Sharp LM7MS623 Datasheet

PREPARED

BY: DATE

SPEC No. LC99404

FILE No.

SHARP

I

_)__oBI:D_ SHARPCORPORATION

LIQUID CRYSTAL DISPLAY GROUP

SPECIFICATION

DEVICE SPECIFICATION for

Passive Matrix Monochrome LCD Module

(640X240 dots)

ISSUE APR. 28.1999

PAGE 25 Pages

REPREZNTATIVE DMSION

ENGINEERING DEPARTMENT I

DUTY LCD

DUTY LIQUID CRYSTAL

DISPLAY GROUP

DEVELOPMENT CENTER

I

q

CUSTOMER’S APPROVAL

DATE

BY

Model No.

LM7MS623

PRESENTED

r

--

DEPARTMENT

ENGINEERING DEPARTMENT I

DUTY LCD DEVELOPMENT CENTER

DUTY LIQUID CRYSTAL DISPLAY GROUP

SHARP CORPORATION

GENERAL MANAGER

SHARP

JWCORDS OF REVISION

DATE REF.PAGE REVISED SUMMARY CHECK

PARAGRAPH

DRAWING No. NO. APPROVAL

DOC.FIRST ISSUE

APR.28 1999

SHARP

0

Precautions

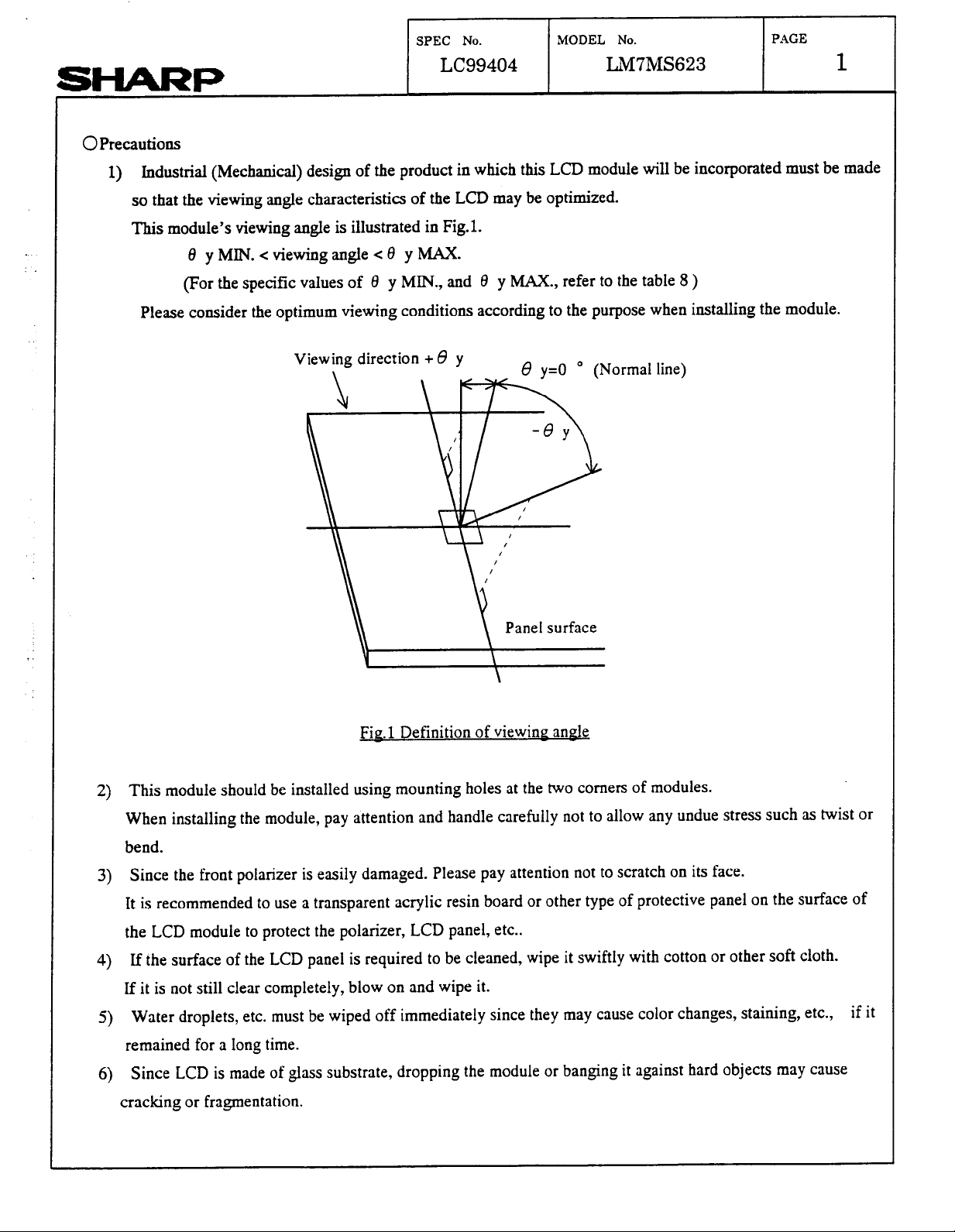

1) Industrial (Mechanical) design of the product in which this LCD module will be incorporated must be made

so that the viewing angle characteristics of the LCD may be optimized.

This module’s viewing angle is illustrated in Fig.1.

Please consider the optimum viewing conditions according to the purpose when installing the module.

SPEC No.

LC99404

8 yMIN.<viewingangle<0 yMAX.

(For the specific values of 0 y MIN., and 8 y MAX., refer to the table 8 )

MODEL No.

LM7MS623

PAGE

1

Viewing direction + 6 y

Fig.1 Definition of viewine angle

This module should be installed using mounting holes at the two corners of modules.

2)

When installing the module, pay attention and handle carefully not to allow any undue stress such as twist or

y=O

’ (Normal line)

Panel surface

bend.

Since the front polarizer is easily damaged. Please pay attention not to scratch on its face.

3)

It is recommended to use a transparent acrylic resin board or other type of protective panel on the surface of

the LCD module to protect the polarizer, LCD panel, etc..

If the surface of the LCD panel is required to be cleaned, wipe it swiftly with cotton or other soft cloth.

4)

If it is not still clear completely, blow on and wipe it.

Water droplets, etc. must be wiped off immediately since they may cause color changes, staining, etc.,

5)

remained for a long time.

Since LCD is made of glass substrate, dropping the module or banging it against hard objects may cause

6)

cracking or fragmentation.

if it

SPEC No. MODEL No. PAGE

LC99404 LM7MS623

SHARP

7) Since CMOS LSIs are equipped in this module, following countermeasures must be taken to avoid

electrostatics charge.

l-Operator

Electrostatic shielding clothes shall be had because it is feared that the static electricity is electrified to

human body in case that operator have a insulating garment.

2.Equipmeot

There is a possibility that the static electricity is charged to equipment which have a function of peeling or

mechanism of friction(EX: Conveyer, soldering iron, working table), so the countermeasure(electrostatic

earth:1 X lo8 Q) should be made.

3.Floor

Floor is a important part to leak static electricity which is generated from human body or equipment.

There is a possibility that the static electricity is charged to them without leakage in case of insulating

floor,so the countermeasure(electrostatic earth: 1 X 10’ Q ) should be made.

4.Humidity

2

Humidity of working room may lower electrostatics generating material’s resistance and have something to

prevent electrifying. So, humidity should be kept over 50% because humidity less than 50 % may increase

material’s electrostatic earth resistance and it become easy to electrify.

S.Transportation/storage

The measure should be made for storage materials because there is a possibility that the static electriicity,

which electrify to human body or storage materials like container by friction or peeling, cause the dielectric

charge.

6.0thers

The laminator is attached on the surface of LCD module to prevent from scratches, fouling and dust.

It should be peeled off unhurriedly with using static eliminator.

And also, static eliminator should be installed to prevent LCD module from electrifying at assembling line.

8) Don’t use any materials which emit gas from epoxy resin(amines’

agent(dealcohol or deoxym) to prevent change polorizer color owing to gas.

9) Avoid to expose the module to the direct sun-light, strong ultraviolet light, etc. for a long time.

10) If stored at temperatures under specified storage temperature, the LC may freeze and be deteriorated.

If storage temperature exceed the specified rating, the molecular orientation of the LC may change to that of

a liquid, and they may not revert to their original state. Therefore, the module should be always stored at norma

hardener) and silicon adhesive

room temperature.

11) Disassembling the LCD module can cause permanent damage and should be strictly avoided.

SPEC No.

LC99404 LM7MS623

MODEL No. PAGE

SHARP

12) Do not use touch TCP/LCD connection area to prevent interconnection breakdown.

13) Do not apply organic solvent to TWLCD connection area where organic materials are used.

14) This specification describes display quality in case of no gray scale. Since display quality can be affected by

gray scaIe methods, display quality shall be carefully evaluated for the usability of LCD module in case gray

scale is displayed on the LCD module.

15) The module should be driven according to the specified ratings to avoid permanent damage.

DC voltage drive leads to rapid deterioration of LC, so ensure that the drive is alternating waveform by

continuous application of the signal M. Esneciallv the Dower ON/OFF seauence shown on Pave 22 should be

kent to avoid latch-un of drive LSI and application of DC voltape to LCD Dane1

3

SHARP

SPEC No.

LC99404

MODEL No.

LM7MS623

PAGE

4

OContents

LApplication

2.Construction and Outline

3.Mechanical Specifications

4.Absolute Maximum Ratings

4-1.Electrica.l absolute maximum ratings

4-2.Enviroment Conditions

S.Electrical Specifications

5-l.Electrical characteristics

5-2.Interface signals -

6.Module Driving Method

6-l.Circuit configuration

6-2.Display face configuration

6-3Jnput data and control signal

7.0ptical Characteristics

8.Supply voltage sequence condition

9.Lot number

Page

5

6

7

8

9

14

16

22

23

lO.Applicable Inspection Standard

ll.LCD Module out line dimension.

24

SPEC No.

MODEL No.

PAGE

LC99404

SHARP

LM’7MS623

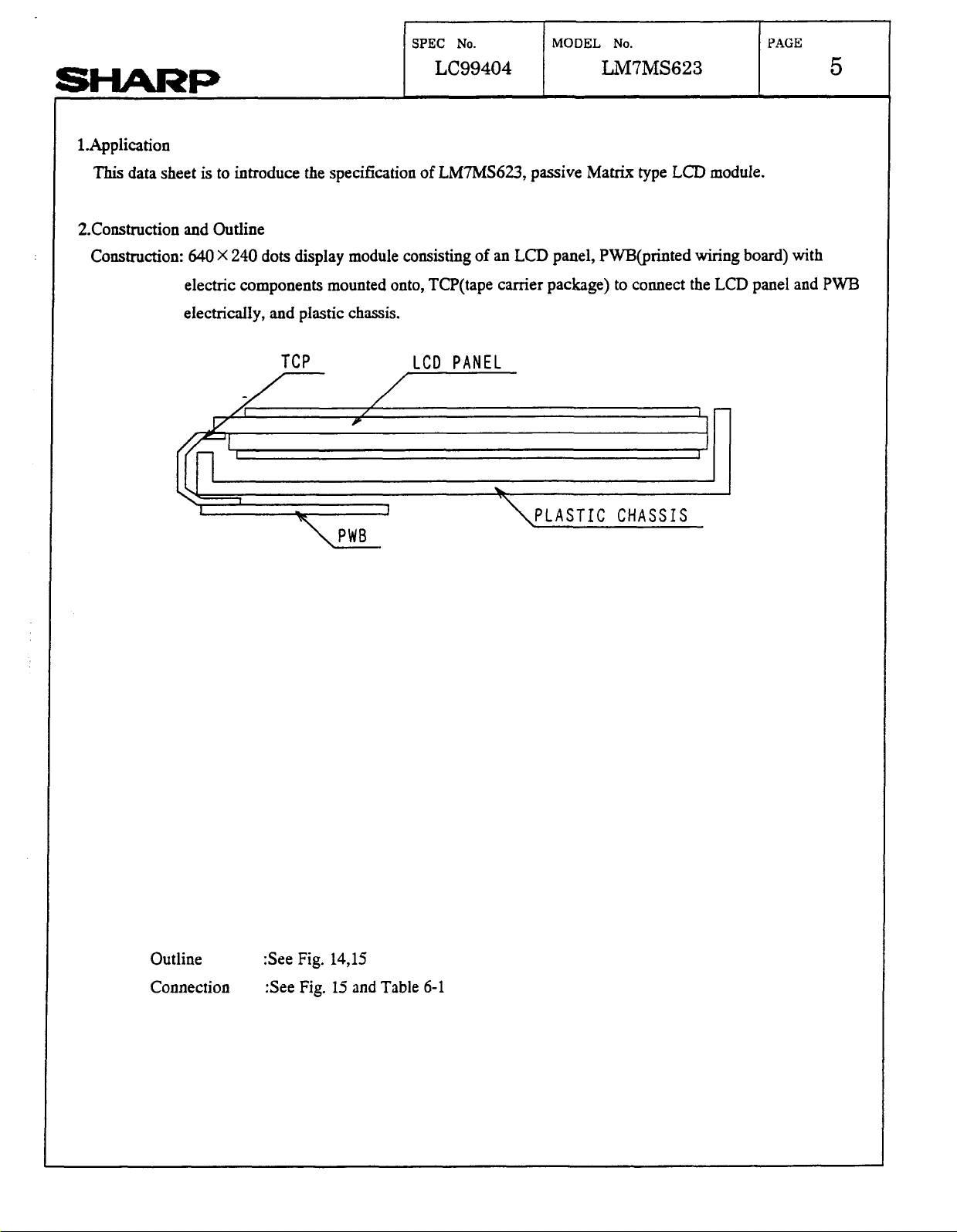

1Application

This data sheet is to introduce the specification of LM7MS623, passive Matrix type LCD module.

Z.Construction and Outline

Construction: 640 X 240 dots display module consisting of an LCD panel, PWEQrinted wiring board) with

electric components mounted onto, TCP(tape carrier package) to connect the LCD panel and PWB

electrically, and plastic chassis.

I/

TCP

Y

/

LCD PANEL

1

.

PLASTIC CHASSIS

v-l

I

PWB

5

Outline

Connection

:See Fig. 14,lS

:See Fig. 15 and Table 6-1

SHARP

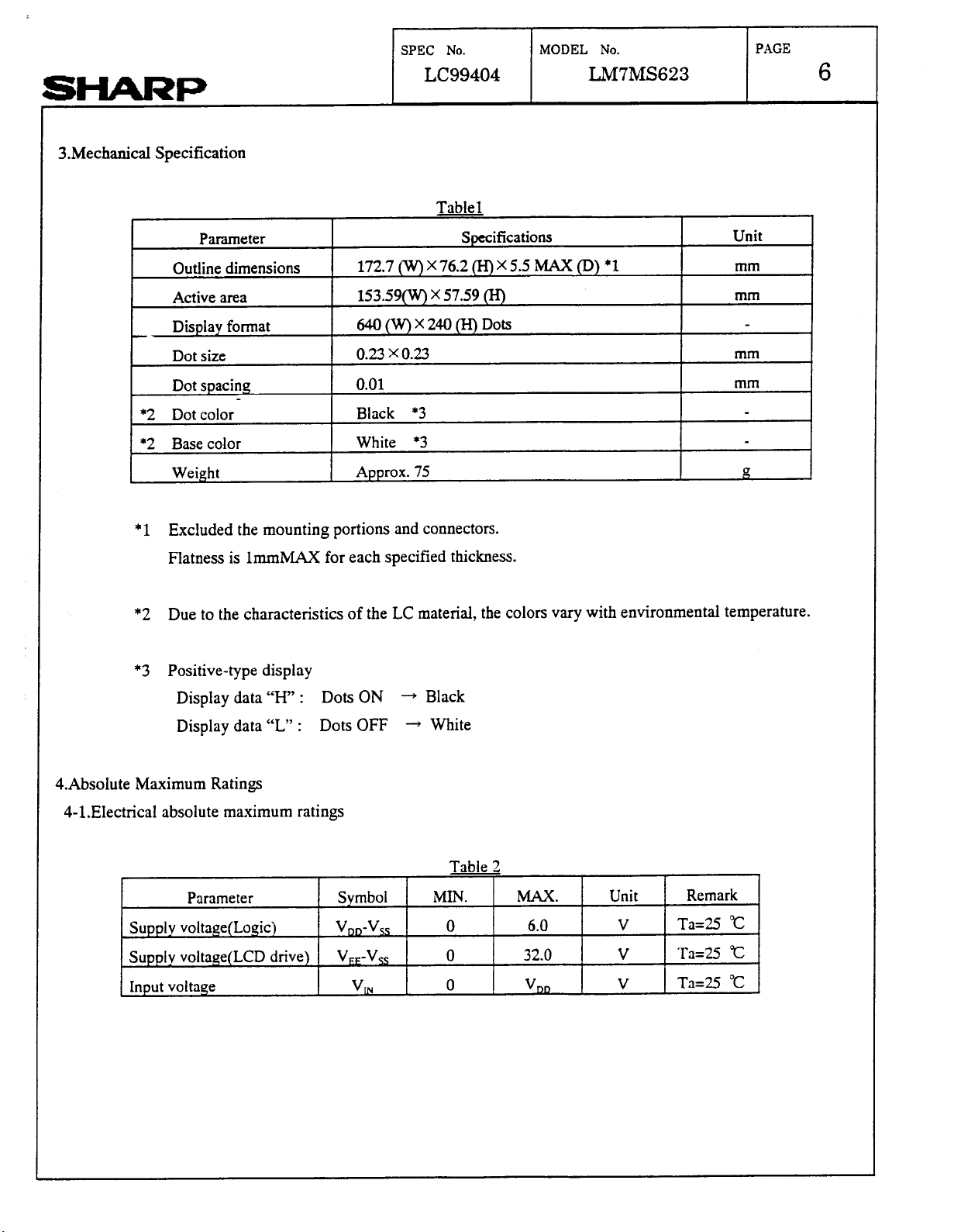

3.Mechanical Specification

SPEC No. MODEL No.

LC99404 LM7MS623

Table1

PAGE

6

* 1 Excluded the mounting portions and connectors.

Flatness is 1mmMAX for each specified thickness.

*2 Due to the characteristics of the LC material, the colors vary with environmental temperature.

‘3 Positive-type display

Display data “I-I” :

Display data “L” : Dots OFF - White

4.Absolute Maximum Ratings

4-l.Electrical absolute maximum ratings

Dots ON - Black

SHARP

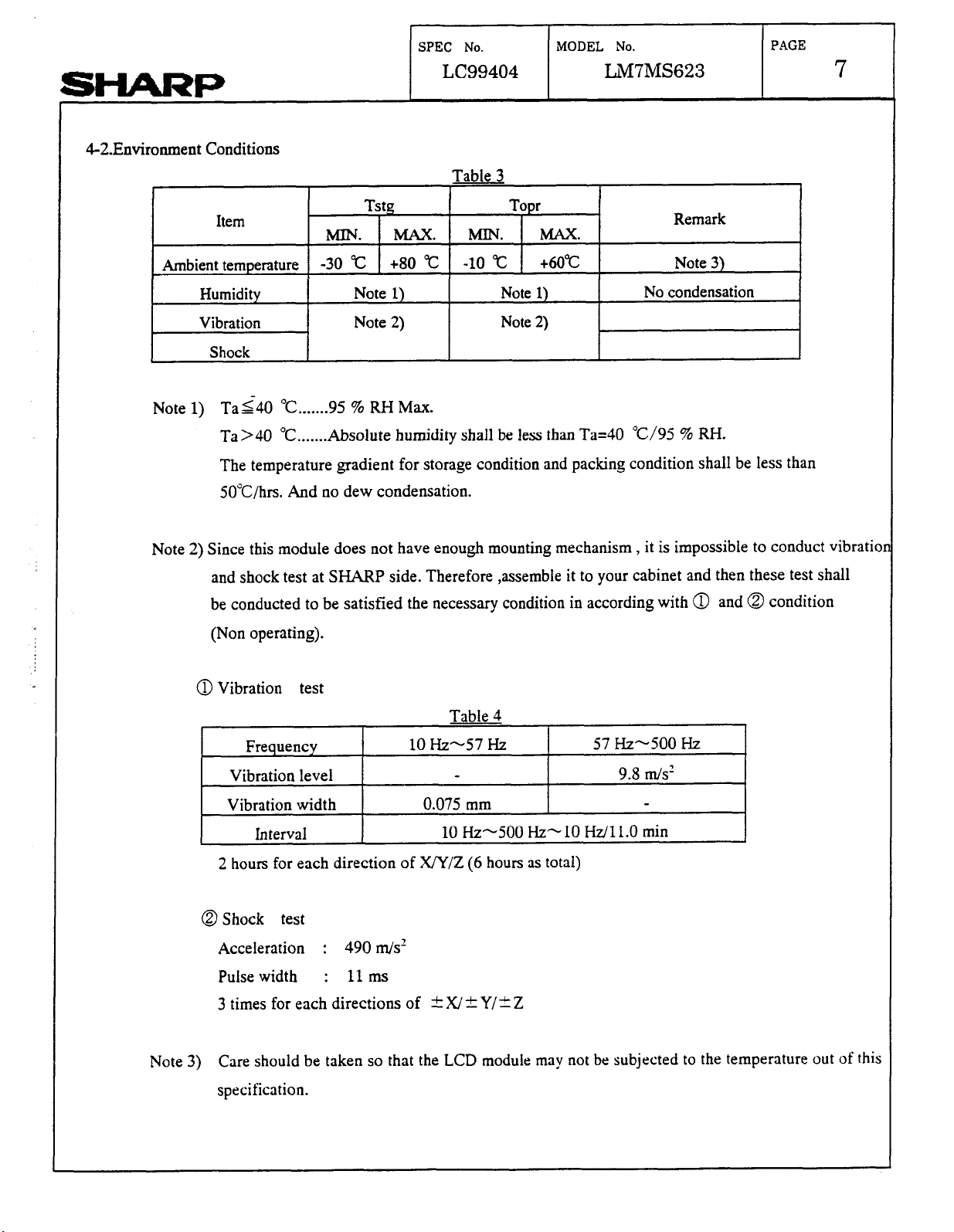

4-2.Environment Conditions

SPEC No.

LC99404

Table 3

MODEL No.

LM7MS623

PAGE

7

Item

Ambient temperature -30 “c +80 “c

Humidity

Vibration Note 2)

Shock

Note 1) Tag40 “C.. .... .95 % RH Max.

Ta>40 “C .....

The temperature gradient for storage condition and packing condition shall be less than

5O”Uhrs. And no dew condensation.

Note 2) Since this module does not have enough mounting mechanism,

and shock test at SHARP side. Therefore ,assemble it to your cabinet and then these test shall

be conducted to be satisfied the necessary condition in according with 0 and @ condition

(Non operating).

Tstg Topr

MIN. MAX. MIN. MAX.

-10 “c +6O”c

Note 1) Note 1)

Note 2)

..AbsoIut e humidity shall be less than Ta=40 “C/95 % RH.

Remark

Note 3)

No condensation

it is impossible to conduct vibratio.

0 Vibration test

Table 4

Frequency

Vibration level

Vibration width

Interval

2 hours for each direction of X/Y/Z (6 hours as total)

@ Shock test

Acceleration : 490 m/s’

Pulse width : llms

3 times for each directions of t X/ t Y/k Z

Note 3) Care should be taken so that the LCD module may not be subjected to the temperature out of this

specification.

10 Hz-57 Hz 57 Hz-500 Hz

-

0.075 mm

10 Hz-500 Hz- 10 Hz/l 1.0 min

9.8 m/s’

Loading...

Loading...