Page 1

Global LCD Panel Exchange Center

www.panelook.com

No. LD –21956A

DATE Oct. 6.2009

Revised

TECHNICAL LITERATURE

TFT - LCD module

MODEL No.

RoHS Compliant

FOR

LQ215M1Lxxx

The technical literature is subject to change without notice.

So, please contact Sharp or its representative before designing

your product based on this literature.

PC DISPLAY & LCD MONITOR

BUSINESS PLANNING & MARKETING PROJECT TEAM,

DIVISIONⅡ,

MOBILE LIQUID CRYSTAL DISPLAY GROUP

SHARP CORPORATION

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 2

Global LCD Panel Exchange Center

LQ215M1Lxxx

www.panelook.com

RECORDS OF REVISION

SPEC No. DATE

No. PAGE

LD-21956A Sep. 17.2009 1st Issue

REVISED

SUMMARY NOTE

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 3

Global LCD Panel Exchange Center

These technical literature sheets are the proprietary product of SHARP CORPORATION(”SHARP) and

include materials protected under copyright of SHARP. Do not reproduce or cause any third party to

reproduce them in any form or by any means, electronic or mechanical, for any purpose, in whole or in part,

without the express written permission of SHARP.

In case of using the device for applications such as control and safety equipment for transportation(aircraft,

trains, automobiles, etc. ), rescue and security equipment and various safety related equipment which require

higher reliability and safety, take into consideration that appropriate measures such as fail-safe functions and

redundant system design should be taken.

Do not use the device for equipment that requires an extreme level of reliability, such as aerospace

applications, telecommunication equipment(trunk lines), nuclear power control equipment and medical or

other equipment for life support.

www.panelook.com

LD-21956A-1

SHARP assumes no responsibility for any damage resulting from the use of the device, which does not

comply with the instructions, and the precautions specified in these technical literature sheets.

Contact and consult with a SHARP sales representative for any questions about this device.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 4

Global LCD Panel Exchange Center

Table of contents

1. .............................................................................................................................................. 3 Application

2. ................................................................................................................................................. 3 Overview

3. ...................................................................................................................... 3 Mechanical Specifications

4. ....................................................................................................................................... 4 Input Terminals

4-1. TFT-LCD panel driving ........................................................................................................................... 4

4-2. LED Backlight driving ............................................................................................................................ 5

5. ................................................................................................................... 6 Absolute Maximum Ratings

6. ......................................................................................................................... 7 Electrical Characteristics

6-1.TFT-LCD panel driving ............................................................................................................................ 7

7. ................................................................................................ 10 Timing Characteristics of Input Signals

7-1. Timing characteristics ............................................................................................................................ 10

7-2. Input data signals and display position on the screen ............................................................................ 11

www.panelook.com

LD-21956A-2

8. ..................................................... 12 Input Signals, Basic Display Colors and Gray Scale of Each Color

9. .......................................................................................................................... 13 Optical Characteristics

10. ..................................................................................................................................... 15 Display Quality

11. ............................................................................................................................ 16 Handling Precautions

12. ......................................................................................................................................... 16 Packing form

13. ................................................................................................................................. 16 RoHS Regulations

14. ..................................................................................................................... 17 Reliability Test Condition

Fig. 1 Outline Dimensions .............................................................................................................. ……….19

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 5

Global LCD Panel Exchange Center

r

r

1. Application

This technical literature applies to a color TFT-LCD module, LQ215M1L***.

2. Overview

This module is a color active matrix LCD module incorporating amorphous silicon TFT (Thin Film

Transistor). It is composed of a color TFT-LCD panel, driver ICs, control circuit and power supply circuit

and a backlight unit. Graphics and texts can be displayed on a 1920 x 3 x 1080 dots panel with 16,777,216

www.panelook.com

LD-21956A-3

colors by using LVDS (L

voltage for TFT-LCD panel driving and supply voltage for backlight.

In this TFT-LCD panel , color filters of excellent color performance and LED backlights of high brightness

are incorporated to realize brighter and clearer pictures, making this model optimum for use in multi-media

applications.

Optimum viewing direction is 6 o'clock.

3. Mechanical Specifications

Paramete

Display size 546.86 (21.53") Diagonal mm

Active area 476.64 (H) x 268.11(V) mm

Pixel format

Aspect ratio 16 : 9

Pixel pitch 0.24825(H) x 0.24825 (V) mm

Pixel configuration R,G,B vertical stripe

ow Voltage Differential Signaling) to interface and supplying +5V DC supply

Specifications Unit

1920(H) x 1080(V) pixel

(1 pixel = R+G+B dots)

Display mode Normally white

Surface treatment Anti-glare, Haze=25%, hard-coating (3H)

Paramete

Unit outline dimensions

[Note 1]

Mass - - TBD g

[Note 1]Outline dimensions is shown in Fig.1

Min. Typ. Max. Unit

Width 495.1 495.6 496.1 mm

Height 291.7 292.2 292.7 mm

Depth 9.35 9.85 10.35 mm

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 6

Global LCD Panel Exchange Center

4. Input Terminals

4-1. TFT-LCD panel driving

CN1 (LVDS signals and +5.0V DC power supply)

Using connector : GS23302-0011R-7F (Foxconn) or equivalent.

Corresponding connector : FI-XB30SRL-HF11 (JAE) [Note 1]

Pin No. Symbol Function Remark

Frame

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

Frame

[Note 1] Sharp is not responsible to its product quality, if the user applies a connector not corresponding

GND GND

RxO0-

RxO0+

RxO1-

RxO1+

RxO2-

RxO2+

GND GND

RxOC-

RxOC+

RxO3-

RxO3+

RxE0-

RxE0+

GND

RxE1-

RxE1+

GND

RxE2-

RxE2+

RxEC-

RxEC+

RxE3-

RxE3+

GND GND

N.C. No Connection, this pin should be open.

N.C. No Connection, this pin should be open.

N.C. No Connection, this pin should be open.

Vcc +5V power supply

Vcc +5V power supply

Vcc +5V power supply

GND GND

www.panelook.com

LD-21956A-4

[Note 3]

Receiver signal of LVDS (O0-) [Note 2]

Receiver signal of LVDS (O0+) [Note 2]

Receiver signal ofLVDS (O1-) [Note 2]

Receiver signal of LVDS (O1+) [Note 2]

Receiver signal of LVDS (O2-) [Note 2]

Receiver signal of LVDS (O2+) [Note 2]

Receiver signal of LVDS CLK (OC-) [Note 2]

Receiver signal of LVDS CLK (OC+) [Note 2]

Receiver signal of LVDS (O3-) [Note 2]

Receiver signal of LVDS (O3+) [Note 2]

Receiver signal of LVDS (E0-) [Note 2]

Receiver signal of LVDS (E0+) [Note 2]

GND

Receiver signal of LVDS (E1-) [Note 2]

Receiver signal of LVDS (E1+) [Note 2]

GND

Receiver signal of LVDS (E2-) [Note 2]

Receiver signal of LVDS (E2+) [Note 2]

Receiver signal of LVDS CLK (EC-) [Note 2]

Receiver signal of LVDS CLK (EC+) [Note 2]

Receiver signal of LVDS (E3-) [Note 2]

Receiver signal of LVDS (E3+) [Note 2]

[Note 4]

[Note 4]

[Note 4]

[Note 3]

to the above model.

[Note 2] Relation between RxINi(i=0,1,2) and actual data is shown in following section (4-3).

[Note 3] The shielding case is connected with signal GND.

[Note 4] Please use NC by OPEN. NC terminal is not connected with the internal circuit.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 7

Global LCD Panel Exchange Center

y

y

y

y

4-2. LED Backlight driving

Upper/Lower FPC Connector Pin Assignment

Using connector : 7080-Q10N-00R (Entery INDUSTRIAL CO.,LTD)

Corresponding FFC specification:

Temperature=80

www.panelook.com

o

C, Voltage=60V, Pin No.=10, 0.5Pitch, PET, HF

LD-21956A-5

Pin No Symbol

1 IRLED1 IRLED1 LED current sense for string 1

2 IRLED1 IRLED1 LED current sense for string 1

3 IRLED2 IRLED1 LED current sense for string 2

4 VLED LED power suppl

5 VLED LED power suppl

6 VLED LED power suppl

7 VLED LED power suppl

8 IRLED2 IRLED1 LED current sense for string 2

9 IRLED3 IRLED1 LED current sense for string 3

10 IRLED3 IRLED1 LED current sense for string 3

Description

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 8

Global LCD Panel Exchange Center

a

5. Absolute Maximum Ratings

www.panelook.com

LD-21956A-6

Parameter Symbol Condition

Input voltage V

Ta=25oC -0.3 +4.3 V [Note 1]

I

Ratings

Min. Max.

Unit Remark

+5V supply voltage Vcc Ta=25oC -0.3 +6.0 V

LED Driver supply voltage LED_V

Ta=25oC(TBD) (TBD) V

CC

LED Current ILED Ta=25oC(TBD) (TBD) A

Storage temperature Tstg

Operating temperature (Ambient) Top

-

-

-20 +60

0+50

o

C

o

C

[Note 3]

[Note 1] LVDS signals

[Note 2] The relative humidity must not exceed 90% non-condensing at temperatures of 40°C or less.

At temperatures greater than 40°C, the wet bulb temperature must not exceed 39°C.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 9

Global LCD Panel Exchange Center

r

–

6. Electrical Characteristics

6-1.TFT-LCD panel driving

Ta=+25

Paramete

Symbol Min. Typ. Max. Unit Remark

Supply voltage Vcc +4.5 +5.0 +5.5 V [Note 2]

Permissive input ripple voltage VRP --150mV

Current dissipation Icc - (TBD) (TBD) mA [Note 3]

Rush Current Irush - 1.6 3.0 A [Note 4]

Input voltage range VI (TBD) (TBD) V LVDS signals

Differential input High VTH --+100mVV

threshold voltage Low VTL

Input current (High) IOH --(TBD)μAVI = +2.4V Vcc = +3.6V

Input current (Low) IOL --(TBD)μAVI = 0V Vcc = 3.6V

Terminal resistor R

[Note 1] VCM : Common mode voltage of LVDS driver.

[Note 2] On-off conditions for supply voltage

www.panelook.com

Vcc = +5.5V

P-P

= +1.2V

CM

100 - - mV [Note 1]

-(TBD)- Ω Differential input

T

LD-21956A-7

o

C

0.1Vcc

Vcc

t1 t2

Valid

0.9Vcc0.9Vcc

0.1Vcc

t3 t5

t4

0.1Vcc

Signal

(LVDS Interface)

Backlight

OFF

t6

Backlight ON

(LED)

t7

OFF

Symbol Min. Typ. Max. Unit Remark

t1 0.1 - 10 ms

t2 0 30 50 ms

t3 0 20 50 ms

t4 0.1 - 10 ms

t5 1000 - - ms

t6 200 250 - ms *1

t7 100 250 - ms *1

*1 : As for the power sequence for backlight, it is recommended to apply above

mentioned input timing. If the backlight is lit on and off at a timing other

than shown above, displaying image may get disturbed. This is due to

variation of output signal from timing generator when LVDS signal is

changed from on to off or vice versa, but has no harm to the module itself.

(Note 2-1) Do not keep the interface signal high-impedance or unusual signal when power is on.

(Note 2-2)Vcc-dip conditions

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 10

Global LCD Panel Exchange Center

www.panelook.com

LD-21956A-8

[Note 3] Typical current situation : 16-gray-bar pattern.

Vcc=+5.0V

Maximum current situation : Vcc=+5.0V

[Note 4] Test condition :

DD = 5 V, VDD rising time = 470 μs ± 10%

(1) V

(2) Pattern: Mosaic pattern

(3) Test circuit

RGB

GS0

RGB

GS4

RGB

GS8

....

RGB

GS56

RGB

GS60

[Note 5] LVDS signal definition

VIN+ = Positive differential DATA & CLK Input

VIN- = Negative differential DATA & CLK Input

VID = VIN+ – VIN- ,

ΔVCM =|VCM+–VCM-|,

ΔVID =|VID+–VID-|,

VID+ =|VIH+–VIH-|,

VID- =|VIL+–VIL-|,

VCM = (VIN+ +VIN-)/2,

VCM+ = (VIH+ +VIH-)/2,

VCM- = (VIL+ +VIL-)/2,

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 11

Global LCD Panel Exchange Center

r

6-2. Backlight driving

www.panelook.com

LD-21956A-9

(Ta=+25

o

C)

Paramete

Symbol Min. Typ. Max. Unit Remark

Supply voltage range VLED - +42.9 +45.5 V (Duty 100%)

Current dissipation ILED

-

- 360 mA [Note 1,2,3]

Power Consumption PLED 16.38 W [Note 4]

Permissive input ripple voltage -

-

-(TBD)mV

[Note 1]

P-P

LED life time LBL - 30,000 - Hour [Note 5]

[Note 1] There are one Light Bar, and the specified current is input LED chip 100% duty current.

[Note 2] The sensing current of each string is 60mA.

[Note 3] Each light bar have three current sensing strings, so that each light bar input current is 180mA.

.

[Note 4] PLED = ILED × VLED.

[Note 5] The life time is determined as the time at which luminance of the LED becomes 50% of the

initial brightness or not normal lighting at ILED=360mA on condition of continuous operating

at 25±2°C.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 12

Global LCD Panel Exchange Center

r

y

y

7. Timing Characteristics of Input Signals

7-1. Timing characteristics

www.panelook.com

Vcc=+3.0V~+3.6V,Ta= 0

LD-21956A-10

o

C~+50 oC

Paramete

Clock Frequenc

Symbol Min. Typ. Max. Unit Remark

1/Tc 60 72 87.5 MHz

Period Tc 11.43 13.89 16.7 ns

Horizontal period TH 1000 1088 1120 clock

Horizontal period (High) THd 960 960 960 clock

Data Enable

Signal

H-Blank (TH-THd) THb 40 128 160 clock

Vertical period TV 1090 1100 1160 Line

Vertical period (High) TVd 1080 1080 1080 line

V-Blank (TV-TVd) TVb 10 20 80 line

Frequenc

fV 50 60 75 Hz

[Note 1] Because this module is operated by DE only mode, Hsync and Vsync input signals should be set

to low Logic level or ground. Otherwise, this module would operate abnormally.

TH

THd

ENAB

O side

(R1,G1,B1)

E side

(R2,G2,B2)

1919

1920

Tc

1 3

2 4

1919

1920

ENAB

12

1080 1079

TV

TVd

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 13

Global LCD Panel Exchange Center

7-2. Input data signals and display position on the screen

R1 G1 B1 R2 G2 B2

(1,1 ) (1,2)

www.panelook.com

LD-21956A-11

1・1 1・2 1・3

1・1920

2・1 2・2

3・1

R G B

1080・1920

1080・1

Display position of input data(V・H)

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 14

Global LCD Panel Exchange Center

È

È

È

È

È

È

8. Input Signals, Basic Display Colors and Gray Scale of Each Color

Colors & Gray

Gray scale Scale

R0 R1 R2 R3 R4 R5 R6 R7 G0 G1 G2 G3 G4 G5 G6 G7 B0 B1 B2 B3 B4 B5 B6 B7

www.panelook.com

LD-21956A-12

Data signal

Black

Blue

Green

Basic Color Gray Scale of Red Gray Scale of Green Gray Scale of Blue

Cyan

Red

Magenta

Yellow

White

Black

×

Darker

×

Ø

Brighter

Ø

Red

Black

×

Darker

×

Ø

Brighter

Ø

Green

Black

×

Darker

×

Ø

Brighter

Ø

Blue

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

-

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1

-

0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0

-

0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

-

1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

-

1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1

-

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0

-

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

-

0

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

1

1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

2

0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

253

1 0 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

254

0 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

255

1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

0

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

1

0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

2

0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0

253

0 0 0 0 0 0 0 0 1 0 1 1 1 1 1 1 0 0 0 0 0 0 0 0

254

0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0

255

0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0

0

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

1

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0

2

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0

253

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 1 1 1 1 1 1

254

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1

255

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1

È

È

È

È

È

È

È È

È È

È È

È È

È È

È È

0 : Low level voltage, 1 : High level voltage

Each basic color can be displayed in 256 gray scales from 8 bit data signals. According to the combination of

total 24 bit data signals, the 16,777,216-color display can be achieved on the screen.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 15

Global LCD Panel Exchange Center

r

(

)

9. Optical Characteristics

www.panelook.com

Ta=+25

LD-21956A-13

o

C, Vcc=+3.3V

Paramete

Viewing

angle

range

Symbol Condition Min. Typ. Max. Unit Remark

Horizontal θ21, θ22

CR≧10

75 85 - Deg.

[Note 1,2,3]

Vertical θ11, θ12 70 80 - Deg.

Contrast ratio CRn θ=0° 700 1000 - [Note 1,3,5]

Response time

τr

θ=0°

- 1.5 3 ms

[Note 1,4,5] τd - 3.5 7 ms

τr +τd - 5 10 ms

Chromaticity of white

x

θ=0°

0.283 0.313 0.343

[Note 1,5]

y 0.299 0.329 0.359

Luminance of white YLI θ=0° (200) 250 - cd/m

2

[Note 1,5]

White Uniformity δW 0.70 0.75 - [Note 1,6]

Cross Talk(In 60HZ) Ct - - 2 % [Note 7]

The measurement shall be executed 30 minutes after lighting at rating. Condition : (D

PWM

=100%)

The optical characteristics shall be measured in a dark room or equivalent.

[Note 1] Optical Characteristics Measurements

400mm

Field=2°

Center of the screen

LCD Panel

BM-5A

(TOPCON)

θ=0°

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 16

Global LCD Panel Exchange Center

[Note 2] Definitions of viewing angle range:

[Note 3] Definition of contrast ratio:

The contrast ratio is defined as the following.

Contrast Ratio (CR) =

www.panelook.com

LD-21956A-14

Luminance (brightness) with all pixels white

Luminance (brightness) with all pixels black

[Note 4] Definition of response time:

The response time is defined as the following figure and shall be measured by switching the input

signal for "black" and "white" .

[Note 5] This shall be measured at center of the screen.

[Note 6] Definition of white uniformity:

White uniformity is defined as the

following with nine measurements

(P1~P9).

Minimum Luminance of nine points (Brightness)

δw =

Maxmum Luminance of nine points (Brightness)

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 17

Global LCD Panel Exchange Center

[Note 7] Definition of the cross talk

l LA-LA’ l / LA x 100%= 2% max., LA and LA’ are brightness at location A and A’

www.panelook.com

LD-21956A-15

l LB-LB’ l / LB x 100%= 2% max., LB and LB’ are brightness at location B and B’

Display Quality

10.

The display quality of the color TFT-LCD module shall be in compliance with the Incoming Inspection Standard.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 18

Global LCD Panel Exchange Center

11. Handling Precautions

a) Be sure to turn off the power supply when inserting or disconnecting the cable.

b) Be sure to design the cabinet so that the module can be installed without any extra stress such as warp or twist.

c) Since the front polarizer is easily damaged, pay attention not to scratch it.

www.panelook.com

LD-21956A-16

Blow away dust on the polarizer with antistatic N

blow. It is undesirable to wipe off because a polarizer is sensitive.

2

It is recommended to peel off softly using the adhesive tape when soil or finger oil is stuck to the polarizer.

When unavoidable, wipe off carefully with a cloth for wiping lenses.

d) Wipe off water drop immediately. Long contact with water may cause discoloration or spots.

e) When the panel surface is soiled, wipe it with absorbent cotton or other soft cloth.

f) Since the panel is made of glass, it may break or crack if dropped or bumped on hard surface.

Handle with care.

g) Since CMOS LSI is used in this module, take care of static electricity and injure the human earth when handling.

Observe all other precautionary requirements in handling components.

h) Since there is a circuit board in the module back, stress is not added at the time of a design assembly.

Please make it like. If stress is added, there is a possibility that circuit parts may be damaged.

i) Protection film is attached to the module surface to prevent it from being scratched .

Peel the film off slowly , just before the use, with strict attention to electrostatic charges.

Blow off 'dust' on the polarizer by using an ionized nitrogen.

j) Do not expose the LCD module to a direct sunlight, for a long period of time to protect the module from

the ultra violet ray.

k) When handling LCD modules and assembling them into cabinets, please avoid that long-terms storage in

the environment of oxidization or deoxidization gas and the use of such materials as reagent, solvent,

adhesive, resin, etc. which generate these gasses, may cause corrosion and discoloration of the modules.

l) Liquid crystal contained in the panel may leak if the LCD is broken. Rinse it as soon as possible if it gets

inside your eye or mouth by mistake.

m) Notice : Never dismantle the module , because it will cause failure.

Please don't remove the fixed tape, insulating tape etc that was pasted on the original module.

(Except for protection film of the panel and the crepe tape (yellow tape) of fixing lamp

cable temporarily.)

n) Be careful when using it for long time with fixed pattern display as it may cause afterimage. (Please use a screen

saver etc., in order to avoid an afterimage.)

o) Please handle carefully not to charge excessive stress onto the back of the module.Excessive stress may cause

unrepairable damage to the module.

Packing form

12.

TBD

13.

RoHS Regulations

This LCD module is compliant with RoHS Directive.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 19

Global LCD Panel Exchange Center

14. Reliability Test Condition

www.panelook.com

LD-21956A-17

Note1: Pass: Normal display image with no obvious non-uniformity and no line defect.

Partial transformation of the module parts should be ignored.

Fail: No display image, obvious non-uniformity, or line defects.

Note2: Evaluation should be tested after storage at room temperature for two hours.

Note 3: The MTBF calculation is based on the assumption that the failure rate distribution meets the

Exponential Model (CCFL excluded).

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 20

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

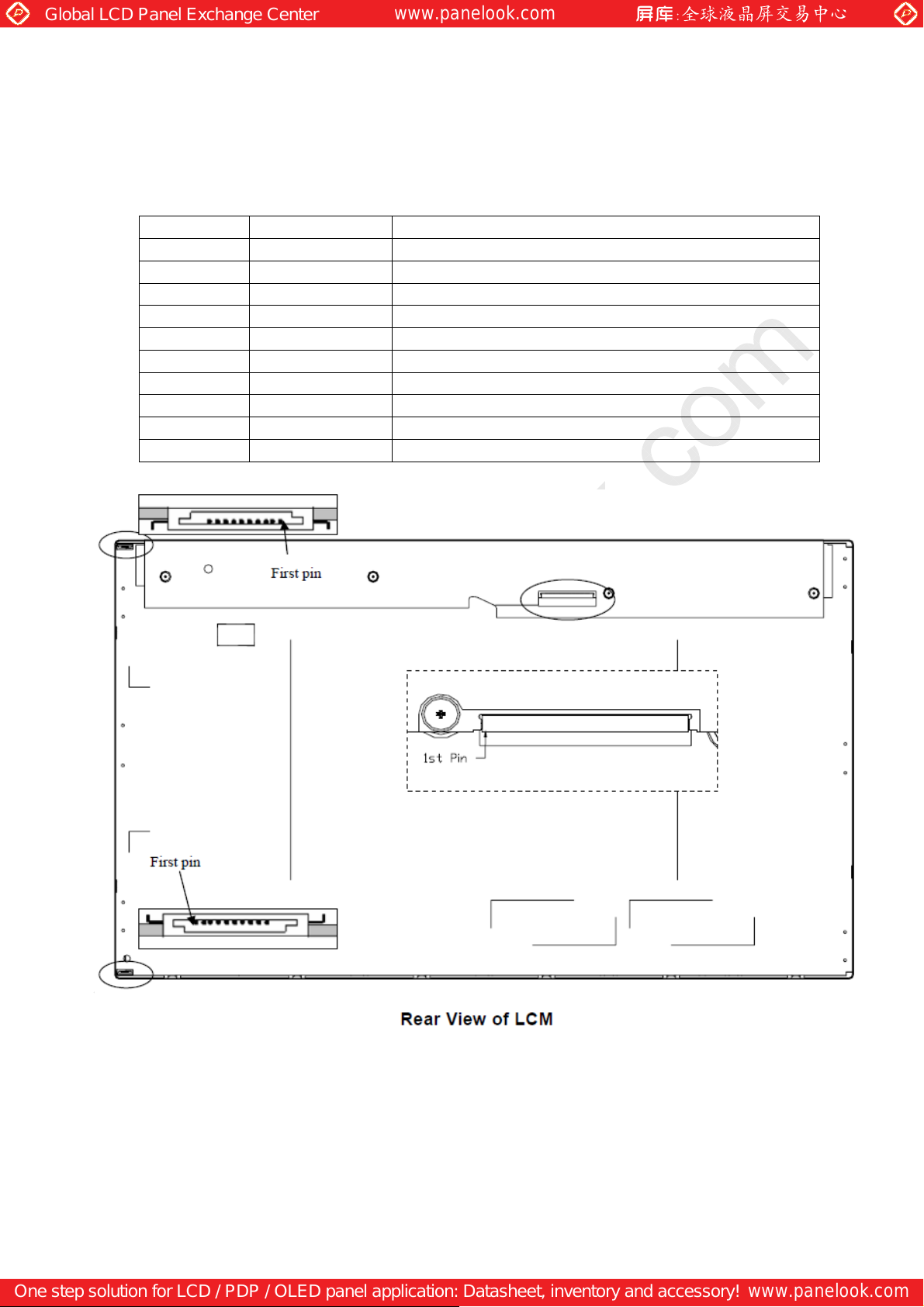

Fig. 1 Outline Dimensions

Front side

LD-21956A-18

Page 21

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Rear side

LD-21956A-19

Loading...

Loading...