Page 1

Date: Oct. 31, 1995

LASER PRINTER: JX-9400/9600

[Trouble Shooting]

No. : LPE-218

TROUBLE SHOOTING PAPER JAMS.

1.Model name: JX-9400/9600 series.

2.General: One of the causes for the occurrence of the trouble, “Paper Jam” during continuous

printing operations is sometimes a malfunctioning of the P-IN sensor actuator.

When paper jams due to this cause occur, the measures described below should be

carried out to return operations to normal.

3.Cause: The P-IN sensor actuator is adjusted by the coil spring in the sensor, but the spring

sometimes becomes immovable due to hardening of the oil used during the shaping

process when the spring is manufactured. When this happens, the movement of the

actuator sometimes becomes impeded. However, even if the movement of the actuator

becomes impeded, repeated adjusting (20 - 30 times) will return it to normal, and as a

result the possibility of jams actually occurring in the markets due to this problem is

considered to be extremely small.

4.Description: When services calls from the market concerning “paper jams” are received, the P-IN

sensor should be checked as described below, to see if it is operating properly or not. If

the P-IN sensor is malfunctioning, the counter measures described below should be

carried out.

Method of Checking the P-IN Sensor.

(1)Insert a piece of paper in the manual feed opening to make the actuator of the P-IN

sensor operate. This should be done several times to see if the actuator will adjust

properly or not (The movement of the actuator should be checked to see if it is sluggish

or responsive.).

Counter measure.

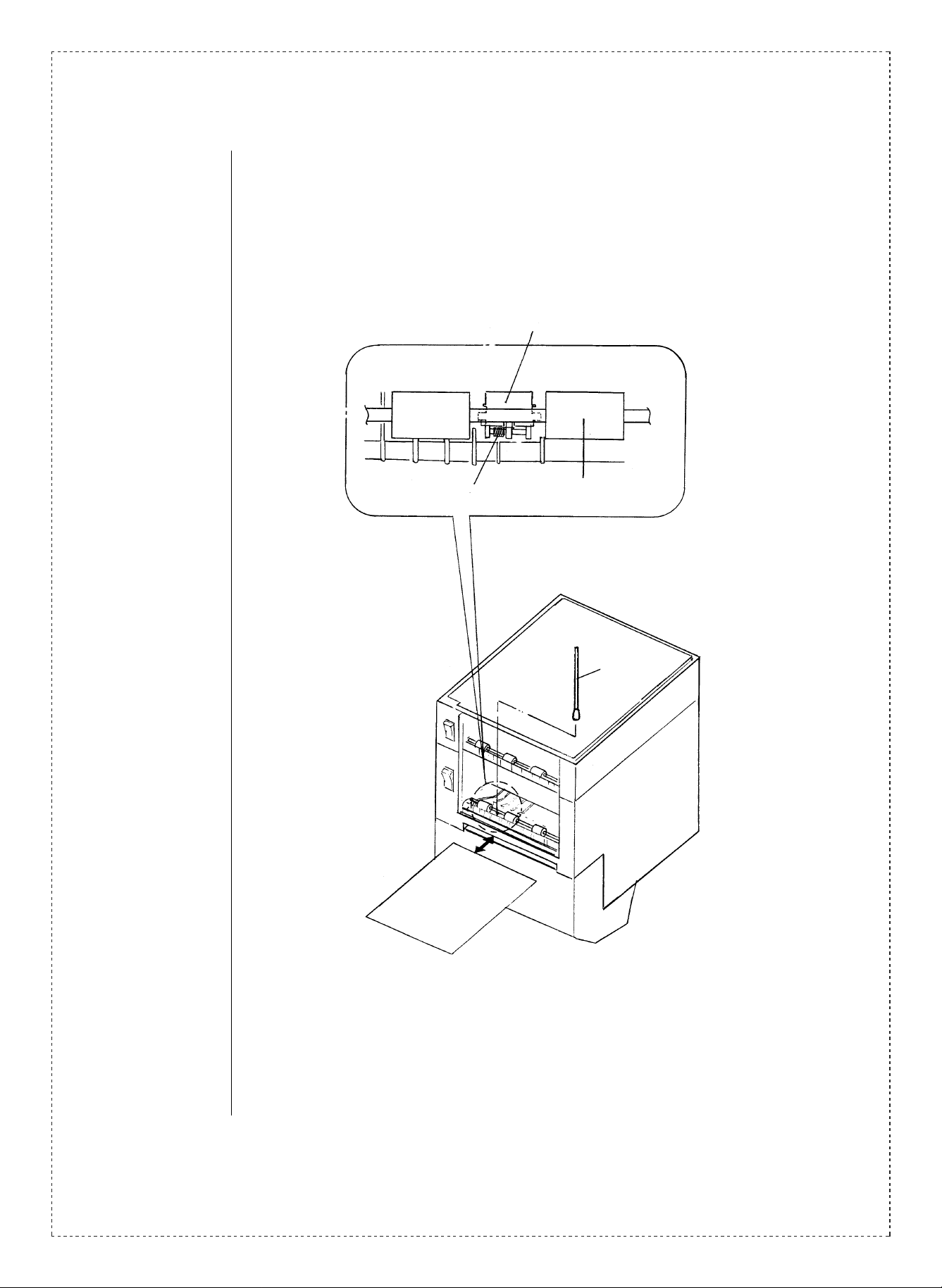

(1)Remove the drum unit, developing tank and paper cassette from the printer.

(2)Turn the printer upside down so that the P-IN sensor spring can be checked.

(3)Dip a thin rod in spindle oil (machine oil), and apply the oil to the spring coil of the

P-IN sensor. Care should be exercised not to apply too much oil or it may come in

contact with the PF roller or other parts. (Please refer to Note 1, described below.)

(4)A piece of paper should be inserted in the manual feed opening several times

(approximately 10 times) and cause the actuator of the P-IN sensor to operate in order

to evenly spread the applied oil.

SHARP CORPORATION Printer and Scanner Division

1/2

Orange

C

Page 2

Note 1:The application of oil as a counter measure, as described above, is carried out

to use the oil as an agent to promote the return of the spring’s performance to normal.

5.Other: The application of oil as one of the production processes is being carried out as of 1995

October production.

P-IN sensor

Spring

PF roller

Thin rod

2/2

Paper

Loading...

Loading...