Page 1

Technical Document

LCD Specification

LCD Group

LQ150X1LG76 LCD Module

Product Specification

Ju ly 2011

XGA Normally Black module with contrast of

700:1 and brightness of 450 nits.

Anti-reflective,anti-glare,and hard coated.

Page 2

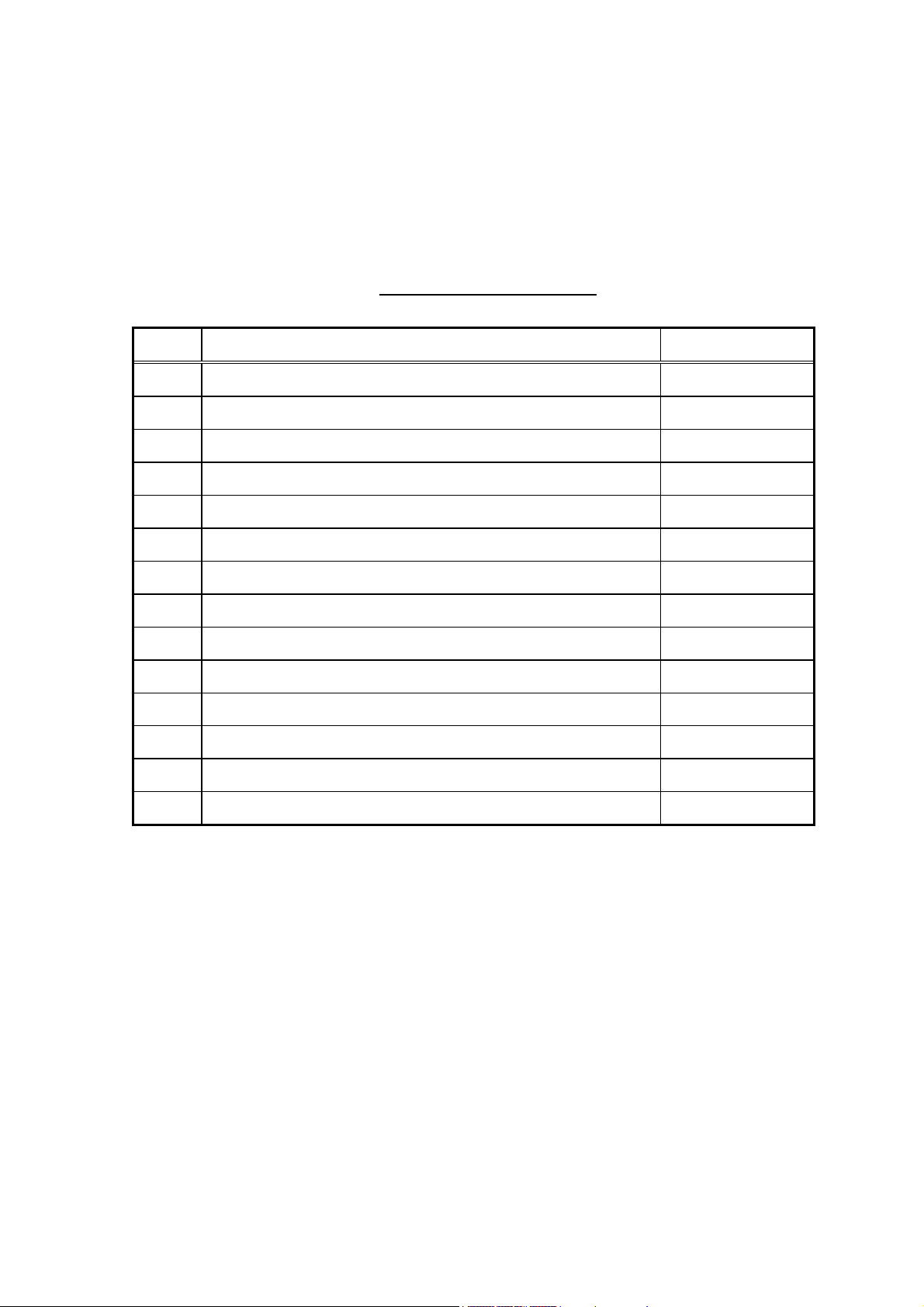

CONTENTS

No. Item Page

-- COVER 1

-- CONTENTS 2

1 APPLICATION 3

2 OVERVIEW 4

3 ABSOLUTE MAXIMUM RATINGS 5

4 ELECTRICAL CHARACTERISTICS 5, 6, 7

5 INTERFACE PIN CONNECTION 8, 9

6 INTERFACE TIMING 10, 11, 12, 13, 14

7 BLOCK DIAGRAM 15

8 MECHANICAL SPECIFICATION 16, 17

9 OPTICAL CHARACTERISTICS 18, 19, 20

10 RELIABILITY TEST CONDITION 21

11 OTHER FEATURE 22

12 HANDLING PRECAUTIONS FOR TFT-LCD MODULE 23, 24, 25

(2/25)

Page 3

1. APPLICATION

This specification applies to color TFT-LCD module,

(1) Standard Usage

Computers, office equipment, factory automation equipment, test and measurement

equipment, communications, transportation equipment(automobiles, ships, trains, etc.),

provided, however, that operation is not influenced by TFT-LCD directly.

(2) Special Usage

Medical equipment, safety equipment, transportation equipment, provided, however, that

TFT-LCD is necessary to its operation.

(3) Specific Usage

Cockpit Equipment, military systems, aerospace equipment, nuclear reactor control

systems, life support systems and any other equipment.

LQ150X1LG76.

(3/25)

Page 4

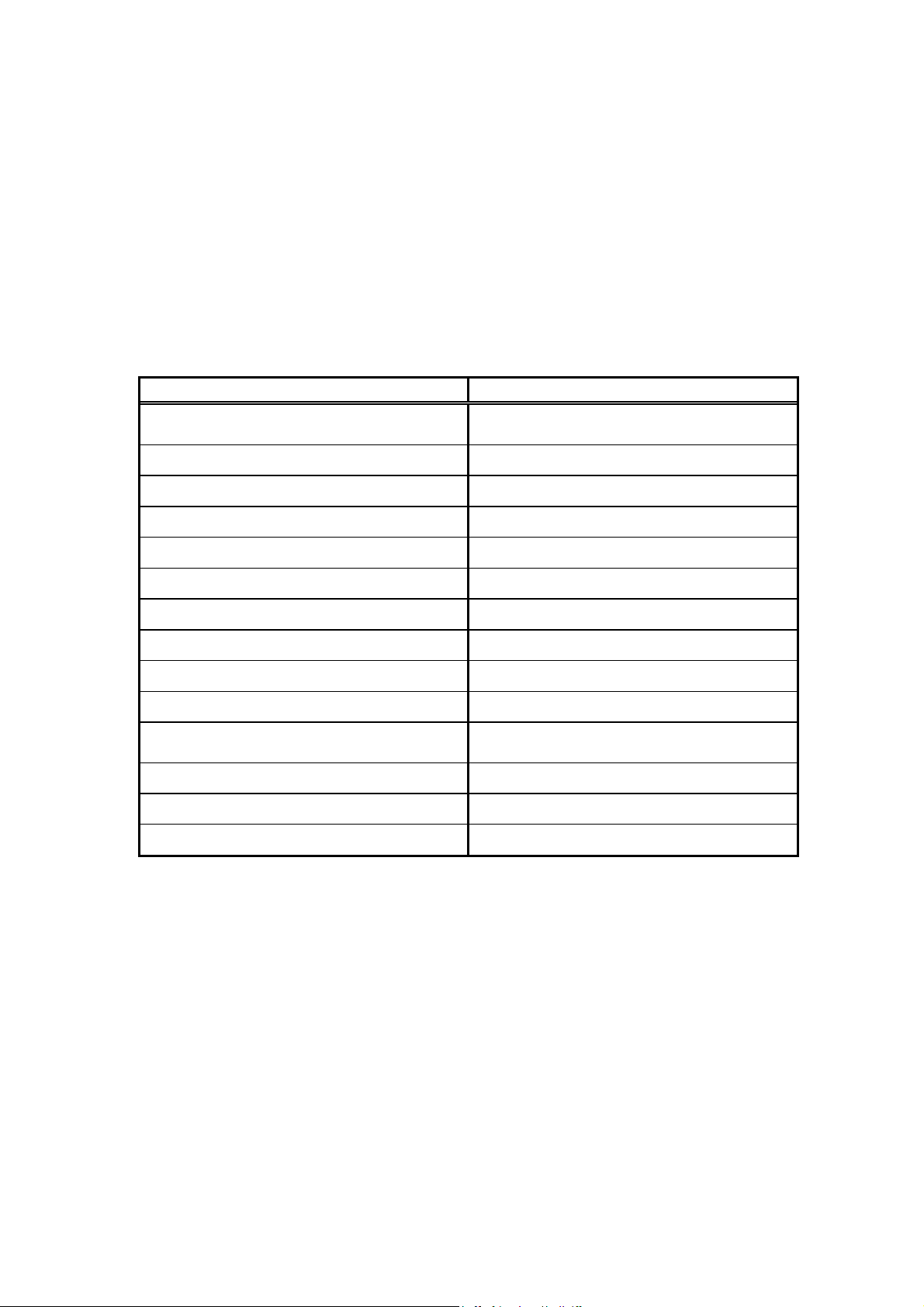

2. OVERVIEW

is 15.0” color TFT-LCD (Thin Film Transistor Liquid Crystal Display) module

LQ150X1LG76

composed of LCD panel, driver ICs, control circuit, LED driver and backlight unit.

By applying 6 bit or 8 bit digital data, 1024 × 768, 262k-color or 16.7M-color images are displayed

on the 15.0” diagonal screen. Input power voltages are 3.3 V for LCD driving and 12.0 V for

backlight unit.

The type of data and control signals are digital and transmitted via LVDS interface per Typ. 65

MHz clock cycle.

General specifications are summarized in the following table:

ITEM SPECIFICATION

Display Area (mm)

Number of Dots

304.1(H) × 228.1(V)

(15.0-inch diagonal)

1024 × 3 (H) × 768 (V)

Pixel Pitch (mm)

Color Pixel Arrangement RGB vertical stripe

Display Mode Normally white

Number of Color 262k(6 bit/color), 16.7M(8 bit/color)

Luminance (cd/m2) 450

Viewing Angle (CR ≥ 10) −80∼80°(H), −70∼70°(V)

Surface Treatment Anti-glare and hard-coating 3H

Electrical Interface LVDS (6 bit/8 bit)

Viewing direction

Module Size (mm)

Module Mass (g) 1050

Backlight Unit LED, Edge-light, Unreplaceable

Characteristic value without any note is typical value.

Less gray scale reversal: 12 o'clock

0.297 (H) × 0.297 (V)

Higher Contrast ratio: 6 o'clock

326.5 (W) × 253.5 (H) × 12.0(D)

(4/25)

Page 5

3. ABSOLUTE MAXIMUM RATINGS

ITEM SYMBOL MIN. MAX. UNIT

Power Supply Voltage for LCD VCC 0 4.0 V

Logic Input Voltage VI

Backlight Power Supply Input Voltage VL

Backlight ON-OFF BLEN

Light Dimming Control (PWM) input voltage V

Operation Temperature (Panel)

Operation Temperature (Ambient)

Storage Temperature

Note 1,2)

T

Note 2)

T

Note 2)

T

PDIM

op(Panel)

op(Ambient)

stg

−0.3

−0.3

−0.3

−0.3

0 65 °C

0 65 °C

−20

VCC+0.3 V

14.0 V

VL V

5.8 V

65 °C

[Note]

1) The relative temperature and humidity range are 90%RHMax. (Ta ≤ 40°C).

2) The maximum wet bulb temperature ≤ 39°C (Ta > 40°C) and without dewing.

3) If you use the product in a environment which over the definition of temperature and humidity

too long to effect the result of eye-aching.

4) If you operate the product in normal temperature range, the center surface of panel should be

under 65°C.

4. ELECTRICAL CHARACTERISTICS

(1) TFT-LCD

Ambient temperature: Ta = 25°C

ITEM SYMBOL MIN. TYP. MAX. UNIT Remarks

Power Supply Voltages for LCD VCC 3.0 3.3 3.6 V *1)

Power Supply Currents for LCD ICC -- 480 800 mA *2)

Permissive Input Ripple Voltage VRP -- -- 100 mVp-p VCC = +3.3V

High VIH

0.8×VCC

-- VCC V MODE

Logic Input Voltage

Low VIL 0 --

0.2×VCC

V MODE

*1) Power and signals sequence:

0.5 ≤ t1 ≤ 10 ms 200 ms ≤ t4

0 < t2 ≤ 50 ms 200 ms ≤ t5

t6

t1

≤

VCC

0.9VCC

data

0.1VCC

t2

t3

t4

0.1VCC

0 < t3 ≤ 50 ms 0 ms

0.9VCC

LCD Power Supply

Logic Signal

Backlight Power Supply

0.1VCC

t5 t6

data: RGB DATA, DCLK, DENA, MODE

(5/25)

Page 6

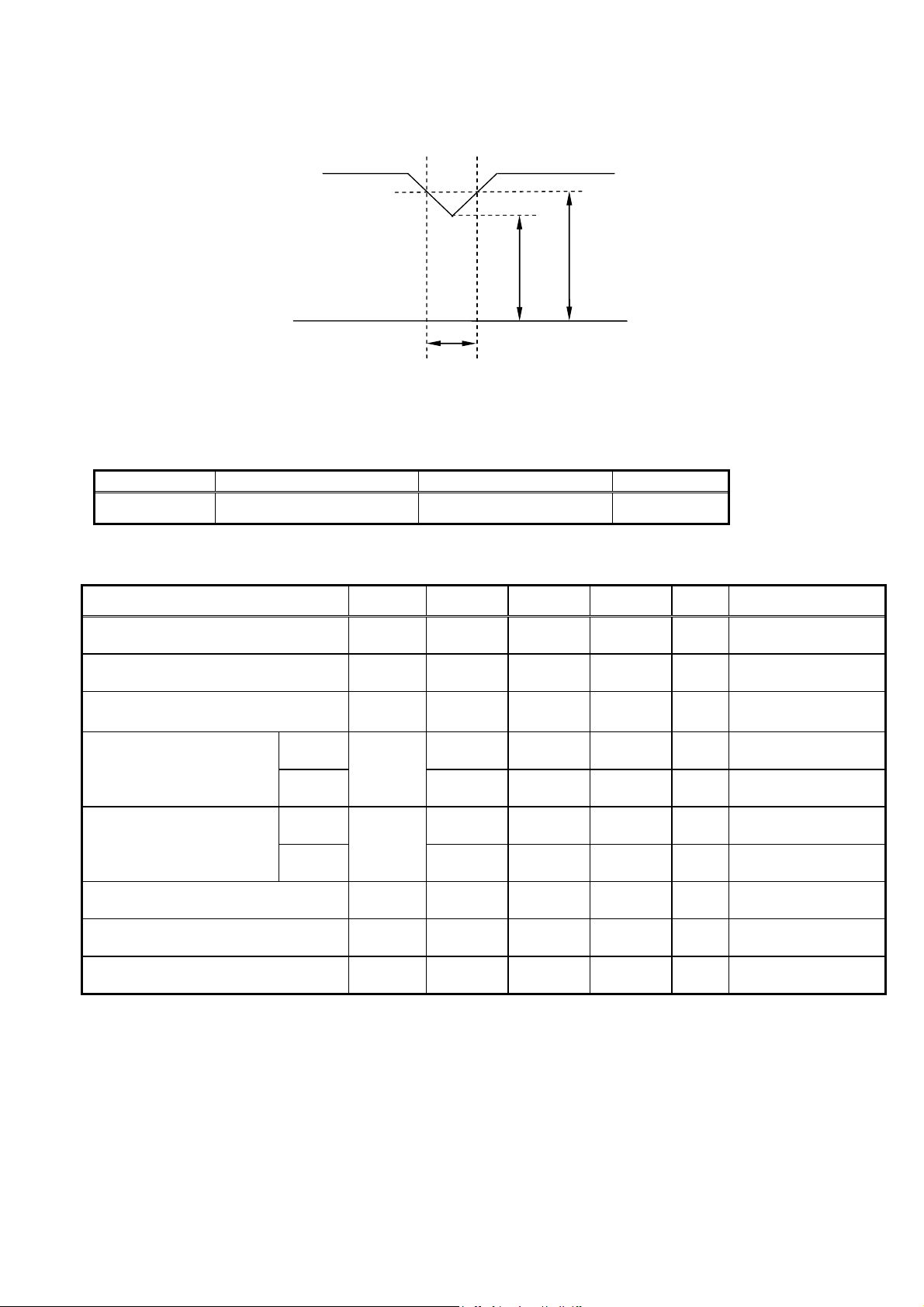

VCC-dip conditions:

1) When 2.7 V

≤

VCC < 3.0 V, td ≤ 10 ms

2) When VCC < 2.7 V

VCC-dip conditions should also follow the power and signals sequence.

3.0 V

2.7 V

VCC

td

*2) VCC = +3.3 V , f

=48.36 kHz, fV=60 Hz, f

H

=65 MHz

CLK

Display image at typical power supply current value is 256-gray-bar pattern (8 bit), 768 line

mode.

*3) Fuse

Parameter Fuse Type Name Supplier Remark

VCC F0603FA3000V032T AEM *)

*) The power supply capacity should be designed to be more than the fusing current.

(2) Backlight Ta=25°C

ITEM SYMBOL MIN. TYP. MAX. UNIT Remarks

Power Supply Input Voltage VL 10.8 12.0 13.2 V *1)

Power Supply Input Current IL 600 700 850 mA *2, *4)

Power Supply Input Current PL -- 8.4 9.2 W

Dimming=100%,

VL=12.0V

High 2.5 -- VL V ON

Backlight ON-OFF

Low

Light Dimming Control

(PWM) input voltage

High 1.8 -- 5.0 V ON

Low

PWM frequency f

Pulse width of PDIM t

BLEN

0 -- 0.4 V OFF

PDIM

V

0 -- 0.8 V OFF

100 400 500 Hz *3)

PDIM

100 -- DC us *3)

PDIM

LED Life Time LT 80,000 100,000 -- h *5), *6)

(6/25)

Page 7

*1) Power and signals sequence:

90% 90%

VL

10%

t1 t2 t6

PDIM

BLEN

t4

12V(Typ)

20 ≤ t1 [ms] 100 ≤ t4 [ms]

0 ≤ t2 [ms] 0 ≤ t5 [ms]

0 ≤ t3 [ms] 1 ≤ t6 [ms]

VL-dip conditions:

1) When 9.72 V

VL < 10.8 V, td ≤ 10 ms

≤

2) When VL < 9.72V

VL-dip conditions should also follow the power and signals sequence.

t5t3

VL

10.8 V

9.72 V

td

*2) Includes rush current. PL≠VL×IL

*3) Lower frequency causes the flicker or the image breaking of motion picture.

Depending on the PDIM signal integrity (jitter etc.), the flicker may be visible. Please evaluate in

advance.

The dimming ratio (D) can be calculated by following equation:

D = f

PDIM

× t

. Therefore, the minimum dimming ratio is f

PDIM

PDIM

× t

PDIM(min)

*4) Fuse

Parameter Fuse Type Name Supplier Remark

VL F0603HI2000V032T AEM *)

*) The power supply capacity should be designed to be more than the fusing current.

*5) LED life time is defined as the time when the brightness becomes 50% of the initial value.

*6) The life time of the backlight depends on the ambient temperature. The life time will decrease

under high temperature.

(7/25)

Page 8

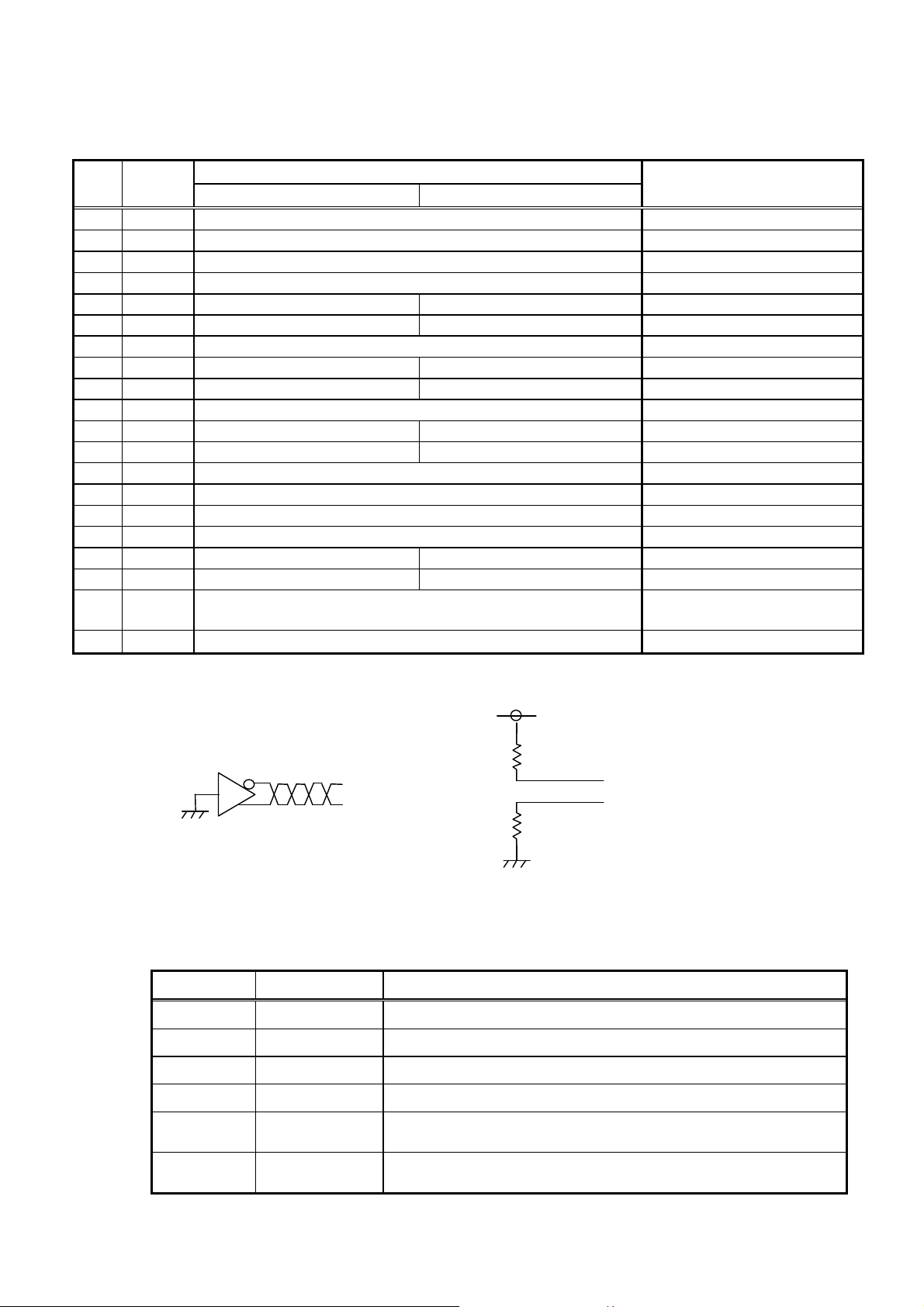

5. INTERFACE PIN CONNECTION

V

(1) CN 1(Interface Signal)

Used connector: MSB240420(STM)

Corresponding connector: DF14-20S-1.25C(Hirose)

Pin

No.

Symbol

1 VCC

2 VCC

3 GND

4 GND

5

Link 0−

Function (ISP 6 bit compatibility mode)

6 bit input 8 bit input

+3.3 V Power supply

+3.3 V Power supply

GND

GND

R0, R1, R2, R3, R4, R5, G0 R2, R3, R4, R5, R6, R7, G2

Function (ISP 8 bit

compatibility mode)

←

←

←

←

R0, R1, R2, R3, R4, R5, G0

6 Link 0+ R0, R1, R2, R3, R4, R5, G0 R2, R3, R4, R5, R6, R7, G2 R0, R1, R2, R3, R4, R5, G0

7 GND

8

Link 1−

G1, G2, G3, G4, G5, B0, B1 G3, G4, G5, G6, G7, B2, B3

GND

←

G1, G2, G3, G4, G5, B0, B1

9 Link 1+ G1, G2, G3, G4, G5, B0, B1 G3, G4, G5, G6, G7, B2, B3 G1, G2, G3, G4, G5, B0, B1

10 GND

11

Link 2−

B2, B3, B4, B5, DENA B4, B5, B6, B7, DENA

GND

←

B2, B3, B4, B5, DENA

12 Link 2+ B2, B3, B4, B5, DENA B4, B5, B6, B7, DENA B2, B3, B4, B5, DENA

13 GND

14

CLKIN− Clock − ←

15 CLKIN+

16 GND

17

Link3−

See: *2) R0, R1, G0, G1, B0, B1

GND

Clock +

GND

←

←

←

R6, R7, G6, G7, B6, B7

18 Link3+ See: *2) R0, R1, G0, G1, B0, B1 R6, R7, G6, G7, B6, B7

19 MODE Low=ISP 6 bit compatibility mode

20 GND

GND

High=ISP

8 bit compatibility mode

←

*1) Metal frame is connected to signal GND.

*2) Recommended wiring of Pin 17,18 (6 bit input)

LVDS

transmitter

(2) CN 2(Backlight)

Backlight-side connector: CR03-P06H2B-2 (CONNTEK)

Corresponding connector: CR03-S06C3 (CONNTEK), FI-S6S (JAE)

Pin No.: The left side pin is No.1.

Pin No. Symbol Function

1 VL Power Supply Input Voltage

2 VL Power Supply Input Voltage

3 GND GND

4 GND GND

5 BLEN

6 V

*1) BLEN is NOT designed for dimming.

LOW data

PDIM

Pin 17

Pin 18

CC

680

Ω

Pin 17

or

620

Ω

Pin 18

Backlight ON-OFF

(High: ON, Low: OFF)

Light Dimming Control (PWM) Input Voltage

(High active)

(8/25)

Page 9

(3) ISP data mapping

a. ISP 6 bit compatibility mode(6 bit input)

CLKIN+/-

Link0+/-

Link1+/-

Link2+/-

b. ISP 6 bit compatibility mode(8 bit input)

CLKIN+/-

Link0+/-

Link1+/-

1CLK

G0 R5 R4 R3 R2 R0

B1 B0 G5 G4 G3 G1

DENA

B5 B4 B2

G2 R7 R6 R5 R4 R2

B3 B2 G7 G6 G5 G3

R1

G2

B3

1CLK

R3

G4

Link2+/-

Link3+/-

c. ISP 8 bit compatibility mode

CLKIN+/-

Link0+/-

Link1+/-

Link2+/-

Link3+/-

DENA

B7 B6 B4

B1 B0 G1 G0 R0

B5

R1

1CLK

G0

B1

DENA

R5

B0

B7

R4

G5

B6

R3

G4

B5

G7

R2

G3

B4

G6

R1

G2

B3

R7

R0

G1

B2

R6

(9/25)

Page 10

6. INTERFACE TIMING

LVDS transmitter input signal

(1) Timing Specifications

ITEM SYMBOL MIN TYP MAX UNIT

DCLK

Frequency f

Period t

Active Time t

Blanking Time t

CLK

CLK

HA

HB

50 65 80 MHz

12.5 15.4 20 ns

1024 1024 1024 t

20 320 -- t

Horizontal

DENA

Frequency f

Period t

Active Time t

Blanking Time t

H

H

VA

VB

42.4 48.4 60 kHz

16.6 20.7 23.6

768 768 768 t

3 38 -- t

Vertical

Frequency f

Period t

V

V

55 60 75 Hz

13.3 16.7 18.2 ms

[Note]

1) DENA (Data Enable) should always be positive polarity as shown in the timing specification.

2) DCLK should appear during all invalid period.

3) LVDS timing follows the timing specifications of LVDS receiver IC: THC63LVDF84B(Thine).

4) In case of blanking time fluctuation, please satisfy following condition.

t

VBn

> t

VBn-1

− 3(tH)

CLK

CLK

μs

H

H

(10/25)

Page 11

(2) Timing Chart

V

V

a. Horizontal Timing Chart

DCLK

DATA

(R, G , B)

DENA

tHB

t

CLK

First Data Last Data

1 2

3Invalid Data Invalid Data

tHA

1023 1024

b. Vertical Timing Chart

LINE DATA

DENA

tVB

t

H

t

1 2 767 768 3In valid Dat a In valid Dat a

t

A

(11/25)

Page 12

(3) Color Data Assignment

a. 6 bit input

COLOR

INPUT DATA

R DATA G DATA B DATA

R5 R4 R3 R2 R1 R0 G5 G4 G3 G2 G1 G0 B5 B4 B3 B2 B1 B0

MSB LSB MSB LSB MSB LSB

BLACK 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

RED(63) 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0

GREEN(63) 0 0 0 0 0 0 1 1 1 1 1 1 0 0 0 0 0 0

BASIC BLUE(63) 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1

COLOR CYAN 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 1 1

MAGENTA 1 1 1 1 1 1 0 0 0 0 0 0 1 1 1 1 1 1

YELLOW 1 1 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0

WHITE 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

RED(1) 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0

RED(2) 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0

RED

RED(62) 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0

RED(63) 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0

GREEN(1) 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0

GREEN(2) 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0

GREEN

GREEN(62) 0 0 0 0 0 0 1 1 1 1 1 0 0 0 0 0 0 0

GREEN(63) 0 0 0 0 0 0 1 1 1 1 1 1 0 0 0 0 0 0

BLUE(1) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1

BLUE(2) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0

BLUE

BLUE(62) 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 0

BLUE(63) 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1

[Note]

1) Definition of gray scale

Color (n) --- n indicates gray scale level.

Higher n means brighter level.

2) Data

1:High, 0: Low

(12/25)

Page 13

b. 8 bit input

INPUT DATA

BASIC

COLOR

RED

GREEN

COLOR

BLACK

RED(255)

GREEN(255)

BLUE(255)

CYAN

MAGENTA

YELLOW

WHITE

RED(1)

RED(2)

RED(255)

GREEN(1)

GREEN(2)

GREEN(255)

R DATA G DATA B DATA

R7 R6 R5 R4 R3 R2 R1 R0 G7 G6 G5 G4 G3 G2 G1 G0 B7 B6 B5 B4 B3 B2 B1 B0

MSB LSB MSB LSB MSB LSB

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1

0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

1 1 1 1 1 1

1

1

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0

BLUE(1)

BLUE(2)

BLUE

BLUE(255)

[Note]

1) Definition of gray scale

Color (n) --- n indicates gray scale level.

2) Data

1:High, 0: Low

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1

Higher n means brighter level.

(13/25)

Page 14

(4) Display Position and Scan Direction

D(X,Y) shows the data number of input signal.

D(1,1) D(1024,1)

D(1,768)

D(1024,768)

(14/25)

Page 15

7. BLOCK DIAGRAM

CN1

Timing signal

Display data

Timing

Controller

G1

G2

TFT-LCD

Power

Brightness/

ON/OFF

Control

Power

I/F Connector

CN2

I/F Connector

Power

Supply

Circuit

Power

Supply

Circuit

Driver(gate)

G768

S1

S2

S3071

Driver(source)

LED B/L

S3072

(15/25)

Page 16

8. MECHANICAL SPECIFICATIONS

(1) Front Side

(Unit: mm)

(16/25)

Page 17

(2) Rear Side

(Unit: mm)

(17/25)

Page 18

9. OPTICAL CHARACTERISTICS

Ta=25°C, VCC=3.3V, VL=12.0V, Input Signals: Typ. values shown in Section 6

ITEM SYMBOL CONDITION MIN TYP MAX UNIT Remarks

Contrast Ratio CR

Luminance Lw

Luminance Uniformity

ΔLw θ

tr

Response Time

tf

Viewing

Angle

Horizontal

Vertical

θ

H

θ

V

θ

=0°, θH=0°

V

θ

=0°, θH=0°

V

=0°, θH=0°

V

θ

=0°, θH=0°

V

θ

=0°, θH=0°

V

−65~65 −80~80

CR ≥ 10

450 700 -- -- *1)*2)*4)

2

360 450 -- cd/m

*1)*4)

75 -- -- % *1)*3)*4)

-- 2 -- ms *1)*4)*5)

-- 10 -- ms *1)*4)*5)

-- ° *1)*4)

−55~55 −70~70

-- ° *1)*4)

Image sticking tis 2 h -- -- 2 s --

Red

Color Gx 0.295 0.345 0.395

Green

Coordinates

Blue

White

Rx 0.584 0.634 0.684

Ry 0.295 0.345 0.395

Gy

θ

=0°, θH=0°

V

0.545 0.595 0.645 --

*1)*4)

Bx 0.100 0.150 0.200

By 0.023 0.073 0.123

Wx 0.263 0.313 0.363

Wy 0.279 0.329 0.379

[Note]

These items are measured using SR-UL1R(TOPCON) for color coordinates, and BM-5A (TOPCON)

for others under the dark room condition. (no ambient light) after more than 20 minutes from

turning on the backlight unless noted.

Condition: V

= 1.8V ∼ 5.0V DC

PDIM

Measurement method for luminance and color coordinates is as follows.

(18/25)

Page 19

*1) Measurement Point

Contrast Ratio, Luminance, Response Time, Viewing Angle, Color Coordinates: Display Center

Luminance Uniformity: point 1∼9 shown in a figure below

384

512

*2) Definition of Contrast Ratio

CR=Luminance with all white pixels / Luminance with all black pixels

*3) Definition of Luminance Uniformity

ΔLw=[Lw(Min)/Lw(Max)]×100%

*4) Definition of Viewing Angle (θ

, θH)

V

θ

V

θ

H

Upper

(1024,768)

Left

Lower

Right

(19/25)

Page 20

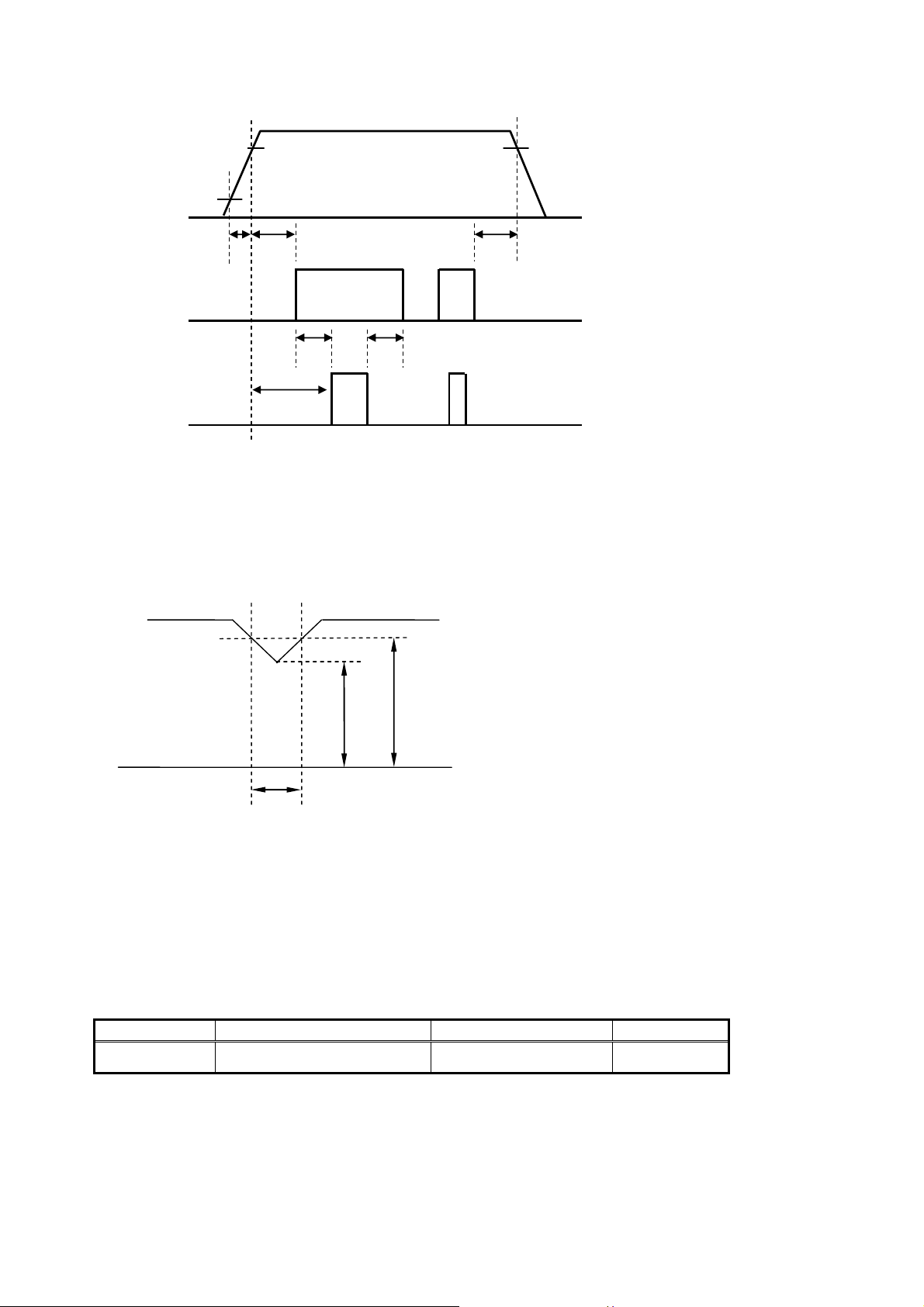

*5) Definition of Response Time

White

Luminance

tr

90 %

10 %

Black

90 %

10 %

tf

(20/25)

Page 21

10. RELIABILITY TEST CONDITION

(1) Temperature and Humidity

TEST ITEM CONDITIONS

HIGH TEMPERATURE

HIGH HUMIDITY OPERATION

HIGH TEMPERATURE OPERATION 65°C, 240 h

LOW TEMPERATURE OPERATION 0°C, 240 h

HIGH TEMPERATURE STORAGE 65°C, 240 h

LOW TEMPERATURE STORAGE

THERMAL SHOCK (NON-OPERATION)

(2) Shock & Vibration

ITEM CONDITIONS

Shock level: 1470 m/s

SHOCK

(NON-OPERATION)

Waveform: half sinusoidal wave, 2 ms

Number of shocks: one shock input in each direction of three mutually

perpendicular axes for a total of six shock inputs

2

(150G)

40°C, 90%RH, 240h

(No condensation)

−20°C, 240 h

−20°C (0.5 h) ∼ 65°C (0.5 h),

100 cycles

Vibration level: 9.8 m/s2 (1.0G)

Waveform: sinusoidal

VIBRATION

(NON-OPERATION)

(3) ESD Test

ITEM CONDITIONS

CONTACT DISCHARGE

(OPERATION)

SIGNAL PIN DISCHARGE

(NON-OPERATION)

Frequency range: 5 to 500 Hz

Frequency sweep rate: 0.5 octave /min

Duration: one sweep from 5 to 500 Hz in each of three mutually

perpendicular axis(each x,y,z axis: 1 hour, total 3 hours)

150pF, 330Ω, ±8kV, 10 times at 1 sec interval

200pF, 0Ω, ±200V, 10 times at 1 sec interval

(4) Judgment standard

The judgment of the above tests should be made as follow:

Pass: Normal display image, no damage of the display function. (ex. no line defect)

Partial transformation of the module parts should be ignored.

Fail: No display image, damage of the display function. (ex. line defect)

(21/25)

Page 22

11. OTHER FEATURE

This LCD module complies with RoHS*) directive.

*)

RoHS: Restriction of the use of certain hazardous substances in electrical and electronic

equipment

(22/25)

Page 23

12. HANDLING PRECAUTIONS FOR TFT-LCD MODULE

Please pay attention to the followings in handling TFT-LCD products;

(1) ASSEMBLY PRECAUTION

a. Please mount the LCD module by using mounting hole with a screw clamping torque less than

0.36 Nm. Please do not bend or wrench the LCD module in assembling. Please do not drop,

bend or twist the LCD module in handling.

b. Please design display housing in accordance with the following guide lines.

(a) Housing case must be designed carefully so as not to put stresses on LCD and not to

wrench module.

(b) Under high temperature environment, performance and life time of LED may heavily

shorten. When you design with our LCD product, please consider radiating heat and

ventilation for good heat management.

(c) Keep sufficient clearance between LCD module back surface and housing when the LCD

module is mounted. Approximately 1.0mm of the clearance in the design is recommended

taking into account the tolerance of LCD module thickness and mounting structure height

on the housing.

(d) When some parts, such as, FPC cable and ferrite plate, are installed underneath the LCD

module, still sufficient clearance is required, such as 0.5mm. This clearance is, especially, to

be reconsidered when the additional parts are implemented for EMI countermeasure.

(e) Keep sufficient clearance between LCD module and the others parts, such as inverter and

speaker so as not to interfere the LCD module. Approximately 1.0 mm of the clearance in

the design is recommended.

(f) To avoid local elevation/decrease of temperature, considering location of heating element,

heat release, thermal design should be done.

c. Please do not push or scratch LCD panel surface with anything hard. And do not soil LCD

panel surface by touching with bare hands. (Polarizer film, surface of LCD panel is easy to be

flawed.)

d. Please wipe off LCD panel surface with absorbent cotton or soft cloth in case of it being soiled.

e. Please wipe off drops of adhesives like saliva and water on LCD panel surface immediately.

They might damage to cause panel surface variation and color change.

f. Please do not take a LCD module to pieces and reconstruct it. Resolving and reconstructing

modules may cause them not to work well.

g. Please do not touch metal frames with bare hands and soiled gloves. A color change of the metal

frames can happen during a long preservation of soiled LCD modules.

h. Please handle metal frame carefully because edge of metal frame is very sharp.

(23/25)

Page 24

i. Please connect the metal frame of LCD module to GND in order to minimize the effect of

external noise and EMI.

j. Be sure to connect the cables and the connecters correctly.

(2) OPERATING PRECAUTIONS

a. Please be sure to turn off the power supply before connecting and disconnecting signal input

cable.

b. Please do not change variable resistance settings in LCD module. They are adjusted to the

most suitable value. If they are changed, it might happen LCD does not satisfy the

characteristics specification.

c. The interface signal speed is very high. Please pay attention to transmission line design and

other high speed signal precautions to satisfy signal specification.

d. Condensation might happen on the surface and inside of LCD module in case of sudden change

of ambient temperature. Please take care so as not to cause any damage mentioned on (1)-d.

e. Please pay attention not to display the same pattern for very long time. Image sticking might

happen on LCD. Although image sticking may disappear as the operation time proceeds,

screen saver function is recommended not to cause image sticking.

f. Please obey the same safe instructions as ones being prepared for ordinary electronic products.

(3) PRECAUTIONS WITH ELECTROSTATICS

a. This LCD module use CMOS-IC on circuit board and TFT-LCD panel, and so it is easy to be

affected by electrostatics. Please be careful with electrostatics by the way of your body

connecting to the ground and so on.

b. Please remove protection film very slowly from the surface of LCD module to prevent from

electrostatics occurrence.

(4) STORAGE PRECAUTIONS

LCD should be stored in the room temperature environment with normal humidity. The LCD

inventory should be processed by first-in first-out method.

(5) SAFETY PRECAUTIONS

a. When you waste damaged or unnecessary LCDs, it is recommended to crush LCDs into pieces

and wash them off with solvents such as acetone and ethanol, which should later be burned.

b. If any liquid leaks out of a damaged glass cell and comes in contact with the hands, wash off

thoroughly with soap and water.

(24/25)

Page 25

(6) OTHERS

a. A strong incident light into LCD panel may cause deterioration to polarizer film, color filter,

and other materials, which will degrade the quality of display characteristics. Please do not

expose LCD module under strong Ultraviolet rays for a long time.

b. Please pay attention to a panel side of LCD module not to contact with other materials in

preserving it alone.

c. For the packaging box handling, please see and obey with the packaging specification

datasheet.

(25/25)

Page 26

Technical Document

LCD Specification

LCD Group

NORTH AMERICA

Sharp Microelectronics of the Americas

5700 NW Pacific Rim Blvd.

Camas, WA 98607, U.S.A.

Phone: (1) 360-834-8700

Fax: (1) 360-834-8903

www.sharpsma.com

TAIWAN

Sharp Electronic Components

(Taiwan) Corporation

8F-A, No. 16, Sec. 4, Nanking E. Rd.

Taipei, Taiwan, Republic of China

Phone: (886) 2-2577-7341

Fax: (886) 2-2577-7326/2-2577-7328

CHINA

Sharp Microelectronics of China

(Shanghai) Co., Ltd.

28 Xin Jin Qiao Road King Tower 16F

Pudong Shanghai, 201206 P.R. China

Phone: (86) 21-5854-7710/21-5834-6056

Fax: (86) 21-5854-4340/21-5834-6057

Head Office:

No. 360, Bashen Road,

Xin Development Bldg. 22

Waigaoqiao Free Trade Zone Shanghai

200131 P.R. China

Email: smc@china.global.sharp.co.jp

EUROPE

Sharp Microelectronics Europe

Division of Sharp Electronics (Europe) GmbH

Sonninstrasse 3

20097 Hamburg, Germany

Phone: 49 (0)180 507 35 07

Fax: (49) 40-2376-2232

www.sharpsme.com

SINGAPORE

Sharp Electronics (Singapore) PTE., Ltd.

438A, Alexandra Road, #05-01/02

Alexandra Technopark,

Singapore 119967

Phone: (65) 271-3566

Fax: (65) 271-3855

KOREA

Sharp Electronic Components

(Korea) Corporation

RM 501 Geosung B/D, 541

Dohwa-dong, Mapo-ku

Seoul 121-701, Korea

Phone: (82) 2-711-5813 ~ 8

Fax: (82) 2-711-5819

JAPAN

Sharp Corporation

Electronic Components & Devices

22-22 Nagaike-cho, Abeno-Ku

Osaka 545-8522, Japan

Phone: (81) 6-6621-1221

Fax: (81) 6117-725300/6117-725301

www.sharp-world.com

HONG KONG

Sharp-Roxy (Hong Kong) Ltd.

Level 26, Tower 1, Kowloon Commerce Centre,

No. 51, Kwai Cheong Road, Kwai Chung,

New Territories, Hong Kong

Phone: (852) 28229311

Fax: (852) 28660779

www.sharp.com.hk

Shenzhen Representative Office:

Room 602-603, 6/F.,

International Chamber of Commerce Tower,

168 Fuhua Rd. 3, CBD,

Futian District, Shenzhen 518048,

Guangdong, P.R. China

Phone: (86) 755-88313505

Fax: (86) 755-88313515

SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

Suggested applications (if any) are for standard use; See Important Restrictions for

limitations on special applications. See Limited Warranty for SHARP’s product warranty.

The Limited Warranty is in lieu, and exclusive of, all other warranties, express or implied.

ALL EXPRESS AN D IMPLIED WARRANTI ES, INCLUDING THE WARRANTIES OF

MERCHANTABILITY, FITNESS FOR USE AND FITN ESS FOR A PARTICULAR PU RPOSE,

ARE SPECI FICALLY EXCLUDED. In no event will SHARP be liable, or responsible in

any way, for any incidental or consequential economic or property damage.

Loading...

Loading...