Page 1

Date: Dec. 10, 1993

LASER PRINTER : JX-9600

1. PS GUIDE CHANGES DUE TO ALTIRATION OF SUPPLY

SHAPE (TO PREVENT REAR TRANSFER MISALIGNMENT.)

2. CHANGE IN COPY PAPER CASSETTE TYPE TO IMPROVE

DIAGONAL PAPER FEED.

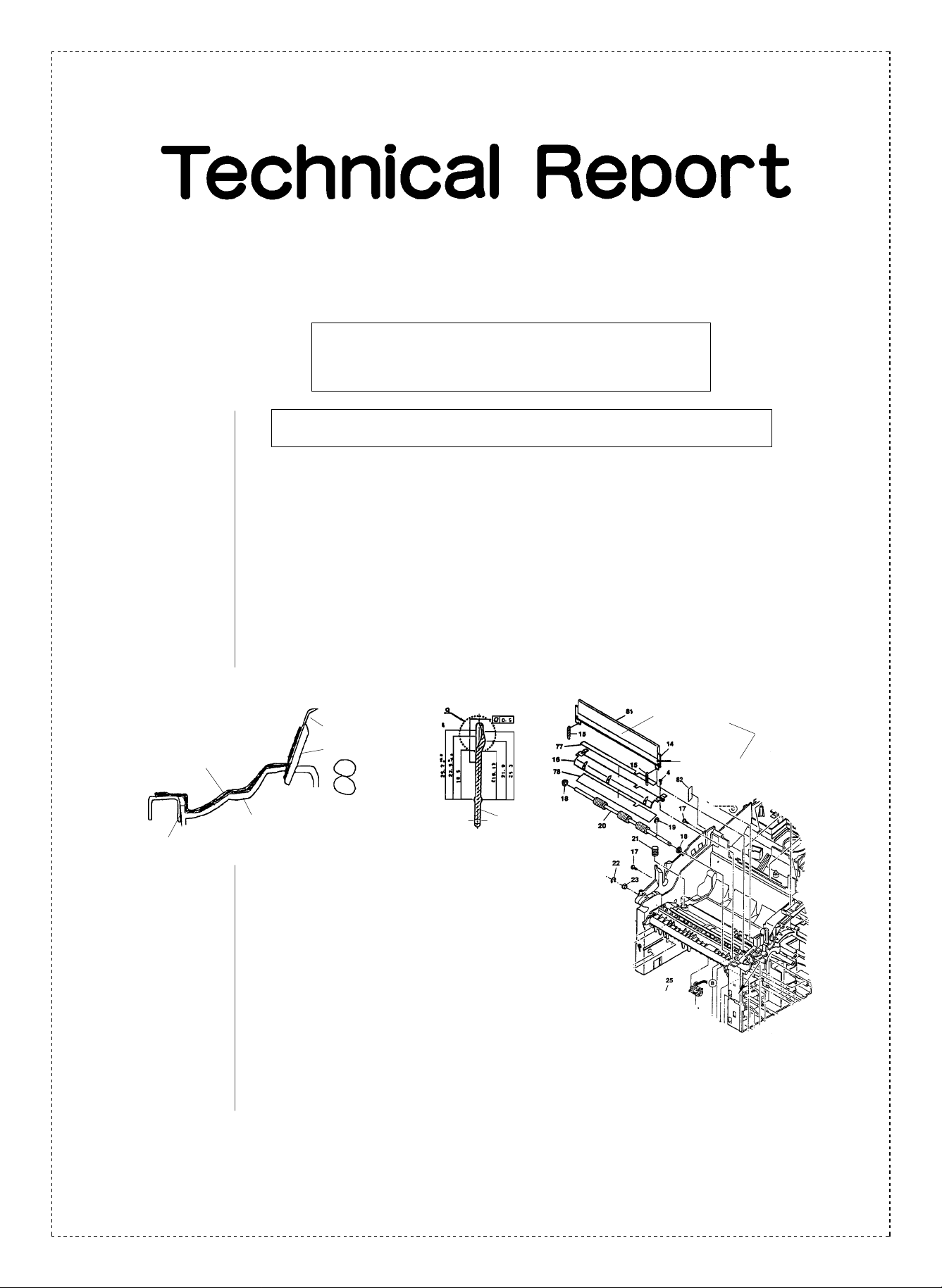

1. PS guide changes due to altiration of supply shape. (To prevent rear transfer

misalignment.)

1.Model name: JX-9400, JX-9600, JX-9600 PS.

No. : LPE-172

2.General: In order to improve transfer misalignment which frequently occurs about 7 mm from the

rear end of the copy, the shape of the front portion of the PS guide has been altered, a

SUS plate has been added and an earth sheet (copper tape) had been attached as

temporary measures, but the PS guide (including the SUS plate) has been changed

and the earth sheet has been discontinued. The color of the PS sheet affected by the

change in PS guide has also been changed from black to semi clear.

The supply shape of PS guide assy will also be change.

<Temporary measures> <Permanent measures>

Copper tape

Frame

Earth plate for sensor

SUS plate

PS guide AS

PS roller

PS Sheet

(Semi clear)

PS Guide

PS Guide

PS Guide

assy

3.Action: From August, 1993.

From September, 1993.

SHARP CORPORATION Printer and Scanner Division

1/3

Orange

C

Page 2

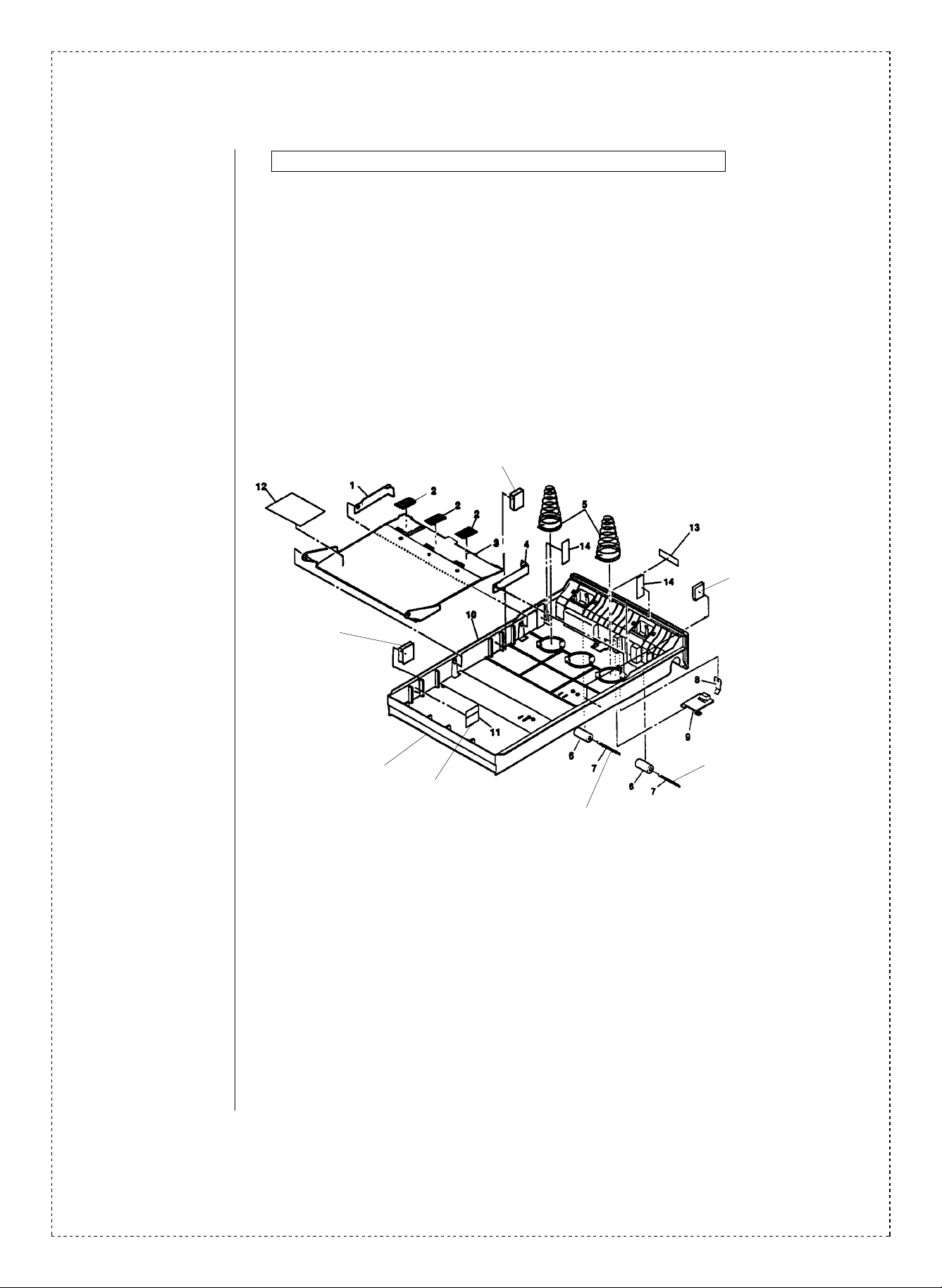

2. Change in copy paper cassette type to improve diagonal paper feed.

1.Model name: JX-9400, JX-9600, JX-9600 PS

2.General: Various parts have been added and eliminated to improve diagonal feeding of copy

paper.

3.Description: ➀ Paper cassette molt A, B have been added (for A4 size paper cassettes).

Paper cassette molt C has been added (for letter and legal size paper cassettes).

➁ PF stopper springs have been changed.

➂ The paper load limit label has been changed.

➃ The shape of the paper cassette has been altered.

➁ Paper cassette molt B (A4 sizes)

➀

Paper cassette molt C

(letter legal sizes)

➀ Paper cassette molt A

(A4 size)

4.Action: From July, 1993.

➁ PF stopper spring (600)

➃

➂

➁ PF stopper spring (200)

2/3

Page 3

Ref.

No.

1

Model

name

JX-9400

JX-9600

JX-9600PS

JX-9400

JX-9600

JX-9600PS

JX-96BC

JX-9400

JX-9600

JX-9600PS

JX-96A4

Version P/G No.

2 -14

2 -81

5 -10

5 -10

Current parts New parts

Parts code Parts code

Price

rank

PGIDM0033GCZZ

CGIDM0033GC01 AQ

PSHEP0092GCZZ

GCASP0007GCL1 GCASP0007GCL2 AS

GCASP0007GCA1 GCASP0007GCA2 AV

Parts name

PS guide assy

Cassette case

letter

Cassette case

A4

Effective

time

’93/8 3

’93/7 3

’93/7 3

Interchangeability

Note

Cassette case

regal

Copy paper load

level limit label

PF stopper spring

(200)

PF stopper spring

(600)

Cassette molt A

(A4)

Cassette molt B

(A4)

Paper cassette

molt C

(letter, legal sizes)

’93/7 3

’93/7 3

’93/7 3

’93/7 6

’93/7 6

’93/7 6

’93/7 6

2

JX-96CC

JX-9400

JX-9600

JX-9600PS

JX-96CC

etc.

1 -10

5 -11

All

GCASP0008GCZZ GCASP0008GCZ1 AX

TLABZ0097GCZZ TLABZ0176GCZZ AC

1 -11

5-7

MSPRT0089GCZZ MSPRT0128GCZZ AB

1-7

5-7

MSPRT0089GCZZ MSPRT0129GCZZ AB

1-7

5

— PMLT-0033GCZZ AB

1

5

— PMLT-0034GCZZ AB

1

5

— PMLT-0034GCZZ AB

1

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. C urr e nt t y pe c a n be u s ed i n p la ce of new t ype .

New ty pe cann ot be us ed i n place of curr ent type .

3. C urre nt ty pe cann ot be used i n place of new ty pe.

New t y pe c a n be u sed in p la c e of c u rr en t ty p e.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

!

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others .

specified ones for maintaining the safety and performance of the set.

3/3

Page 4

Ref.

No.

1

Model

name

JX-9400

JX-9600

JX-9600PS

Version P/G No.

All

2 -14

Current parts New parts

Parts code Parts code

PGIDM0033GCZZ PGIDM0033GCZ2

Price

rank

Parts name

PS guide

Effective

time

’93/8 3

Interchangeability

Note

JX-9400

JX-9600

JX-9600PS

JX-96BC

JX-9400

JX-9600

JX-9600PS

JX-96A4

JX96CC

JX-9400

JX-9600

JX-9600PS

JX-96CC

etc.

2 -81

5 -10

5 -10

1 -10

5 -11

1 -11

5-7

1-7

5-7

1-7

5

1

PSHEZP0092GCZZ PSHEP0104GCZZ AH

GCASP0007GCL1 GCAS0007GCL2 AS

GCASP0007GCA1 GCASP0007GCA2 AV

GCASP0008GCZZ GCASP0008GCZ1 AX

PS sheet

Cassette case

letter

Cassette case

A4

Cassette case

regal

’93/8 3

’93/7 3

’93/7 3

’93/7 3

TLABZ0097GCZZ TLABZ0176GCZZ AC ’93/7 3

’93/7 3

MSPRT0089GCZZ MSPRT0128GCZZ AB

PF stopper

spring (200)

’93/7 3

AB ’93/7 3

— MSPRT0129GCZZ AB

— PMLT-0033GCZZ AB

PF stopper

spring (600)

Cassette mort A

(A4)

’93/7 6

’93/7 6

AB

5

— PMLT-0034GCZZ AB

Cassette mort B

(A4)

’93/7 6

1

5

1

— PMLT-0034GCZZ AB

—

Cassette mort C

(letter regal)

’93/7 6

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. C urr e nt t y pe c a n be u s ed i n p la ce of new t ype .

New ty pe cann ot be us ed i n place of curr ent type .

3. C urre nt ty pe cann ot be used i n place of new ty pe.

New t y pe c a n be u sed in p la c e of c u rr en t ty p e.

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others .

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

Loading...

Loading...