Page 1

No.

DATE Jul. 29. 2005

LCP-05019A

TECHNICAL LITERATURE

FOR

TFT - LCD module

MODEL No.

LQ035Q7DH03

TENTATIVE

The technical literature is subject to change without notice.

So , please contact Sharp or its representative before designing

your product based on this literature.

SHARP CORPORATION

MOBILE LIQUID CRYSTAL DISPLAY GROUP

Page 2

RECORDS OF REVISION

MODEL No:LQ035Q7DH03

SPEC No :LCP-05019

NO. PAGE SUMMARY NOTE

2005.6.10 LCP-05019 - - 1 st Issue

2005.7.29 LCP-05019A 3,16 Fitting CN for ROHS Change

Page 3

LCP-05019-1

NOTICE

This publication is the proprietary of SHARP and is copyrighted, with all rights reserved. Under the copyright

laws, no part of this publication may be reproduced or transmitted in any form or by any means, electronic or

mechanical for any purpose, in whole or in part, without the express written permission of SHARP. Express

written permission is also required before any use of this publication may be made by a third party.

The application circuit examples in this publication are provided to explain the representative applications of

SHARP's devices and are not intended to guarantee any circuit design or permit any industrial property right or

other rights to be executed. SHARP takes no responsibility for any problems related to any industrial property

right or a third party resulting from the use of SHARP's devices, except for those resulting directly from device

manufacturing processes.

In the absence of confirmation by device specification sheets, SHARP takes no responsibility for any defects that

occur in equipment using any of SHARP's devices, shown in catalogs, data books, etc. Contact SHARP in order to

obtain the latest device specification sheets before using any SHARP's device.

SHARP reserves the right to make changes in the specifications, characteristics, data, materials, structures and

other contents described herein at any time without notice in order to improve design or reliability. Contact SHARP

in order to obtain the latest specification sheets before using any SHARP's device. Manufacturing locations are also

subject to change without notice.

Observe the following points when using any device in this publication. SHARP takes no responsibility for

damage caused by improper use of the devices.

The devices in this publication are designed for use in general electronic equipment designs, such as:

・Personal computers ・Office automation ・Telecommunication equipment

・Test and measurement equipment ・Industrial control

・Audio visual and multimedia equipment ・Consumer electronics

The appropriate design measures should be taken to ensure reliability and safety when SHARP's

devices are used for equipment such as:

・Transportation control and safety equipment(i.e., aircraft, trains, automobiles, etc.)

・Traffic signals ・Gas leakage sensor breakers

・Alarm equipment ・Various safety devices etc.

SHARP's devices shall not be used for equipment that requires extremely high level of reliability,

such as:

・Military and space applications ・Nuclear power control equipment

・Medical equipment for life support

Contact a SHARP representative, in advance, when intending to use SHARP's devices for any "specific"

applications other than those recommended by SHARP.

Contact and consult with a SHARP representative if there are any questions about the contents of this

publication.

Page 4

LCP-05019-2

(1) Application

This specification applies to LQ035Q7DH03

(2) Overview

This module is a color active matrix LCD module incorporating amorphous silicon TFT (Thin Film

Transistor), named AD-TFT (Advanced TFT). It is practicable in both transmissive-type and reflectiontype modes. It is composed of a color TFT-LCD panel, driver ICs, an FPC, a back light, and a back sealed

casing. It isn’t composed control circuit. Graphics and texts can be displayed on a 240×3×320 dots panel

with 262,144 colors by supplying.

Optimum view angle is 6 o’clock. An inverted display mode is selective in the vertical or the horizontal

direction.

(3)Mechanical specifications

Table 1

Parameter Specifications Units Remarks

Screen size (Diagonal)

Display active area

Pixel format

Pixel pitch

Pixel configuration R,G,B vertical stripe

Unit outline dimension

Mass T.B.D. g TYP.

Surface hardness 3H

【Note 3-1】

Excluding protrusion. Including FPC cover portion

Excluding protrusion. For detailed measurements and tolerances, please refer to Fig. 1.

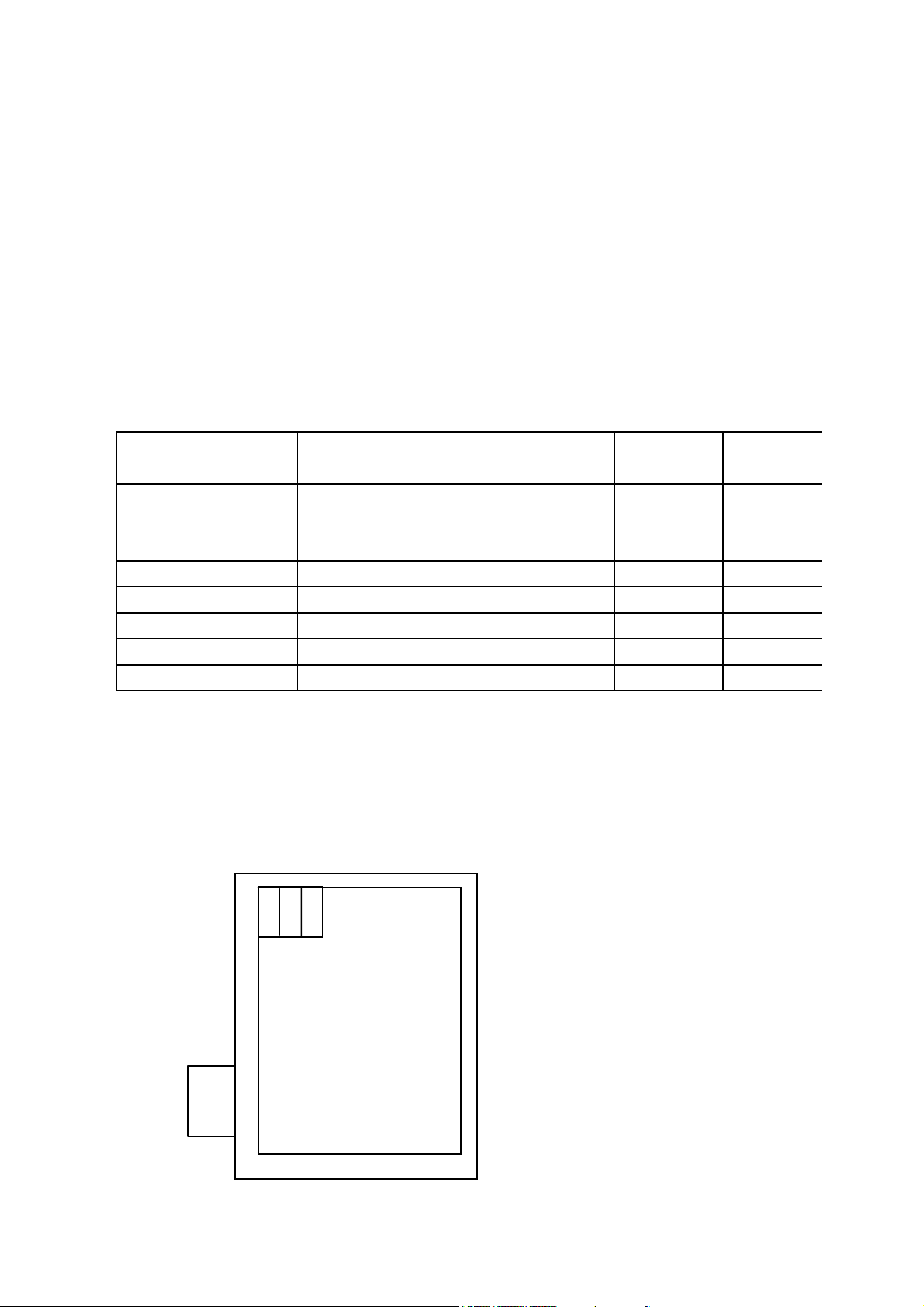

(4)Pixel configuration

8.9 [3.52”] Diagonal

53.64(H)×71.52(V)

240(H)×320(V)

(1 pixel = R+G+B dots)

0.2235(H)×0.2235(V)

65.0(W)×86.2(H)×3.2(D)

cm

mm

pixels

mm

mm

【Note3-1】

FPC

R G B

(240,1)

(1,1)

Display area

(1,320) (240,320)

Page 5

LCP-05019-3

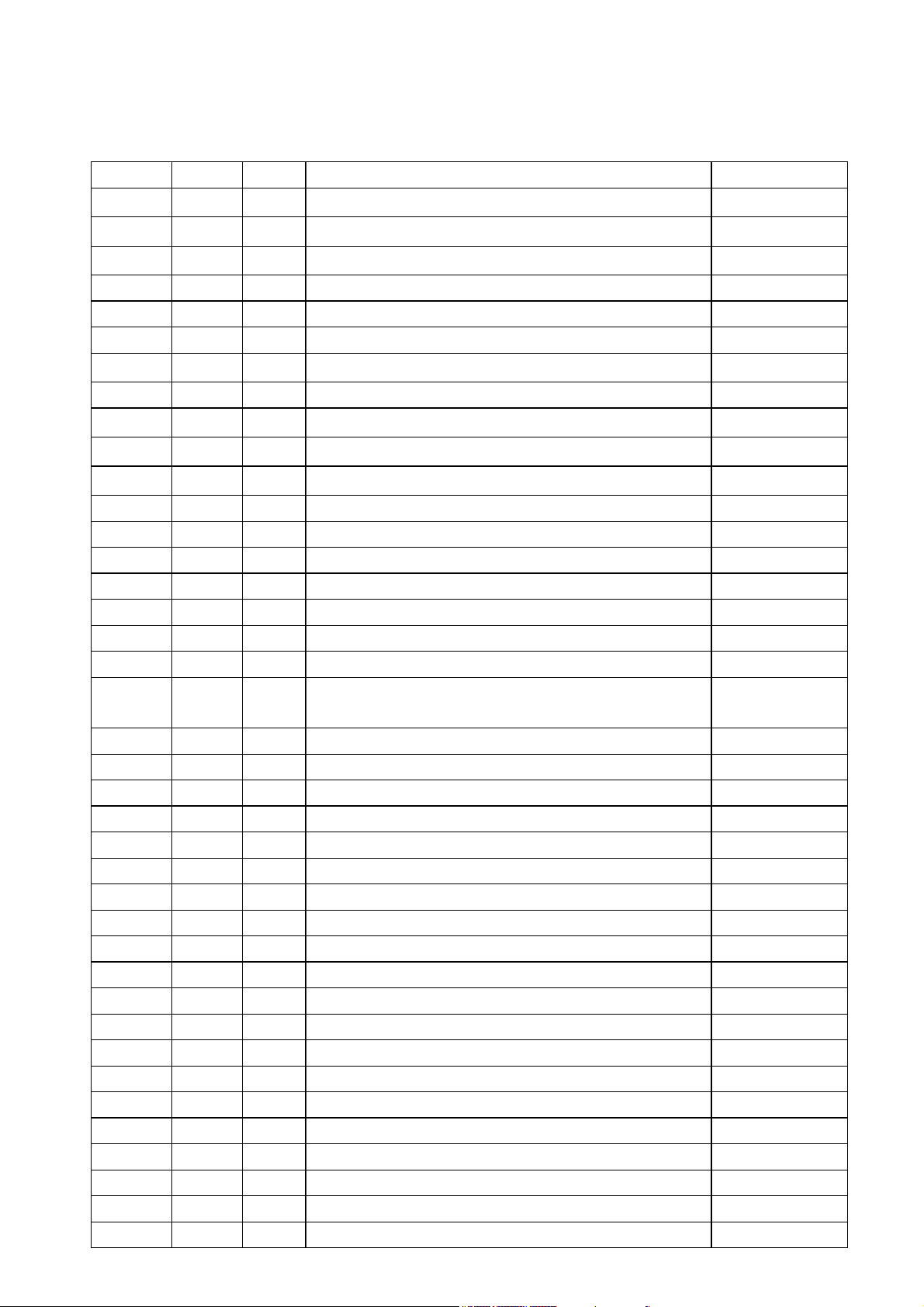

(5)Input/Output terminal

5-1)TFT-LCD panel driving section

Table2 Recommendation CN:FH12-50S-0.5SH(55)(HIROSE)

Pin No. Symbol I/O Description Remarks

1

2

VL1 I Power supply for LED (High voltage)

NC

-

3

4 VEE

5 VSHD

6 DGND

7 CLS I

8 DGND

9

10

11

12 VDD

13 VCOM I Common electrode driving signal

14 DGND

15 SPR I/O Sampling start signal

16 DGND

17 VSHA

18 LBR I Selection for horizontal scanning direction

19 PS I Power save signal

20 REV I reverse control signal

21 DGND

22 B5 I BLUE data signal(MSB)

23 B4 I BLUE data signal

24 B3 I BLUE data signal

25 B2 I BLUE data signal

26 B1 I BLUE data signal

27 B0 I BLUE data signal(LSB)

28 LP I Data latch signal of source driver

29 DGND

30 SPL I/O Sampling start signal

31 DGND

32 DCLK I Data sampling clock signal

33 DGND

34 G5 I GREEN data signal(MSB)

35 G4 I GREEN data signal

36 G3 I GREEN data signal

37 G2 I GREEN data signal

38 G1 I GREEN data signal

39 G0 I GREEN data signal(LSB)

VL2 I Power supply for LED (Low voltage)

-

Power supply of gate driver(low level)

-

Power supply of digital

-

Ground(digital)

Clock signal of gate driver

-

Ground(digital)

SPS I Start signal of gate driver

U/L I Selection for vertical scanning direction

MOD I Control signal of gate driver

-

Power supply of gate driver(high level)

-

Ground(digital)

-

Ground(digital)

-

Power supply(analog)

(Please don’t carry out use by “Low” fixation)

-

Ground(digital)

-

Ground(digital)

-

Ground(digital)

-

Ground(digital)

【Note5-1】

【Note5-2】

【Note5-3】

【Note5-4】

Page 6

LCP-05019-4

Pin No. Symbol I/O Description Remarks

40 DGND

41 R5 I RED data signal(MSB)

42 R4 I RED data signal

43 R3 I RED data signal

44 R2 I RED data signal

45 R1 I RED data signal

46 R0 I RED data signal(LSB)

47

AGND

48 COM O

49 DGND

50 DGND

【Note5-1】Selection for vertical scanning direction

U/L Scanning direction (Pixel configuration)

Low Normal scanning ( X , 1 )

High Inverted scanning ( X , 1)

【Note5-2】See section(7-1)-(A) ”※Cautions when you turn on or off the power supply”.

【Note5-3】Selection for horizontal scanning direction

-

Ground(digital)

-

Ground(analog)

Produce REV signal with the amplitude of

-

Ground(digital)

-

Ground(digital)

↓

( X , 320 )

↑

( X , 320)

AGND-VSHA

【Note5-4】

LBR SPL SPR Scanning direction (Pixel configuration)

High Input Output

Low Output Input

Normal scanning (1,Y) → (240,Y)

Inverted scanning (1,Y) ← (240,Y)

【Note5-4】

REV(IN)

“H” “L”

“H” “L”

COM(OUT)

VSHA

AGND

VCOM(IN)

Page 7

LCP-05019-5

(6)Absolute Maximum Ratings

Table 5

Parameter Symbol Condition Ratings Unit Remark

Power supply(source/Analog) VSHA

Power supply(source/Digital) VSHD

Power supply (gate) VDD

Power supply (gate) VDD-VEE

Input voltage (Digital) VID

Operating temperature

(panel surface)

Storage temperature

[Terminal①] MOD,U/L,SPS,CLS,SPL,R0~R5,G0~G5,B0~B5,LP,DCLK,LBR,SPR,PS,REV

【Note6-2】Humidity: 95%RH Max.(at Ta ≦ 40℃). Maximum wet-bulb temperature is less than 39℃

(at Ta > 40℃). Condensation of dew must be avoided.

Topp - -10~70 ℃ 【Note6】

Tstg - -25~70 ℃ 【Note6-2】

Ta=25℃ -0.3~+7.0

Ta=25℃ -0.3~+7.0

Ta=25℃ -0.3~+35.0

Ta=25℃ -0.3~+35.0

Ta=25℃ -0.3~VSHD+0.3

V

V

V

V

[Terminal①]

V

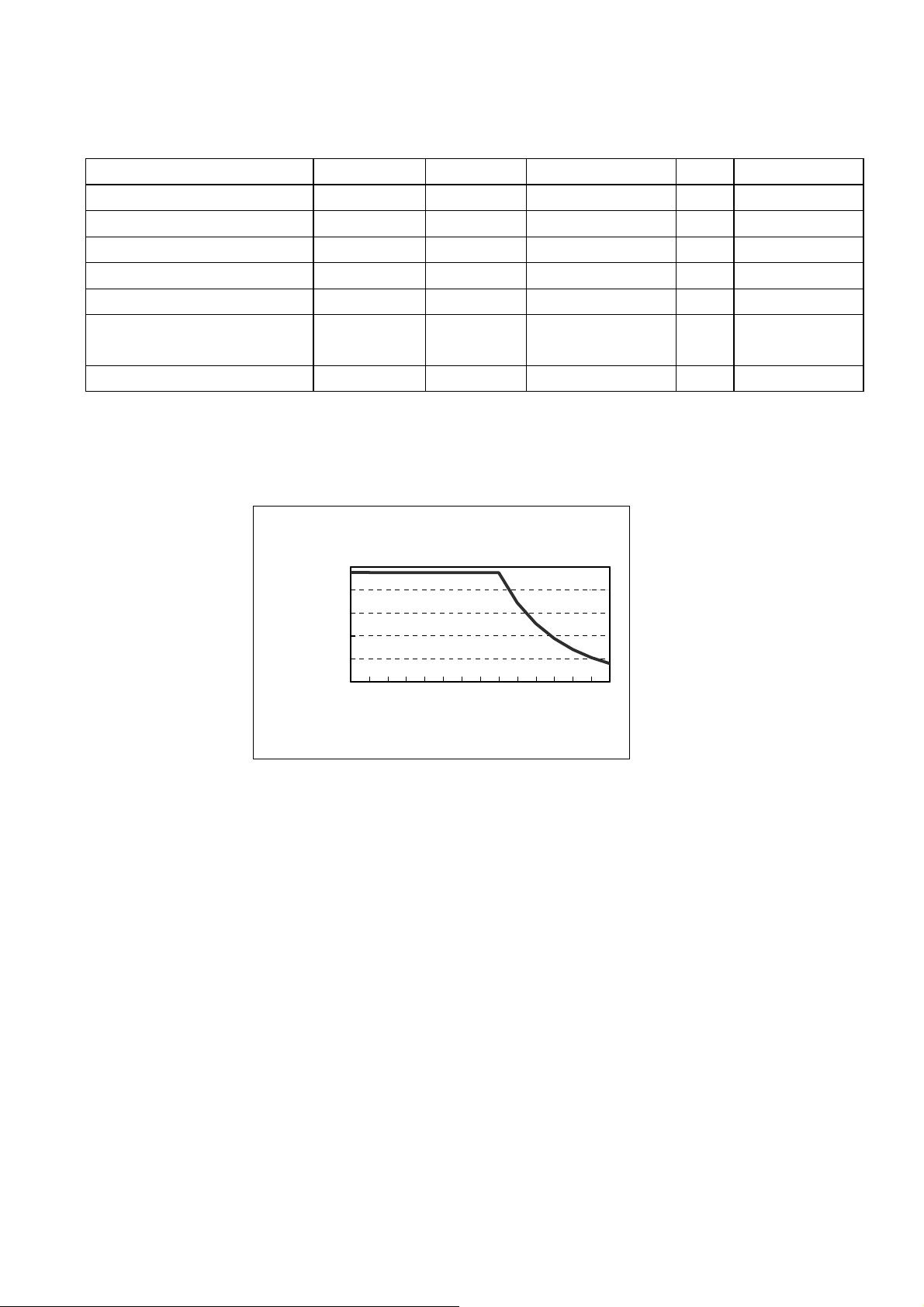

Humidity guarantee range

(Wet-bulb temperature:39℃)

100

80

60

40

20

0

Relative humidity[%]

0

10

20

30

40

50

60

Circumference temperature[℃]

The maximum humidity in the temperature

70

Page 8

LCP-05019-6

(7)Electrical characteristics

7-1)Recommended operating conditions

A) TFT-LCD panel driving section

Table 6 GND=0V

Parameter Symbol Min. Typ. Max. Unit Remarks

Supply voltage for source driver

(Analog)

Supply voltage for source driver

(Digital)

Supply voltage

High voltage VDD +14.5 +15.0 +15.5 V

for gate driver

Low voltage VEE -10.5 -10.0 -9.5 V

Input voltage for Source driver (Low) VILS GND - 0.2VSHD V

Input voltage for Source driver (High)

Input current for Source driver (Low) IILS - - 30

Input current for Source driver (High)

Input voltage for Gate driver (Low) VILG GND - 0.2VSHD V

Input voltage for Gate driver (High) VIHG 0.8VSHD - VSHD V

Input current for Gate driver (Low) IILG - - 4

Input current for Gate driver (High) IIHG - - 4

Common electrode AC component

driving signal DC component

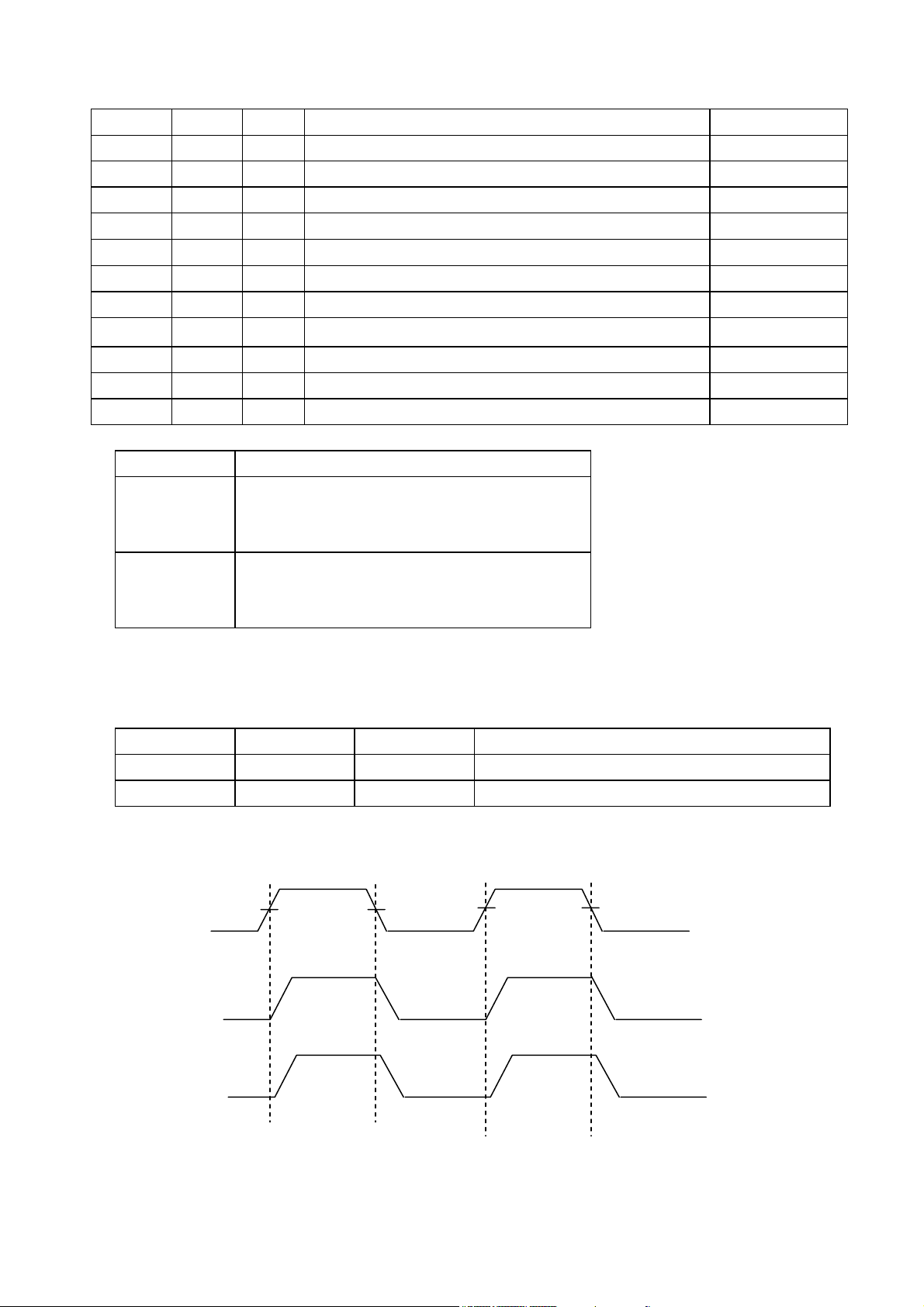

※ Cautions when you turn on or off the power supply

① Turn on or off the power supply with simultaneously or the following sequence.

② The input signal of “MOD” Terminals(Pin No.11) must be low voltage when turning on the power

supply, and it is held until more than double vertical periods after DATA is turned on completely.

After then, it must be held high voltage until turning off the power supply.(Connect Pin No.11

terminals to the same signal.)

VSHA

GND

VSHD

90%

10%

GND

GND

0≦T1

10%

2V≦Tmod

0≦T2

DATA

90%

0≦T3

MOD

10%

VSHA +4.5 +5.0 +5.5 V

VSHD +3.0 +3.3 +3.6 V

VIHS 0.8VSHD - VSHD V

μA 【Note 7-1】

IIHS1 - - 30

IIHS2 - - 1200

μA 【Note 7-2】

μA 【Note 7-3】

μA 【Note 7-4】

μA 【Note 7-4】

VCOMAC

VCOMDC

10%

0≦T4

VEE

-

-0.8

VDD

±2.5 ±2.6

Vp-p

+0.2 +1.2 V

90%

0≦T5

90%

0≦T6

【Note 7-1】

【Note 7-1】

【Note 7-4】

【Note 7-4】

【Note 7-5】

【Note 7-5】

90%

90%

0≦T7

0≦T8

10%

10%

Page 9

LCP-05019-7

【Note 7-1】DCLK,SPL,SPR,LBR,LP,PS,REV,R0~R5,G0~G5 and B0~B5 terminals are applied.

【Note 7-2】DCLK,SPL,SPR,LBR,LP,REV,R0~R5,G0~G5 and B0~B5 terminals are applied.

【Note 7-3】PS terminal is applied.

【Note 7-4】MOD,CLS,SPS and U/L terminals are applied.

【Note 7-5】VCOMAC should be alternated on VCOMDC every 1 horizontal period and 1 vertical period.

VCOMDC bias is adjusted so as to minimize flicker or maximum contrast every each

module.

B) Back light driving section

Table 7 Ta=25℃

Parameter Symbol MIN TYP MAX Units Remarks terminal

LED voltage VL

LED current IL

Power consumption WL

【Note 7-6】Calculated reference value(IL×VL)

-

-

-

21.6

20 22 mA

0.432

-

-

V

W

【Note 7-6】

Page 10

LCP-05019-8

7-2) Timing Characteristics of input signals

Table 8 AC Characteristics (1) (VSHA=+5V, VSHD=+3.3V, Ta=25℃)

Parameter Symbol Min. Typ. Max. Unit Remark

Clock frequency of source driver fCK 4.5

Rising time of clock Tcr

Falling time of clock Tcf

Pulse width (High level) Tcwh 40

Pulse width (Low level) Tcwl 40

Frequency of start pulse fsp 16.5

Setup time of start pulse Tsusp 15

Source

driver

Set up time of data Tsud 15

Hold time of data Thd 10

Gate

driver

Vcom Setup time of Vcom Tsuvcom 0

Hold time of Vcom Thvcom 1

【Note 7-7】There must be only one up-edge of DCLK (includes Tsusp and Thsp time) in the period of

SPL=”Hi”.

Hold time of start pulse Thsp 10

Pulse width of start pulse Twsp

Setup time of latch pulse Tsulp 20

Hold time of latch pulse Thlp 20

Pulse width of latch pulse Twlp 60

Setup time of PS Tsups 0

Setup time of PS Tsulps 1

Hold time of PS Thps 0

Hold time of PS Thlps 30

Clock frequency fcls 16.5

Pulse width of clock(Low) Twlcls 5

Pulse width of clock(High) Twhcls 30

Rising time of clock Trcls

Falling time of clock Tfcls

Setup time of clock Tsucls 3

Hold time of clock Thcls 0

Frequency of start pulse fsps 58

Setup time of start pulse Tsusps 100

Hold time of start pulse Thsps 300

Rising time of start pulse Trsps

Falling

time of start pulse Tfsps

- -

- -

- -

- -

- -

- -

- -

-

- -

- -

-

- -

- -

- -

- -

- -

- - μs

- - μs

- - μs

- -

- -

- -

-

-

- - μs

- - μs

- - μs

-

- -

- -

- - μs

- - μs

6.8 MHz

20 ns

20 ns

ns

ns

28 kHz

ns

ns

1.5/fCK ns

ns

ns LP

ns

ns

ns

ns

28 kHz

(1/fcls)-30

100 ns

100 ns

86 Hz

100 ns

100 ns

μs

ns

ns

DCLK

SPL,SPR

【Note 7-7】

PS

R0~R5,G0~G5

,B0~B5

CLS

SPS

Vcom

Page 11

DCLK

LP

SPL

R0~R5

G0~G5

B0~B5

CLS

PS

VCOM

T

wlp

Tch Tcr

80%

20%

T

T

T

T

hcls

sulp

susp

T

T

sups

hsp

T

wsp

T

T

80%

1

Thd

sud

(1,n) (2,n) (240,n)

80%

2 240

20%

T

cwl Tcwh

Twh

hps

Fig.(a) Horizontal timing chart

LCP-05019-9

T

Twl

wlp

(1,n+1)

Thlps

T

hlp

sucls

Tsulps

T

T

hvcom

suvcom

Page 12

CLS

SPS

R0~R5

G0~G5

B0~B5

1

fcls

T

T

wlcls

T

fsps

whcls

80%

20%

T

80% 80%

susps

20%

1

20%

Non-display period

T

20% 20%

T

hsps

20%

T

rsps

rcls

T

80%

2

fcls

LCP-05019-10

8 9

1

fsps

(1~240,1) (1~240,2) (1~240,320)

LINE1

LINE2

Fig.(b) Vertical timing chart

327

LINE320

1

Non-display period

2

Page 13

LCP-05019-11

7-3) Power consumption

Measurement condition: SPS=60Hz,CLS=15.73kHz,SPL=15.73kHz,DCLK=6.3MHz

The term of PS=”Lo” in one horizontal period … 37μsec(234DCLK)

Ta=25℃

Table 9 when normal scan mode

Parameter Sym Conditions MIN TYP MAX Unit Remarks

【Note 7-8】

Source

current

Gate

current

【Note 7-8】Vertical stripe pattern alternating 21 gray scale (GS21) with 42 gray scale (GS42) every 1 dot.

【Note 7-9】64-Gray-bar vertical pattern (GS0 ~ GS63 for horizontal way)

Analog ISHA VSHA=+5.0V

Digital ISHD VSHD=+3.3V

High IDD VDD=+15.0V

Low IEE VEE=-10.0V

-

-

-

-

3.0 6.0

1.5 3.0

0.05 0.10

-0.05 -0.10

mA

mA

mA

mA

【Note 7-8】

【Note 7-9】

【Note 7-9】

Page 14

LCP-05019-12

y

y

g

y

(8)Input Signals, Basic Display Color and Gray Scale of Each Color

Table 10

Colors & Data signal

Gray scale Gray

Scale

R0 R1 R2 R3 R4 R5 G0 G1 G2 G3 G4 G5 B0 B1 B2 B3 B4 B5

Black

Blue

Basic color

Green

Cyan

Red

Magenta

Yellow

White

Black GS0 0 0 0 0 0 00000000 0 0 000

Gra

Scale of red

×

Darker GS2 0 1 0 0 0 00000000 0 0 000

×

Ø

Brighter GS61 1 0 1 1 1 10000000 0 0 000

Ø

Red GS63 1 1 1 1 1 10000000 0 0 000

-

-

-

-

-

-

-

-

GS1 1 0 0 0 0 00000000 0 0 000

È

È

GS62 0 1 1 1 1 10000000 0 0 000

0 0 0 0 0 00000000 0 0 000

0 0 0 0 0 00000001 1 1 111

0 0 0 0 0 01111110 0 0 000

0 0 0 0 0 01111111 1 1 111

1 1 1 1 1 10000000 0 0 000

1 1 1 1 1 10000001 1 1 111

1 1 1 1 1 11111110 0 0 000

1 1 1 1 1 11111111 1 1 111

È

È

È

È

È

È

Black GS0 0 0 0 0 0 00000000 0 0 000

Gra

Scale of

reen

Gra

Scale of bleu

×

Darker GS2 0 0 0 0 0 00100000 0 0 000

×

Ø

Brighter GS61 0 0 0 0 0 01011110 0 0 000

Ø

Green GS63 0 0 0 0 0 01111110 0 0 000

Black GS0 0 0 0 0 0 00000000 0 0 000

×

Darker GS2 0 0 0 0 0 00000000 1 0 000

×

Ø

Brighter GS61 0 0 0 0 0 00000001 0 1 111

Ø

Bleu GS63 0 0 0 0 0 00000001 1 1 111

GS1 0 0 0 0 0 01000000 0 0 000

È

È

GS62 0 0 0 0 0 00111110 0 0 000

GS1 0 0 0 0 0 00000001 0 0 000

È

È

GS62 0 0 0 0 0 00000000 1 1 111

È

È

È

È

È

È

È

È

È

È

È

È

0 :Low level voltage 1 :High level voltage

Each basic color can be displayed in 64 gray scales from 6 bit data signals. According to the combination of

total 18 bit data signals, the 262,144-color display can be achieved on the screen.

Page 15

LCP-05019-13

(9)Optical characteristics

9-1)Not driving the Back light condition

Table 11

Parameter Symbol Condition Min Typ Max Unit Remarks

Viewing angle

range

Contrast ratio CRmax

Response Rise τ r - 30 60 ms [Note 9-3]

time Fall τ d - 50 100 ms

White chromaticity x

y

Red chromaticity x

y

Green chromaticity x

y

Blue chromaticity x

y

Reflection ratio R

θ21,22 35 50 - degree [Note 9-1,2]

θ11 CR≥1.5 35 50 - degree

θ12 35 50 - degree

θ =0

°

θ =0

°

θ =0

°

(VSHA=+5V, VSHD=+3.3V, VDD=+15V, VEE=-10V ,Ta=25℃)

2 3 - [Note 9-2,4]

(0.273) (0.323) (0.373)

(0.303) (0.353) (0.403)

(0.310) (0.360) (0.410)

(0.267) (0.317) (0.367)

(0.257) (0.307) (0.357)

(0.322) (0.372) (0.422)

(0.194) (0.244) (0.294)

(0.222) (0.272) (0.322)

2.5 4 - % [Note 9-5]

[Note 9-4]

* The measuring method of the optical characteristics is shown by the following figure.

* A measurement device is Otsuka luminance meter LCD5000.(With the diffusion reflection unit.)

Chemical coated surface

(Optical diffusion treatment)

Normal line

Photodetector

(with luminosity correction system)

A diffusion beam

A diffusion beam

(through an optical fiber)

A beam

Module

Center of display

Measuring method (a) for optical characteristics

Page 16

LCP-05019-14

9-2)Driving the Back light condition

Table 12

Parameter Symbol Condition Min Typ Max Unit Remarks

Viewing angle

range

Contrast ratio Crmax

Response Rise τ r - 30 60 ms [Note 9-3]

time Fall τ d - 50 100 ms

White chromaticity x

y

Red chromaticity x

y

Green chromaticity x

y

Blue chromaticity x

y

Brightness Y

LED life time LL IL=15mA

θ21,22 30 40 - degree [Note 9-1,2,6]

θ11 CR≥2 40 50 - degree

θ12 30 40 - degree

θ = 0

θ = 0

(VSHA=+5V, VSHD=+3.3V, VDD=+15V, VEE=-10V ,Ta=25℃)

°

°

50 80 - [Note 9-2]

(0.250) (0.300) (0.350)

(0.280) (0.330) (0.380)

(0.470) (0.520) (0.570)

(0.280) (0.330) (0.380)

(0.280) (0.330) (0.380)

(0.430) (0.480) (0.530)

(0.110) (0.160) (0.210)

(0.140) (0.190) (0.240)

110 150 - cd/m2 I

-

5,000

-

hour [Note 9-7]

L=18mA

* The measuring method of the optical characteristics is shown by the following figure.

* A measurement device is TOPCON luminance meter BM-5(A).(Viewing cone 1)

Photodetector(including luminosity facter)

LCD modu le

Center

Measuring method (c) for optical characteristics

Page 17

[Note 9-1] Viewing angle range is defined as follows.

LCP-05019-15

Normal line

θ

12

θ

21

6o’clock direction

θ

θ22

11

Definition for viewing angle

[Note 9-2] Definition of contrast ratio:

The contrast ratio is defined as follows:

Photodetecter output with all pixels white(GS63)

Contrast ratio(CR)=

Photodetecter output with all pixels black(GS0)

V

COMAC=5.0Vp-p

[Note 9-3] Definition of response time:

The response time is defined as the following figure and shall be measured by switching

the input signal for "black" and "white".

Black WhiteWhite

100%

90%

Photodetecter output

(arbitrary unit)

10%

0%

r

τ

Time

d

τ

[Note 9-4] A measurement device is Minolta CM-2002.

[Note 9-5] Definition of reflecti on rat i o

Reflection ratio =

Light detected level of the reflection by the LCD module

Light detected level of the reflection by the standard white board

[Note 9-6] A measurement device is ELDIM EZContrast

[Note 9-7] This is the reference value. The White-LED life time is defind as a time when brightness not to become

under 50% of the original value(at Ta=25 ℃)

Page 18

LCP-05019-16

(10) Display quality

The display quality of the color TFT-LCD module shall be in compliance with

the Incoming Inspection Standards for TFT-LCD.

(11)Mechanical characteristics

11-1) External appearance

See Fig. 1

11-2) FPC (for LCD panel) characteristics

(1)Specific connector

FH12-50S-0.5SH(55)(HIROSE)

(2) Bending endurance of the bending slits portion

No line of the FPC is broken for the bending test (Bending radius=0.6mm and

angle=90°) in 30 cycles.

(12)Handling Precautions

12-1) Insertion and taking out of FPCs

Be sure insert and take out of the FPC into the connector of the set after turning off the power

supply on the set side.

12-2) Handling of FPCs

The FPC for LCD panel shall be bent only slit portion. The bending slit shall be bent uniformly

on the whole slit portion with bending radius larger than 0.6mm ,and only inner side (back side

of the module). Don’t bend it outer side (display surface side).

Don’t give the FPCs too large force, for example, hanging the module with holding FPC.

12-3) Installation of the module

On mounting the module, be sure to fix the module on the same plane. Taking care not to warp or

twist the module.

12-4) Precautions when mounting

(1) If water droplets and oil attaches to it for a long time, discoloration and staining occurs. Wipe them off

immediately.

(2) Glass is used for the TFT-LCD panel. If it is dropped or bumped against a hard object, it may be broken.

Handle it with sufficient care.

(3) As the CMOS IC is used in this module, pay attention to static electricity when handling it. Take a

measure for grounding on the human body.

12-5) Others

(1) The liquid-crystal is deteriorated by ultraviolet rays. Do not leave it in direct sunlight and strong

ultraviolet rays for many hours.

(2) If it is kept at a temperature below the rated storage temperature, it becomes coagulated and the panel

may be broken. Also, if it is kept at a temperature above the rated storage temperature, it becomes

isotropic liquid and does not return to its original state. Therefore, it is desirable to keep it at room

temperature as much as possible.

(3) If the LCD breaks, don’t put internal liquid crystal into the mouth. When the liquid crystal sticks to the

hands, feet and clothes, wash it out immediately.

(4) Wipe off water drop or finger grease immediately. Long contact with water may cause discoloration or

spots.

(5) Observe general precautions for all electronic components.

(6) VCOM must be adjusted on condition of your final product. No adjustment causes the deterioration for

display quality.

Page 19

LCP-05019-17

(7) Static image should not be displayed more than 5 minutes in order to prevent from occurrence of

residual image.

(13)Reliability Test Conditions for TFT-LCD Module

Table 14

No. Test items Test conditions

1 High temperature storage test

2 Low temperature storage test

3 High temperature and high

humidity operating test

4 High temperature operating

test

5 Low temperature operating test

6 Electro static discharge test

Ta=+70℃ 240h

Ta=-25℃ 240h

Tp=+40℃ , 95%RH 240h

(But no condensation of dew)

Tp=+70℃ 240h

Tp=-10℃

±200V・200pF(0Ω) to Terminals(Contact)

±8kV・150pF(330Ω) to Housing bezel or TP(Contact)

±15kV・150pF(330Ω) to Housing bezel or TP(in Air)

240h

(1 time for each terminals)

7 Shock tset 980 m/s2, 6 ms

±X,±Y,±Z 3 times for each direction

(JIS C0041, A-7 Condition C)

8 Vibration test

9 Heat shock test

10 FPC Bending Test

【Note】Ta = Ambient temperature, Tp = Panel temperature

【Check items】

(a)Test No.1~9

In the standard condition, there shall be no practical problems that may

affect the display function.

(14) Others

14-1) Indication of lot number

The lot number is shown on a label. Attached location is shown in Fig.1 (Outline Dimensions).

LQ035Q7DH03 ○○○○○○○○

model No. lot No.

Frequency range: 10Hz~55Hz

Stroke: 1.5 mm Sweep: 10Hz~55Hz

X,Y,Z 2 hours for each direction (total 6 hours)

(JIS C0040,A-10 Condition A)

Ta=-25℃~+70℃ / 5 cycles

(1h) (1h)

Bending 30 times by bending radius R0.6mm and angle=90°

(LCD FPC)

Page 20

LCP-05019-18

14-2) Used Regulation of Chemical Substances Breaking Ozone Stratum

Substances with the object of regulating: CFCS, Carbon tetrachloride, Halon

1,1,1-Trichloro ethane (Methyl chloroform)

(a) This LCD module, Constructed part and Parts don’t contain the above substances.

(b) This LCD module, Constructed part and Parts don’t contain the above substances in processes of

manufacture.

14-3) If some problems arise about mentioned items in this document and other items, the user of

the TFT-LCD module and Sharp will cooperate and make efforts to solve the problems with mutual

respect and good will.

15)Forwarding form

a) Piling number of cartons : Max 20

b) Package quality in one cartons : 100pcs

c) Carton size : (T.B.D.)

d) Total mass of 1 carton filled with full modules : (T.B.D.)g

Conditions for storage.

Environment

(1)Temperature : 0~40℃

(2)Humidity : 60%RH or less (at 40℃)

No dew condensation at low temperature and high humidity.

(3)Atmosphere : Harmful gas, such as acid or alkali which bites electronic

components and/or wires, must not be detected.

(4)Period : about 3 months

(5)Opening of the package : In order to prevent the LCD module from breakdown by

electrostatic charges, please control the room humidity

over 50%RH and open the package taking sufficient

countermeasures against electrostatic charges, such as

earth, etc

Page 21

Loading...

Loading...