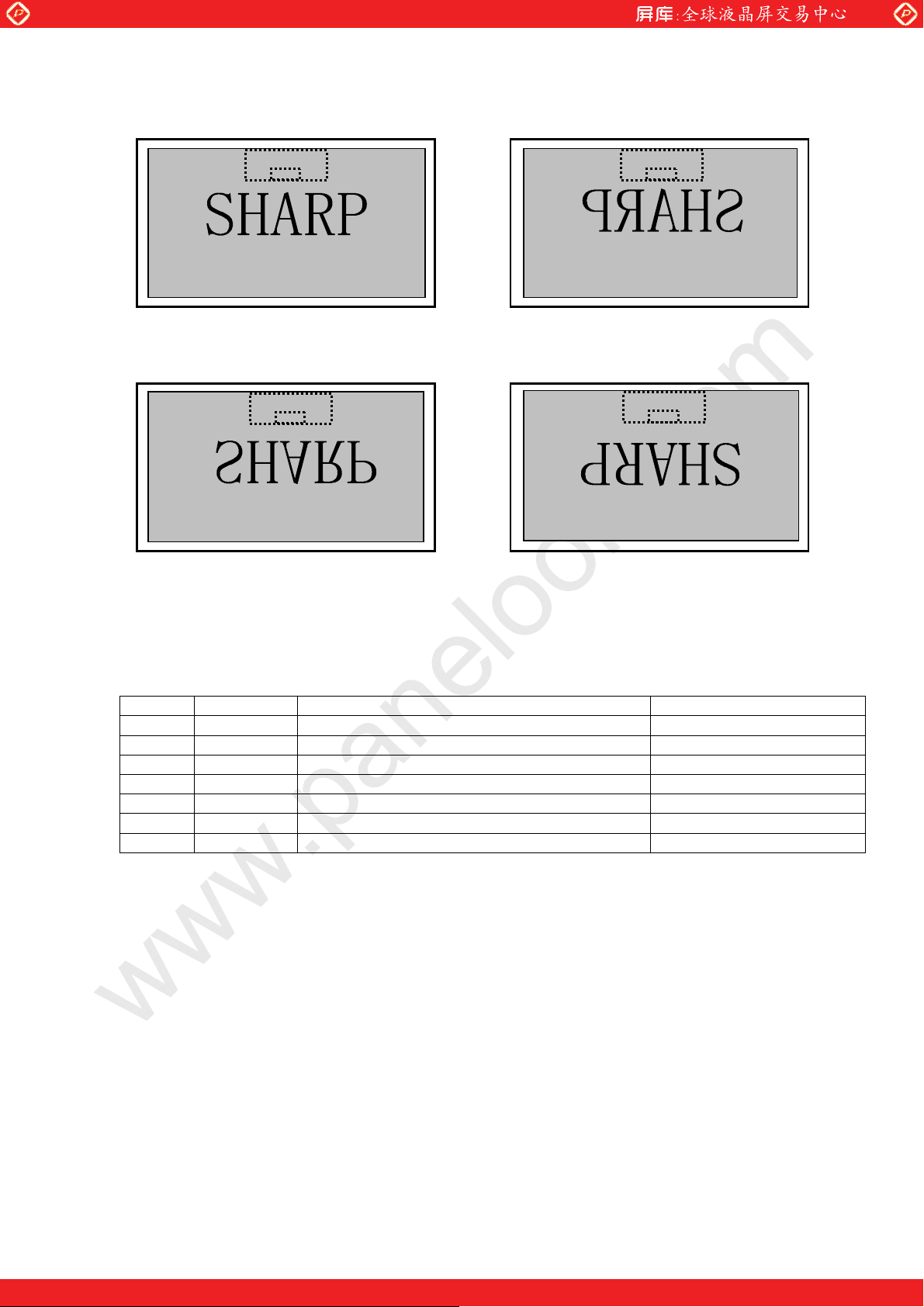

13. Reliability test item

No. Test item Condition

1 High temperature storage test

2 Low temperature storage test

High temperature and high humidity

3

4 High temperature operation test

5 Low temperature operation test

6

7

8 ESD

Result evaluation criteria

【

Under the display quality test condition with normal operation state, there shall be no change which may

affect practical display function.

operation test

Vibration test

(non-operation)

Shock test

(non-operation)

】

www.panelook.com

LD- 17408-19

Ta=60

℃

Ta=-25

Ta=40℃ ; 95%RH

(No condensation)

Ta=50

℃

Ta=0

℃

Frequency : 10~57Hz/Vibration width(one side) : 0.075mm

: 58~500Hz/Acceleration : 9.8 m/s2

Sweep time: 11 minutes

Test period : 3 hours(1h for each direction of X,Y,Z)

Maximum acceleration : 490m/s2

Pulse width : 11ms,sinusoidal half wave

Direction : +/-X,+/-Y,+/-Z,once for each direction.

* At the following conditions, it is a thing without incorrect

operation and destruction.

(1)Non-operation: Contact electric discharge ±10kV

(2)Operation Contact electric discharge ±8kV

240h

℃

240h

240h

240h

240h

Non-contact electric discharge±20kV

Non-contact electric discharge ±15kV

Conditions: 150pF、330ohm

MTBF (Mean Time Between Failures)

- Calculation of MTBF (Based on MIL-HDBK-217F)

MTBF is calculated by using Parts Count Prediction Method with Sharp’s market data.

(Except MTBF of lamp)

MTBF = Min 50,000 hours

- MTBF of lamp (based on supplier’s data)

MTBF =Min 10,288,065hours (Min 185,185,185hours/1 lamp)

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 22

Global LCD Panel Exchange Center

A

A

(4S)

LQ315T3LZ23

14. Others

1) Lot No. Label ;

www.panelook.com

LD- 17408-20

SHARP

LQ315T3LZ23

ModelNo.

Barcode

53XXXXXX

MADEINJAPAN

How to express Lot No.

production year(the last figures of the Christian Era)

2) Module Label

3) Packing Label

␠ౝຠ⇟㧦

Bar code

(①)

LotNo.

○

production month (1-9, X,Y, Z)

User’s code

Model No. (LQ315T3LZ23)

①

Lot No. (Date)

②

○○○○○○○

Serial No.

㧸㨛㨠㧺㧻㧚 㧦

Bar code

㧽㨡㨍㨚㨠㨕㨠㨥㧦

Bar code

࡙ࠩຠ⇟㧦

シャープ物流用ラベルです。

(1T)2005.x.xx

(②)

(Q)

5pcs

(③)

Quantity

③

4) Cold cathode fluorescent lamp in LCD PANEL contains a small amount of mercury. Please follow local

ordinances or regulations for disposal. This sentence is stamped on the backside of the module.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 23

Global LCD Panel Exchange Center

MATERIALINFORMATION

OPTICALFILM:>PC

,PEST,AKUR‑X,PC<

LENSFILM:>PET

,AK‑X<

DIFFUSERSHEET:>PMMA‑X,PET<

DIFFUSERBOARD:>SMMA,PS

<

REFLECTOR:>PAK‑QD,PET+PMP

<

5) Label of using material information

It is displaying the material of the optical parts with the label on the backside of the module.

6) Adjusting volume have been set optimally before shipment, so do not change any adjusted value.

If adjusted value is changed, the specification may not be satisfied.

7) Disassembling the module can cause permanent damage and should be strictly avoided.

8) Please be careful since image retention may occur when a fixed pattern is displayed for a long time.

9) Be sure to turn off the power supply of the inverter circuit before turning off the one of the control circuit.

10) When any question or issue occurs, it shall be solved by mutual discussion.

11) This module is corresponded to RoHS.

www.panelook.com

LD- 17408-21

15. Carton storage condition

Temperature 0℃ to 40℃

Humidity 95%RH or less

Reference condition : 20℃ to 35℃ , 85%RH or less (summer)

: 5

Sunlight Be sure to shelter a product from the direct sunlight.

Atmosphere Harmful gas, such as acid and alkali which bites electronic components and/or

wires must not be detected.

Notes Be sure to put cartons on palette or base, don’t put it on floor, and store them with

removing from wall

Please take care of ventilation in storehouse and around cartons, and control

changing temperature is within limits of natural environment

Storage period 1 year

to 15℃ , 85%RH or less (winter)

℃

the total storage time (40℃,95%RH) : 240H or less

・

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 24

LD‑17408‑22

www.panelook.com

www.panelook.com

Global LCD Panel Exchange Center

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Page 25

䌍䌁䌔䌅䌒䌉䌁䌌䇭䌉䌎䌆䌏䌒䌍䌁䌔䌉䌏䌎

䋳䋰

䋱

䌁䌃䌔䌉䌖䌅䇭䌁䌒䌅䌁䇭䌃䌅䌎䌔䌅䌒

䋱

䋶

䋱

䋷

䋱䋱䋰

䋱䋱䋰

䌂䌅䌚䌅䌌䋯䌄䌉䌓䌐䌌䌁䌙䇭䌐䌏䌓䌉䌔䌉䌏䌎

䌁䌃䌔䌉䌖䌅䇭䌁䌒䌅䌁

䌂䌅䌚䌅䌌䇭䌏䌐䌅䌎䌉䌎䌇

䋳䋩䌏䌂䌌䌉䌑䌕䌉䌔䌙䇭䌏䌆䇭䌄䌉䌓䌐䌌䌁䌙䇭䌁䌒䌅䌁䇭䇭䌼䌃䋭䌄䌼䋼䋱䋮䋲

䋲䋩䌔䌏䌌䌅䌒䌁䌎䌃䌅䇭䌙䋭䌄䌉䌒䌅䌃䌔䌉䌏䌎䇭䌂䋺䋲䋮䋵㫧䋱䋮䋲

䋱䋩䌔䌏䌌䌅䌒䌁䌎䌃䌅䇭䌘䋭䌄䌉䌒䌅䌃䌔䌉䌏䌎䇭䌁䋺䋲䋮䋵㫧䋱䋮䋲

䋨䌔䌏䌒䌑䌕䌅䋺䌍䌁䌘䋵䋮䋰䌋䌧䌦䊶䌣䌭䋩

䋨䌄䌅䌐䌔䌈䋺䌍䌁䌘䋸䌭䌭䋩

Page 26

Global LCD Panel Exchange Center

N

y

Reference:

The management temperature of each part

The controlled temperature for critical parts is described as follows.

The following temperature is specified temperature to maintain the reliability as LCD module.

Therefore, it should be evaluated as TV set to confirm that no problem is found.

1) Specified temperature

The management temperature of each part

The management par ts

LCD pane l surface

www.panelook.com

Panel surface 1 to 9

The management

temperature

䋨

䋩

degre eC

65 Measurement point

Reference 2-1

LD- 17408-24

Remark

LCD unit backside Inverter PWB

Control PWB

Lamp unit from inside

2) Measurement point

2-1. LCD panel surface (front view of panel)

Transformer 1 to 18

Transistor 1 to 18

IC1

IC2

ASIC(IC1)

IC501

Coil 1, 2

Diffuser Board 1 to 3

Reflector 1 to 3

Lamp1 to 18

104

106

100

97 Measurement point

95 Re ference 2-2

100

100

80 Measurement point

80 Re ference 2-3

120

o.1 to 9 are measurement points of LCD panel

are quartered each side and measured in each point of intersection

The

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 27

Global LCD Panel Exchange Center

2-2. LCD panel backside

㪚㫆㫀㫃㩷㪉

㪚㫆㫀㫃㩷㪈

㪘㪪㪠㪚㩿㪠㪚㪈㪀

㪠㪚㪌㪇㪈

www.panelook.com

LD- 17408-25

㪠㪚㪈

㪫㫉㪸㫅㫊㫀㫊㫋㫆㫉㩷㪈䌾㪈㪏

㪠㪚㩷㪉

㪫㫉㪸㫅㫊㪽㫆㫉㫄㪼㫉㩷㪈䌾㪈㪏

2-3. Lamp unit from inside *The front perspective view

Lamp1 to 16

(High voltage side)

Frontside of Reflector 2

&

Backside of Diffuser Board 2

Frontside of Reflector 3

&

Backside of Diffuser Board 3

Frontside of Reflector 1

&

Backside of Diffuser Board 1

The cross section

Backside of the

Diffuser Board

Frontside of the

Reflector

* Frontside of the Reflector :

Surface of Reflector at lamp side

* Backside of the Diffuser Board :

Surface of Diffuser Board at lamp side

[Representative point of resin temperature next to heat source]

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 28

㪣㫌㫄㫀㫅㪸㫅㪺㪼㩷㫄㪸㫀㫅㫋㪼㫅㪸㫅㪺㪼㩷㫉㪸㫋㪼㩷㪺㫌㫉㫍㪼

㩿㪜㫊㫋㫀㫄㪸㫋㪼㪻㩷㫍㪸㫃㫌㪼㪀

㪋㪇

㪌㪇

㪍㪇

㪎㪇

㪏㪇

㪐㪇

㪈㪇㪇

㪈㪈㪇

䋷䋰㷄

䋲䋵㷄

㪘㫃㫃㩷㪾㫉㪸㫇㪿㫊䋺㪣㪼㪿㫄㪸㫅㫅㩾㫊

㪸㫇㫇㫉㫆㫏㫀㫄㪸㫋㫀㫆㫅㩷㪽㫆㫉㫄㫌㫃㪸

㪝㫆㫉㩷㫉㪼㪽㪼㫉㪼㫅㪺㪼

LD‑17408‑26

www.panelook.com

www.panelook.com

Global LCD Panel Exchange Center

㪚㪼㫅㫋㪼㫉㩷㫃㫌㫄㫀㫅㪸㫅㪺㪼㩷㫆㪽㩷㫃㪸㫄㫇

㪦㫇㪼㫉㪸㫋㫀㫆㫅㩷㪫㫀㫄㪼䇭䌛䌨䌝

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

㪈 㪈㪇 㪈㪇㪇 㪈㪇㪇㪇 㪈㪇㪇㪇㪇 㪈㪇㪇㪇㪇㪇

㪣㫌㫄㫀㫅㪸㫅㪺㪼䇭䌛䋦䌝

Loading...

Loading...