Page 1

Date: Oct. 29, 1993

LASER PRINTER : JX-9600

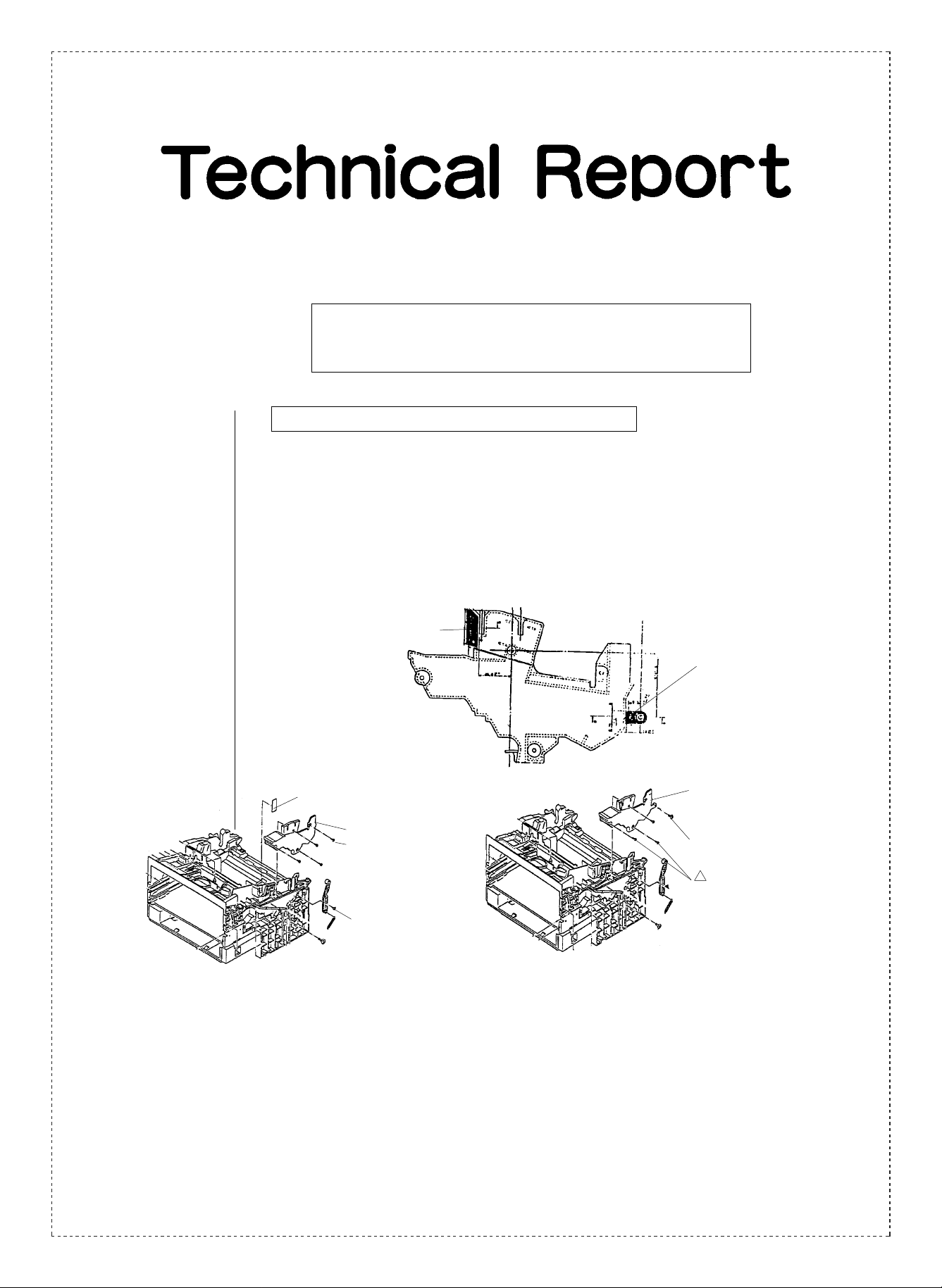

1. CHANGE OF THE FIXED INSULATION PLATE AND THE DUCT CASE

2. ADDITION OF PROTECTION CAPS FOR THE CENTRAL CONNECTOR

OF THE ICU BOARD

3. ADDITION OF PAPER GUIDES AND PAPER GUIDE SHEETS

No. : LPE-176

1. Change of the fixed insulation plate and the duct case

1.Model name: JX-9400, JX-9600, JX-9600PS

2.General: The duct case and the fixed insulation plate materials were changed to improve

productivity. Duct case and the fixed insulation plate shapes were also changed.

3.Description: ➀ Duct case (chape change):Due to the duct cace change one slide sheet has been

eliminated (Q’ty; 2 to 1) and a screw has been added.

<Shape changes >

Coricave surface

Fixed stopper for

the conveyor.

Addition of boss.

Slide sheet. (PSHEP0078GCZZ)

Discontinued

Duct case.

XEBSD30P08000

Discontinued

Screw

(LX-BZ0012GCZZ)

Discontinued

Duct case

PCASZ0015GCZ3

Change.

XEBSE30P10000

Addition.

!

XEBSE30P10000

Change.

➁ The fixed insulation plate material was changed from aluminum to SECCT2J.

SHARP CORPORATION Printer and Scanner Division

1/3

Orange

Page 2

4.Effective time: (Production)

September, 1993 : ➀ Due to the duct case change, parts have been added and

eliminated.

(Production)

July, 1993 : ➁ Fixed insulation sheet.

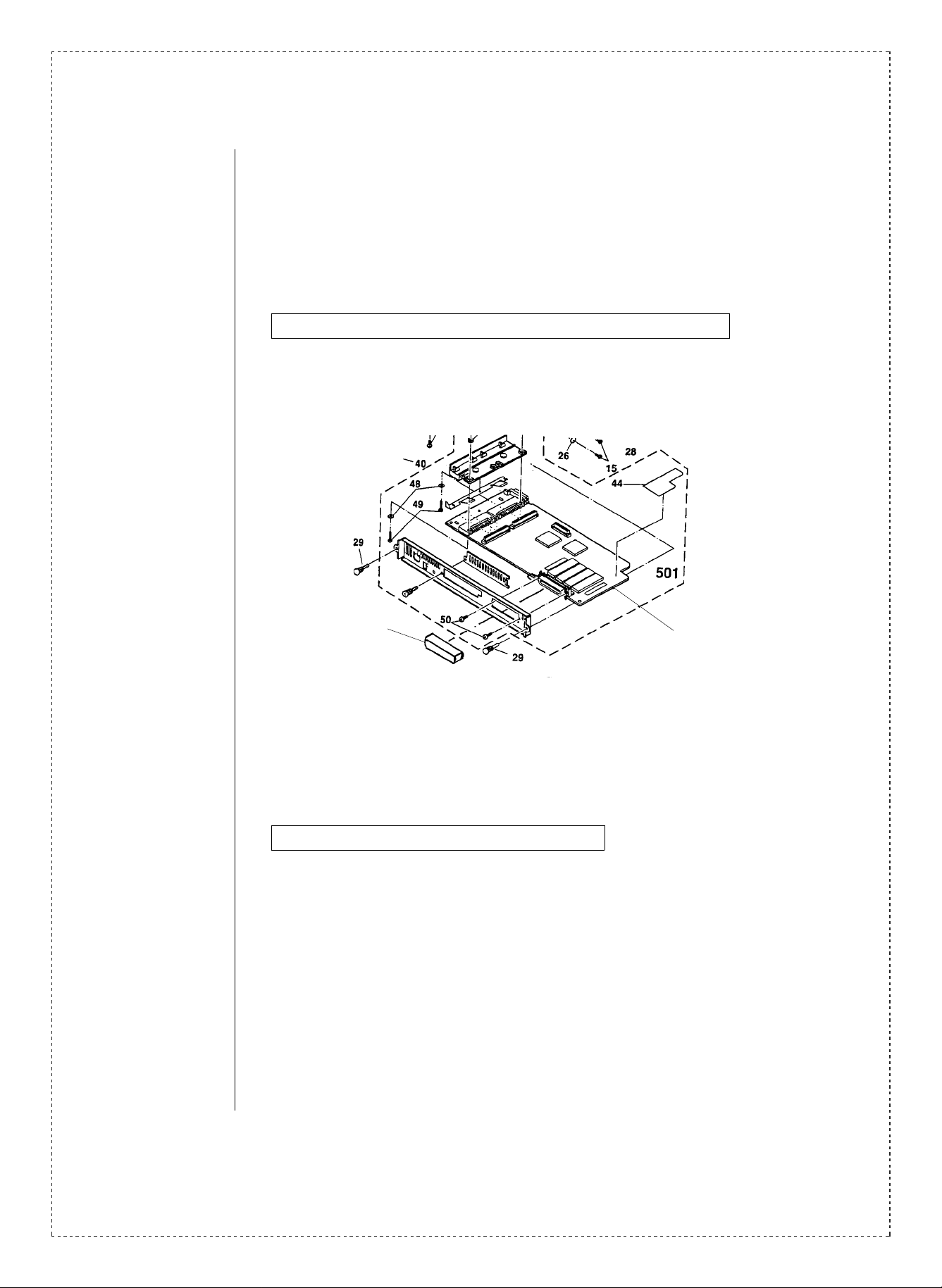

2. Addition of protection caps for the central connector of the ICU board

1.Model name: JX-9400, JX-9600, JX-9600PS

2.General: A protection cap for the central connector of the ICU board was added.

Protection cap.

3.Effective time: (Production)

May, 1993.

3. Addition of paper guides and paper guide sheets

1.Model name: JX-9400, JX-9600, JX-9600PS

2.General: Paper guide sheets were added to correct paper misalignment and poor copy printouts.

3.Description: ➀ Four (4) guide sheets were attached to the main frame unit to prevent misalignment

of label sheets during copy printing.

ICU board

➁ Paper guide sheets were attached to the conveyor frame unit to prevent poor copy

print outs under HH conditions.

2/3

Page 3

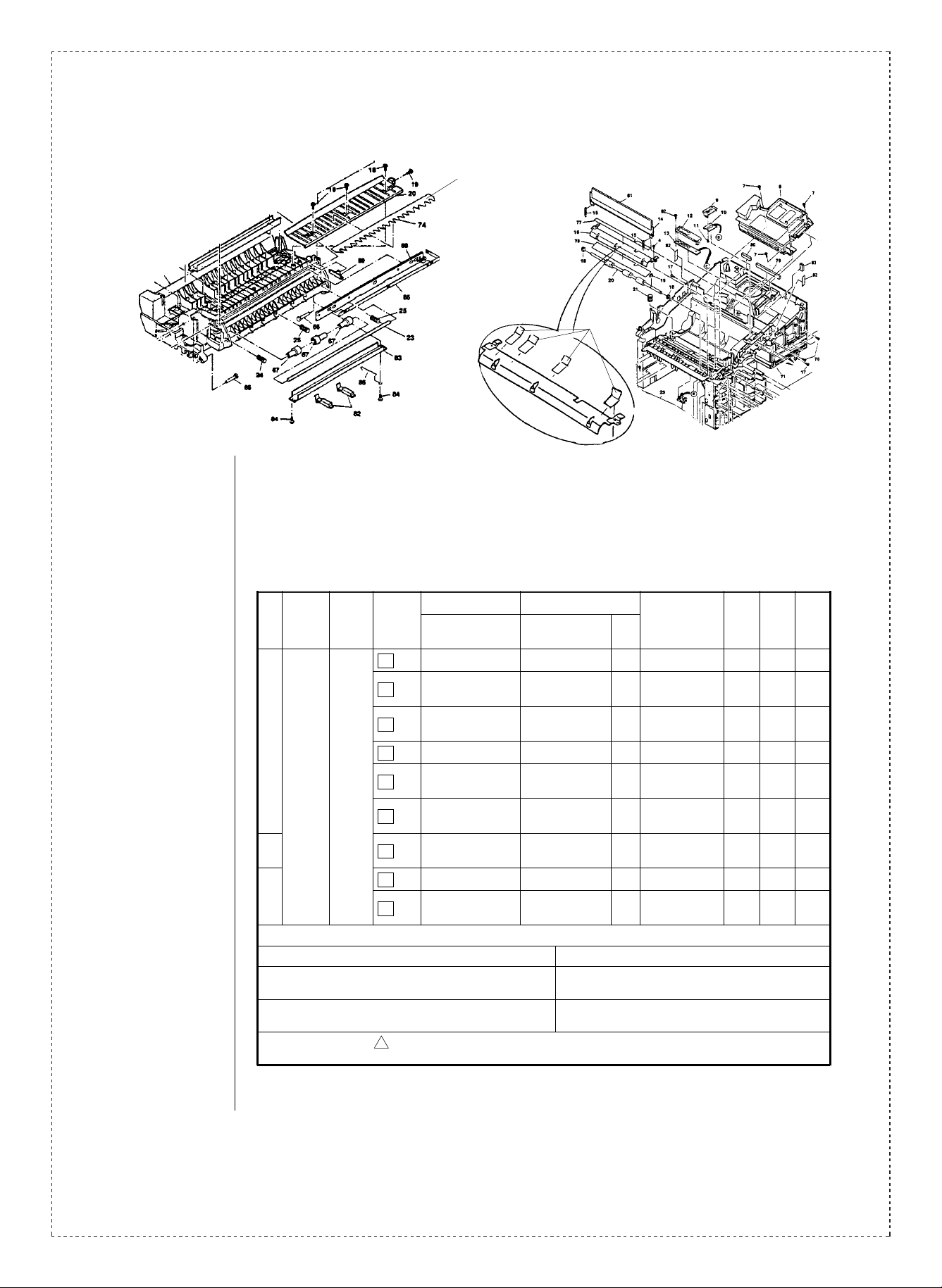

4.Effective time: (Production):

April, 1993.

Paper guide sheet.

Guide

Sheets.

Ref.

Model

No.

1

JX-9600

JX-9600PS

JX-9400

2

3

<Inter ch an ge>

1. Interchangeable. 4. Not interchangeable.

2. C urr e nt t y pe c a n be u s ed i n p la ce of new ty pe .

New ty pe cann ot be us ed i n place of curr ent type .

3. C urre nt ty pe cann ot be used i n place of new ty pe.

New t y pe c a n be u sed in pla c e of c u rr en t ty p e.

Parts m ar ke d wi t h “ ” is i mp ort an t fo r m a inta i ni ng t he sa fe ty of t he s e t. B e su r e to re pl ace these pa r ts wi t h

specified ones for maintaining the safety and performance of the set.

name

Version P/G No.

3-9

3 -10

3

3 -12

All

2 -82

4 -72

3

2

4 -74

!

Current parts New parts

Parts code Parts code

PCASZ0015GCZ1 PCASZ0015GCZ3 AK Duct case ’93/9 3

— XEBSD30P08000 AA Screw (3x8) ’93/9 6

— XEBSE30P10000 AA Screw (3x10) ’93/9 6

LX-BZ0012GCZZ — — Screw ’93/9 6

— PSHEP0078GCZZ AA Slide sheet ’93/9 6

LPLTM0134GCZZ LPLTM0134GCZ1 AG

— PCAPH1001ACZZ AE

— PSHEP0101GCZZ AC Guide Sheets ’93/4 6

— PSHEP0100GCZZ AF

Price

rank

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others.

Parts name

Fixed insulation

plate

Connector

protection cap

Paper guide

sheet

Effective

time

’93/7 1

’93/5 6

’93/4 6

Interchangability

Note

Q’ty:

6 to 2

Q’ty:

4 to 8

Q’ty:

2 to 1

3/3

Loading...

Loading...